Composite demetalization agent and preparation method thereof

A technology of demetallizer and dispersant, which is applied in the field of compound demetallizer for removing metals in crude oil and its preparation, can solve the problem of large dosage, and achieve the effect of promoting reaction and improving metal removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1 is the preparation method of the composite demetallizer, and Examples 2 to 7 are the demetallization test results of the composite demetallizer.

[0023] Example 1

[0024] Compounding any one of the organic acids with any one of the precipitation and chelating agents in different weight ratios is as follows:

[0025] T1: Glacial acetic acid: sodium hexametaphosphate = 1:1

[0026] T2: Glacial acetic acid: ammonium phosphate = 1:5

[0027] T3: citric acid: ethylenediaminetetraacetic acid = 2:5

[0028] T4: oxalic acid: sodium hexametaphosphate = 1:3

[0029] T5: methanesulfonic acid: sodium polyphosphate = 2:1

[0030] T6: fumaric acid: ammonium sulfate = 3:1

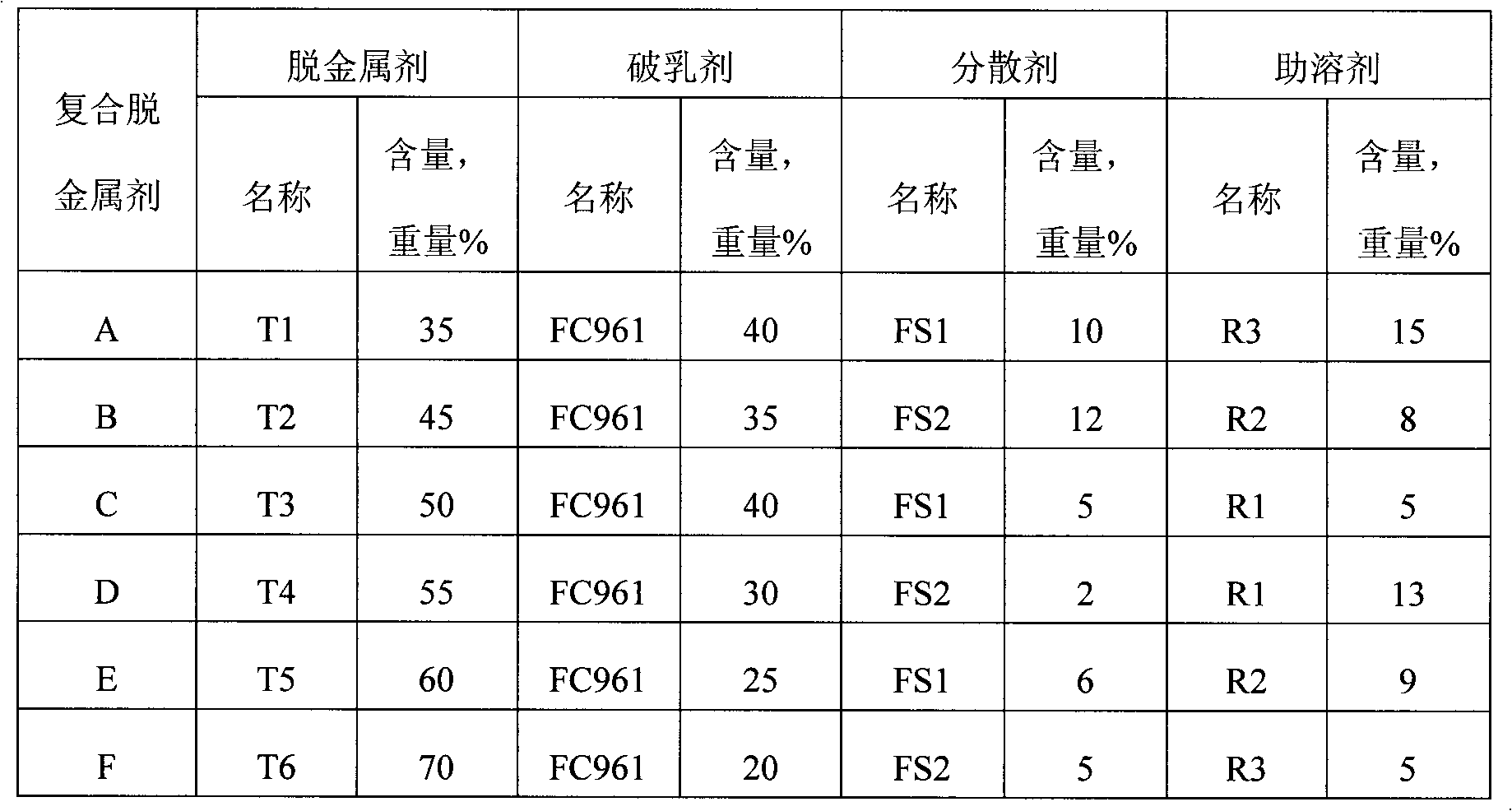

[0031] The preferred metal removal agent T1-T6, dispersant (FS1-dodecyltrimethylammonium chloride, FS2-dodecyltrimethylammonium bromide), cosolvent (R1-ethylene glycol butyl ether , R2-diethylene glycol butyl ether, R3-diethylene glycol monobutyl ether) and demulsifier (FC961) were mixed according...

Embodiment 2

[0035] Raw oil 1: a crude oil with a density of 920.2kg / m 3 , the salt content is 55 mg / l, the calcium content is 144.8 μg / g, the iron content is 38.4 μg / g, the nickel content is 14.3 μg / g, and the magnesium content is 8.5 μg / g. The metal content of crude oil before and after stripping was determined by inductively coupled plasma optical emission spectrometer (ICPOES).

[0036] 50g of the above crude oil was fully mixed with 0.30% by weight of composite demetallizing agent A and 6% by weight of water, and reacted at 80°C for 10 minutes. After the reaction, the oil was separated from water by electric desalting. After separation, 0.65% by weight of crude oil composite demetallization agent A and 6% by weight of water were added, stirred and reacted at 250° C. for 30 minutes, and after the reaction was completed, the mixed solution was taken out and separated from oil and water by electric desalination. The metal content analysis of the crude oil after demetallization showed th...

Embodiment 3

[0038] Raw material oil is with embodiment 2.

[0039] 100 g of the above-mentioned crude oil was fully mixed with 0.75% by weight of the composite demetallizing agent B of crude oil and 4% by weight of water, and reacted at 100° C. for 5 minutes. After the reaction, the mixture was separated from oil and water by electric desalination. After separation, 0.75% by weight of crude oil composite demetallization agent B and 8% by weight of water were added and stirred for 30 minutes at 300°C. After the reaction, the mixed solution was taken out and separated from oil and water by electrical desalination. The metal content analysis of the crude oil after demetallization showed that the calcium content was 1.3 μg / g, and the removal rate was 99.1%; the iron content was 0.9 μg / g, the removal rate was 97.6%, and the nickel content was 3.2 μg / g, The rate was 77.6%; the magnesium content was <0.05 μg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com