Production method and production equipment of fireproof polystyrene board

A technology of production equipment and production method, applied in the field of production and production equipment of fireproof polystyrene board, can solve the problems of uneven penetration, inability to continuously produce, low wrapping rate, etc., achieve short penetration time, improve production efficiency, The effect of high penetration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The scheme and principle of the present invention will be described below in conjunction with the accompanying drawings and specific embodiments, so as to help understand the content of the present invention.

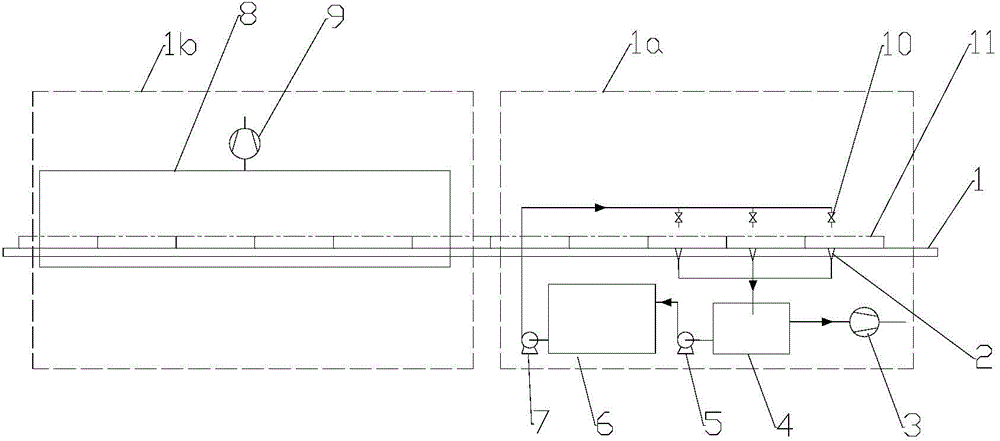

[0031] Such as figure 1 Shown, be the flowing water production line of fireproof polystyrene board of the present invention, in conjunction with production equipment explanation production method is as follows:

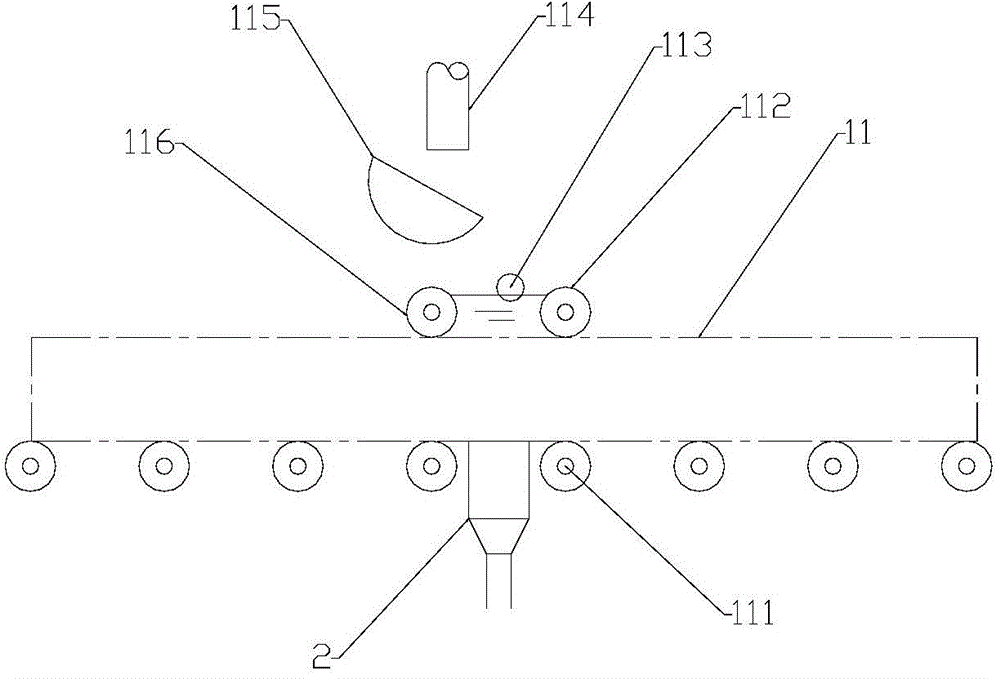

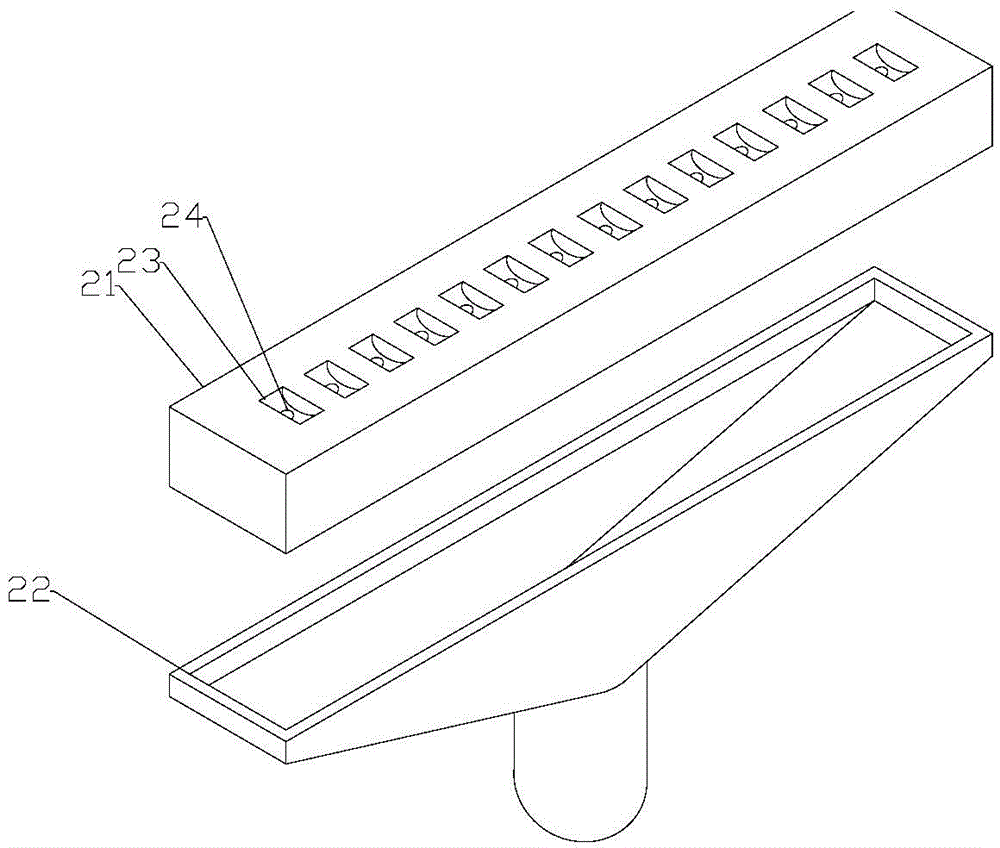

[0032] Fireproof polystyrene board production equipment, including a conveying line 1 for conveying polystyrene boards, so that polystyrene boards 11 can be conveyed forward on the conveying line 1 and pass through the infiltration station and curing station successively, so it is necessary for the convenience of description , the conveying line is artificially divided into the permeating section 1a and the curing section 1b behind the permeating section. Actually, for the conveying line 1 itself, the permeating section 1a and the curing section 1b behin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com