Electric-conducting carbon felt and lead tab connection method

A connection method and conductive carbon technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of battery product safety, hidden quality problems, low mechanical strength of grid joints, large interface ohmic resistance, etc. A large amount of lead, easy implementation, and high pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment, the present invention will be further described.

[0017] The method of conductive carbon felt and lead lug of the present invention is a kind of physical connection method, and it is carried out according to the following steps:

[0018] A. Material preparation—cut the conductive carbon felt according to the size, and cut the flaky lead tab. The size of the conductive carbon felt in this embodiment is 200×150×2.0mm, and the size of the lead tab is 170×30×1.0mm;

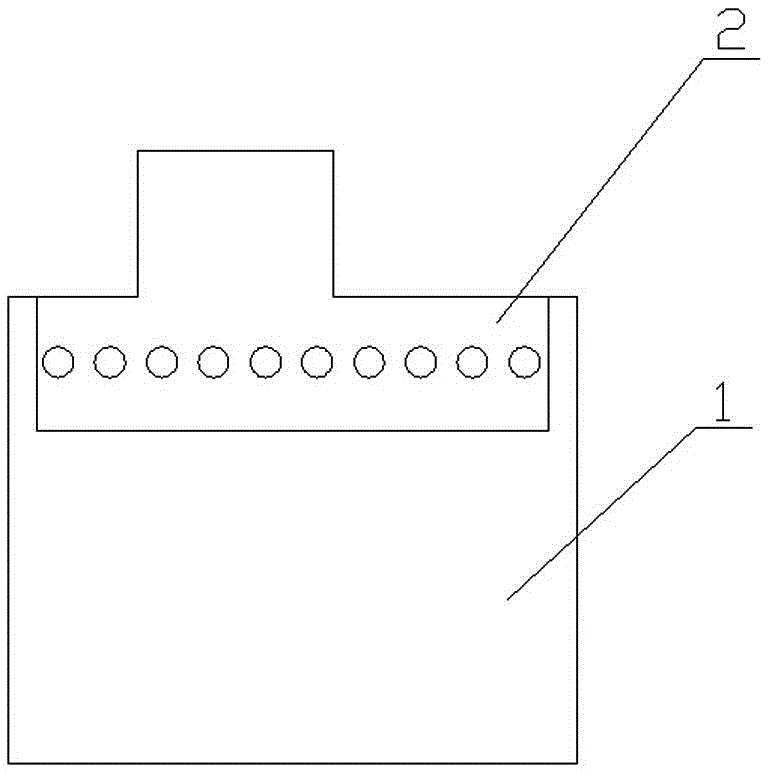

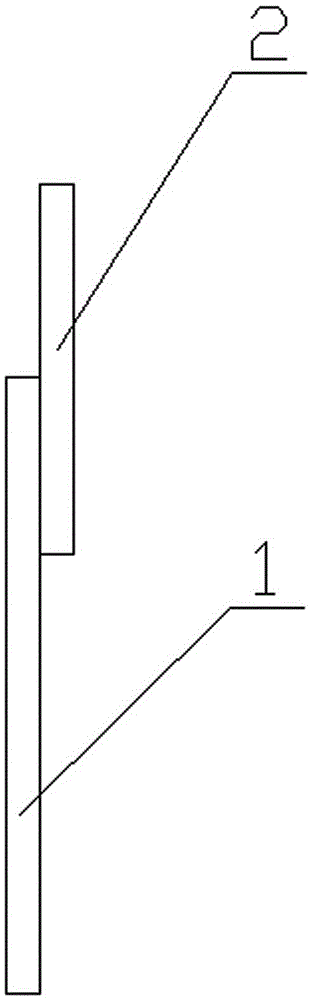

[0019] B. Lamination——a piece of lead lug is laminated flat on one side of the upper frame of the conductive carbon felt. This embodiment is for example figure 1 with figure 2 As shown in the figure, a sheet-shaped lead lug is laid flat on one side of the upper frame of the conductive carbon felt;

[0020] C. Spot welding - Spot welding is carried out at intervals of 10mm along the length of the lead lug. The spot welding pole head is a plane of φ5.0mm. The heating tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com