Aluminum/magnesium/aluminum composite plate with Zn solder reinforced interfaces and powder hot-pressing preparation method thereof

A technology of aluminum composite plate and composite powder, which is applied in heat treatment equipment, heat treatment furnaces, manufacturing tools, etc., can solve the problems of affecting the bonding quality of the interface of the composite plate, the inclusion of oxides at the rolling interface, and the difficulty in realizing automatic production, etc. Effective contact area, high interface bonding quality, and excellent comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A powder hot pressing method for preparing an aluminum / magnesium / aluminum composite board with a Zn brazing filler metal-enhanced interface includes the following steps:

[0046] (1) Use aluminum-containing powder and magnesium-containing powder to spread powder in the mold in the order of aluminum / magnesium / aluminum, and add Zn solder at the aluminum / magnesium interface;

[0047] (2) In step (1), the powder layer is pre-pressed with a pressing head for each layer of powder, and the powder is flattened and compacted to finally form a pre-pressed composite powder block with a certain layer thickness;

[0048] (3) The pre-compressed composite powder block processed in step (2) is subjected to hot-compression composite, pressure-maintained and cooled to obtain an aluminum / magnesium / aluminum composite board with a Zn brazing filler metal-enhanced interface.

[0049] Wherein, the mesh number of the aluminum-containing powder and magnesium-containing powder is controlled at 220-800 me...

Embodiment 1

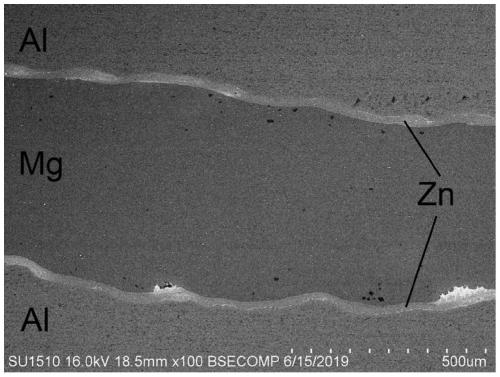

[0064] In this embodiment, 400 mesh AZ31 magnesium alloy powder, AlSi10Mg aluminum alloy powder and 0.1mm thick pure zinc brazing filler metal are selected respectively, and the powder is spread layer by layer in the mold in the order of aluminum / magnesium / aluminum, and added at the aluminum / magnesium interface Zn solder, the thickness of each layer of powder is 5mm, and after each layer is spread, it is flattened and compacted to obtain a pre-pressed composite powder block with a structure such as figure 1 As shown, in the figure, A, B, and C represent the magnesium alloy powder layer, Zn solder, and aluminum alloy powder layer, respectively.

[0065] Place the mold containing the pre-compressed composite powder block between the two rear steel plates with several heating resistance wires and thermocouples, and surround it with asbestos to prevent heat dissipation. Mica plates are placed on the outside of the thick steel plates for heat insulation , And one of the mica plates is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com