A method for preparing high-performance composite strip by pulse current asynchronous rolling

A technology of clad strip and pulse current, applied in the direction of metal rolling, etc., can solve the problems of difficult control and difference of the interface bonding quality of metal clad plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

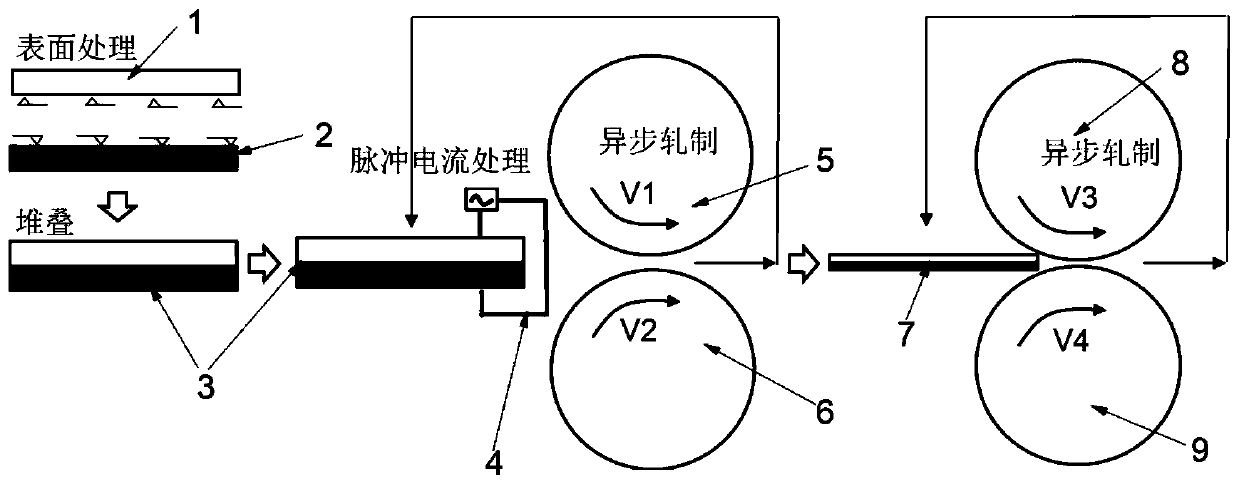

[0022] Embodiment 1: preparation of copper-aluminum composite strip, reference figure 1 .

[0023] The first step: use the strip A1 and the strip B2 as raw materials, the strip A1 is a copper strip, and the strip B2 is an aluminum strip. The thicknesses of strip A1 and strip B2 before rolling were each 2 mm. The strip A1 and the strip B2 were processed into exactly the same size 1m (length)×0.2m (width).

[0024] Step 2: Surface treatment of strip A1 and strip B2 with a wire brush to remove surface oxides.

[0025] Step 3: Stack the surface-treated surfaces of the strip A1 and the strip B2, wherein the treated surfaces face each other to obtain an A / B composite strip 3 .

[0026] Step 4: At the rolling entrance, a pulse current is applied to the A / B composite strip 3 by using the pulse current device 4, so that a partial area on the surface of the material is discharged, and the surface metal is melted. During the rolling process, the pulse current power is 90KVA.

[0027...

Embodiment 2

[0030] Embodiment 2: preparation of titanium-aluminum composite strip, reference figure 1 .

[0031] The first step: take the strip A1 and the strip B2 as raw materials, the strip A1 is a titanium strip, and the strip B2 is an aluminum strip. The thicknesses of strip A1 and strip B2 before rolling were 1.5 mm, respectively. The strip A1 and the strip B2 were processed into exactly the same size of 0.5m (length)×0.1m (width).

[0032] Step 2: Surface treatment of strip A1 and strip B2 with a wire brush to remove surface oxides.

[0033] Step 3: Stack the surface-treated surfaces of the strip A1 and the strip B2, wherein the treated surfaces face each other to obtain an A / B composite strip 3 .

[0034] Step 4: At the rolling entrance, a pulse current is applied to the A / B composite strip 3 by using the pulse current device 4, so that a partial area on the surface of the material is discharged, and the surface metal is melted. The pulse current power is set to be 120KVA.

[...

Embodiment 3

[0038] Example 3: Interface welding between ordinary carbon steel and ordinary carbon steel with pulse current plastic deformation

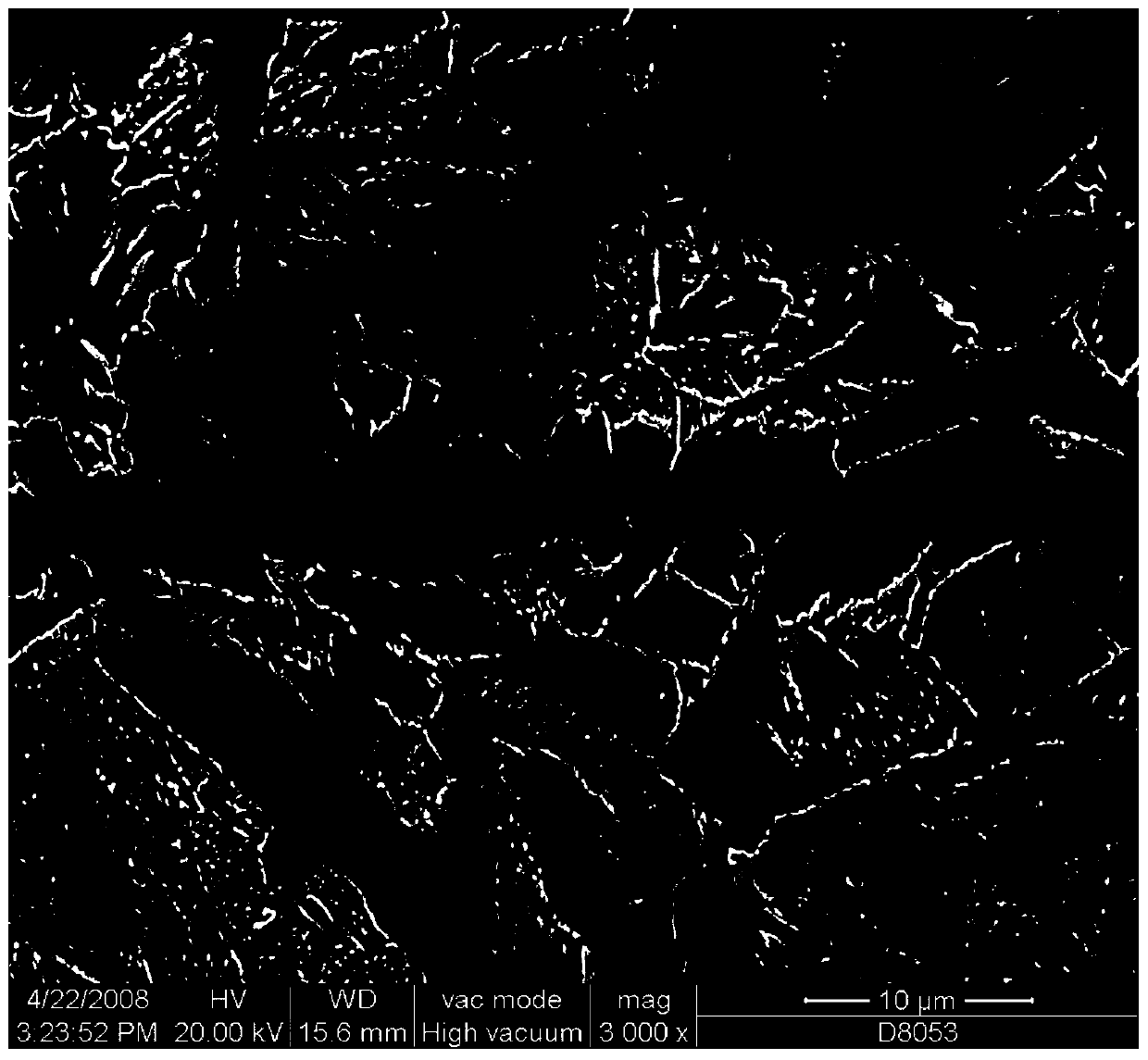

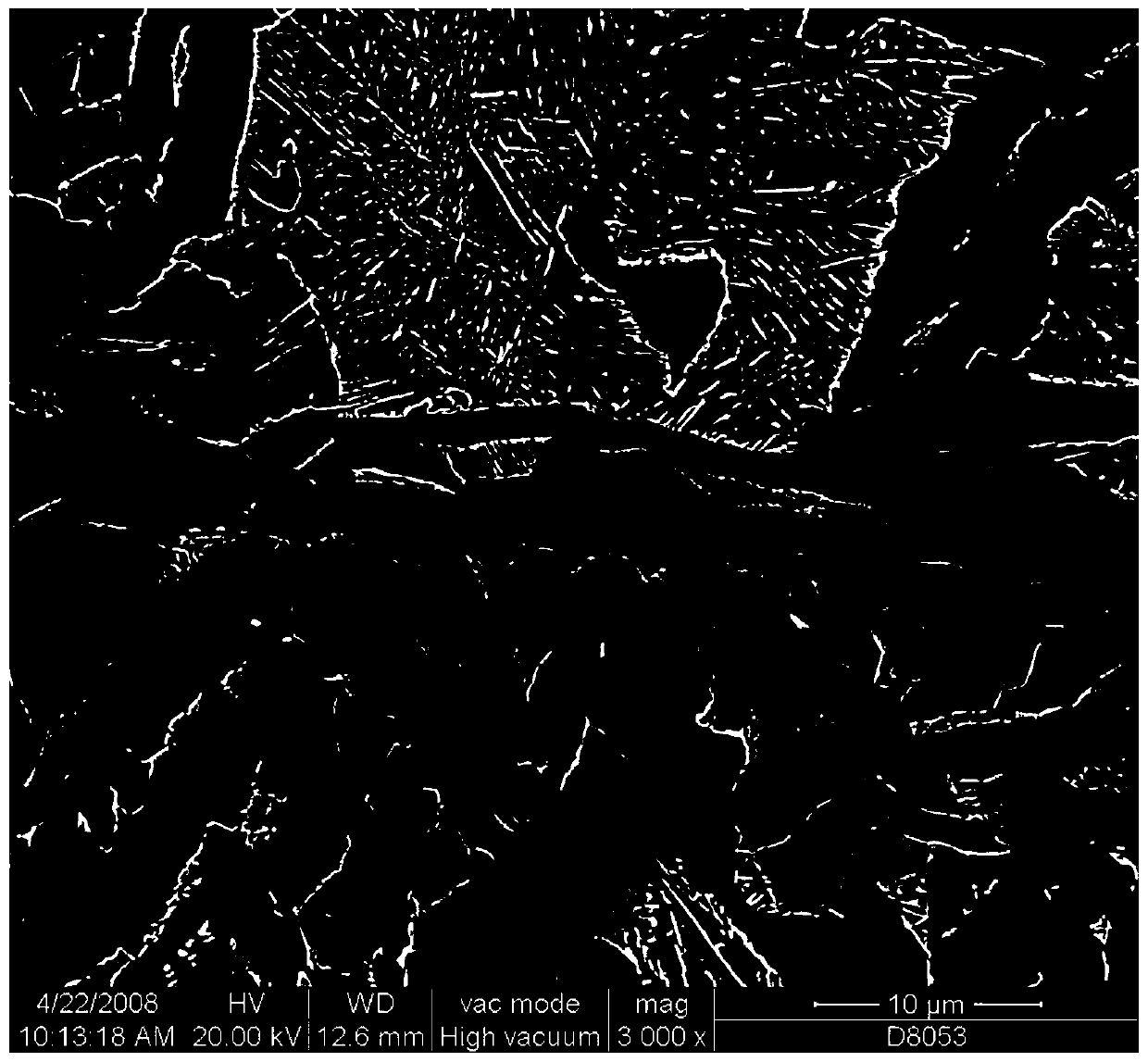

[0039] In order to verify the above method, an experiment was carried out using a thermal simulation testing machine, using ordinary carbon steel as raw material, the thickness of the strip is 4mm and 4mm, the pulse current power is 90KVA, and the reduction rate is 50%. The interface of the composite material is fully metallurgically welded without any residual voids. Such as figure 2 Under the action of pulse current, some areas of the interface are welded. image 3 After the pulse current shown, the interface achieves complete metallurgical bonding after applying a reduction rate of 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com