Shaping method of bimetallic composite-material brake drum

A technology of composite materials and forming methods, which is applied in the forming field of brake drums, can solve the problems of poor thermal fatigue resistance, fracture and scrapping, and easy fatigue, etc., and achieve the effects of weight reduction, increased joint surface, and high interface joint quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

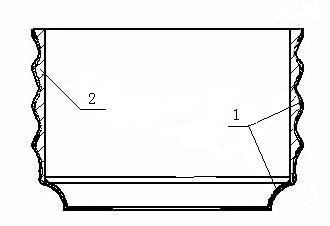

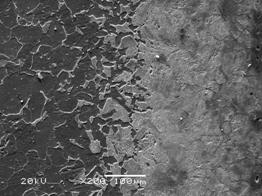

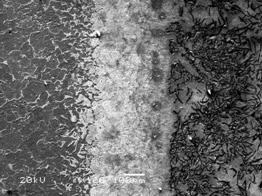

[0016] A method for forming a brake drum made of bimetallic composite material, the process is as follows: First, a low-carbon steel (08 steel or 10 steel) steel pipe with a wall thickness of 8mm is punched to form a brake drum jacket with a wavy circumferential wall, and the The wall thickness of the completed brake drum jacket is 5mm, the height is 270mm, and the maximum outer diameter is 400mm; then the molten iron is melted, and the molten iron is kept warm at 1380~1390°C; the low carbon steel brake drum jacket is placed in a horizontal centrifugal In the casting machine, and control the rotating speed of the horizontal centrifugal casting machine to 750~980r / min, after the brake drum cover is preheated to 900°C, then pour molten iron into the brake drum cover, and the rotation of the casting machine Casting is completed in the middle, the amount of molten iron is 5780~5860cm 3 , the process of casting molten iron is guaranteed to be completed within 10 minutes to prevent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com