Light thermal insulation polystyrene foam plastic

A technology of polystyrene and foam plastics, which is applied in the field of light thermal insulation polystyrene foam plastics. It can solve the problems of no qualitative change in fire protection and heat preservation performance, difficulty in meeting fire protection requirements, uneven product quality and performance, and achieve excellent physical performance. Small changes in performance and thermal conductivity, good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

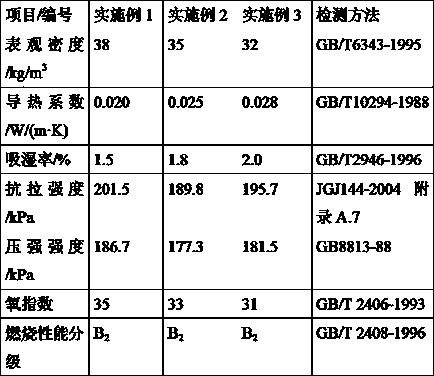

Examples

Embodiment 1

[0021] A light-duty thermal insulation polystyrene foam plastic is prepared from the following raw materials in parts by weight.

[0022] 98 parts of styrene resin, CO 2 3 parts of foaming agent, 6 parts of pentane foaming agent, 13 parts of polyethylene acrylate, 9 parts of silicone resin, 9 parts of polyvinyl n-butyl ether, 3 parts of nano zinc oxide, 4 parts of carbon black, talcum powder 2 parts, 9 parts of hexabromocyclododecane and 1 part of ricinoleic acid.

[0023] Its preparation steps are as follows.

[0024] (1) Pre-foaming: Styrene resin, CO 2 Foaming agent, pentane foaming agent, polyethylene acrylate, silicone resin, polyvinyl n-butyl ether, nano zinc oxide, carbon black, talcum powder, hexabromocyclododecane and ricinoleic acid are uniformly mixed , Put the mixed raw materials into the pre-foaming machine for pre-foaming, the steam pressure is 0.2-0.5Mpa, the pre-expansion temperature is 90°C-105°C, the stirring speed is 80r / min, and the time is controlled at...

Embodiment 2

[0028] A light-duty thermal insulation polystyrene foam plastic is prepared from the following raw materials in parts by weight.

[0029] 105 parts of styrene resin, CO 2 4 parts of foaming agent, 7 parts of pentane foaming agent, 11 parts of polyethylene acrylate, 7 parts of silicone resin, 11 parts of polyvinyl n-butyl ether, 3 parts of nano zinc oxide, 4 parts of carbon black, talcum powder 4 parts, 7 parts of hexabromocyclododecane and 1 part of ricinoleic acid.

[0030] Its preparation steps are as follows.

[0031] (1) Pre-foaming: Styrene resin, CO 2 Foaming agent, pentane foaming agent, polyethylene acrylate, silicone resin, polyvinyl n-butyl ether, nano zinc oxide, carbon black, talcum powder, hexabromocyclododecane and ricinoleic acid are uniformly mixed , Put the mixed raw materials into the pre-foaming machine for pre-foaming, the steam pressure is 0.2-0.5Mpa, the pre-expansion temperature is 90°C-105°C, the stirring speed is 80r / min, and the time is controlled ...

Embodiment 3

[0035] A light-duty thermal insulation polystyrene foam plastic is prepared from the following raw materials in parts by weight.

[0036] 90 parts of styrene resin, 5 parts of CO2 blowing agent, 10 parts of pentane blowing agent, 14 parts of polyvinyl acrylate, 11 parts of silicone resin, 7 parts of polyvinyl n-butyl ether, 3 parts of nano zinc oxide, 4 parts of carbon black, 4 parts of talc, 10 parts of hexabromocyclododecane and 1 part of ricinoleic acid.

[0037] Its preparation steps are as follows.

[0038] (1) Pre-foaming: Styrene resin, CO 2 Foaming agent, pentane foaming agent, polyethylene acrylate, silicone resin, polyvinyl n-butyl ether, nano zinc oxide, carbon black, talcum powder, hexabromocyclododecane and ricinoleic acid are uniformly mixed , Put the mixed raw materials into the pre-foaming machine for pre-foaming, the steam pressure is 0.2-0.5Mpa, the pre-expansion temperature is 90°C-105°C, the stirring speed is 80r / min, and the time is controlled at 5 min. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com