Inclusion precipitation control technology for silicon steel for motor

A production process and material technology, which is applied in the field of inclusion precipitation control process of silicon steel for motors, can solve the problems of difficult grain growth and reduced magnetic properties of finished products, so as to improve production efficiency, increase coercive force, and reduce production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

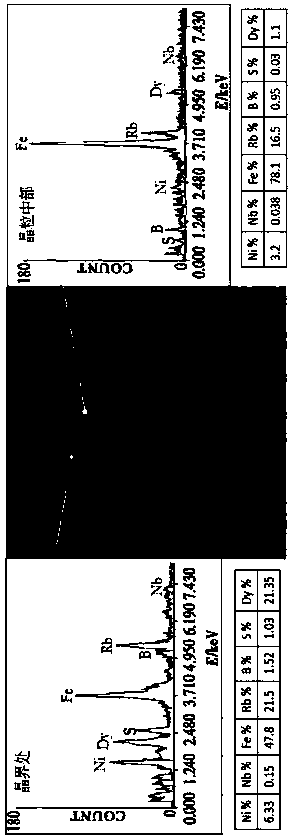

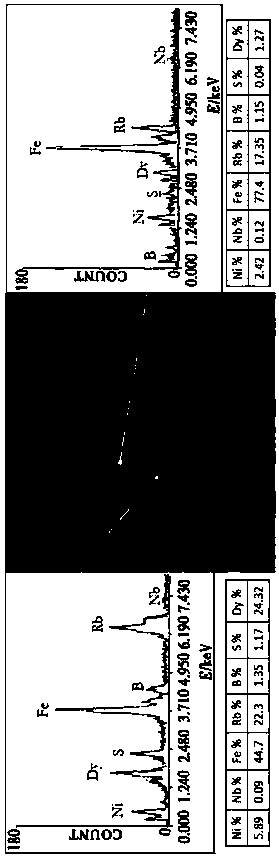

[0033] 1. Ingredients: The proportion of materials according to weight percentage is as follows: Rb (rubidium) 16%, Fe (iron) 75.7%, B (boron) 1.3%, Dy (dysprosium) 3.5%, Ni (nickel) 3.3%, S ( Sulfur) 0.09%, Nb (niobium) 0.04%; (specifically, pure iron, boron-iron alloy, rare earth alloy containing Rb and Dy, nickel-iron alloy, niobium-iron alloy and sulfur can be used to prepare materials according to the above ratio)

[0034] 2. Vacuum melting: put the material into the melting furnace for melting, the vacuum in the melting furnace is kept below 0.1 Torr, and the melting temperature of the prepared material is between 1580 ° C and 1620 ° C;

[0035] 3. Throwing flakes: After vacuum smelting, pour fully melted molten steel onto the high-speed rotating water-cooled copper rollers, and control the thickness of the casting flakes by controlling the speed of the copper rollers, and the thickness of the flakes should be controlled below 10mm , the tablet should not be too thick in...

Embodiment 2

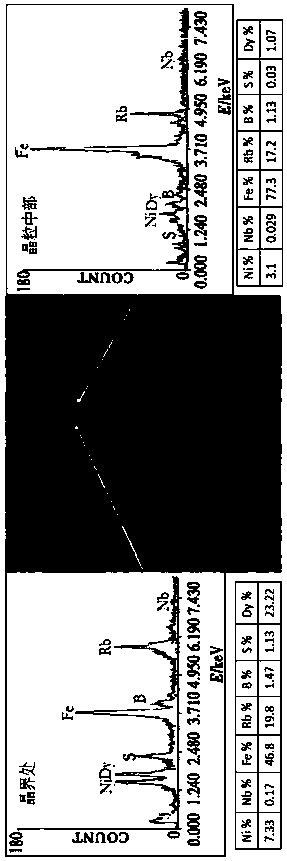

[0061] 1. Ingredients: The ratio of materials according to weight percentage is as follows: Rb (rubidium) 17.8%, Fe (iron) 76.6%, B (boron) 1.1%, Dy (dysprosium) 2%, Ni (nickel) 2.4%, S ( sulfur) 0.07%, Nb (niobium) 0.025%. (Specifically, pure iron, boron-iron alloy, rare earth alloy containing Rb and Dy, nickel-iron alloy, niobium-iron alloy and sulfur can be used to prepare materials according to the above ratio)

[0062] 2. Vacuum melting: put the material into the melting furnace for melting, the vacuum in the melting furnace is kept below 0.1 Torr, and the melting temperature of the prepared material is between 1580 ° C and 1620 ° C;

[0063] 3. Throwing flakes: After vacuum smelting, pour fully melted molten steel onto the high-speed rotating water-cooled copper rollers, and control the thickness of the casting flakes by controlling the speed of the copper rollers, and the thickness of the flakes should be controlled below 10mm , the tablet should not be too thick in or...

Embodiment 3

[0089] 1. Ingredients: The proportion of materials according to weight percentage is as follows: Rb (rubidium) 16.5%, Fe (iron) 76.15%, B (boron) 1.2%, Dy (dysprosium) 3%, Ni (nickel) 3%, S ( sulfur) 0.08%, Nb (niobium) 0.03%. (Specifically, pure iron, boron-iron alloy, rare earth alloy containing Rb and Dy, nickel-iron alloy, niobium-iron alloy and sulfur can be used to prepare materials according to the above ratio)

[0090] 2. Vacuum melting: put the material into the melting furnace for melting, the vacuum in the melting furnace is kept below 0.1 Torr, and the melting temperature of the prepared material is between 1580 ° C and 1620 ° C;

[0091] 3. Throwing flakes: After vacuum smelting, pour fully melted molten steel onto the high-speed rotating water-cooled copper rollers, and control the thickness of the casting flakes by controlling the speed of the copper rollers, and the thickness of the flakes should be controlled below 10mm , the tablet should not be too thick in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com