Preparation method of traditional Chinese medicine velvet viscose fiber

A technology of viscose fiber and traditional Chinese medicine, applied in the direction of fiber chemical characteristics, single-component cellulose artificial filament, wet spinning method, etc., can solve the problem that the functional durability of functional fibers cannot be guaranteed, and achieve long-term release, strong Targeting effect, facilitate the effect of penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

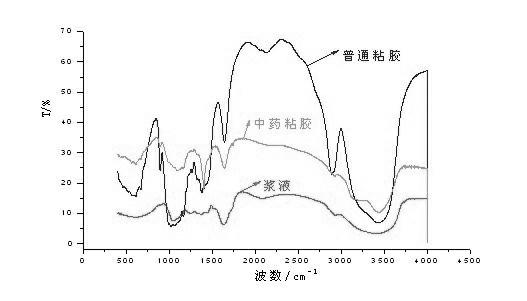

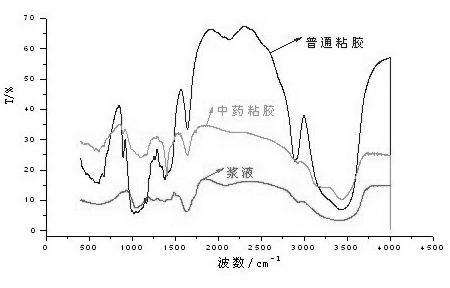

Image

Examples

Embodiment 1

[0024] The preparation method of Chinese medicine imitation velvet colored viscose fiber of the present invention is:

[0025] Step 1: At 60°C, dry the licorice, Codonopsis pilosula, and raw ground with a weight ratio of 1:1:1 to a moisture content of 5% (which can better maintain the activity of traditional Chinese medicine and make it difficult for nano-processing to occur in the equipment wall. Adhesion, so as to ensure that the processed particle size meets the requirements);

[0026] Step 2: Grinding the traditional Chinese medicine obtained in Step 1 to 100 mesh powder;

[0027] Step 3: The powder obtained in Step 2 is made into micropowder with a particle size of 200nm through nanotechnology;

[0028] Step 4: Add the micropowder obtained in Step 3 into pure water or distilled water with a weight ratio of 1:3, and then grind it into a slurry with a particle size of less than 100nm;

[0029] Step 5: Process the coffee grounds into a slurry with a particle size of less t...

Embodiment 2

[0037] The preparation method of Chinese medicine imitation velvet colored viscose fiber of the present invention is:

[0038] Step 1: Dry the gentian, Alisma and keel with a weight ratio of 18:14:13 at 65°C until the water content is 8%;

[0039] Step 2: Grinding the traditional Chinese medicine obtained in Step 1 to 120 mesh powder;

[0040] Step 3: The powder obtained in Step 2 is made into micropowder with a particle size of 250nm through nanotechnology;

[0041] Step 4: Add the micropowder obtained in Step 3 into pure water or distilled water with a weight ratio of 1:4, and then grind it into a slurry with a particle size of less than 100nm;

[0042] Step 5: Process the coffee grounds into a slurry with a particle size of less than 100nm according to the above steps 1 to 4, and fully mix the coffee grounds to the traditional Chinese medicine at a ratio of 1:4 to make a mixed slurry.

[0043] Step 6: Place the slurry obtained in Step 5 in a vacuum environment at 55°C and d...

Embodiment 3

[0050] The preparation method of Chinese medicine imitation velvet colored viscose fiber of the present invention is:

[0051] Step 1: At 70°C, dry the Adenophora radix, Ophiopogon japonicus, and mulberry leaves with a weight ratio of 10:10:3 until the water content is 10%;

[0052] Step 2: Grinding the traditional Chinese medicine obtained in Step 1 to 150 mesh powder;

[0053] Step 3: The powder obtained in Step 2 is made into micropowder with a particle size of 300nm through nanotechnology;

[0054] Step 4: Add the micropowder obtained in Step 3 to pure water or distilled water with a weight ratio of 1:5, and then grind it into a slurry with a particle size of less than 100nm;

[0055] Step 5: Place the slurry obtained in Step 4 in a vacuum environment at 55°C and dry for 35 hours to make a micropowder raw material;

[0056] Step 6: adding salt-free pure water with a weight ratio of 1:6 to the micropowder raw material obtained in step 5, and adding a dispersant with a wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com