Preparation method of aerogel material and application thereof

A gel material and airgel technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of loss of silanization reagents, high recycling costs and environmental protection costs, and limited special structure processes, etc. Achieve the effects of reducing waste water, waste solvents and exhaust gas, reducing costs and environmental impact, and shortening the surface modification cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

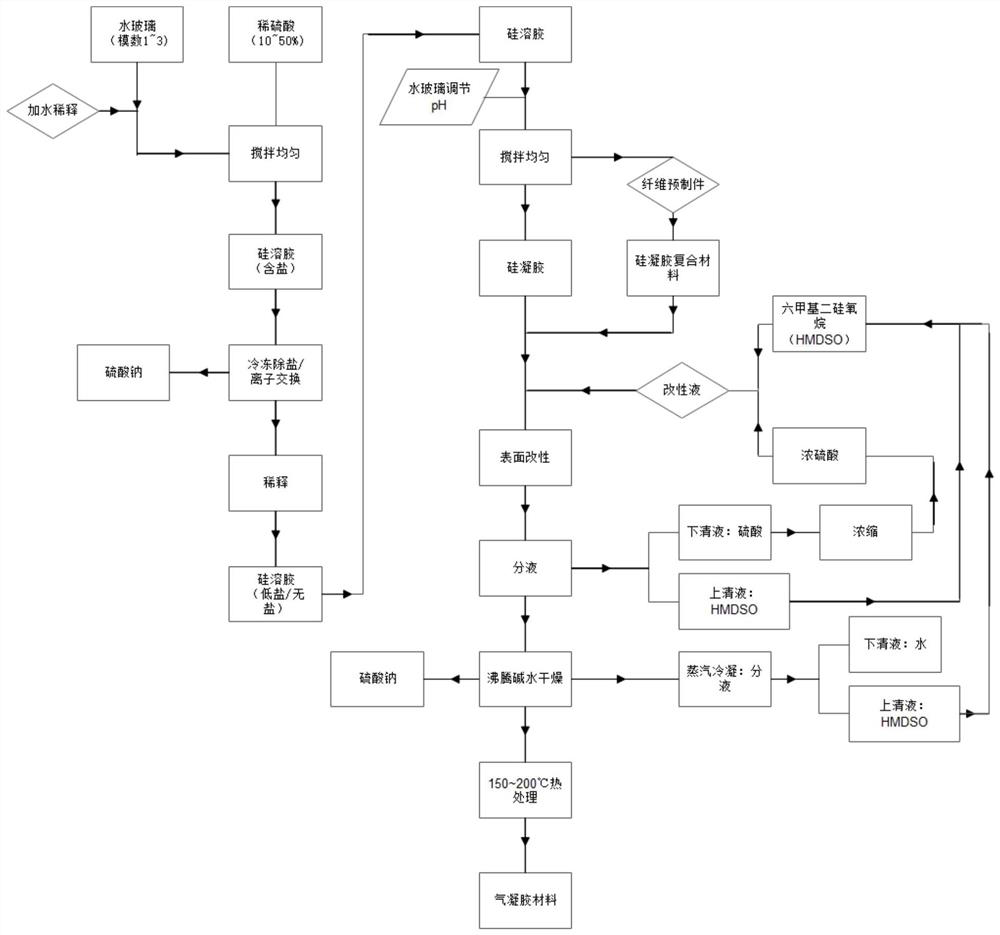

[0085] The preparation method of the airgel material of the present invention, the preparation process is as follows figure 1 As shown, it specifically includes the following steps:

[0086] Step (1) Preparation of silica sol: use water glass with a modulus of 2.0-3.5 as raw material, use water as solvent, dilute to 2-5 times, add it to the aqueous acid solution, control the pH to 3-5, and then dissolve the sol Cool to below 0°C, filter or centrifuge to remove salt, and obtain low-sodium silica sol. Further, sodium-free silica sol can be obtained through ion exchange resin.

[0087] Step (2) Silica gel preparation: add water to dilute the silica sol described in step (1) to the target concentration, add alkali to adjust the pH to 6.5-7.5, and after standing still, the silica gel can be obtained. Silicone gel composites can be obtained by impregnating the fiber preforms before gelling.

[0088] Step (3) Modification solution preparation: Mix 1 part of hexamethyldisiloxane w...

Embodiment 1

[0094] An airgel material and a preparation method thereof, comprising the steps of:

[0095] (1) Preparation of silica sol: Add 1 part of water glass with a modulus of 3.2 to the stirring tank, use water as solvent, dilute the water glass to 5 times the volume, and slowly add 0.5 parts to a concentration of 50% under stirring conditions In the aqueous solution of sulfuric acid, the pH was controlled to be 4.5 during the process. After the water glass was completely added, the stirring was continued for 10 minutes to obtain a salt-containing silica sol. Then cool the salt-containing silica sol to 0°C, filter to remove the salt and sodium sulfate crystals, and the mother liquor is the low-sodium silica sol.

[0096] (2) Silica gel preparation: transfer the low-sodium silica sol described in step (1) to a stirring tank, add 0.1 part of water glass dropwise under stirring conditions, adjust the pH to 7.5, and obtain silica gel.

[0097] (3) Modification solution preparation: Mix...

Embodiment 2

[0103] An airgel material and a preparation method thereof, comprising the steps of:

[0104] (1) Preparation of silica sol: Use 1 part of water glass with a modulus of 3.2 as raw material, use water as solvent, dilute to 5 times the volume, and slowly add it to 0.5 parts of 50% sulfuric acid aqueous solution under stirring conditions, During the process, the pH was controlled to be 5. After the water glass was completely added, the stirring was continued for 10 minutes to obtain a salt-containing silica sol. Then cool the sol to 0°C, filter to remove the salt, and the mother liquor is low-sodium silica sol.

[0105] (2) Preparation of silica gel: Add low-sodium silica sol described in step (1) dropwise with 0.1 part of water glass to adjust the pH to 7.0 under stirring conditions, then quickly pour it into the surface of the water-absorbent fiber mat, and let it stand for 30 minutes After that, a gel composite material is obtained.

[0106] (3) Modification solution prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com