Hydrothermal preparation method of chromium-doped aluminum oxide photoluminescence material

A technology of photoluminescent materials, alumina, applied in luminescent materials, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problem of inability to precisely control the doping ratio, high energy consumption, and long reaction time and other problems, to achieve the effect of being conducive to popularization and application, reducing sintering temperature and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

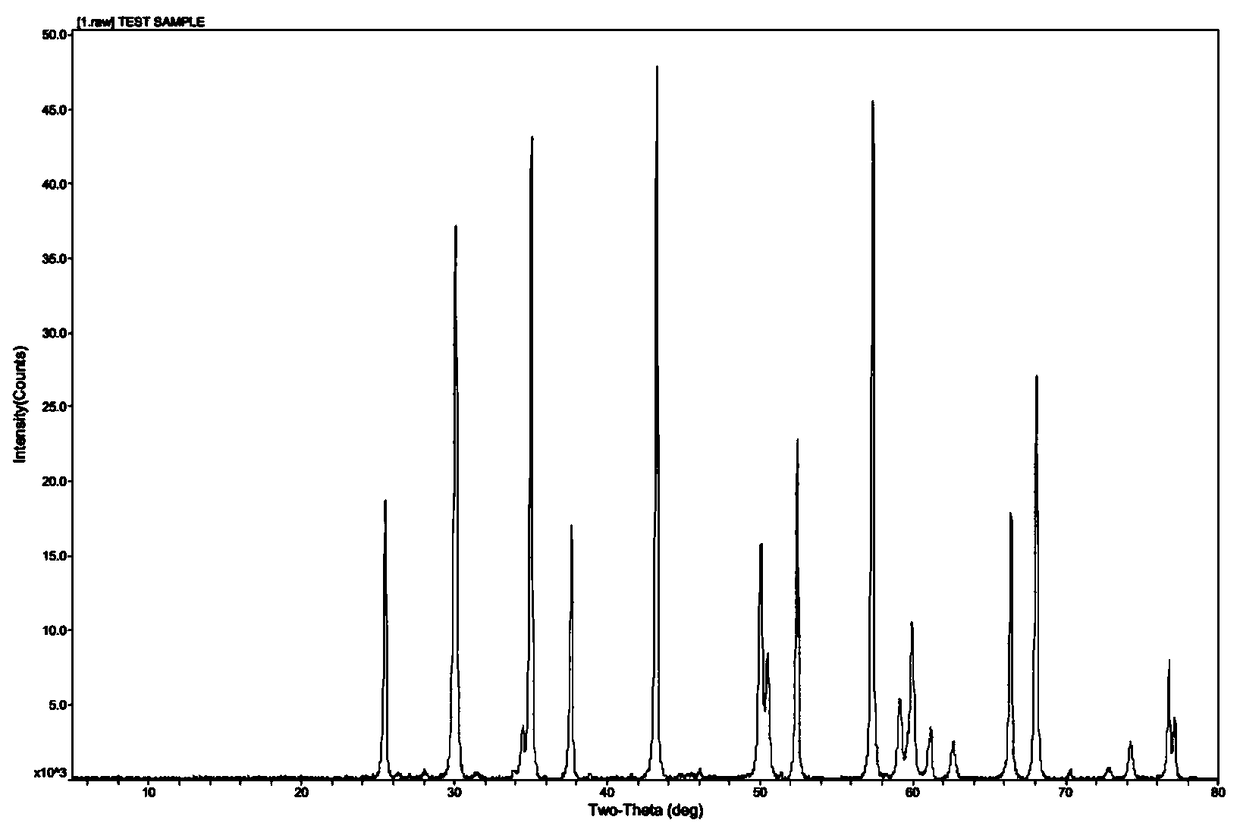

[0030] Adjust the temperature of the water bath to 40°C, dissolve aluminum chloride (5.3336g) in 35mL of 5mol / L KOH solution, and stir for 30min to form a uniform aluminum precursor solution; dissolve chromium chloride (0.0192g) in 35mL of 5mol / L KOH solution, stirred for 30min, then slowly added to the aluminum precursor solution; after continuing to stir for 30min, put it into a stainless steel reaction kettle with a Teflon liner, heated to 280°C water Thermally react for 6 hours, and cool down to room temperature naturally; filter the prepared powder, wash with water until neutral, and dry it at 80°C to obtain chromium-doped alumina powder.

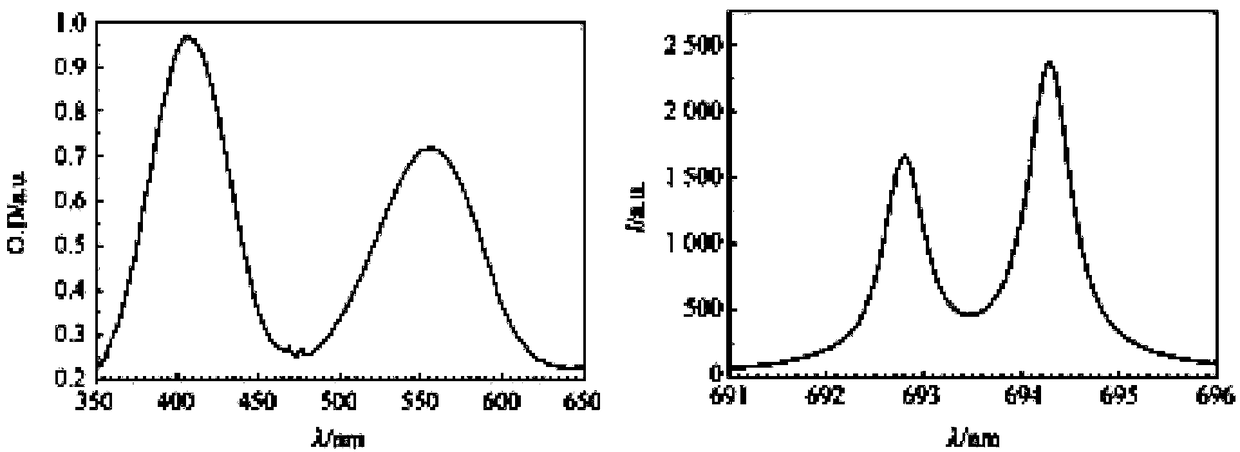

[0031] The PL spectrum of the prepared chromium-doped alumina nanopowder is tested by a spectrophotometer, and it can be seen that there is an obvious absorption peak at 410nm in the excitation spectrum; the emission wavelength in the emission spectrum is 692nm.

Embodiment 2

[0033] The temperature of the hydrothermal reaction in Example 1 was adjusted to 240° C., and the process flow and other process parameters remained unchanged, and the chromium-doped alumina powder was prepared.

[0034] The PL spectrum of the prepared chromium-doped alumina nanopowder was tested by a spectrophotometer, and it can be seen that there are obvious absorption peaks at 410nm and 558nm of the excitation spectrum. In the emission spectrum, the emission wavelength is 693nm.

Embodiment 3

[0036] The hydrothermal reaction temperature in Example 1 was adjusted to 220° C., the process flow and other process parameters remained unchanged, and chromium-doped alumina powder was prepared.

[0037] The PL spectrum of the prepared chromium-doped alumina nanopowder was tested by a spectrophotometer, and it can be seen that there are obvious absorption peaks at 410nm and 560nm of the excitation spectrum. In the emission spectrum, the emission wavelengths are 692.9 nm and 694.3 nm.

[0038]Compared with the photoluminescent material prepared by the traditional preparation method, the chromium-doped alumina photoluminescent material prepared by the preparation method of the present invention has higher luminous intensity, but the synthesis temperature is greatly reduced, and the method is simple and easy to synthesize. The product has high purity and good uniformity; and the inventive method has a wide application range, and also has the advantages of simple process, low si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com