Patents

Literature

45results about How to "Improve interface bonding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

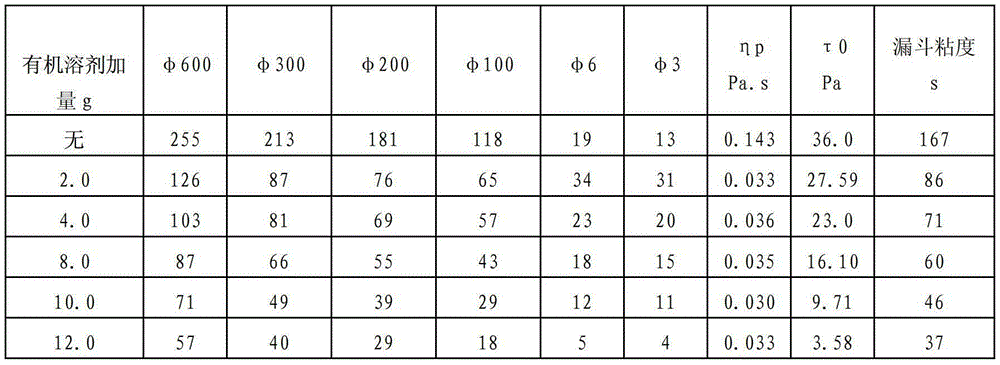

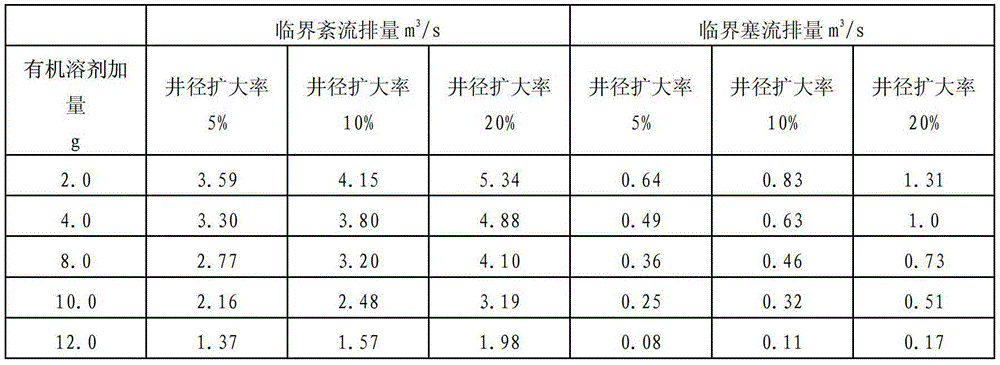

Dual-effect well cementing pad fluid using suspending agent as surfactant

ActiveCN103224774AWide range of density adaptationImprove cleanlinessDrilling compositionActive agentDual effect

The invention relates to a dual-effect well-cementing pad fluid using a suspending agent as a surfactant, and mainly solves problems that present well-cementing pad fluid is added with high-molecular polymer grade inorganic suspending agent which can influence compatibility and cement sheath cementation and thus influence sealing effect of well cementing and exploitation operation in a later stage. The dual-effect well-cementing pad fluid comprises the following components by weight parts: 12-20 parts of a flushing suspending agent, 0.2-1 part of an antifoaming agent, 0-420 parts of a weighting agent and 100 parts of water. The dual-effect well-cementing pad fluid using a suspending agent as a surfactant can eliminate adverse influences of inorganic soil and the high-molecular polymer in the well-cementing pad fluid on the compatibility and the cement sheath cementation, improve flushing and displacing effects on a drilling fluid, and guarantee quality of well cementing and the exploitation operation in the later stage.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

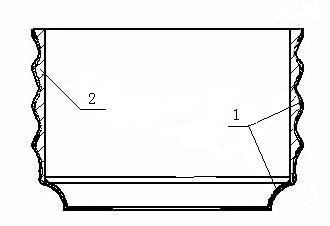

Shaping method of bimetallic composite-material brake drum

The invention discloses a shaping method of a bimetallic composite-material brake drum, and relates to the shaping method of the brake drum. The shaping method includes the steps of manufacturing a brake drum jacket with a waved circumferential pipe wall by using a low carbon steel pipe, placing the brake drum jacket in a horizontal centrifugal casting machine, and pouring molten iron at a certain temperature, thus finishing casting in the casting machine and finally obtaining the brake drum compositing two metal materials of low carbon steel and cast iron. The brake drum compositing two metal materials manufactured according to the shaping method provided by the invention can fully bring respective advantages into play, is high in combination quality of an interface, and light in weight.

Owner:HENAN UNIV OF SCI & TECH

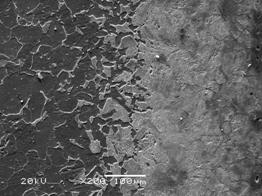

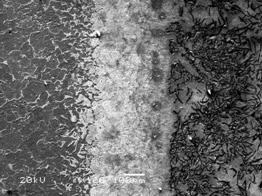

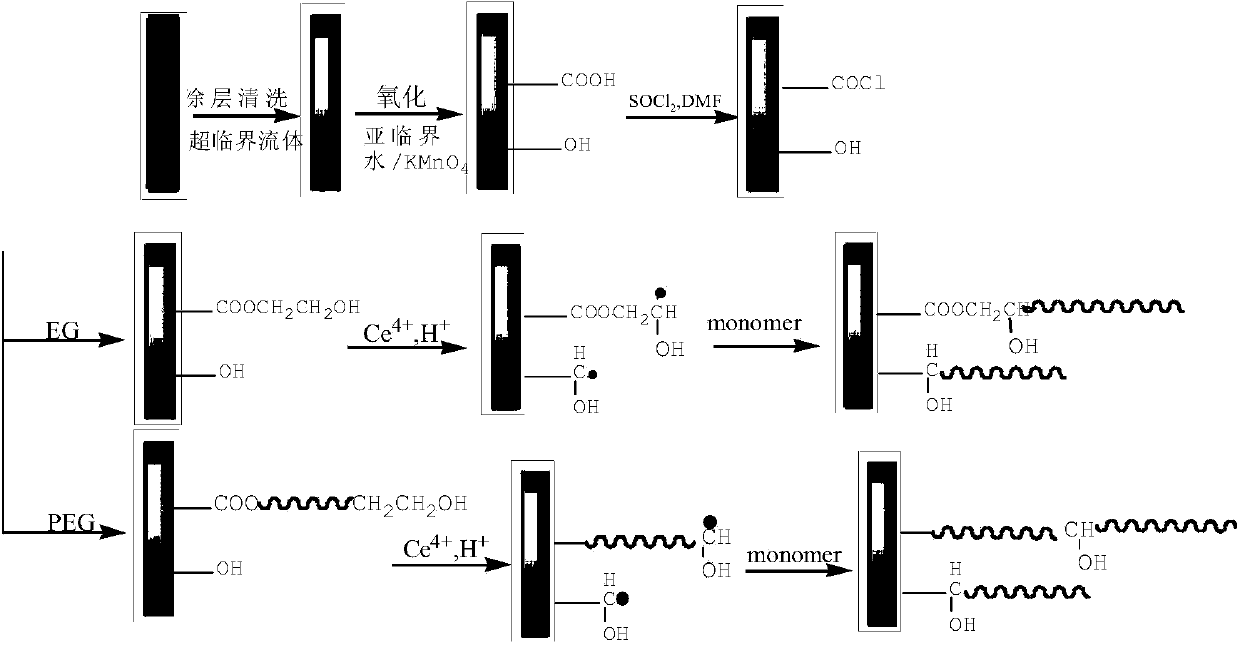

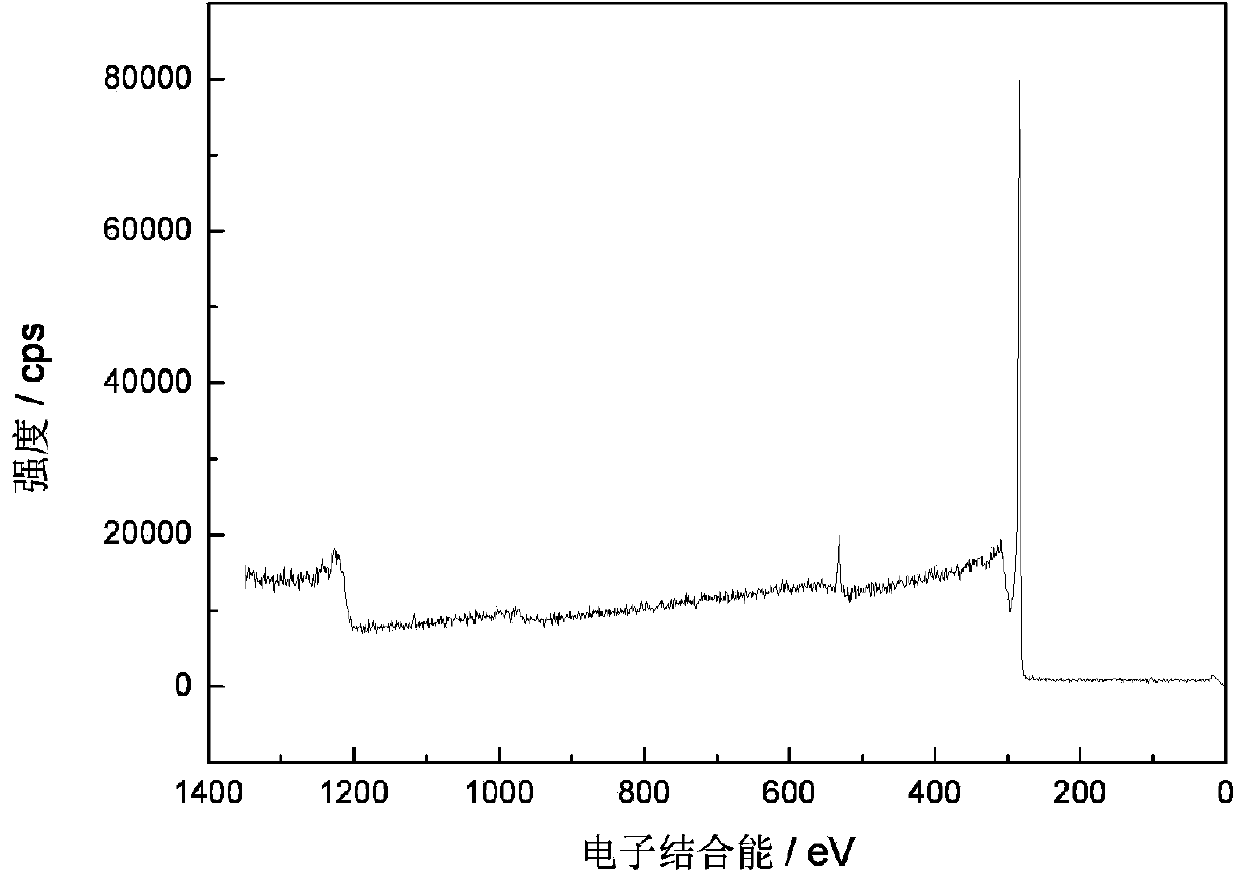

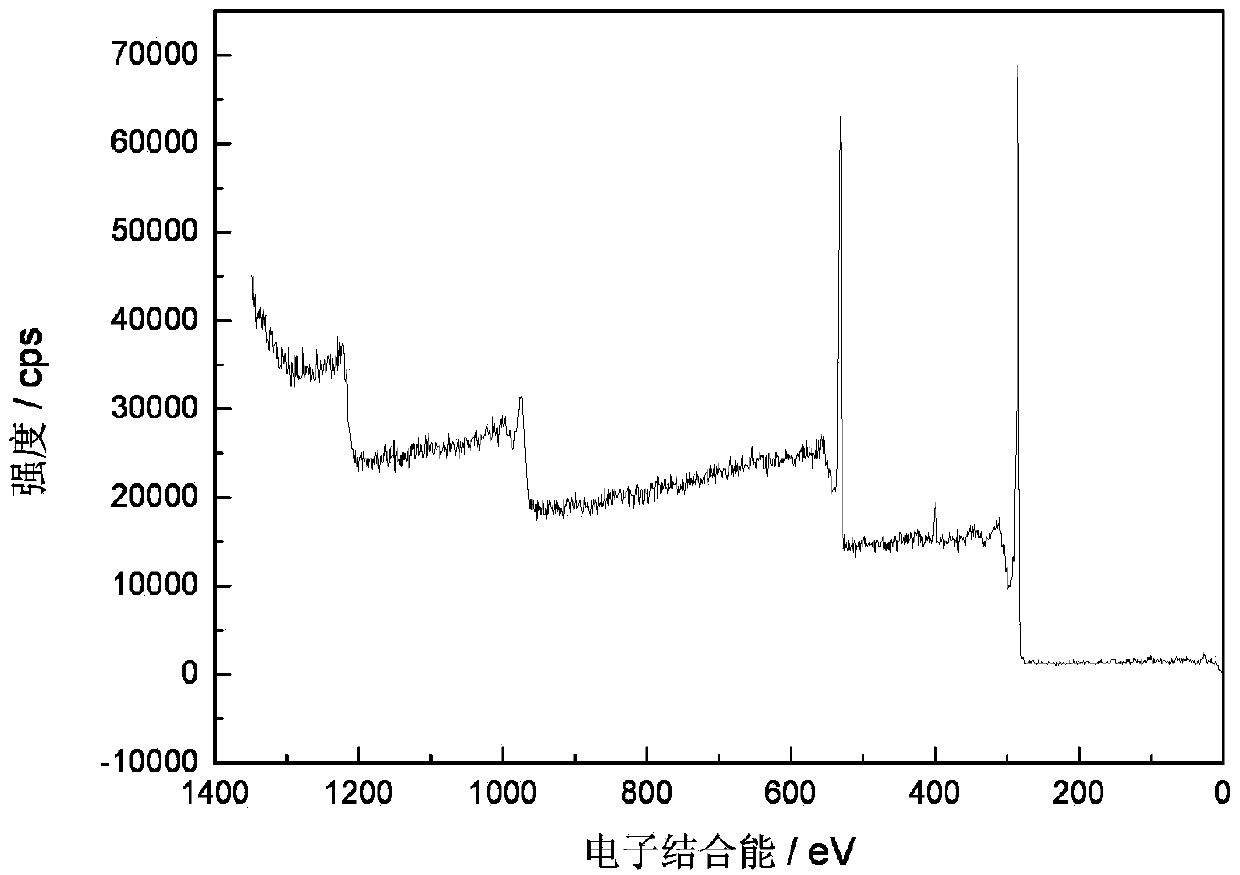

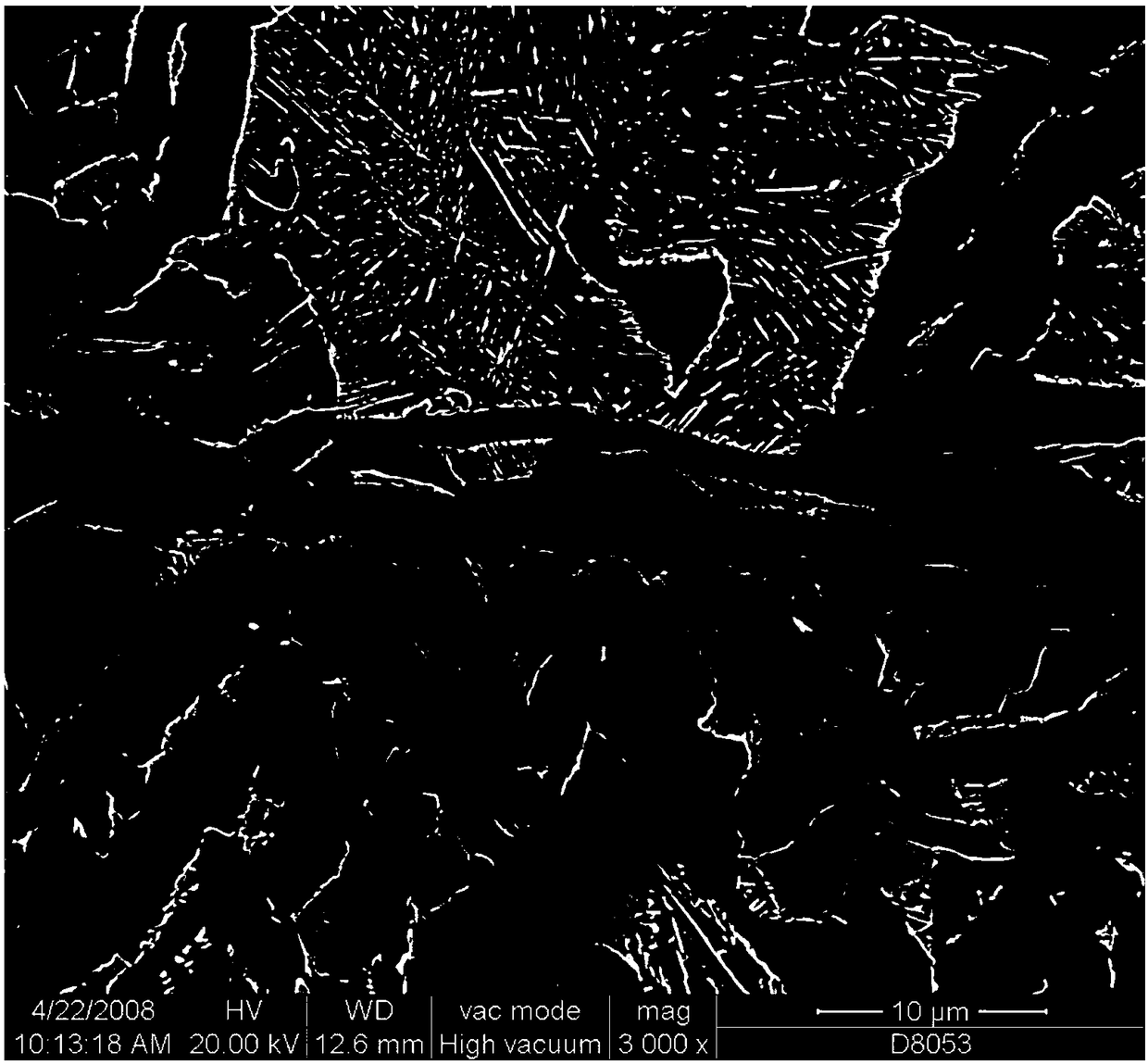

Polymer surface grafting method for carbon fiber

The invention relates to a polymer surface grafting method for a carbon fiber, and aims to overcome the defects of high system temperature, difficulty in control over conditions, solvent environment unfriendliness and limited monomer selection of an existing grafting from method. The method comprises the following steps: (1) removing an epoxy coating; (2) oxidizing the carbon fiber; (3) acylating and chlorinating the carbon fiber to obtain the acylated and chlorinated carbon fiber; (4) performing alcoholysis on the carbon fiber; and (5) grafting a polymer under a Ce<4+> initiating system of the carbon fiber to complete the operation. According to the method, reaction conditions of a Ce<4+> oxidation-reduction initiating system are mild, the operation is simple, monomers with different characteristics can be selected, and different performances are provided; the polymer can carry a great number of polar groups, so that the surface activity of the carbon fiber is improved, and the interfacial bonding quality of the carbon fiber and resin is further improved. The invention relates to the field of carbon fiber modification.

Owner:HARBIN INST OF TECH

Carbon nanotube/polytetrafluoroethylene composite material and preparation method thereof

InactiveCN105949688AImprove surface roughnessImprove mechanical propertiesCoatingsAl powderCarbon fibers

The invention discloses a carbon nanotube / polytetrafluoroethylene composite material and a preparation method thereof. The composite material is characterized in that steel fibers and carbon fibers are utilized to enhance the stretching resistance and frictional properties of the polytetrafluoroethylene; and the improved fusion process is utilized to sinter fine fillers, such as SiO2, Al powder and the like, onto the polytetrafluoroethylene surface at high temperature, so that the surface sintering behavior of the polytetrafluoroethylene is improved, thereby obviously enhancing the bonding strength. Besides, the carbon nanotubes are added to effectively enhance the strength, high temperature resistance, oxidation resistance and corrosion resistance of the composite material and lower the friction factor of the composite material.

Owner:ANHU WUHU CHANGJIANG JACK UP EQUIP CO LTD

Self-adhesive carbon fiber and steel fiber modified polytetrafluoroethylene material and preparation method thereof

The invention discloses a self-adhesive carbon fiber and steel fiber modified polytetrafluoroethylene material and a preparation method thereof. The preparation method is characterized in that steel fibers and carbon fibers are used to improve the tensile strength and friction performance of polytetrafluoroethylene; at the same time, an improved melting method is used to sinter fine filling materials such as SiO2, Al powder, and the like, thus the fine filling materials can be sintered on the surface of polytetrafluoroethylene; the surface sintering state of polytetrafluoroethylene is improved, and the joint strength is obviously improved. Furthermore, aviation kerosene is used to promote the permeation and fusion among polytetrafluoroethylene materials, and thus the polytetrafluoroethylene materials can be adhered without using any adhesive.

Owner:ANHU WUHU CHANGJIANG JACK UP EQUIP CO LTD

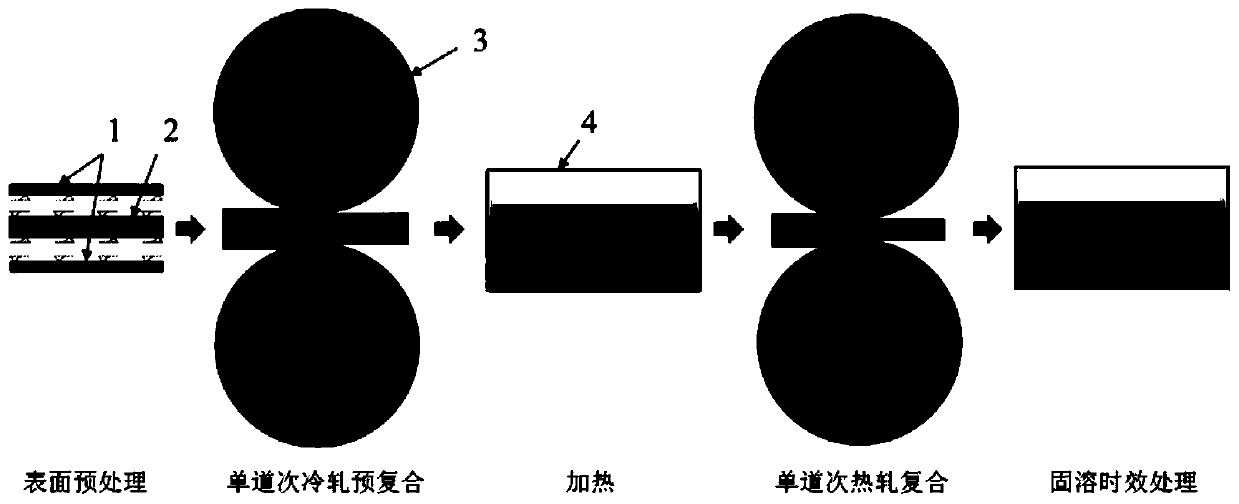

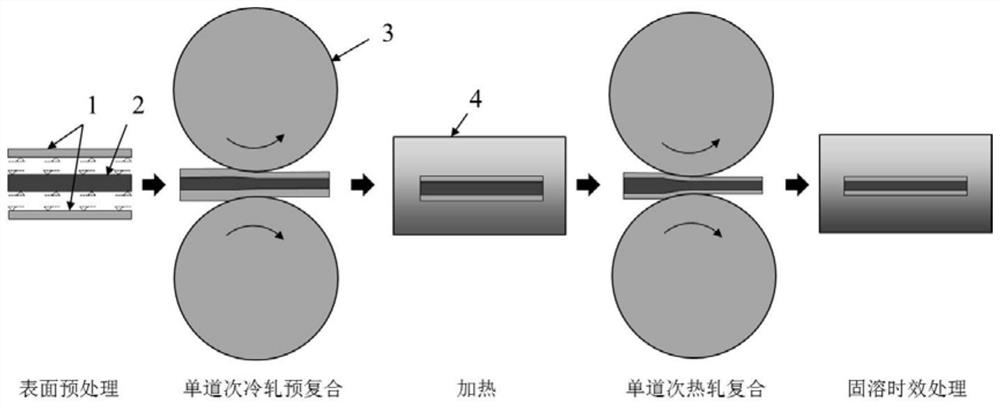

High-strength, high-plasticity and anti-corrosion aluminum alloy laminated composite material and manufacture method thereof

ActiveCN110665968AHigh strengthImprove plasticityTemperature control deviceFurnace typesLaminated compositesCorrosion resistant

The invention discloses a high-strength, high-plasticity and anti-corrosion aluminum alloy laminated composite material and a manufacture method thereof, and belongs to the technical field of aluminumalloy laminated composite materials. The high-strength, high-plasticity and anti-corrosion aluminum alloy laminated composite material is composed of a 1-series or 3-series aluminum alloy multi-layermaterial and a 6-sereis aluminum alloy base layer material. Annealing treatment is conducted on the aluminum alloy multi-layer material and the aluminum alloy base layer material; washing degreasingand polishing treatment are conducted on to-be-composited surfaces, wherein the polishing stripe direction is perpendicular to the rolling direction; then, a combined blank material is obtained through laminating; single-pass cold rolling pre-compositing, heating and single-pass hot rolling compositing are sequentially conducted on the combined blank material subjected to head riveting; and finally, the high-strength, high-plasticity and anti-corrosion aluminum alloy laminated composite material with strong alloy combination adopted for the interface is obtained through solid solution-aging treatment. The high-strength, high-plasticity and anti-corrosion aluminum alloy laminated composite material and the manufacture method are low in device requirement, simple in process flow, short in period, high in production efficiency, low in energy consumption and low in cost, and the manufactured aluminum alloy laminated composite material has high strength, high plasticity and excellent anti-corrosion performance at the same time.

Owner:UNIV OF SCI & TECH BEIJING

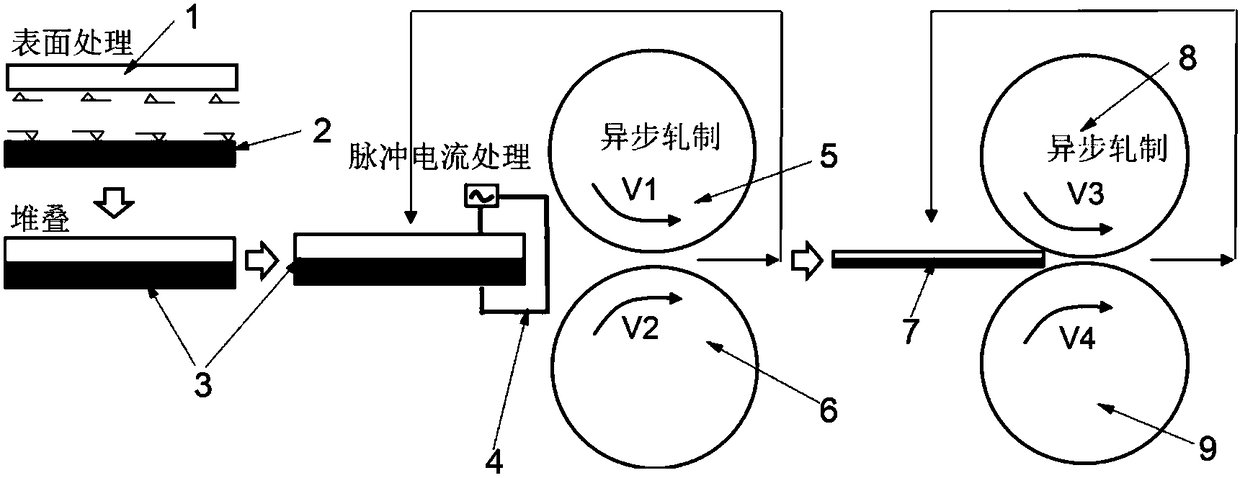

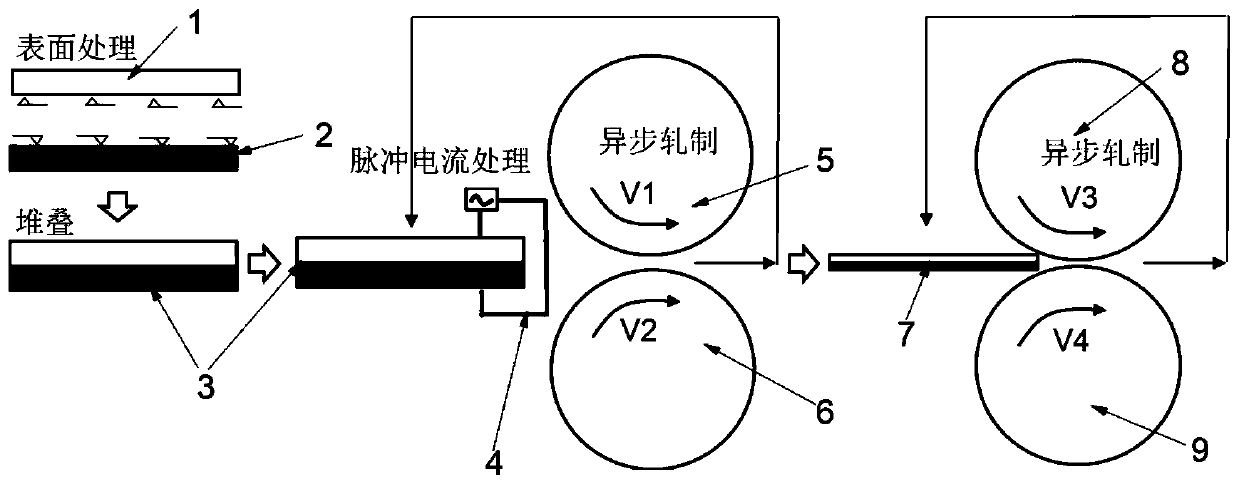

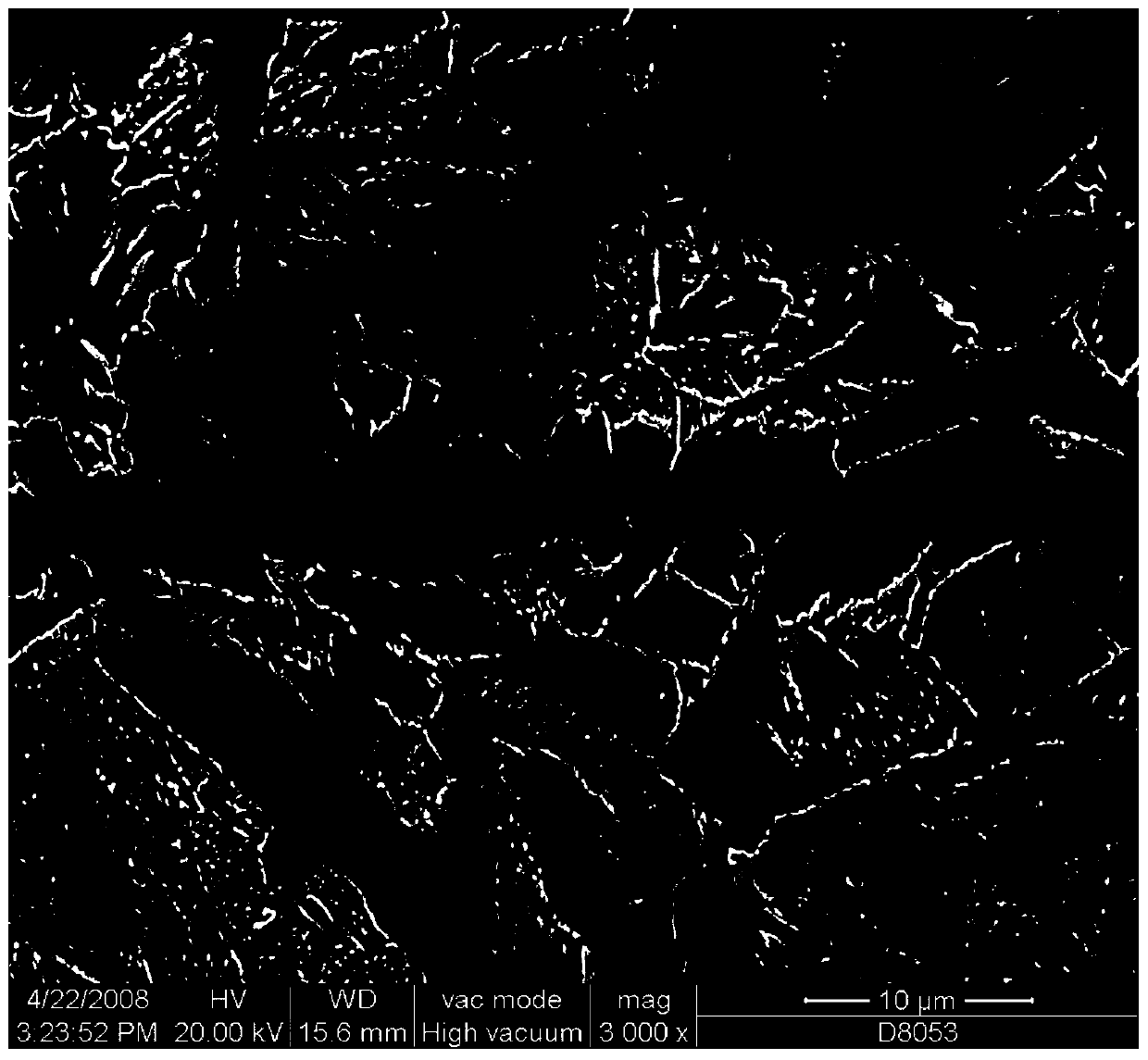

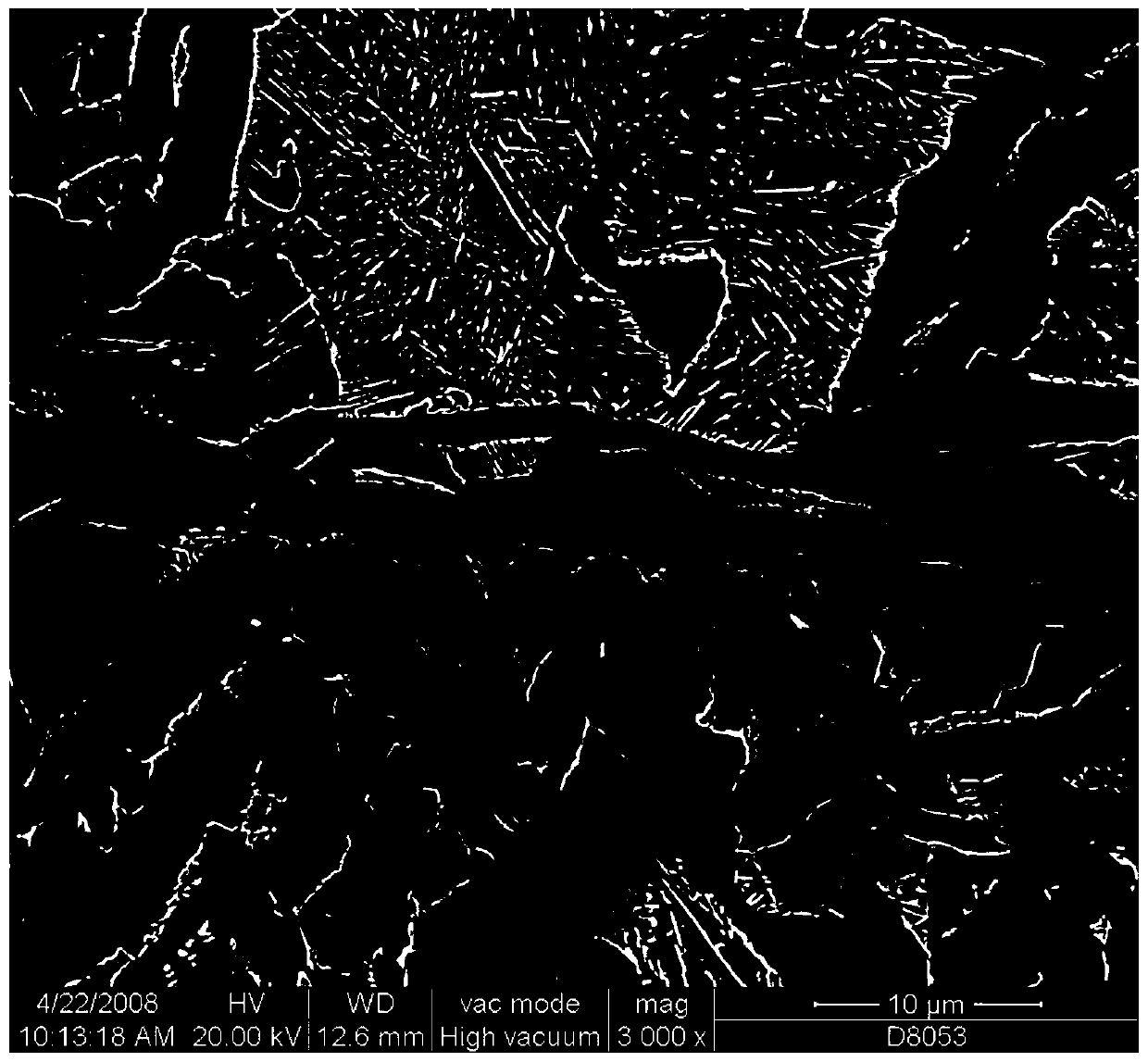

Method for preparing high-performance composite strip through pulse current asymmetrical rolling

ActiveCN108126982AImprove interface bonding qualityMetal rolling arrangementsReduction rateNoise reduction

The invention relates to a method for preparing a high-performance composite strip through pulse current asymmetrical rolling. The method comprises the steps that surfaces, subjected to surface treatment, of a strip A and a strip B are stacked, wherein the surfaces subjected to surface treatment are opposite to each other; at a rolling inlet, pulse current is applied to an A / B composite strip, thelocal area of the material surface is subjected to discharging, and surface metal is melted; the A / B composite strip obtained after pulse current treatment is subjected to asymmetrical rolling, material interface seaming is conducted, the differential speed ratio range is adjusted, and uniform deformation of the strip A and the strip B is achieved; the step is repeated 2-3 times; the obtained A / Bcomposite strip is subjected to asymmetrical rolling till the total reduction rate of the strip reaches 85%-90%. According to the composite metal material prepared through the method, the interface bonding quality is greatly improved compared with the interface of the composite metal material prepared through a traditional rolling method, and the high-performance composite metal strip can be usedfor the fields of bulletproof protection, aerospace, sound insulation and noise reduction, automobile weight lightening and the like.

Owner:CENT SOUTH UNIV

Non-formaldehyde waterproof plastic film reinforced flexible decorative veneer and preparation method thereof

ActiveCN106272804AReduce heat stressLower bonding temperatureElectric wood treatmentSynthetic resin layered productsEngineeringPlastic film

The invention discloses a non-formaldehyde waterproof plastic film reinforced flexible decorative veneer. Composting faces of a rotary cut or sliced decorative veneer and a plastic film are subjected to low-temperature plasma modification treatment, the treated composite faces of the decorative veneer and the plastic film are stacked to form composite blanks, and the non-formaldehyde waterproof plastic film reinforced flexible decorative veneer is obtained through hot-press gluing. The invention further discloses a preparation method of the non-formaldehyde waterproof plastic film reinforced flexible decorative veneer. The product prepared by adopting the method releases no formaldehyde, no adhesive or gluing procedure is omitted, the production cost is lowered, the product suppleness is good, and the non-formaldehyde waterproof plastic film reinforced flexible decorative veneer has the enough transverse tensile strength, will not cause glue penetration, is good in water resistance, saves energy, and is environmentally friendly, easy and convenient to operate and high in efficiency.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

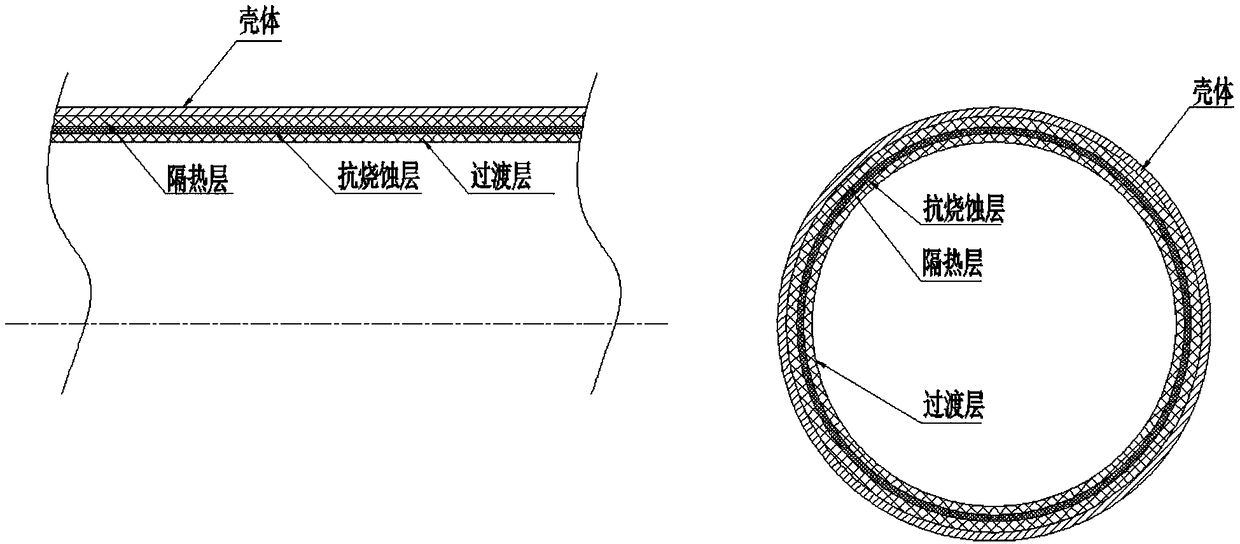

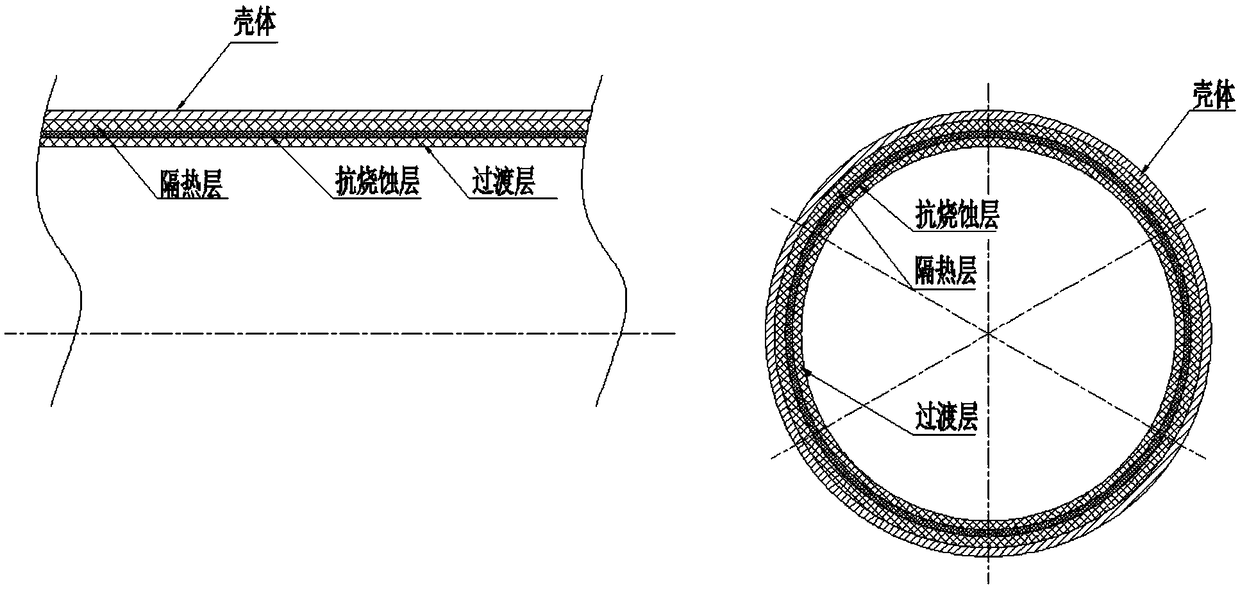

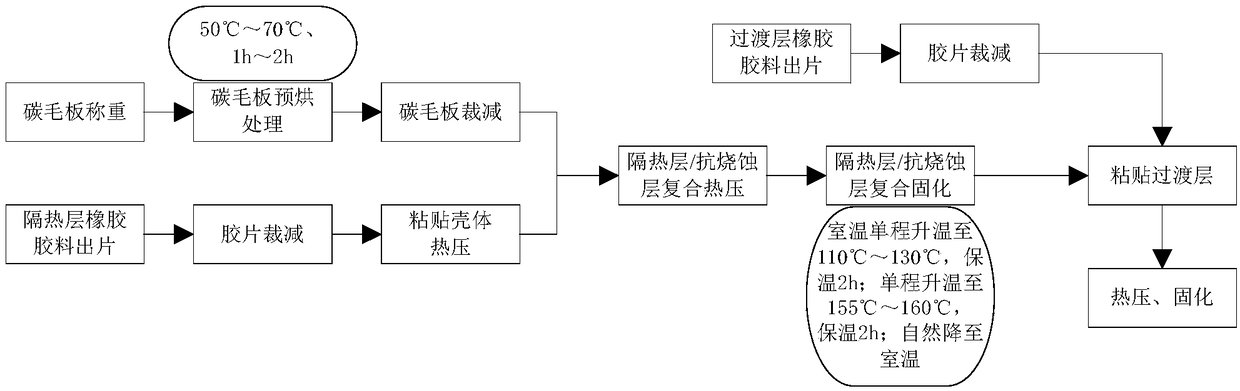

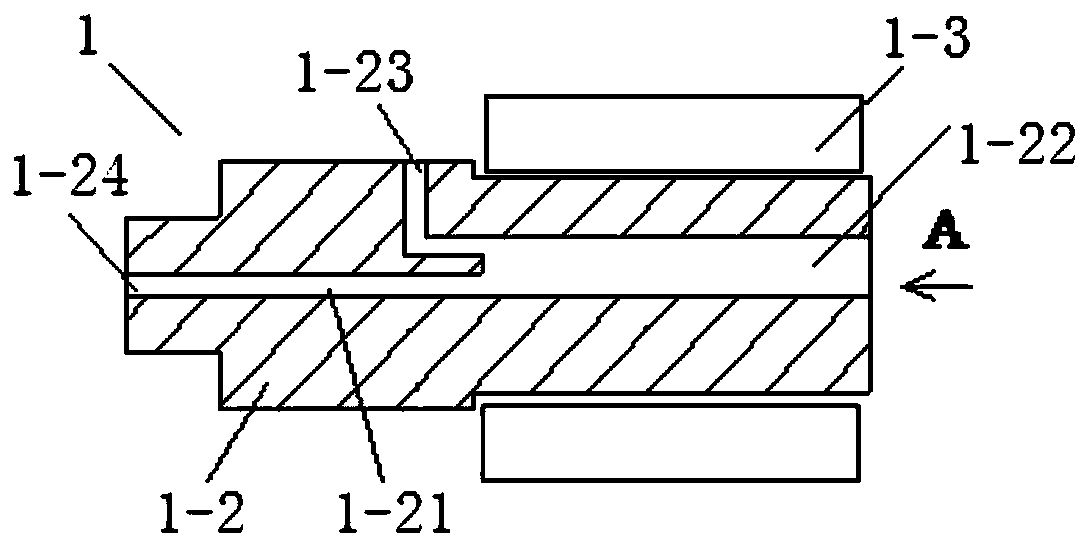

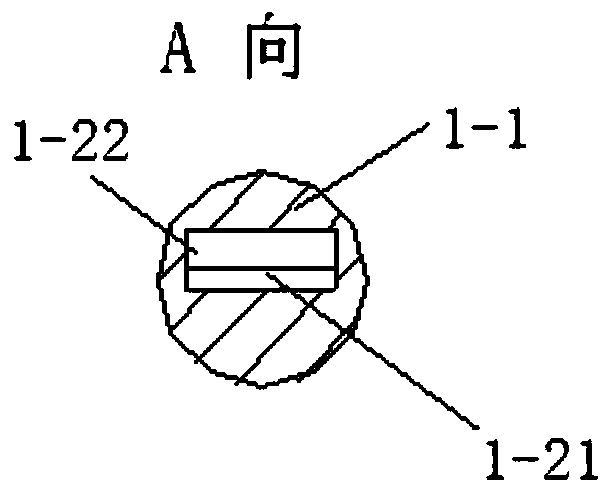

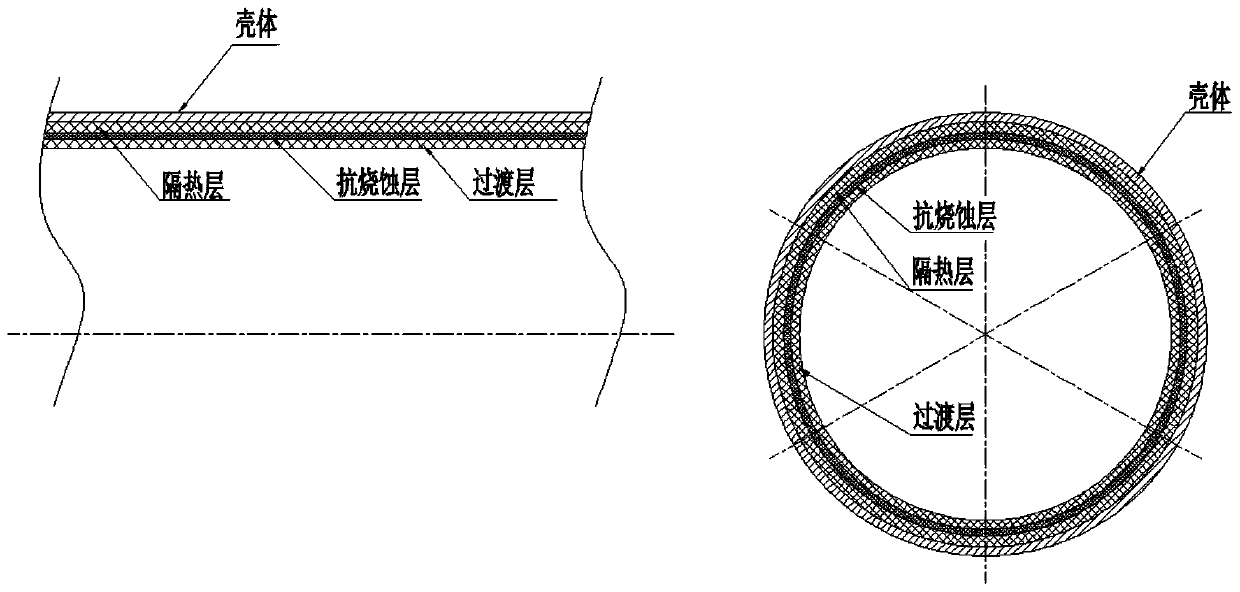

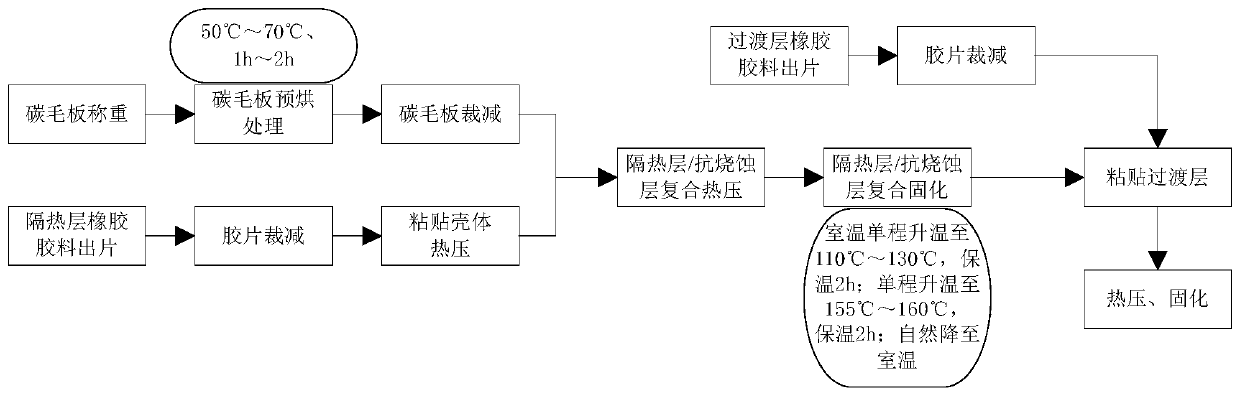

Sandwiched composite heat insulating layer structure and preparation method thereof

ActiveCN109058661AComplete structureConsistent thicknessThermal insulationLaminationFiberCombustion chamber

The invention provides a sandwiched composite heat insulating layer structure and a preparation method thereof. The preparation method comprises the following steps of: pasting a heat insulating layer, an ablation resistant layer and a transition layer in an engine combustion chamber housing, wherein the heat insulating layer and the transition layer are made of a heat insulating layer material ofan ethylene-propylene-diene monomer system, the ablation resistant layer is made of a carbon fiber phenolic aldehyde butyronitrile rubber soft sheet material, and the ablation resistant layer is divided into a plurality of pieces in a peripheral direction in the engine combustion chamber housing; and performing hot-pressing after pasting each layer, pre-drying the material of the ablation resistant layer before use, and curing a carbon rough board of the ablation resistant layer and the heat insulating layer before pasting the transition layer. The sandwiched composite heat insulating layer structure can improve integrity of the composite heat insulating layer, and strengthens reliability of a composite interface.

Owner:西安长峰机电研究所

Preparation method of high-performance gold coated copper bonding wire

ActiveCN104353669AUniform thicknessDense tissueHot-dipping/immersion processesSemiconductor/solid-state device detailsReduction rateWire rod

The invention relates to a gold coated copper bonding wire and a preparation method thereof. The gold coated copper bonding wire is formed by combining core wire copper and a gold coating layer, the diameter of the bonding wire is 10-50 mum, and the ratio of the area of the gold coating layer to that of the cross section is 10-30%. The preparation method comprises the following steps: adopting an oxygen-free copper rod with the diameter of 5-30 mm as the core material, and adopting the reversed solidification method to prepare a gold coated copper composite wire blank; carrying out multi-pass hole pattern rolling and / or drawing processing on the composite wire blank to obtain a wire rod with the diameter of 3-8 mm, wherein the rolling speed is 10-200 m / min, and the reduction rate of the single-pass section is 10-50%, or the drawing speed is 5-50 m / min, and the reduction rate of the single-pass section is 10-30%; then, carrying out rough drawing processing and fine drawing processing on the composite wire rod formed by rolling processing and / or drawing processing to prepare the gold coated copper bonding wire; middle annealing can be exerted in the drawing process, the annealing temperature is 100-400 DEG C, and the annealing time is 10-60 min. The gold coated copper bonding wire is compact in coating layer, uniform in thickness, high in bonding strength of the interface, excellent in processability, low in possibility of web breaking and wire breaking, short in preparation technological process, high in yield and low in manufacturing cost.

Owner:UNIV OF SCI & TECH BEIJING

Method for reinforcing magnesium alloy compound material through zinc oxide-covering graphene

The invention discloses a method for reinforcing a magnesium alloy compound material through zinc oxide-covering graphene. The method comprises the following steps that a liquid-state dispersion method is adopted for firstly preparing a preform green body with a mass ratio of the zinc oxide-covering graphene to pure aluminum powder equal to 10-25%, then the preform green body is added into magnesium alloy melt, and after ultrasonic dispersion treatment with power of 500-1000 W is conducted for 120 min, under a condition of 550-630 DEG C, a casting method is adopted for preparing the AZ91 magnesium alloy compound material reinforced by the zinc oxide-covering graphene with a content of 0.1-5%. By means of the method for reinforcing the magnesium alloy compound material through the zinc oxide-covering graphene, the even dispersion of the graphene in a magnesium matrix can be effectively improved, the interface bonding quality of the graphene and the magnesium matrix is improved, meanwhile, a good crystal grain refining effect is obtained, and the mechanical performance of the compound material is greatly improved, so that the method for reinforcing the magnesium alloy compound material through the zinc oxide-covering graphene is suitable for preparing the graphene-magnesium alloy compound material excellent in performance on a large scale.

Owner:JIANGXI TIANYUE AUTOMOBILE PARTS

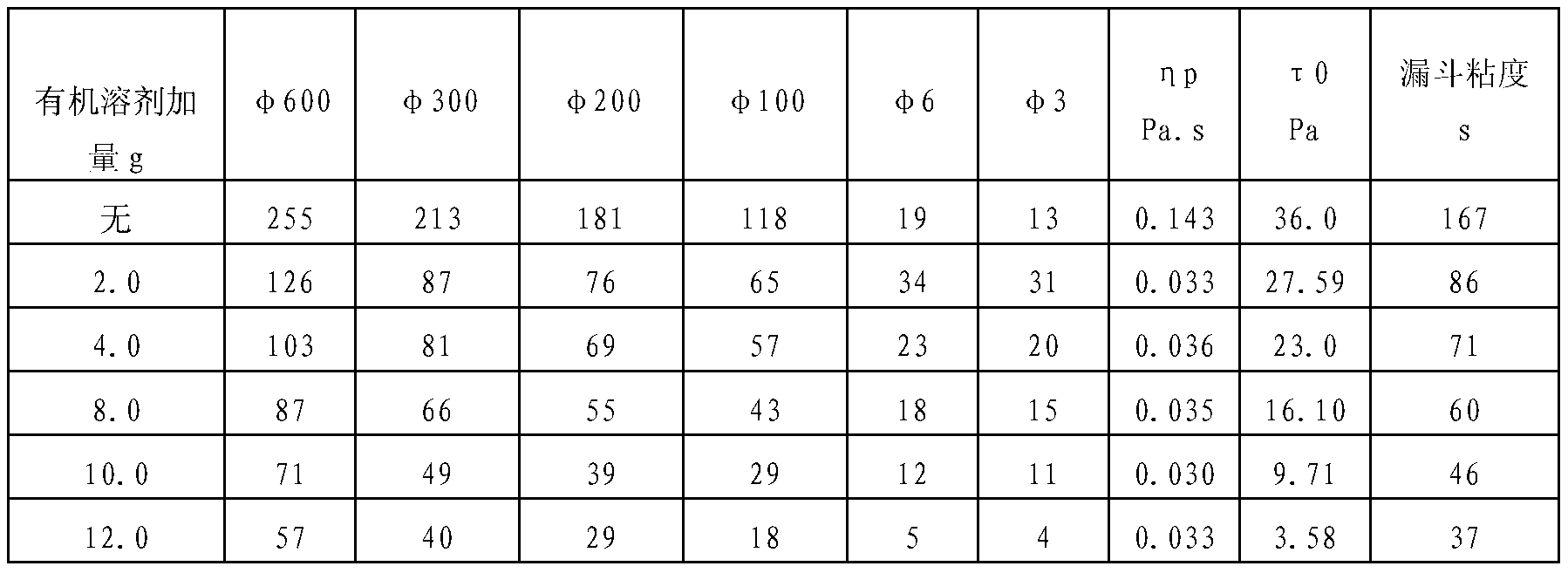

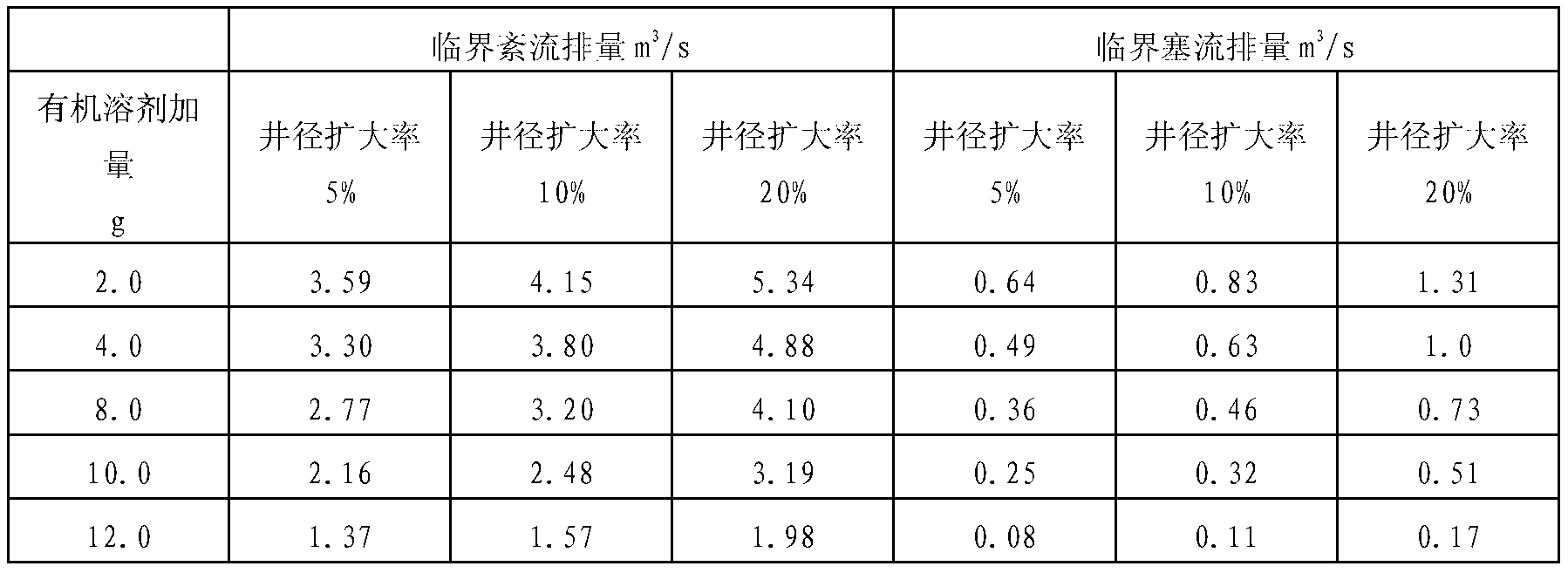

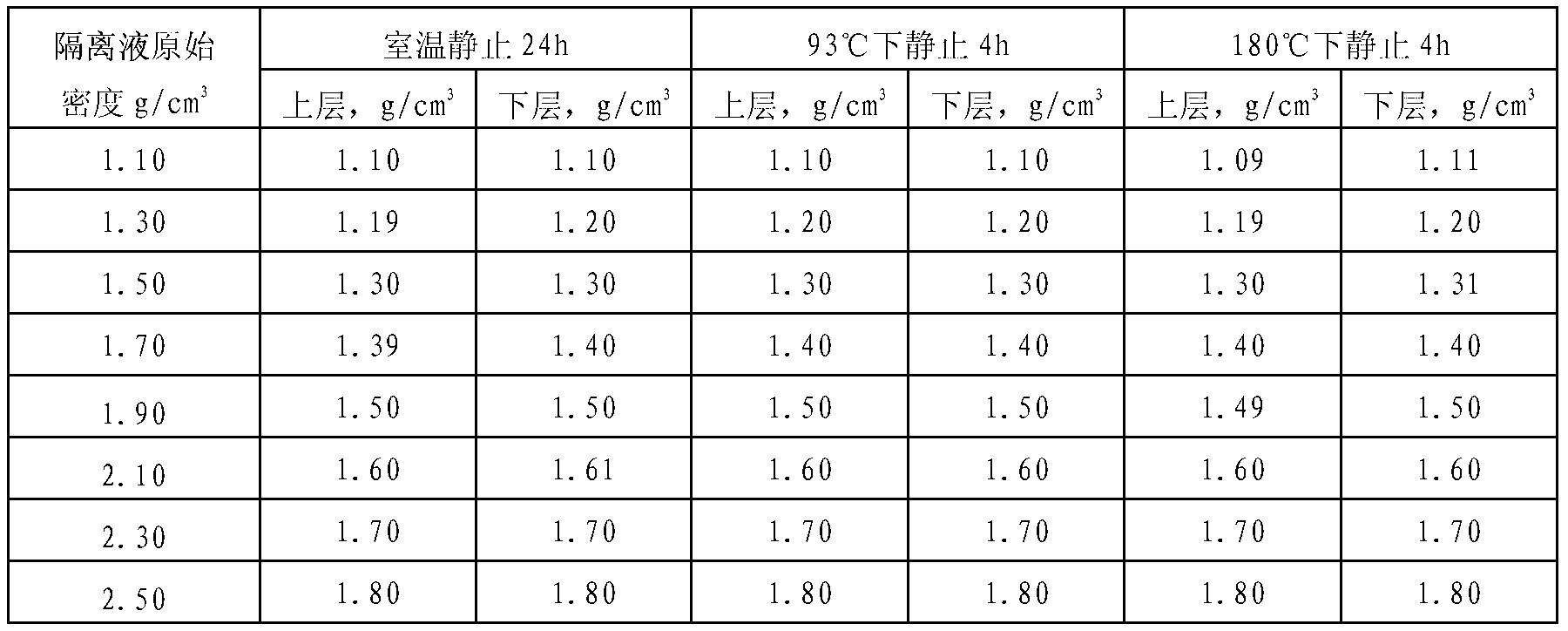

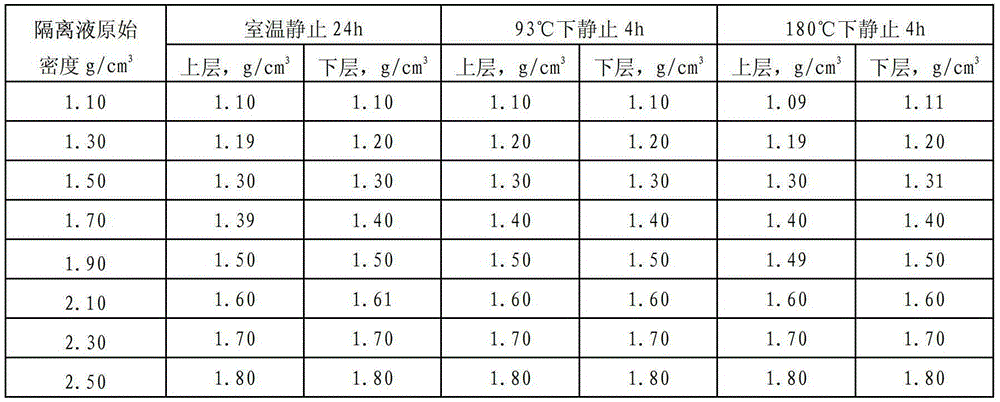

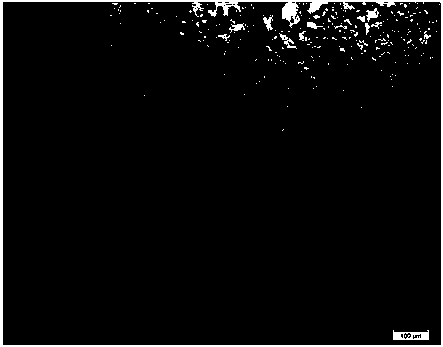

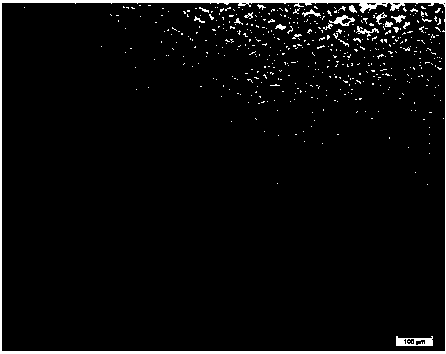

Double-effect washing type spacer fluid for well cementation and preparation method of spacer fluid

InactiveCN109370550AImprove permeabilityExcellent emulsification and solubilizationDrilling compositionSuspending AgentsFatty alcohol

The invention belongs to the field of petroleum and gas well drilling and cementation technologies and oilfield chemical technologies and provides a double-effect washing type spacer fluid for well cementation and a preparation method of the spacer fluid. The spacer fluid is prepared from raw materials as follows: clear water, a washing agent, a suspending agent, a retarder, a weighting agent anda defoaming agent; the washing agent is prepared from raw materials as follows: water, sodium alcohol ether sulfate, octylphenol polyethylene-10, fatty alcohol polyethylene ether, alkyl glycoside anda cleaning aid. The double-effect washing type spacer fluid for well cementation has dual functions of washing and spacing, has efficient oil film cleaning capacity, can improve the interface cementing quality, realize high-quality cementing and sealing of annulus interfaces and guarantee stability of mud and has a function of avoiding contact pollution and thickening of oil-based mud and the spacer fluid. The preparation method of the double-effect washing type spacer fluid is scientific in design, simple to operate and suitable for industrial mass production.

Owner:成都欧美克石油科技股份有限公司

Fluorescent polytetrafluoroethylene material modified with carbon fibers and steel fibers and preparing method of fluorescent polytetrafluoroethylene material

The invention discloses a fluorescent polytetrafluoroethylene material modified with carbon fibers and steel fibers and a preparing method of the fluorescent polytetrafluoroethylene material. The fluorescent polytetrafluoroethylene material modified with carbon fibers and steel fibers and the preparing method of the fluorescent polytetrafluoroethylene material are characterized in that steel fibers and carbon fibers are used for improving the tensile strength and the friction performance of polytetrafluoroethylene; meanwhile, an improved melting method is used for sintering fine filler such as SiO2 powder and Al powder to the surface of polytetrafluoroethylene at a high temperature, the surface sintered state of polytetrafluoroethylene is improved, and the joint strength is obviously improved. Besides, fluorescent powder is added in a matched mode, and the material can absorb energy after being illuminated by light and can automatically emit light in dark places.

Owner:ANHU WUHU CHANGJIANG JACK UP EQUIP CO LTD

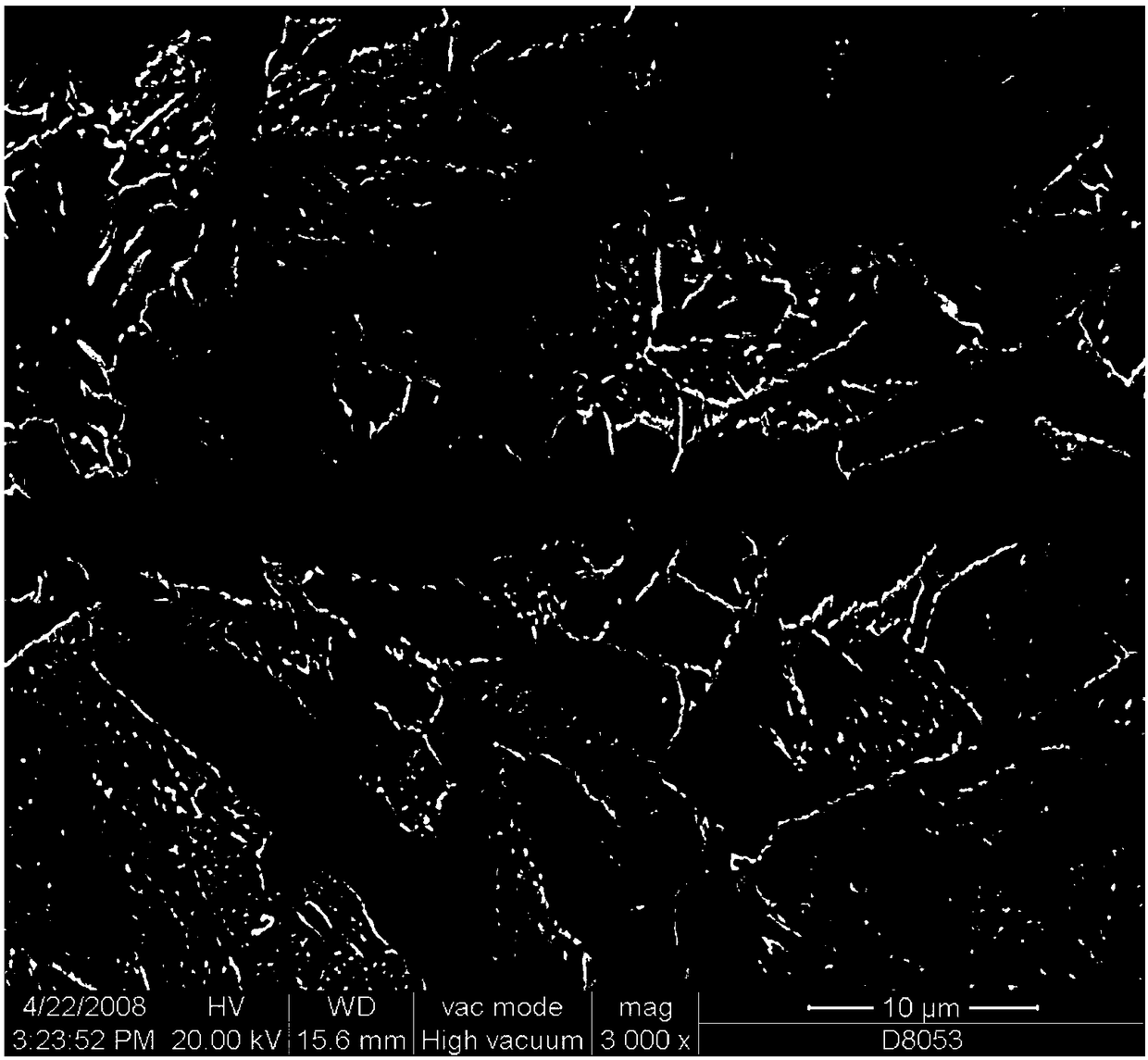

Short-flow efficient production process of double-metal composite belt material

ActiveCN108580849AShort processIncrease productivityMetal rolling arrangementsAcid washingComposite plate

Owner:UNIV OF SCI & TECH BEIJING

Self-cleaning polytetrafluoroethylene material and preparation method thereof

The present invention discloses a self-cleaning polytetrafluoroethylene material and a preparation method thereof, characterized in that steel fiber and carbon fiber are utilized to improve tensile strength and frictional performance of polytetrafluoroethylene, the modified melting method is also utilized to sinter the fine fillers such as SiO2 and Al powder at high temperature to the surface of the polytetrafluoroethylene, the surface sintering state of the polytetrafluoroethylene is improved, and gluing strength is significantly improved. In addition, the sol-gel method is utilized to synthesize nano titanium dioxide and spread it to the surface of a composite, and the self-cleaning functionality is imparted to the material.

Owner:ANHUI RONGDA VALVE

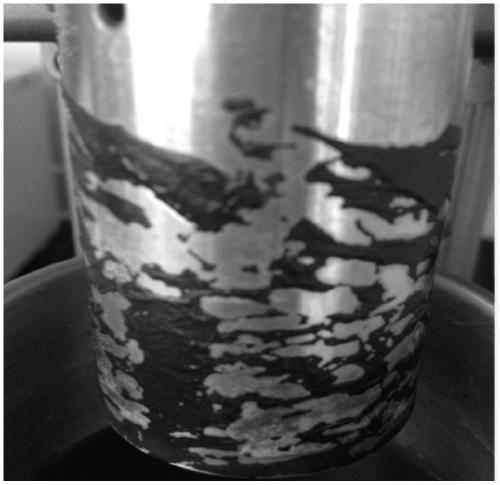

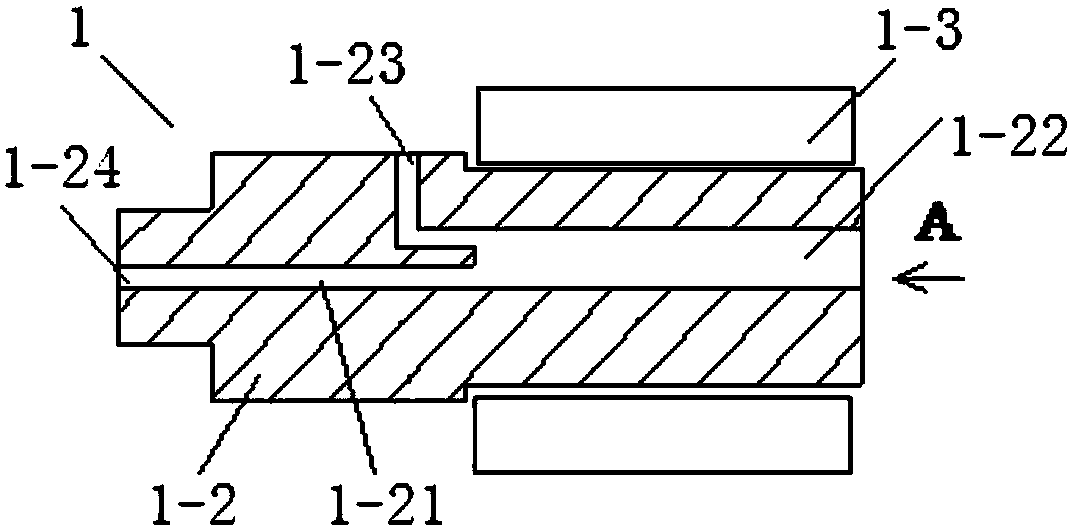

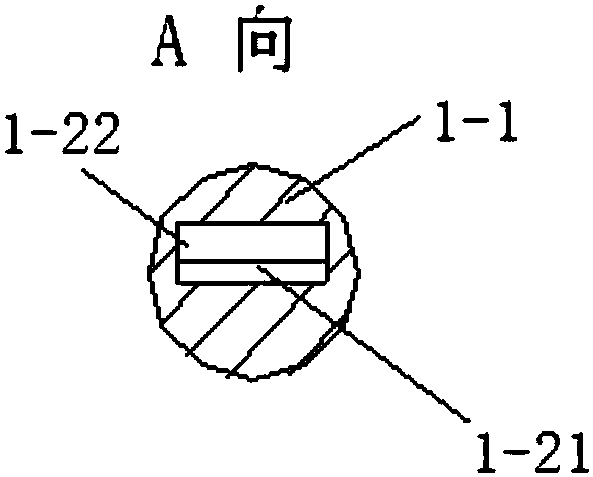

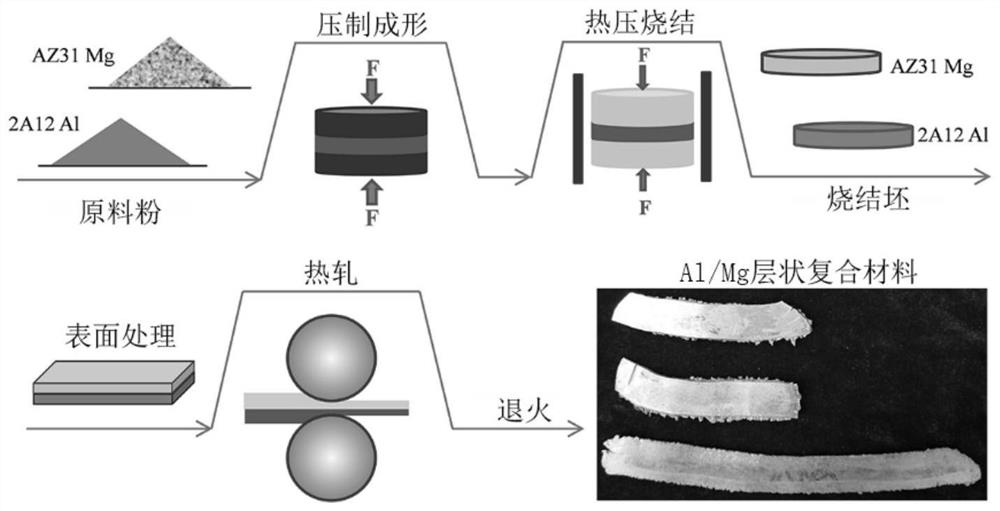

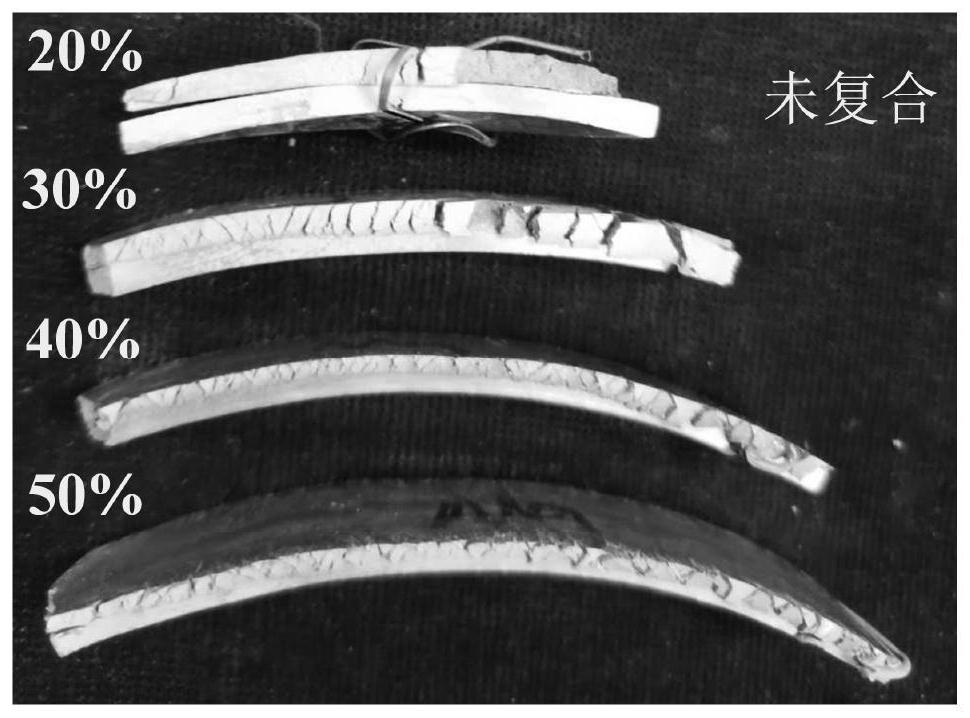

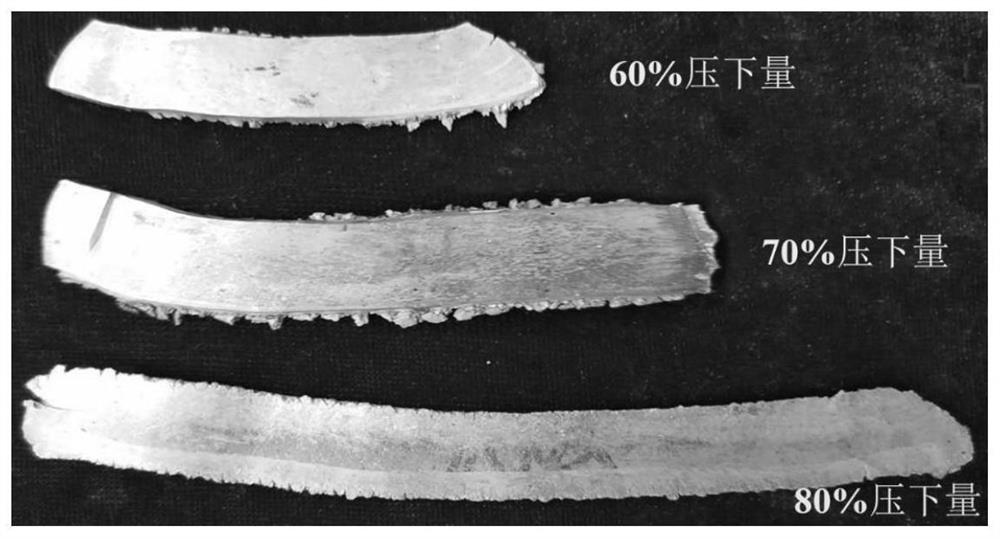

Method for preparing ultrathin aluminum-magnesium layered composite material through low-temperature rolling

ActiveCN112828037AImprove interface bonding qualityImprove performanceTemperature control deviceAuxillary arrangementsMagnesium alloyAluminium alloy

The invention relates to a preparation method of an ultrathin aluminum-magnesium layered composite material, and belongs to the technical field of aluminum-magnesium composite materials. The preparation method comprises processes of aluminum alloy powder and magnesium alloy powder pressing and forming, presintering, composite rolling and post-treatment. When the aluminum alloy powder is presintered after being pressed and formed, a temperature is controlled to be 500-630 DEG C, and time is larger than or equal to 60 minutes; when the magnesium alloy powder is presintered after being pressed and formed, a temperature is controlled to be 500-630 DEG C, and time is more than or equal to 60 minutes; during composite rolling, a temperature is controlled to be 270-450 DEG C, preferably 275-350 DEG C, and during composite rolling, single-pass rolling reduction is 30-80%; and when the composite rolling temperature is lower than 310 DEG C, the single-pass rolling reduction is 40-80%. According to the preparation method of the ultrathin aluminum-magnesium layered composite material, the aluminum-magnesium layered composite material with excellent performance is obtained under a low-temperature condition (lower than 300 DEG C) for the first time. Meanwhile, the product yield is greatly improved under a low-temperature hot rolling condition.

Owner:CENT SOUTH UNIV

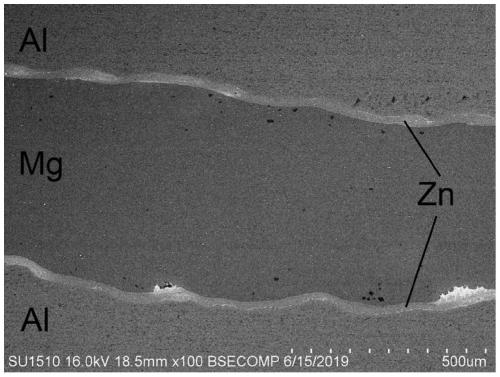

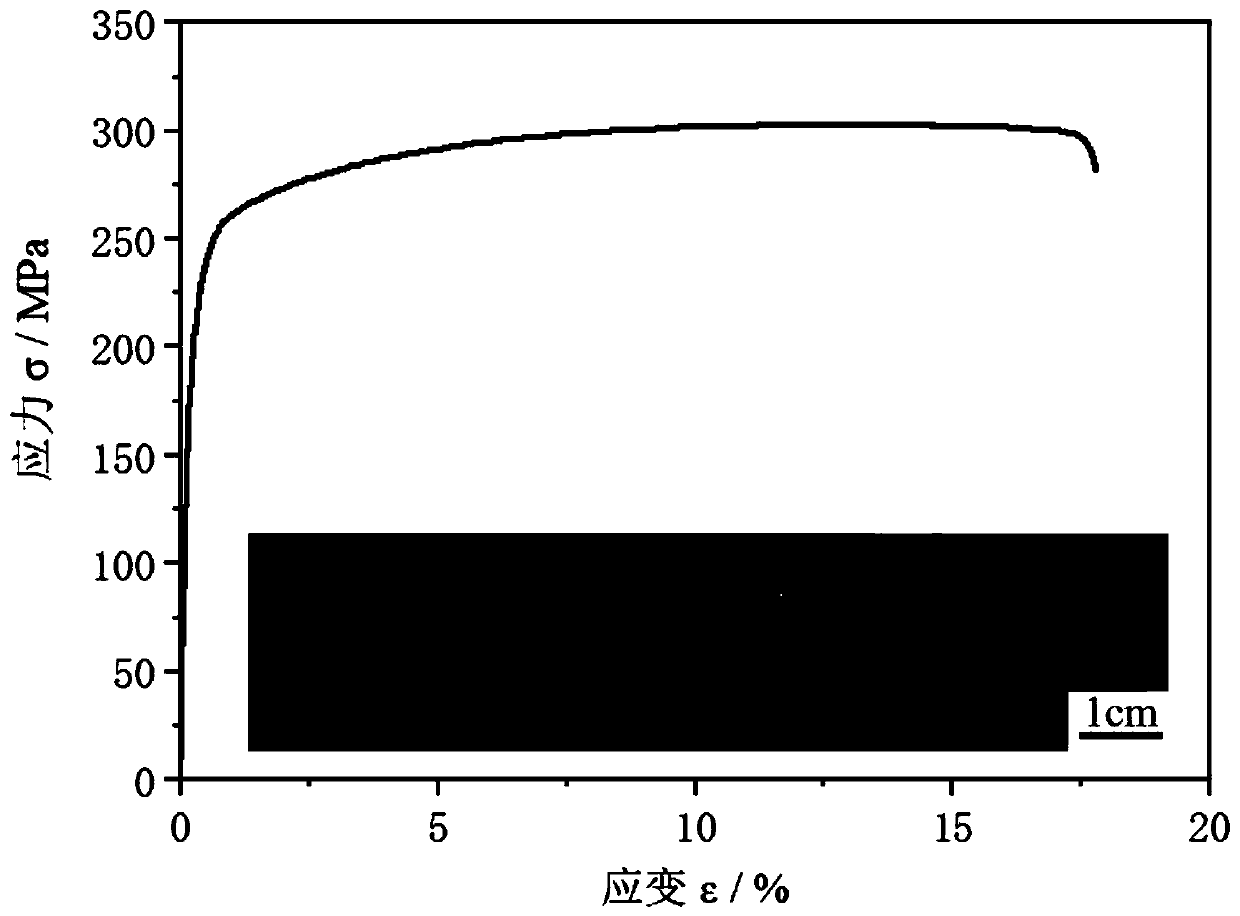

Aluminum/magnesium/aluminum composite plate with Zn solder reinforced interfaces and powder hot-pressing preparation method thereof

InactiveCN111054926AIncrease contact areaImprove liquidityFurnace typesHeat treatment furnacesComposite plateAluminum composites

The invention relates to an aluminum / magnesium / aluminum composite plate with Zn solder reinforced interfaces and a powder hot-pressing preparation method thereof. The method comprises the following steps: (1) respectively spreading aluminum-containing powder and magnesium-containing powder in a mold according to an aluminum-magnesium-aluminum sequence, and adding Zn solder at aluminum / magnesium interfaces; (2) pre-pressing each powder layer immediately after the powder layer is spread in the step (1) by using a pressure head, and flattening and compacting the powder to finally form a pre-pressed composite powder block with a certain layer thickness; and (3) subjecting the pre-pressed composite powder block treated in the step (2) to hot-pressing compounding, and carrying out pressure-maintained cooling so as to obtain the aluminum / magnesium / aluminum composite plate with the Zn solder reinforced interfaces. The aluminum / magnesium / aluminum composite plate with the Zn solder reinforced interfaces has the advantages of light weight, high specific strength, high interface bonding strength, excellent comprehensive mechanical properties and the like. The composite plate and the powder hot-pressing preparation method have the advantages of low powder quality requirement, high composite plate interface bonding quality, simple preparation method, high yield, high production efficiency, production cost conservation and the like.

Owner:TONGJI UNIV

A method for preparing high-performance composite strip by pulse current asynchronous rolling

ActiveCN108126982BImprove interface bonding qualityMetal rolling arrangementsReduction rateMetallurgy

The invention relates to a method for preparing a high-performance composite strip through pulse current asymmetrical rolling. The method comprises the steps that surfaces, subjected to surface treatment, of a strip A and a strip B are stacked, wherein the surfaces subjected to surface treatment are opposite to each other; at a rolling inlet, pulse current is applied to an A / B composite strip, thelocal area of the material surface is subjected to discharging, and surface metal is melted; the A / B composite strip obtained after pulse current treatment is subjected to asymmetrical rolling, material interface seaming is conducted, the differential speed ratio range is adjusted, and uniform deformation of the strip A and the strip B is achieved; the step is repeated 2-3 times; the obtained A / Bcomposite strip is subjected to asymmetrical rolling till the total reduction rate of the strip reaches 85%-90%. According to the composite metal material prepared through the method, the interface bonding quality is greatly improved compared with the interface of the composite metal material prepared through a traditional rolling method, and the high-performance composite metal strip can be usedfor the fields of bulletproof protection, aerospace, sound insulation and noise reduction, automobile weight lightening and the like.

Owner:CENT SOUTH UNIV

Polytetrafluoroethylene/barium sulfate composite and preparation method thereof

The invention discloses a polytetrafluoroethylene / barium sulfate composite and a preparation method thereof. The composite is characterized in that the tensile strength and friction performance of polytetrafluoroethylene are improved by means of steel fiber and carbon fiber, the polytetrafluoroethylene surface is sintered at high temperature through an improved melting method by means of fine filler such as SiO2 and Al powder, the sintering state of the polytetrafluoroethylene surface is improved, and the cementing strength is remarkably improved. In addition, the color and luster and biocompatibility of the material are improved by means of erucyl amide and barium sulfate, and a foundation is laid for the application of the material in the medicine field.

Owner:ANHU WUHU CHANGJIANG JACK UP EQUIP CO LTD

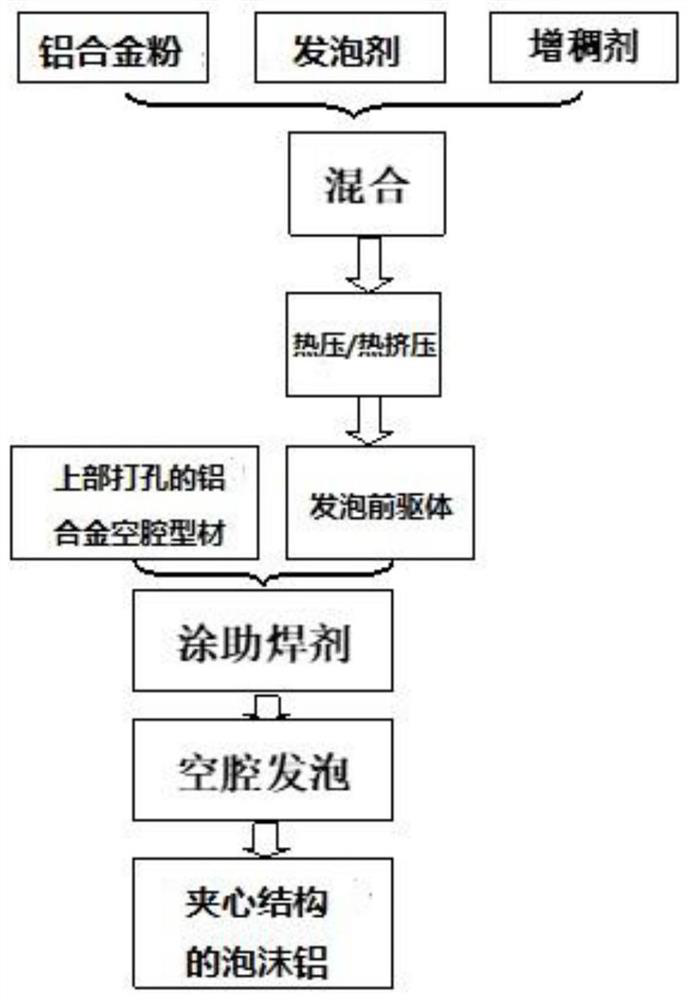

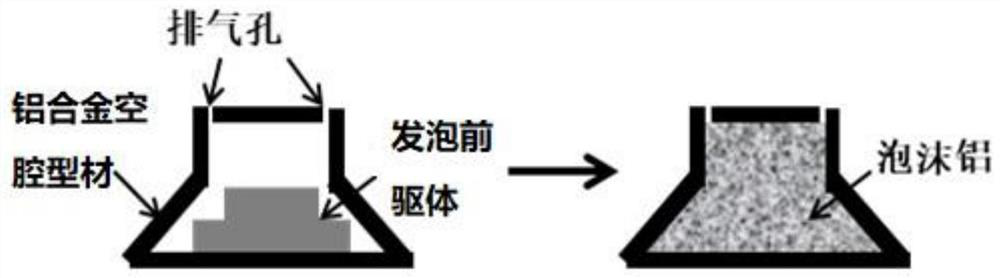

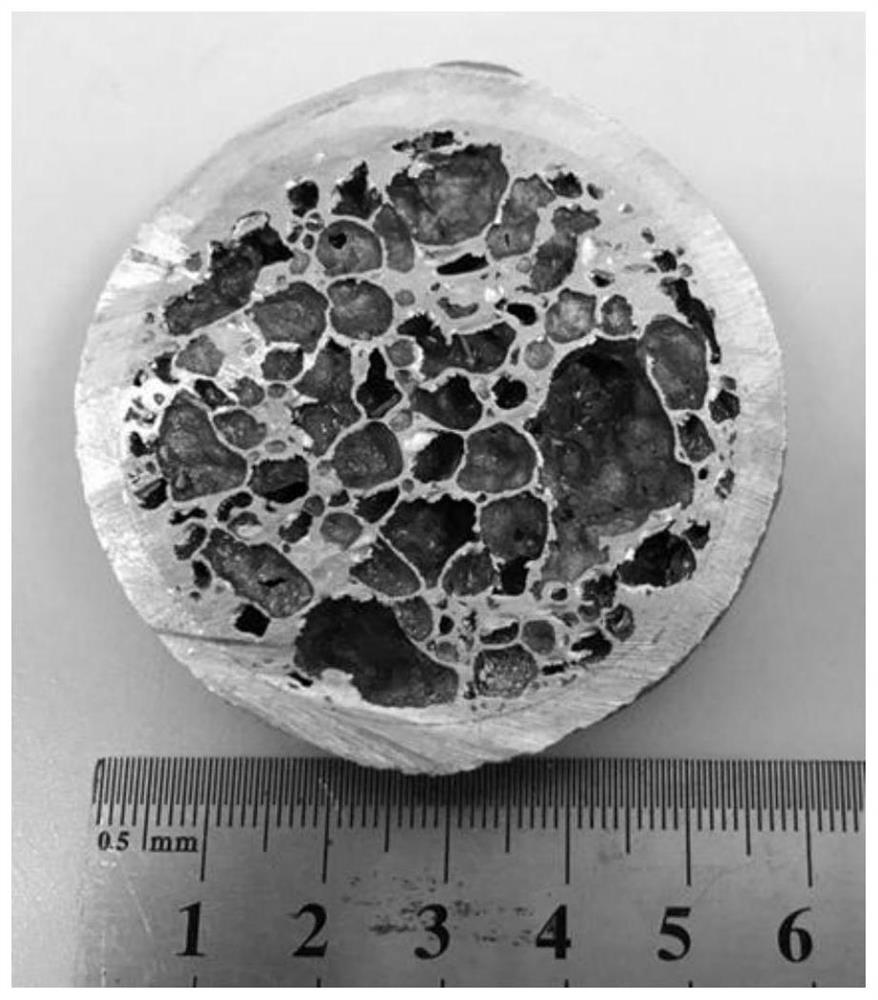

Foamed aluminum with sandwich structure and preparation method of foamed aluminum with sandwich structure

ActiveCN112122611AImprove interface bonding qualityEnhanced interface bindingFoaming agentNonferrous metal

The invention provides a preparation method of foamed aluminum with a sandwich structure, and belongs to the technical field of non-ferrous metals. The method comprises the following steps that aluminum alloy powder is mixed with a foaming agent and a thickening agent, after hot pressing or hot extrusion is conducted, a prepared foaming precursor is placed in an aluminum alloy cavity profile withexhaust holes, scaling powder is smeared, foaming is conducted after preheating, and the foamed aluminum with the sandwich structure is obtained. The invention also provides the foamed aluminum with the sandwich structure prepared by the method, and the foamed aluminum can be a special-shaped part. The method has the advantages that the exhaust holes are used for controlling complete filling of the foamed aluminum, the soldering flux is used for improving the interface bonding quality, preheating is used for improving the uniformity of the foaming temperature, and finally the foamed aluminum material with the sandwich structure, which is completely filled and has good interface bonding, is obtained.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Interface coated reinforced biological magnesium-based metal ceramic and preparing method and application thereof

InactiveCN110614367APromote infiltrationEffective dispersionAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingCrystal orientation

The invention relates to interface coated reinforced biological magnesium-based metal ceramic and a preparing method thereof. Particularly, through MgO coating, dispersion of beta-TCP ceramic particles in a magnesium alloy matrix can be improved, through the selective laser melting technology, the interface coated reinforced biological magnesium-based metal ceramic is prepared, the surface of thebeta-TCP ceramic particles is coated with MgO, on one hand, the MgO can be evenly separated out and coated on the surface of the beta-TCP, on the other hand, the MgO and the magnesium matrix has the good crystal orientation relation, in the selective laser fusion process, the wettability of beta-TCP in the magnesium melt can be improved, effective dispersion is achieved, and the agglomeration problem can be solved. In addition, the MgO and magnesium have good crystal orientation relation to enable beta-TCP to serve as heterogeneous nuclear particles of the magnesium matrix, the magnesium alloygrains are refined, meanwhile, due to existence of the nano MgO transition layer on the interface, the interface combination quality of the beta-TCP and the matrix can be improved, the composite material strength can be improved, and the high-property biological magnesium-based metal ceramic can be prepared.

Owner:CENT SOUTH UNIV

Carbon-fiber-reinforced polytetrafluoroethylene composite material for valve sealing and preparation method of carbon-fiber-reinforced polytetrafluoroethylene composite material for valve sealing

The invention discloses a carbon-fiber-reinforced polytetrafluoroethylene composite material for valve sealing and a preparation method of the carbon-fiber-reinforced polytetrafluoroethylene composite material for valve sealing. The carbon-fiber-reinforced polytetrafluoroethylene composite material for valve sealing is characterized by being prepared from, by weight, 2-3 parts of carbon fibers, 5-10 parts of carbon nano tubes, 10-15 parts of ethyl alcohol, 25-35 parts of polytetrafluoroethylene emulsion, an appropriate amount of acetic acid, 15-25 parts of hydrofluoric acid, 15-25 parts of nitric acid, 1-2 parts of lanthanum chloride, 4-6 parts of silane coupling agent KH550, 2-3 parts of edetic acid, 1-2 parts of Fe(NO3)3, 1-2 parts of Co(NO3)3, an appropriate amount of ammonium hydroxide, an appropriate amount of nickel foam, 3-5 parts of diamond, 5-7 parts of dodecyltrimethylammonium bromide, an appropriate amount of methane, an appropriate amount of argon, an appropriate amount of nitrogen and100-150 parts of distilled water. The carbon-fiber-reinforced polytetrafluoroethylene composite material for valve sealing has the advantages that the nickel foam in a three-dimensional form serves as polymer filler, so that mechanical performance of the composite material is improved, and the added carbon nano tubes can be distributed more evenly; through treatment of the carbon fibers, surface wettability is improved and the interface adhesion quality of the composite material is improved.

Owner:ANHUI RONGDA VALVE

Double-effect cementing prefluid with surfactant as suspending agent

ActiveCN103224774BWide range of density adaptationImprove cleanlinessDrilling compositionDual effectWell cementing

The invention relates to a dual-effect well-cementing pad fluid using a suspending agent as a surfactant, and mainly solves problems that present well-cementing pad fluid is added with high-molecular polymer grade inorganic suspending agent which can influence compatibility and cement sheath cementation and thus influence sealing effect of well cementing and exploitation operation in a later stage. The dual-effect well-cementing pad fluid comprises the following components by weight parts: 12-20 parts of a flushing suspending agent, 0.2-1 part of an antifoaming agent, 0-420 parts of a weighting agent and 100 parts of water. The dual-effect well-cementing pad fluid using a suspending agent as a surfactant can eliminate adverse influences of inorganic soil and the high-molecular polymer in the well-cementing pad fluid on the compatibility and the cement sheath cementation, improve flushing and displacing effects on a drilling fluid, and guarantee quality of well cementing and the exploitation operation in the later stage.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of method of coating zinc oxide graphene reinforced magnesium alloy composite material

The invention discloses a method for reinforcing a magnesium alloy compound material through zinc oxide-covering graphene. The method comprises the following steps that a liquid-state dispersion method is adopted for firstly preparing a preform green body with a mass ratio of the zinc oxide-covering graphene to pure aluminum powder equal to 10-25%, then the preform green body is added into magnesium alloy melt, and after ultrasonic dispersion treatment with power of 500-1000 W is conducted for 120 min, under a condition of 550-630 DEG C, a casting method is adopted for preparing the AZ91 magnesium alloy compound material reinforced by the zinc oxide-covering graphene with a content of 0.1-5%. By means of the method for reinforcing the magnesium alloy compound material through the zinc oxide-covering graphene, the even dispersion of the graphene in a magnesium matrix can be effectively improved, the interface bonding quality of the graphene and the magnesium matrix is improved, meanwhile, a good crystal grain refining effect is obtained, and the mechanical performance of the compound material is greatly improved, so that the method for reinforcing the magnesium alloy compound material through the zinc oxide-covering graphene is suitable for preparing the graphene-magnesium alloy compound material excellent in performance on a large scale.

Owner:JIANGXI TIANYUE AUTOMOBILE PARTS

Sterilization and deodorization carbon fiber and steel fiber modified polytetrafluoroethylene material and method for preparing same

The invention discloses a sterilization and deodorization carbon fiber and steel fiber modified polytetrafluoroethylene material and a method for preparing the same. The sterilization and deodorization carbon fiber and steel fiber modified polytetrafluoroethylene material and the method have the advantages that the tensile strength and the friction performance of polytetrafluoroethylene can be improved by steel fibers and carbon fibers; fine fillers such as SiO2 and Al powder are sintered on the surfaces of the polytetrafluoroethylene by the aid of improved melting processes at the high temperatures, accordingly, surface sintered states of the polytetrafluoroethylene can be improved, and the bonding strength can be obviously enhanced; surrounding environments can be sterilized owing to characteristics of high adsorption capacity of diatomaceous earth, the humidity can be regulated, and deodorization effects and the like can be realized by the sterilization and deodorization carbon fiber and steel fiber modified polytetrafluoroethylene material.

Owner:ANHU WUHU CHANGJIANG JACK UP EQUIP CO LTD

A kind of high-strength, high-plasticity and corrosion-resistant aluminum alloy layered composite material and preparation method thereof

ActiveCN110665968BHigh strengthImprove plasticityTemperature control deviceFurnace typesCorrosion resistantPlastic property

The invention discloses a high-strength, high-plasticity, corrosion-resistant aluminum alloy layered composite material and a preparation method thereof, belonging to the technical field of aluminum alloy layered composite materials. The high-strength, high-plasticity and corrosion-resistant aluminum alloy layered composite material is composed of a 1-series or 3-series aluminum alloy cladding material and a 6-series aluminum alloy base material. Anneal the aluminum alloy cladding material and the aluminum alloy base material, clean, degrease and polish the surface to be composited. The direction of the grinding stripes is perpendicular to the rolling direction. A high-strength, high-plasticity, corrosion-resistant aluminum alloy layered composite material with a strong metallurgical interface is obtained by cold-rolling pre-compositing, heating, single-pass hot-rolling and compounding, and finally solution-aging treatment. The invention has low equipment requirements, simple process flow, short cycle, high production efficiency, low energy consumption and low cost, and the prepared aluminum alloy layered composite material has high strength, high plasticity and excellent corrosion resistance.

Owner:UNIV OF SCI & TECH BEIJING

A short process production process of bimetallic composite strip

ActiveCN108580849BShort processIncrease productivityMetal rolling arrangementsAcid washingComposite plate

The invention relates to a short-flow efficient production process of a double-metal composite belt material. The short-flow efficient production process of the double-metal composite belt material comprises the following steps: preparing a high-quality double-metal composite plate blanket with a metallurgical bonding interface by a continuous casting composite process and putting the high-qualitydouble-metal composite plate blanket into a heating furnace to heat; performing multi-pass rolling on the heated plate blanket by a rolling machine, wherein the pass reduction rate of the first passis controlled to be 50 to 70 percent, the pass reduction rate of the subsequent passes is controlled to be 25 to 45 percetn and the total rolling deformation quantity is controlled to be 85 to 95 percent; performing warm rolling forming, wherein the rolling process avoids lubrication; after performing acid-washing treatment, performing rolling forming on a cold-rolling machine, wherein the pass reduction rate is controlled to be 15 to 30 percent, the total rolling deformation quantity is controlled to be less than 90 percent and the rolling speed is 1 to 25 m / min; and performing rapid sensingheating continuous heat treatment on the composite belt material after cold rolling to obtain the double-metal composite belt material. The plate material prepared by the method is short in process flow, high in production efficiency and favorable for realizing large-scale production.

Owner:UNIV OF SCI & TECH BEIJING

Sound-absorbing carbon fiber/steel fiber modified polytetrafluoroethylene material and preparation method thereof

The invention discloses a sound-absorbing carbon fiber / steel fiber modified polytetrafluoroethylene material and a preparation method thereof. The invention is characterized in that steel fiber and carbon fiber are used for enhancing tensile strength and friction performance of polytetrafluoroethylene; and fine fillers such as SiO2, Al powder, etc. are sintered onto the surface of polytetrafluoroethylene at high temperature by an improved melting method so as to improve surface sintering condition of polytetrafluoroethylene and obviously raise joint strength. In addition, by the addition of sound absorbing materials such as natural zeolite, etc., sound-absorbing effect of the composite material is enhanced.

Owner:ANHU WUHU CHANGJIANG JACK UP EQUIP CO LTD

Heat insulation carbon fiber and steel fiber-modified polytetrafluoroethylene material and preparation method thereof

InactiveCN105907005AImprove surface roughnessImprove adhesionCoatingsCarbon fibersUltimate tensile strength

The invention discloses a heat insulation carbon fiber and steel fiber-modified polytetrafluoroethylene material and a preparation method thereof. The material is characterized in that not only are carbon fibers and steel fibers used for improving the tensile strength and friction performance of polytetrafluoroethylene, but fine fillers such as SiO2 powder and Al powder are also sintered onto the surface of the polytetrafluoroethylene at high temperature by utilizing an improved melting method, so that the surface sintering state of the polytetrafluoroethylene is improved, and the bonding strength is obviously improved. Furthermore, a pearl cotton leftover material having a heat insulation effect is added into the polytetrafluoroethylene material in a matching way, so that the polytetrafluoroethylene material is good in heat insulation effect, and the production cost is lowered.

Owner:ANHUI RONGDA VALVE

A sandwich composite heat insulation layer structure and manufacturing method

ActiveCN109058661BComplete structureConsistent thicknessThermal insulationLaminationFiberCombustion chamber

The invention provides a sandwiched composite heat insulating layer structure and a preparation method thereof. The preparation method comprises the following steps of: pasting a heat insulating layer, an ablation resistant layer and a transition layer in an engine combustion chamber housing, wherein the heat insulating layer and the transition layer are made of a heat insulating layer material ofan ethylene-propylene-diene monomer system, the ablation resistant layer is made of a carbon fiber phenolic aldehyde butyronitrile rubber soft sheet material, and the ablation resistant layer is divided into a plurality of pieces in a peripheral direction in the engine combustion chamber housing; and performing hot-pressing after pasting each layer, pre-drying the material of the ablation resistant layer before use, and curing a carbon rough board of the ablation resistant layer and the heat insulating layer before pasting the transition layer. The sandwiched composite heat insulating layer structure can improve integrity of the composite heat insulating layer, and strengthens reliability of a composite interface.

Owner:西安长峰机电研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com