Foamed aluminum with sandwich structure and preparation method of foamed aluminum with sandwich structure

A sandwich structure, foamed aluminum technology, applied in the field of non-ferrous metals, can solve the problems of poor interface bonding, difficulty in uniform foaming and heating process, and difficulty in achieving metallurgical bonding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

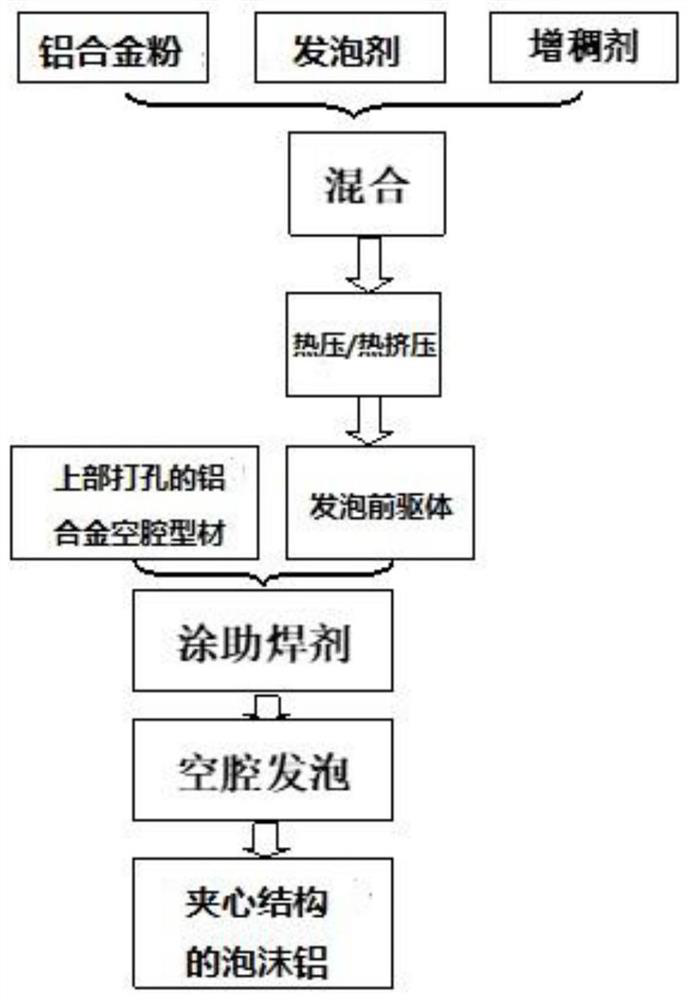

[0029] according to figure 1 The process flow chart of the present invention for preparing foamed aluminum with sandwich structure prepares foamed aluminum with sandwich structure.

[0030] Wherein, raw material is counted as 2 parts of blowing agent TiH by weight 2 (300 mesh), 1.8 parts thickener MnO 2 (300 mesh), and 96.2 parts of Al-6Si-6Cu aluminum alloy powder (300 mesh). The composition of the Al-6Si-6Cu aluminum alloy powder is 6 parts by weight of Si, 6 parts of Cu, and the rest is aluminum and unavoidable impurities. The above raw materials are purchased from the market with a purity higher than 99%.

[0031] The powder mixing process adopts ball milling for 15 minutes to obtain the mixed powder. Hot press the mixed powder with a pressure of 180MPa and a temperature of 500°C. The density of the foamed precursor obtained after hot pressing is 98%, without obvious defects.

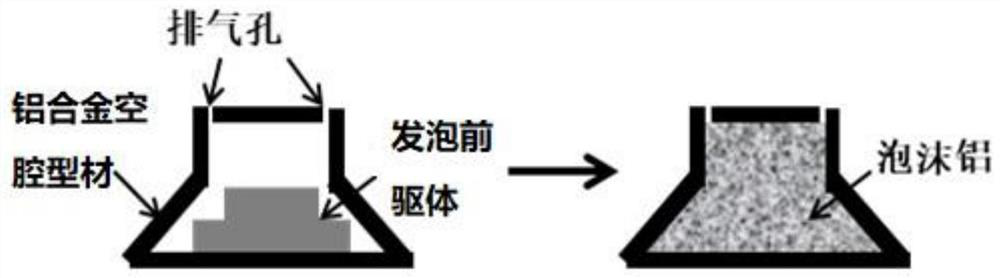

[0032] The aluminum alloy cavity profiles are processed from 3003 aluminum alloy pipes and...

Embodiment 2

[0034] according to figure 1 The process flow chart of the present invention for preparing foamed aluminum with sandwich structure prepares foamed aluminum with sandwich structure.

[0035] Wherein, the raw material is 1 part of blowing agent TiH by weight 2 (300 mesh), 2 parts of thickener Mg (200 mesh), and 97 parts of Al-12Si aluminum alloy powder (400 mesh). The composition of the Al-12Si aluminum alloy powder is 12 parts by weight of Si, the rest is aluminum and unavoidable impurities. The above raw materials are purchased from the market with a purity higher than 99%.

[0036] The powder mixing process adopts manual powder mixing for 40 minutes to obtain the mixed powder. Hot press the mixed powder with a pressure of 300MPa and a temperature of 450°C. The density of the foamed precursor obtained after hot pressing is 97%, without obvious defects.

[0037] The aluminum alloy cavity profiles are processed from 3003 aluminum alloy pipes and plates purchased on the mark...

Embodiment 3

[0039] according to figure 1 The process flow chart of the present invention for preparing foamed aluminum with sandwich structure prepares foamed aluminum with sandwich structure.

[0040] Wherein, the raw material is 3 parts of blowing agent TiH by weight 2 (300 mesh), 0.5 parts thickener MnO 2 (300 mesh), and 96.5 parts of Al-6Si-5Mg aluminum alloy powder (300 mesh). The composition of the Al-6Si-5Mg aluminum alloy powder is 6 parts by weight of Si, 5 parts of Mg, and the rest is aluminum and unavoidable impurities. The above raw materials are purchased from the market with a purity higher than 99%.

[0041] The powder mixing process adopts ball milling for 25 minutes to obtain the mixed powder. Hot press the mixed powder with a pressure of 150MPa and a temperature of 480°C. The density of the foamed precursor obtained after hot pressing is 98%, without obvious defects.

[0042] The aluminum alloy cavity profiles are processed from 3003 aluminum alloy pipes and plates...

PUM

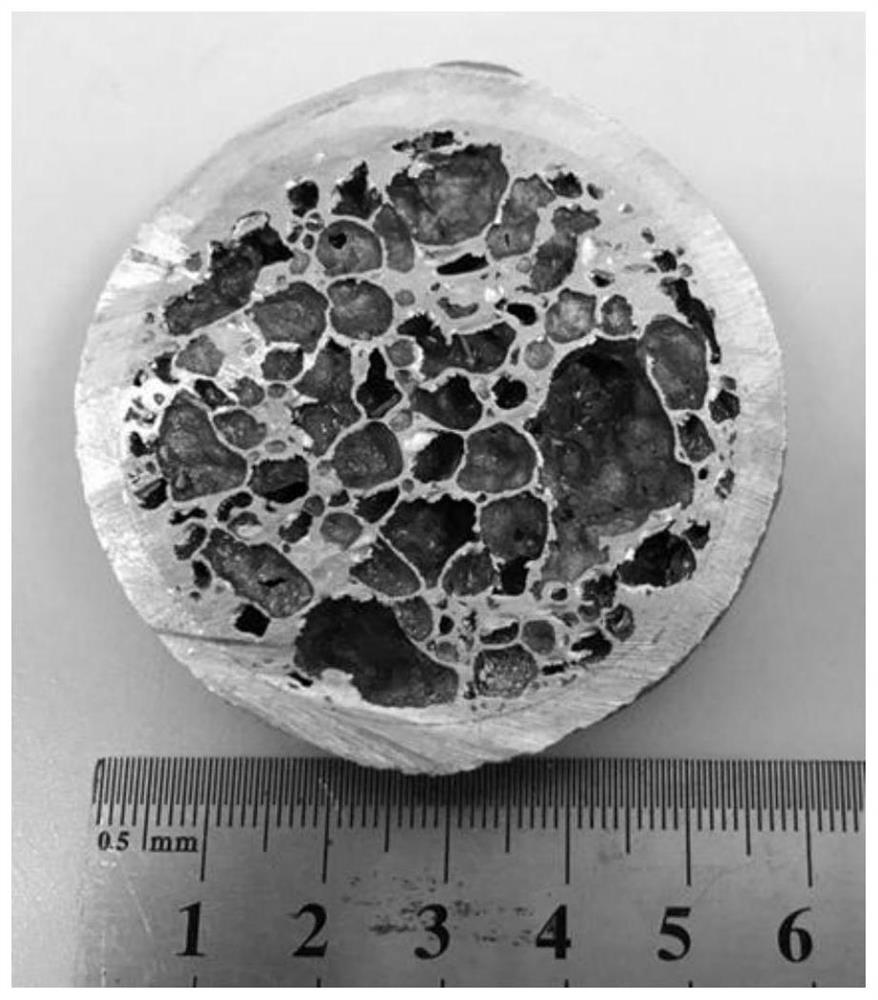

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com