Zero drainage circulation ultilization process and equipment of electroplate waste water

A technology of electroplating wastewater and zero discharge, applied in the direction of electrolysis process, electrolysis components, cells, etc., to achieve the effect of small investment, overcome high energy consumption, and occupy a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

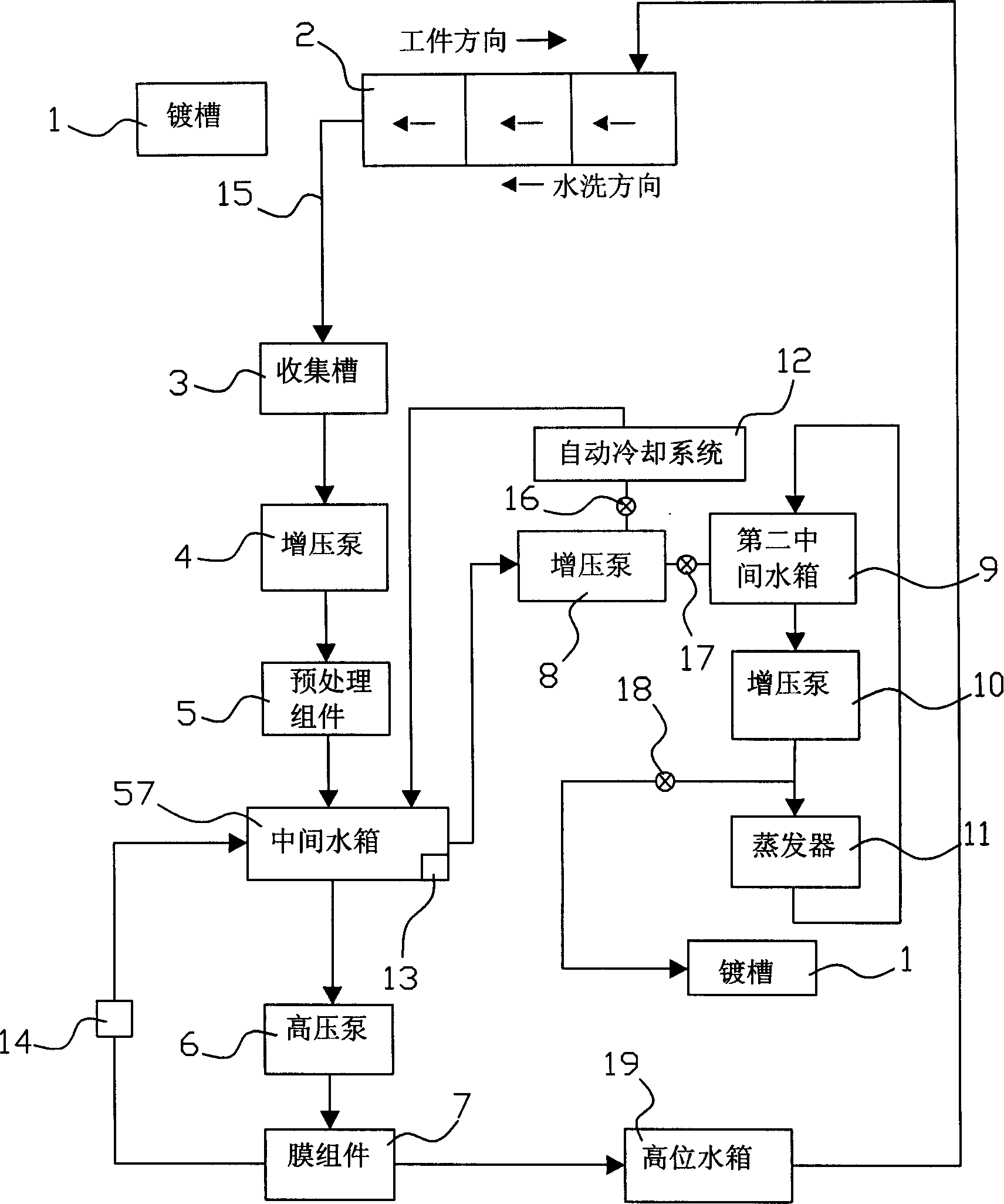

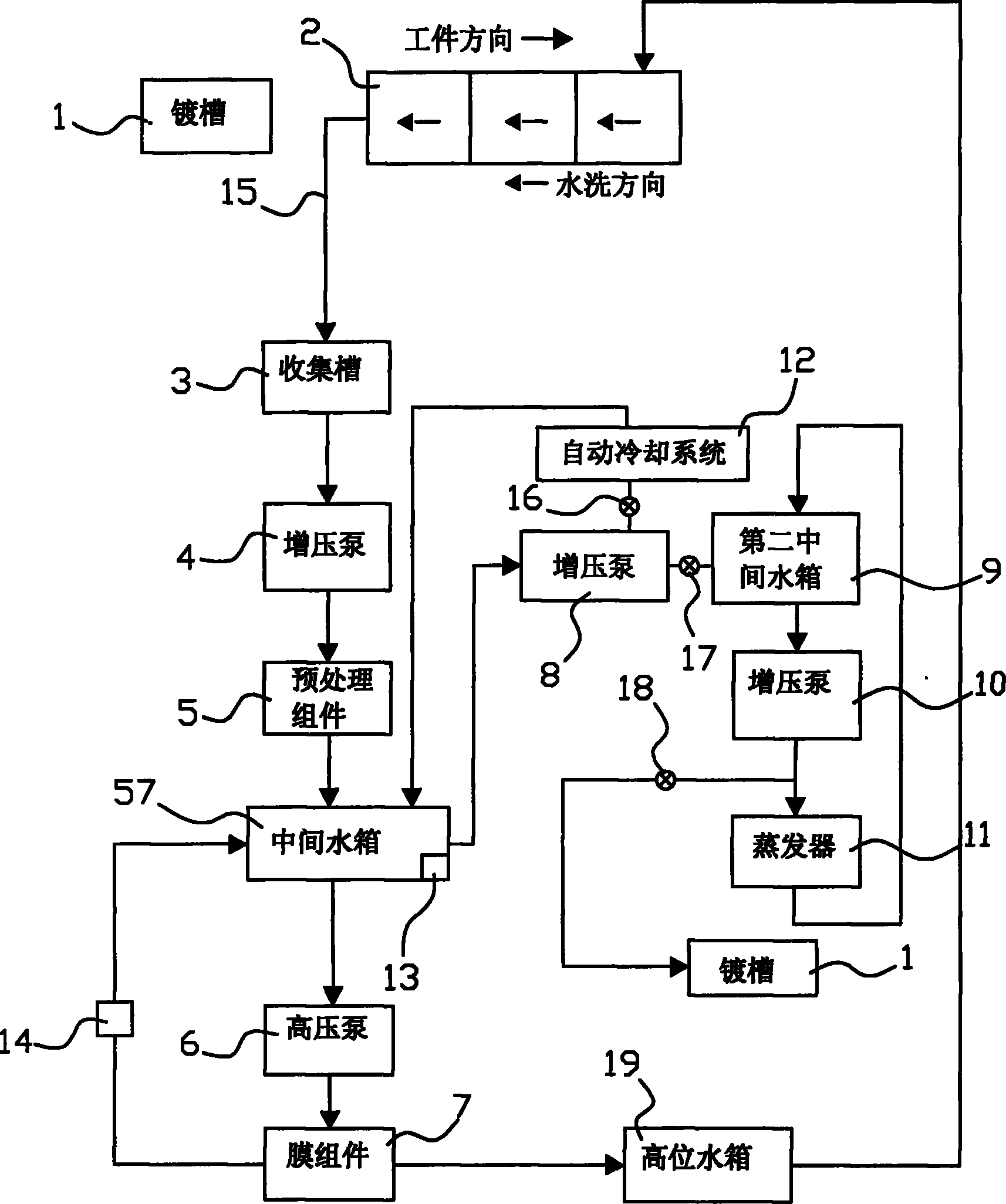

[0018] Refer below figure 1 A specific embodiment of the present invention will be described.

[0019] The zero-discharge recycling equipment for electroplating wastewater mainly includes a collection tank 3 , a pretreatment module 5 , a membrane module 7 , and an evaporator 11 . The collection tank 3 is connected to the electroplating rinse tank 2 through an overflow pipe 15 for collecting the electroplating waste water produced by the electroplating rinse tank 2 . The entrance of pretreatment assembly 5 is connected with collection tank 3 by pipeline, and booster pump 4 is provided in this pipeline, and this pretreatment assembly 5 is the serial combination of activated carbon filtration assembly, microfiltration membrane assembly, ultrafiltration membrane assembly, for Preliminary separation is performed on the electroplating wastewater in the collection tank 3, and small molecular weight organic matter and suspended matter are intercepted. The inlet of the membrane modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com