Preparation and application of water-borne polyurethane polyacrylate compound emulsion

A technology of polyacrylate emulsion and water-based polyurethane, which is applied in the field of polymers, can solve the problems of complex process, non-environmental protection, and high cost, and achieve the effect of overcoming high energy consumption and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

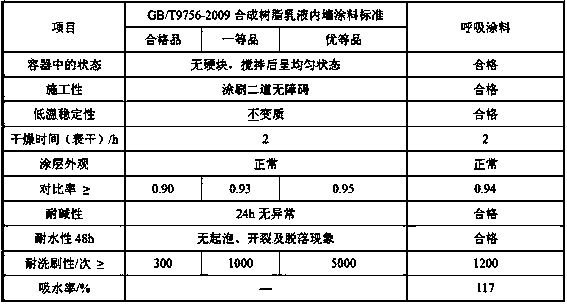

Embodiment 1

[0047] (1) Preparation of waterborne polyurethane polyacrylate composite emulsion

[0048] Take 1g of polypropylene glycol, 20g of isophorone diisocyanate, and 0.1g of 2,2-dimethylolpropionic acid into a four-neck flask, dissolve with 12g of acetone; heat up to 100°C to start the reaction, react for 80 minutes, and cool down to 30°C ℃, add 0.1g of triethylamine, neutralize for 30 minutes; add 15g of distilled water, stir at high speed (120r / min) and disperse for 30 minutes to obtain a water-based polyurethane emulsion.

[0049] Take another four-necked flask and add 0.1g of compound emulsifier (0.05g of sodium lauryl sulfate, Tween -20 0.05g), distilled water 20g, heat up to 60°C, add dropwise 20g of methyl methacrylate, 1g of acrylic acid, 50g of butyl acrylate, 5g of diacetone acrylamide, and 0.1g of ammonium persulfate as an initiator; Hours, a mixed solution was obtained; the temperature was lowered to 30°C, and the pH value was adjusted to 8 with ammonia water with a mas...

Embodiment 2

[0055] (1) Preparation of waterborne polyurethane polyacrylate composite emulsion

[0056] Weigh 50g of polypropylene glycol, 20g of isophorone diisocyanate, and 0.1g of 2,2-dimethylolpropionic acid into a four-neck flask, dissolve with 1g of acetone; heat up to 100°C to start the reaction, and react for 240 minutes; then cool down At 30°C, add 0.1g of triethylamine and react for 30 minutes; add 5g of distilled water and disperse for 30 minutes with high-speed stirring (300r / min) to obtain a water-based polyurethane emulsion.

[0057] Take another four-necked flask, add compound emulsifier 0.1g (sodium lauryl sulfate 0.02g, Tween -20 0.08g), distilled water 1g, heat up to 60°C, dropwise add 20g of methyl methacrylate, 15g of acrylic acid, 50g of butyl acrylate, 5g of diacetone acrylamide, 0.1g of initiator potassium persulfate, keep warm for 1 Hours, a mixed solution was obtained; the temperature was lowered to 30°C, and the pH value was adjusted to 7 with 5% ammonia water by...

Embodiment 3

[0063] (1) Preparation of waterborne polyurethane polyacrylate composite emulsion

[0064] Weigh 40g of polypropylene glycol, 20g of isophorone diisocyanate, and 12g of 2,2-dimethylolpropionic acid, add them into a four-necked flask, and dissolve them with 15g of acetone; heat up to 40°C and react for 100 minutes; cool down to 30°C , add 0.1g of triethylamine, neutralize and react for 30 minutes; add 30g of distilled water, stir at high speed (300r / min) and disperse for 5 minutes to obtain a water-based polyurethane emulsion.

[0065] Get another four-necked flask, add compound emulsifier 20g (sodium lauryl sulfate 5g, Tween -20 15g), distilled water 50g, heat up to 60°C, start dropwise adding 1g of methyl methacrylate, 20g of acrylic acid, 50g of butyl acrylate, 5g of diacetone acrylamide, 0.1g of initiator ammonium persulfate, and keep warm for 3 Hours, a mixed solution is obtained; the temperature is lowered to 30°C, and the pH value is adjusted to 10 with 10% by mass perc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com