A kind of high-strength, high-plasticity and corrosion-resistant aluminum alloy layered composite material and preparation method thereof

A technology of aluminum alloy material and aluminum alloy layer, which is applied in the direction of metal rolling, metal rolling, metal processing equipment, etc., can solve the problems of instability, high production cost, and inability to produce, so as to improve the interface bonding strength and excellent durability. Corrosion performance, the effect of achieving strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

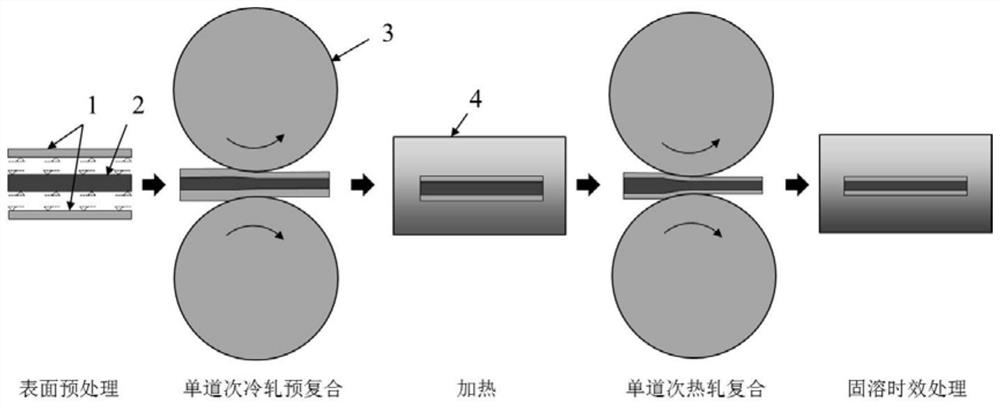

[0032] The invention provides a method for preparing a high-strength, high-plasticity and corrosion-resistant aluminum alloy layered composite material. The preparation process is as follows: figure 1 shown. This preparation method comprises the steps:

[0033] Step 1: performing heat treatment on the aluminum alloy clad material and the aluminum alloy base material, the aluminum alloy clad material is subjected to O state heat treatment, and the aluminum alloy base material is subjected to O state or T4 state heat treatment;

[0034] Step 2: Use a louver, a grinding wheel or a wire brush to polish the surface to be compounded of the aluminum alloy cladding material and the aluminum alloy base material after surface cleaning and degreasing, to remove pollutants and oxidation on the surface to be compounded layer to obtain a clean and rough surface to be compounded, and the direction of the grinding stripes formed by the grinding treatment is perpendicular to the rolling direc...

Embodiment 1

[0047] Preparation of high-strength, high-plasticity and corrosion-resistant AA3003 / AA6061 / AA3003 aluminum alloy layered composites.

[0048] The 1mm thick AA3003 slab and the 6mm thick AA6061 slab were annealed to make them into the O state. The annealing system was 420°C for 0.5h and then air cooled; the AA3003 slabs and The surface to be compounded of AA6061 slab is mechanically polished to remove pollutants and oxide layers on the surface to be compounded, and a clean and rough surface to be compounded is obtained. The direction of the grinding stripes formed by the grinding process is perpendicular to the rolling direction; The AA3003 slab and AA6061 slab are stacked and placed in the order of AA3003 / AA6061 / AA3003, and the two sides of the head of the AA3003 slab and AA6061 slab are riveted and fixed with aluminum rivets to obtain a combined blank, AA3003 slab and AA6061 slab The length and width of the billet are equal; 3 pairs of rolls are used to carry out single-pass ...

Embodiment 2

[0050] Preparation of high-strength, high-plasticity and corrosion-resistant AA1100 / AA6063 / AA3A21 aluminum alloy layered composites.

[0051] The 1mm-thick AA1100 slab and the 2mm-thick AA3A21 slab were annealed to make them into O state. The annealing system was 420°C for 0.5h and then air-cooled. The 5mm-thick AA6063 slab was subjected to solution-aging treatment to make it It becomes T4 state, and the solid solution-aging system is 520°C for 40 minutes and quenching, then natural aging for 100 hours; use a wire brush to mechanically polish the surface of the AA1100 slab, AA3A21 slab and AA6063 slab to be composited after surface cleaning and degreasing, and remove Pollutants and oxide layers on the surface to be compounded to obtain a clean and rough surface to be compounded, and the direction of the grinding stripes formed by the grinding treatment is perpendicular to the rolling direction; the AA1100 slab, AA3A21 slab and AA6063 slab to be compounded surface treated accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com