Patents

Literature

62results about How to "Not easy to stretch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

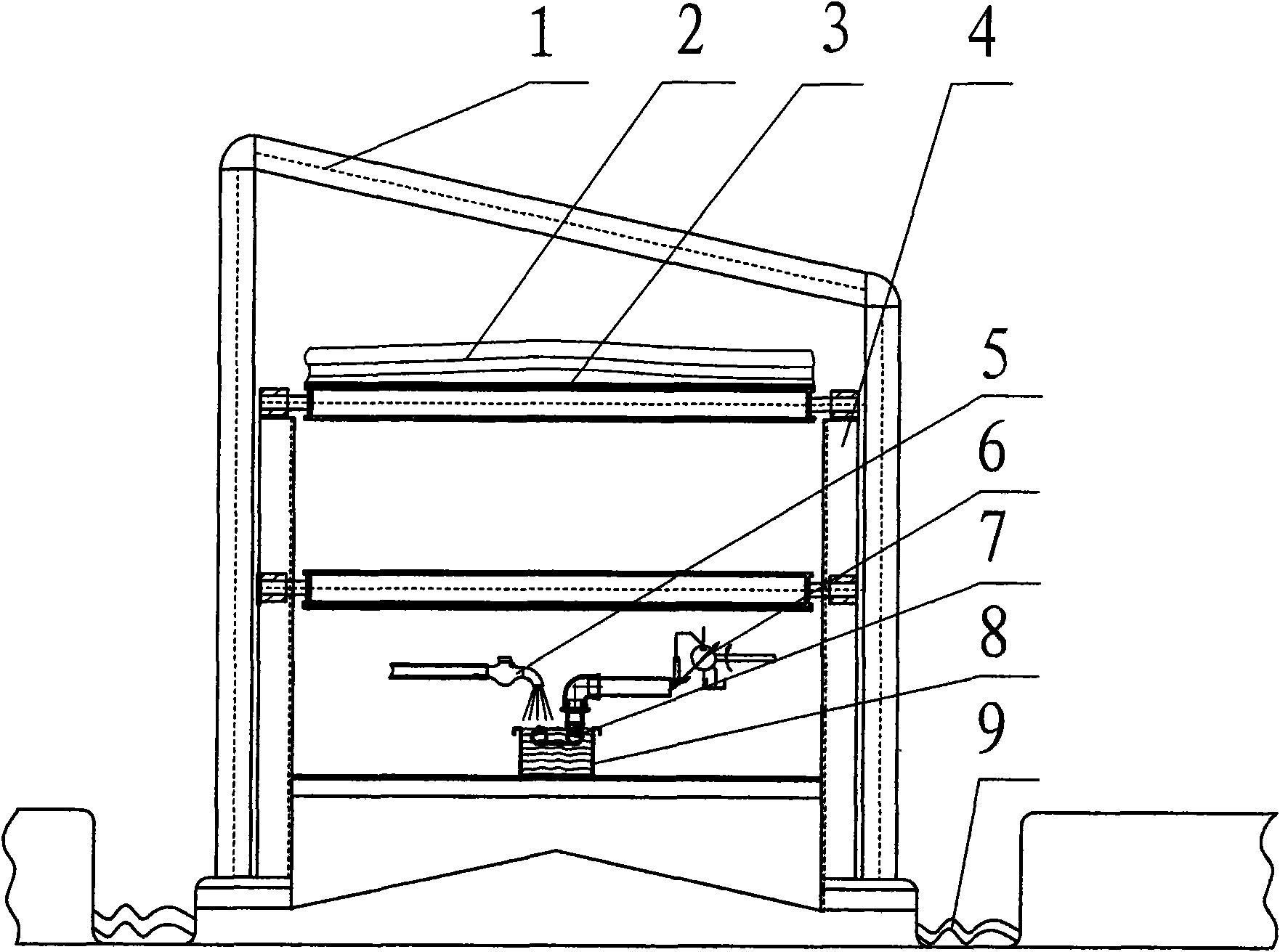

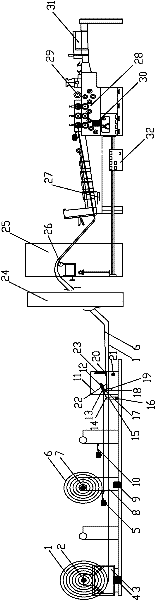

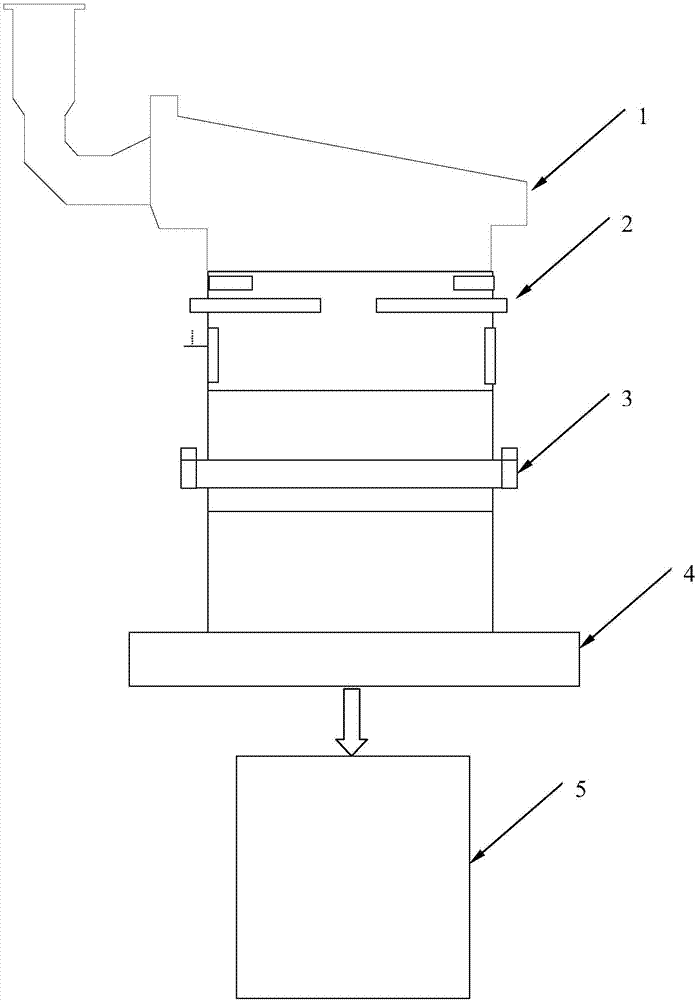

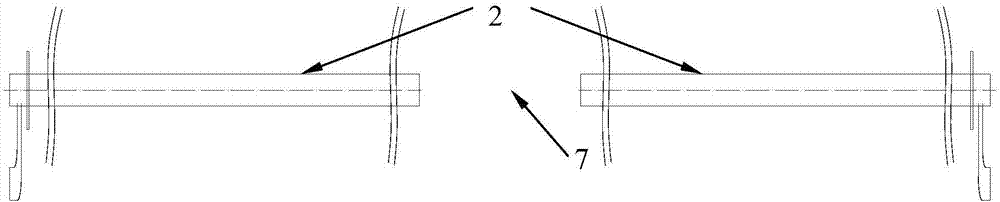

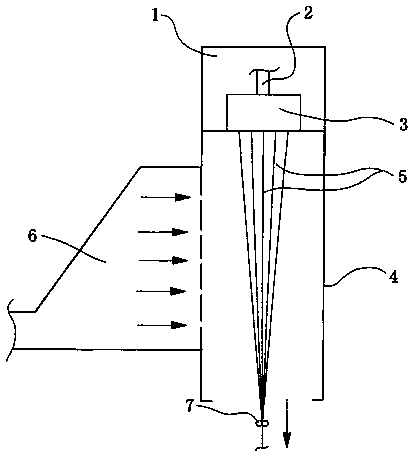

Ripening technology and ripening device in fine dried noodle production

ActiveCN101606655AEasy to adjust temperatureAvoid drippingFood preparationDough processingTemperature controlStable state

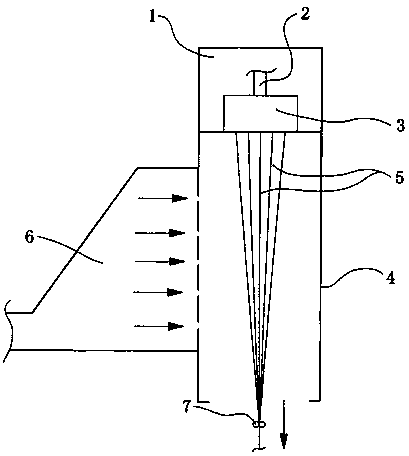

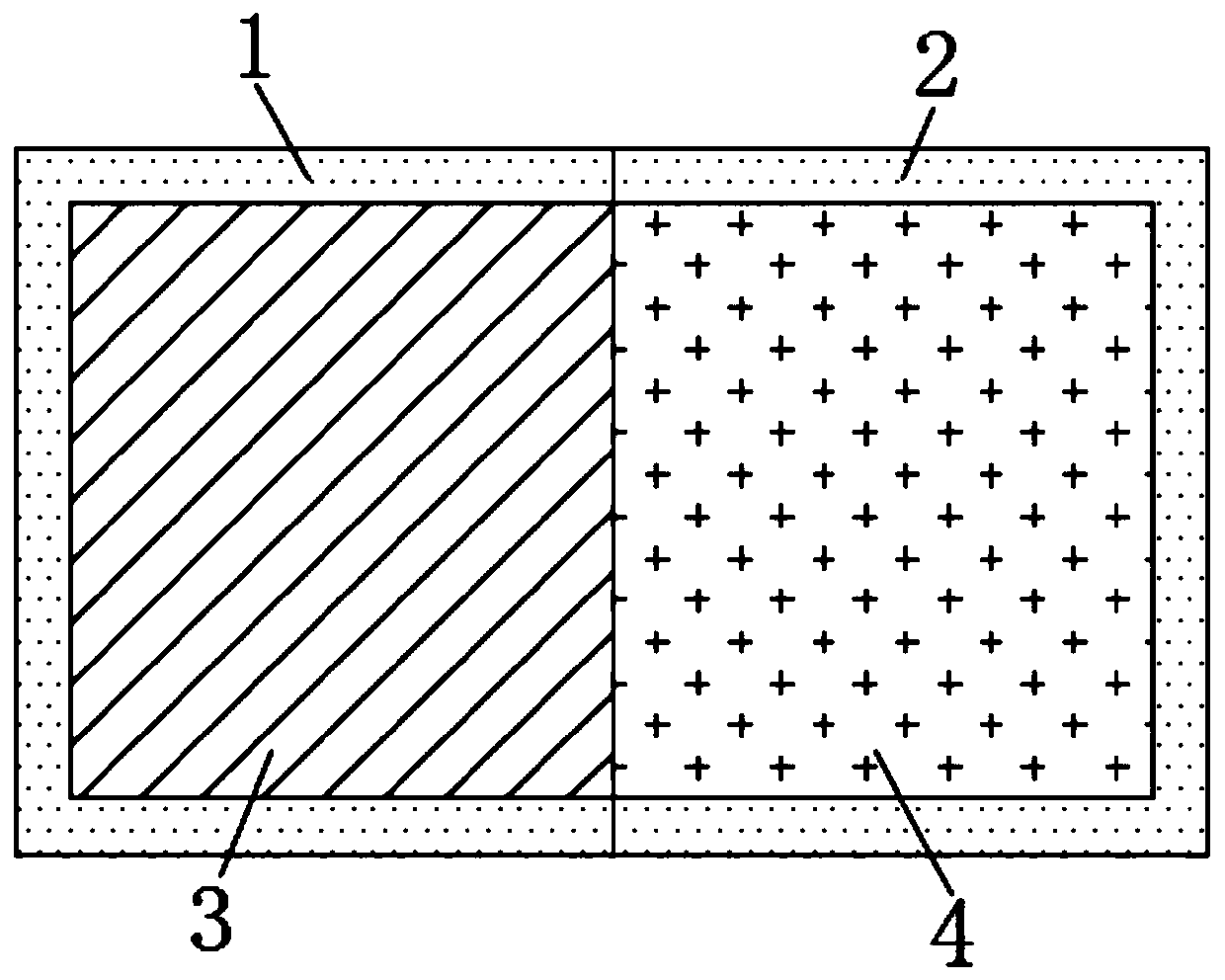

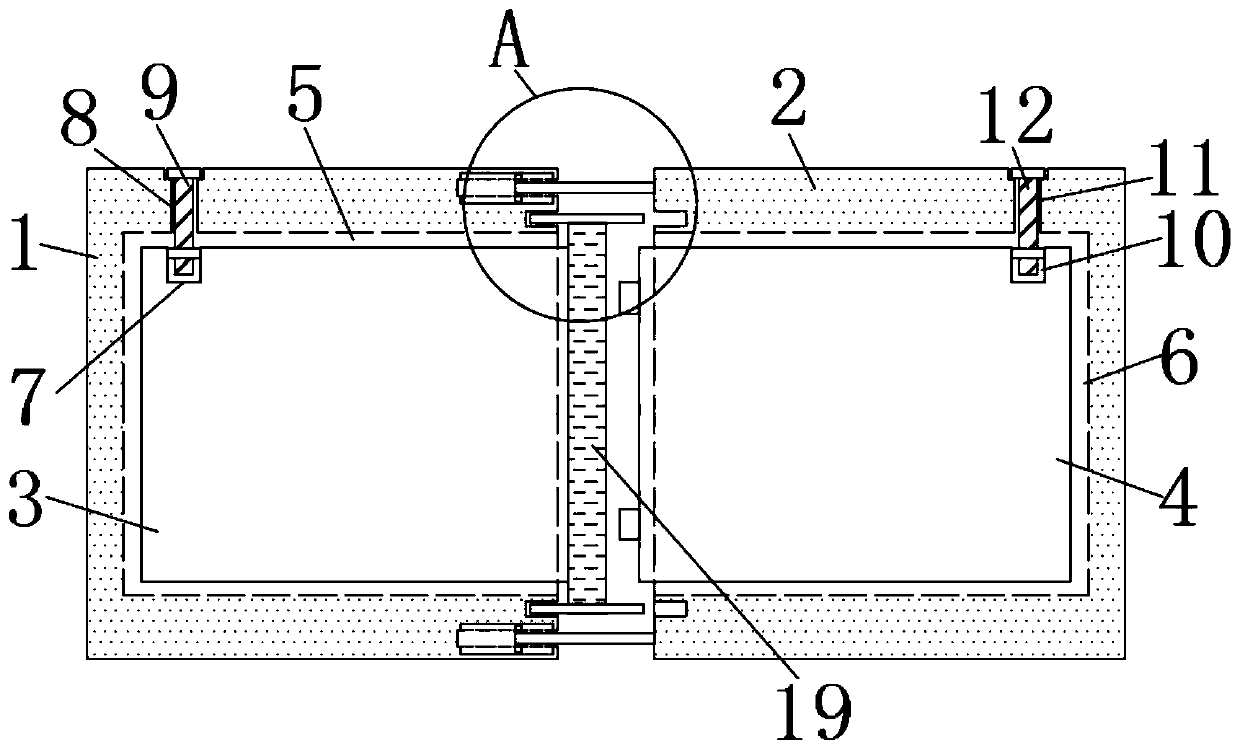

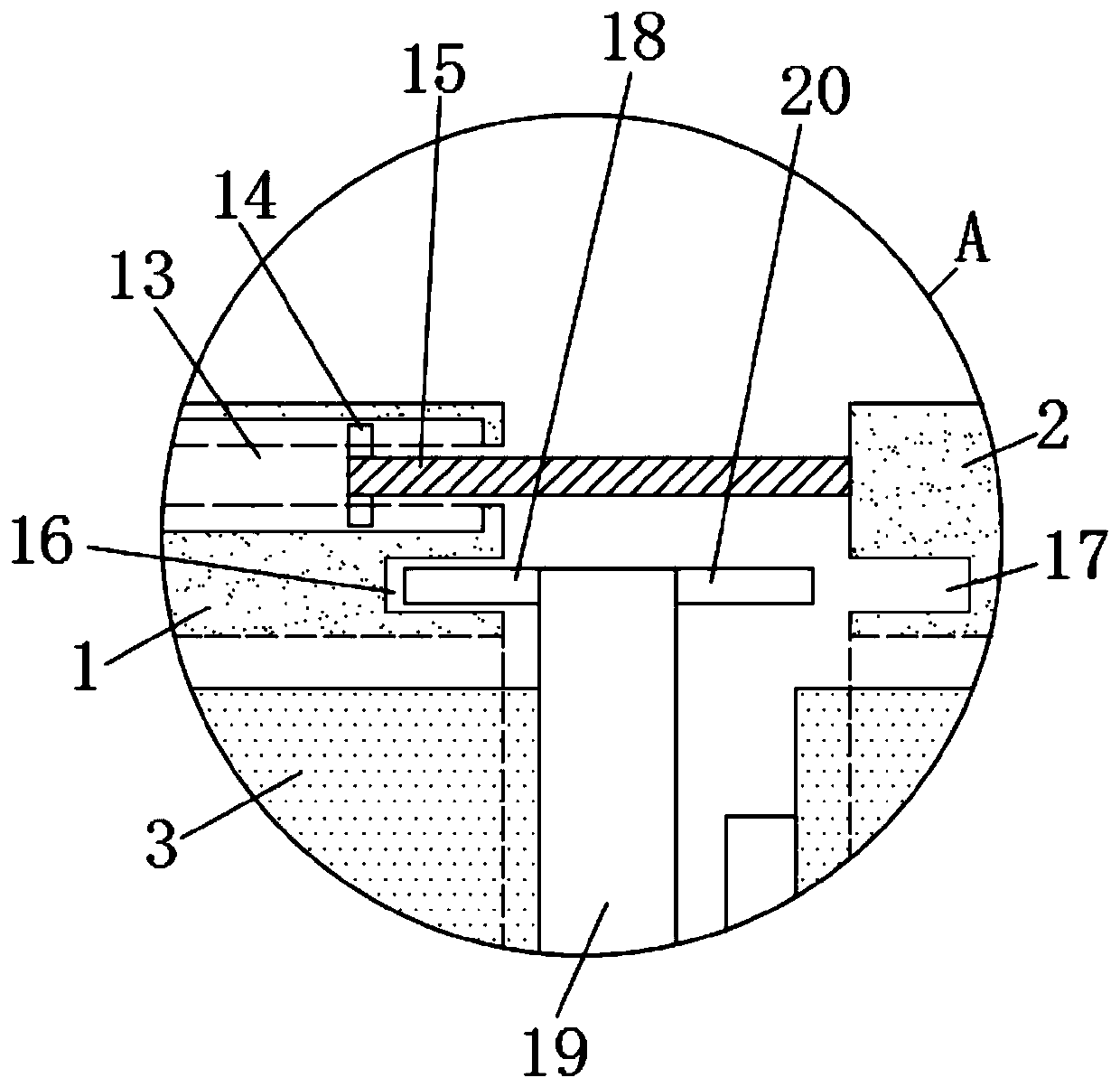

The invention discloses a ripening technology in fine dried noodle production and a ripening device which has simple structure and easy operation control. The ripening technology comprises the step of putting dough sheets in an insulating and moistening cover (1) for ripening, and is characterized in that the time is controlled to be 15-25 min, the temperature is controlled to be 25-32 DEG C and the relative humidity is controlled to be 80-90 percent during the ripening. The ripening device comprises a transport unit connected with a composite calender and a continuous calendar, wherein the continuous calendar is arranged on a stand (4) and arranged in the insulating and moistening cover (1), and a heating and moistening device is arranged in the insulating and moistening cover (1). The invention has the advantages that the internal gluten structure of the dough sheets after ripening has stable state and has flexibility, viscoelasticity and very good tractility so as to be convenient for being processed by the following procedures; the heating and moistening device is simple, and compared with heating and moistening by steam generated by a boiler, the operation control is convenient and also pollution to the environment is reduced.

Owner:KEMEN NOODLE MFG CO LTD

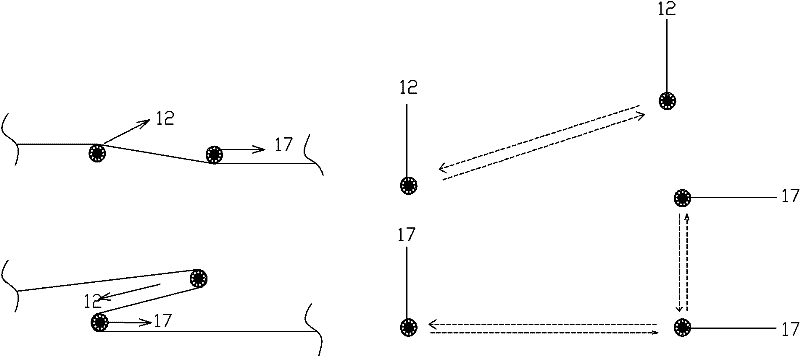

Annealing system for multi-strand superfine copper wires and annealing method of annealing system for multi-strand superfine copper wires

ActiveCN102787232AIncrease production speedSimplify the subsequent weaving processFurnace typesHeat treatment furnacesElectricityCopper wire

The invention discloses an annealing system for multi-strand superfine copper wires. The system comprises a wire payoff rack, a first capstan, a first drying oven, a water tank, a felt, a second capstan, a second drying oven, a cooling gas blowing kettle and a wire winding disc, wherein a gas outlet of the cooling gas blowing kettle is located on an outlet of the second drying oven. The invention also discloses an annealing method by the annealing system for multi-strand superfine copper wires. With the adoption of the method provided by the invention, the time, electricity and power can be saved and large output is obtained; and meanwhile, the produced superfine copper wires is strong in antioxidant capability and long in service life.

Owner:TAICANG LINYUAN CABLES & CORDS CO LTD

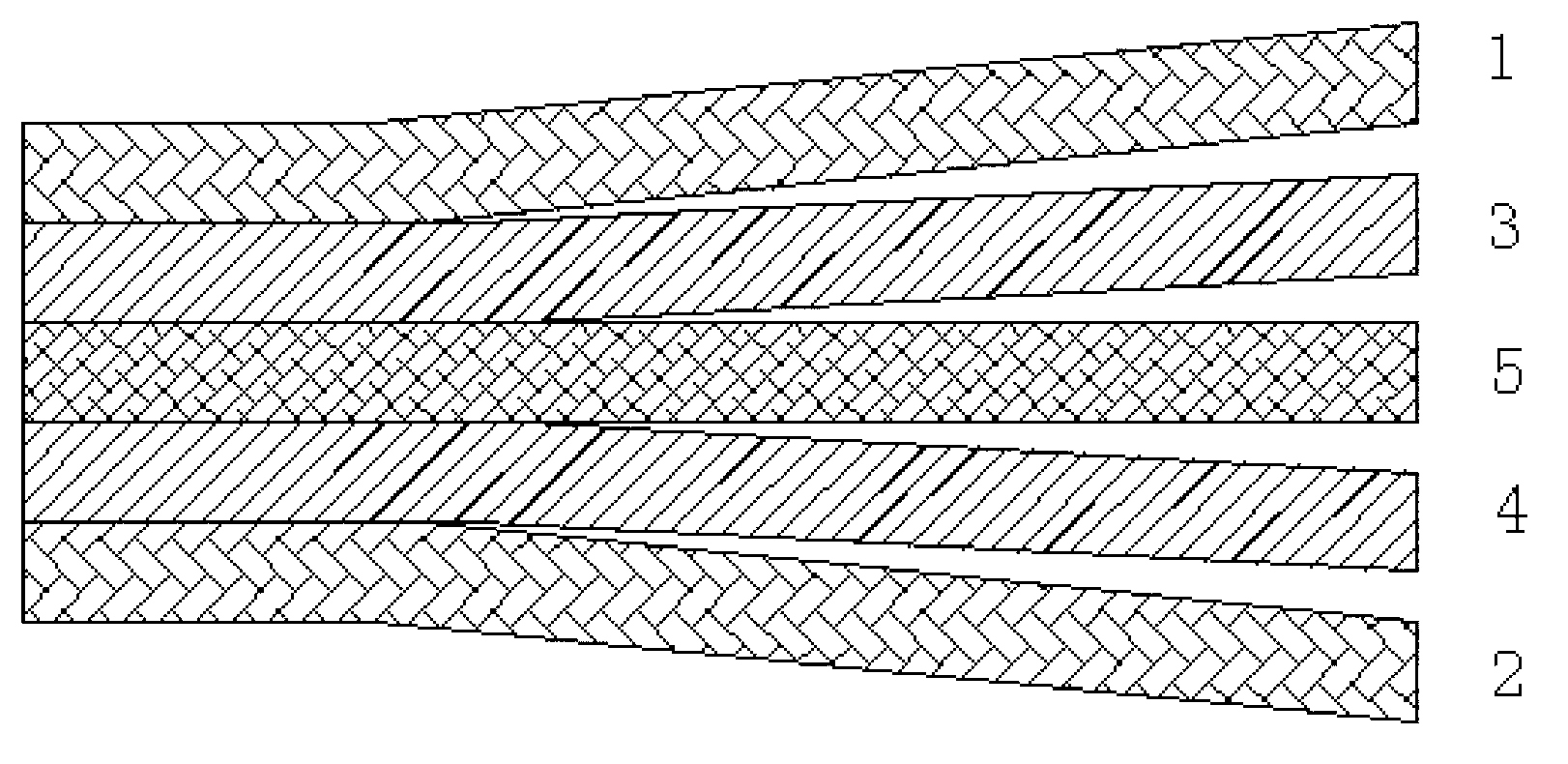

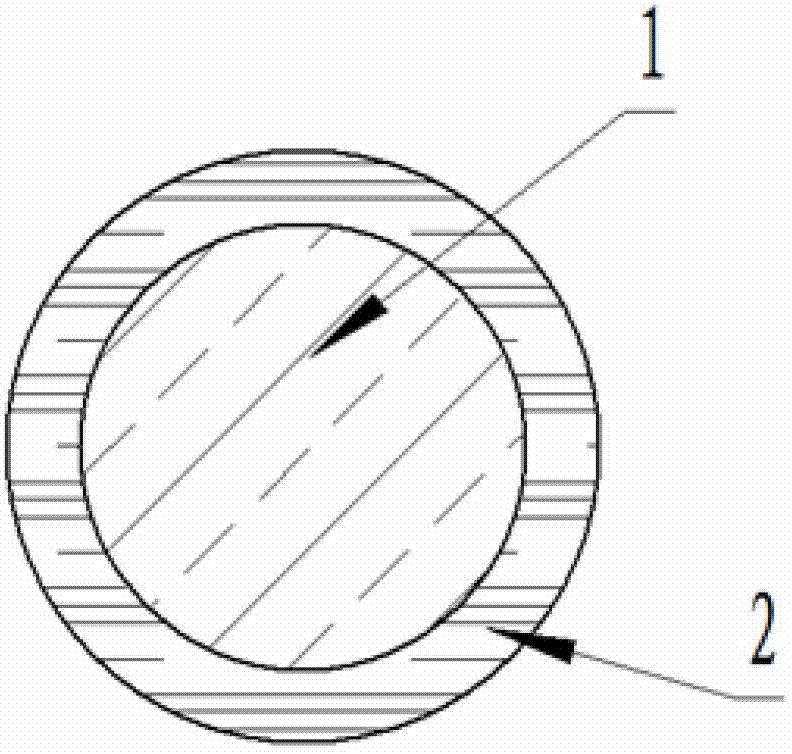

Five-layer composite freshness-keeping isolating membrane and preparation method thereof

ActiveCN103317803AHigh tensile strengthNot easy to stretchSynthetic resin layered productsPolyolefinSingle use

The invention relates to a five-layer composite freshness-keeping isolating membrane and a preparation method thereof and in particular relates to an isolating freshness-keeping membrane in the production and use process of a rubber radial tire. The five-layer composite freshness-keeping isolating membrane can be used for a rubber tire as an auxiliary material and belongs to the technical field of plastic membranes. According to the five-layer composite freshness-keeping isolating membrane, originally single disposable isolating membrane is changed to be a new material, namely the five-layer coextrusion composite membrane which is used for the rubber tire composed of two layers of surface polyethylene surface layers, two layers of polyolefins interlayers and one layer of polypropylene fiber woven wire mesh positioned among the four layers and can be recycled. The freshness-keeping isolating layer is firm in structure and not easy to stretch, deform, damage or discolor after hot-pressing solidification, the thickness of the freshness-keeping isolating layer is 0.3-1.3mm, and the freshness-keeping isolating layer can be reused.

Owner:HAOCHEN WUXI PLASTIC IND CO LTD

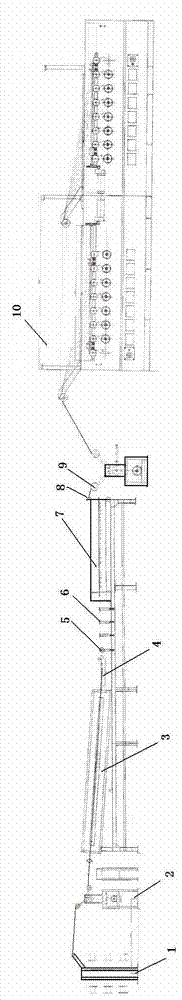

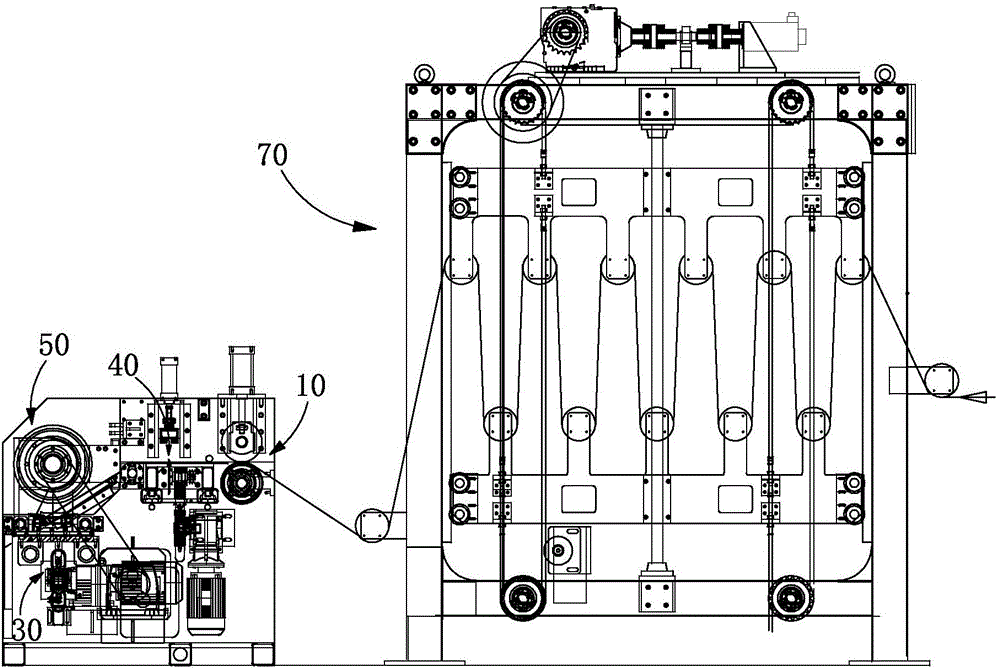

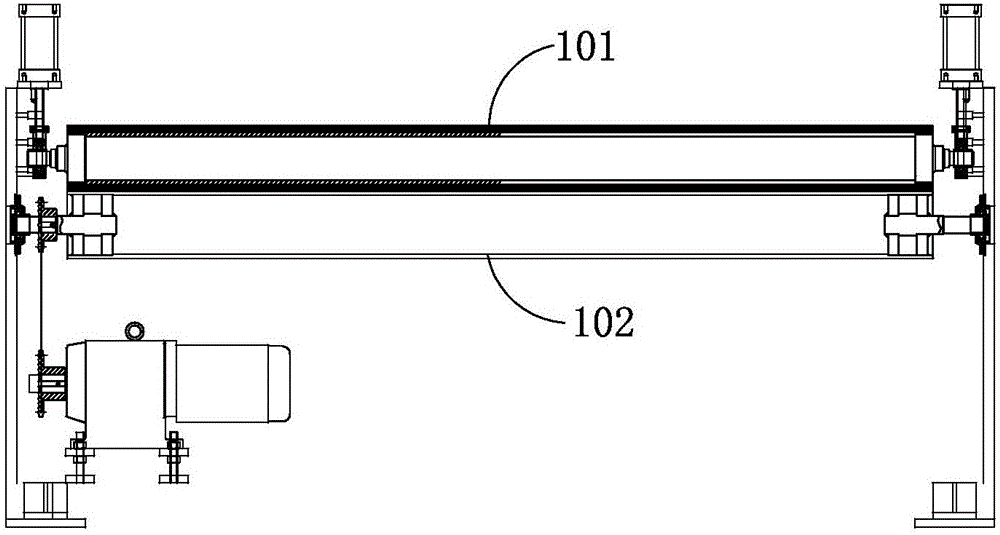

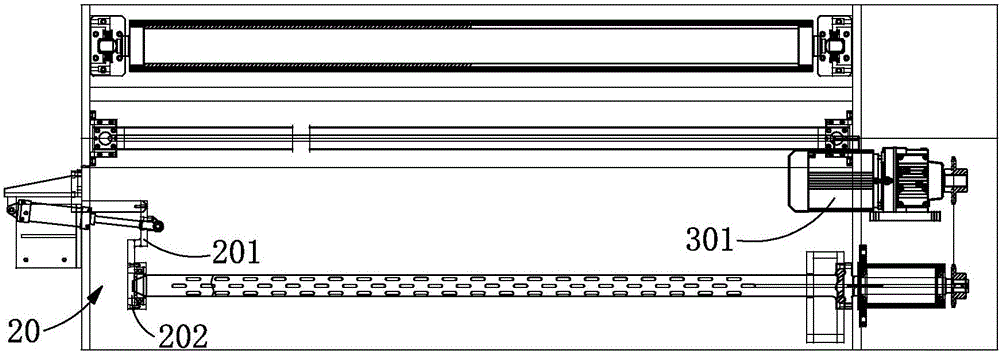

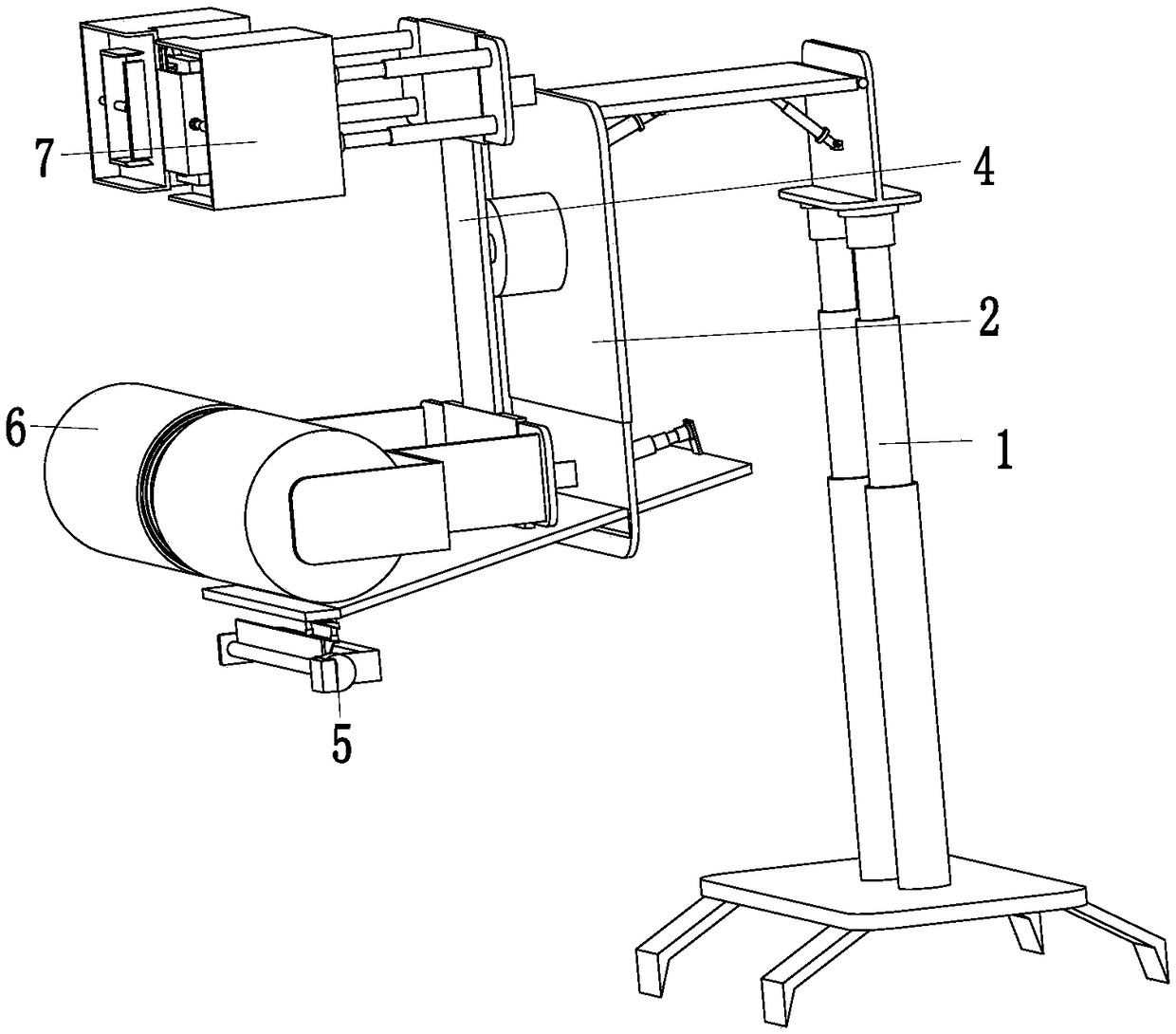

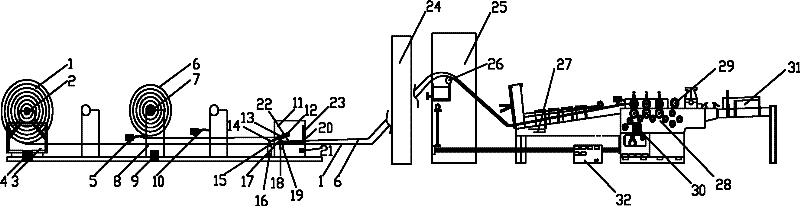

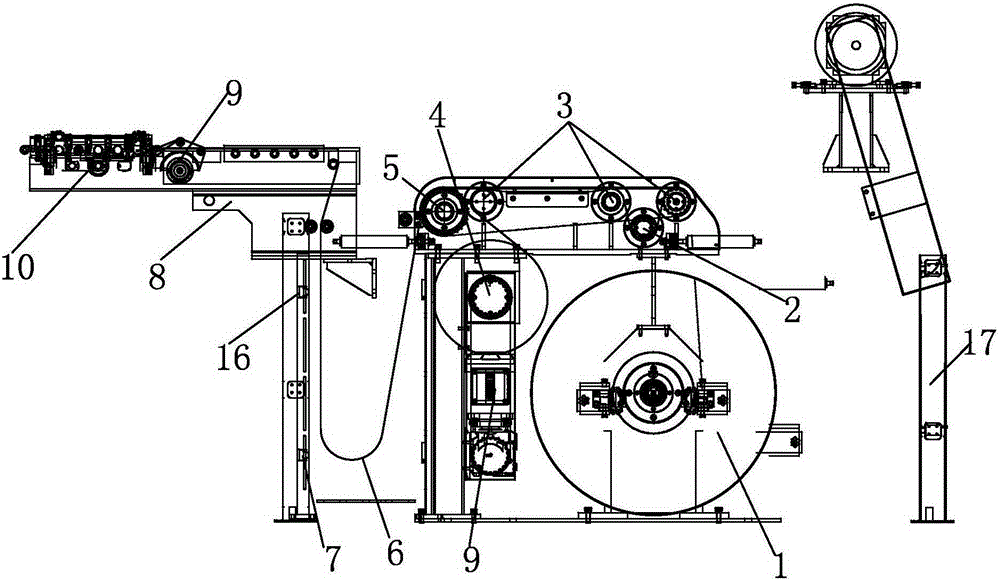

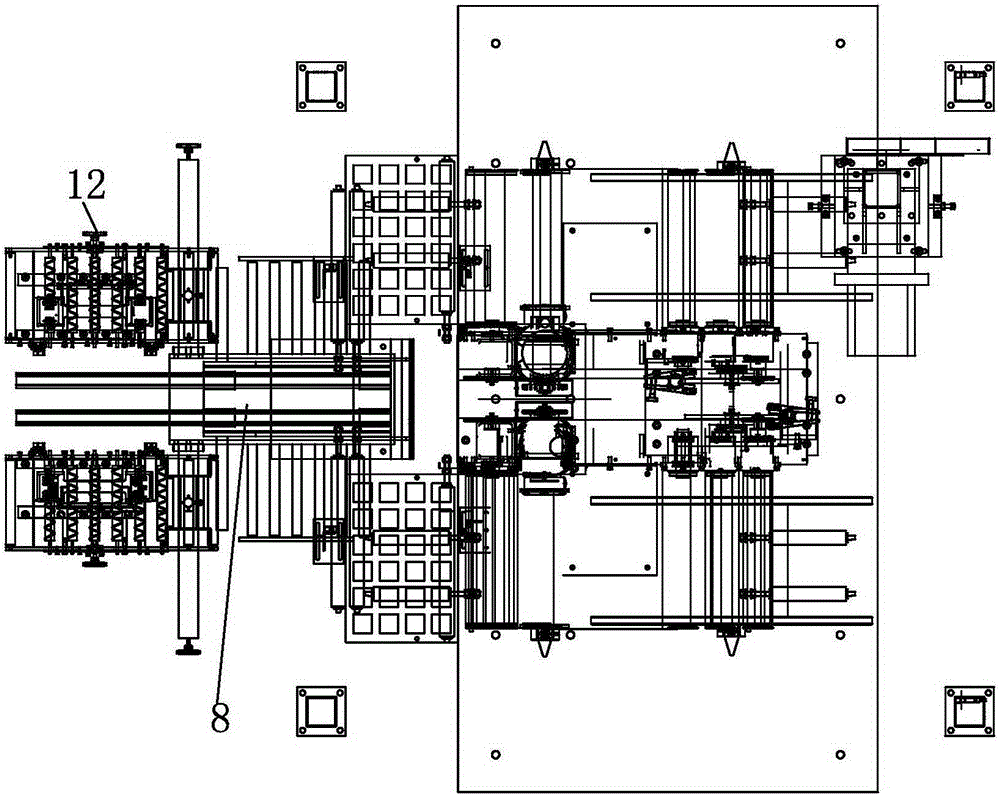

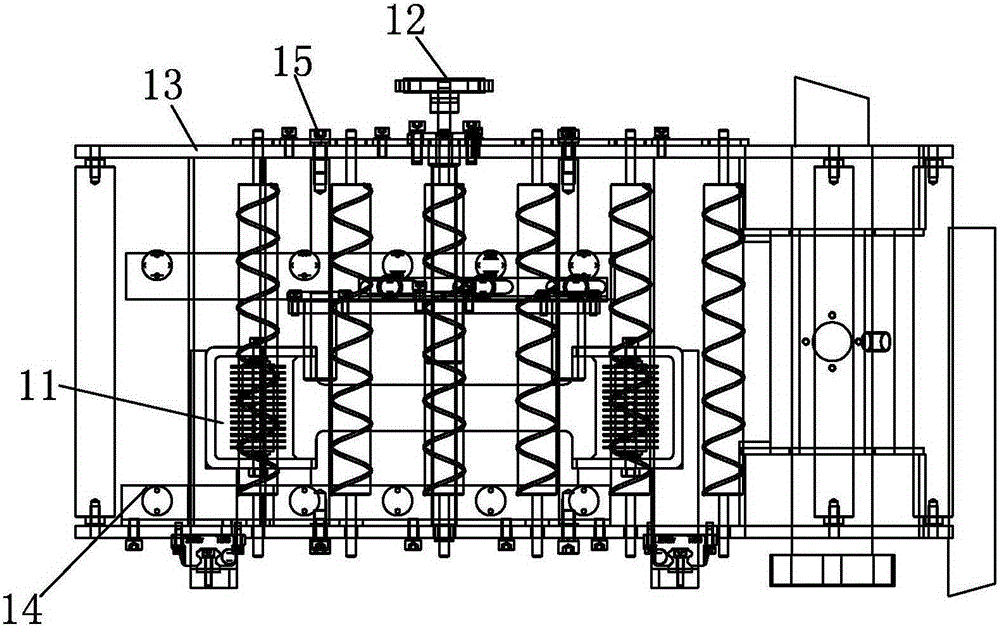

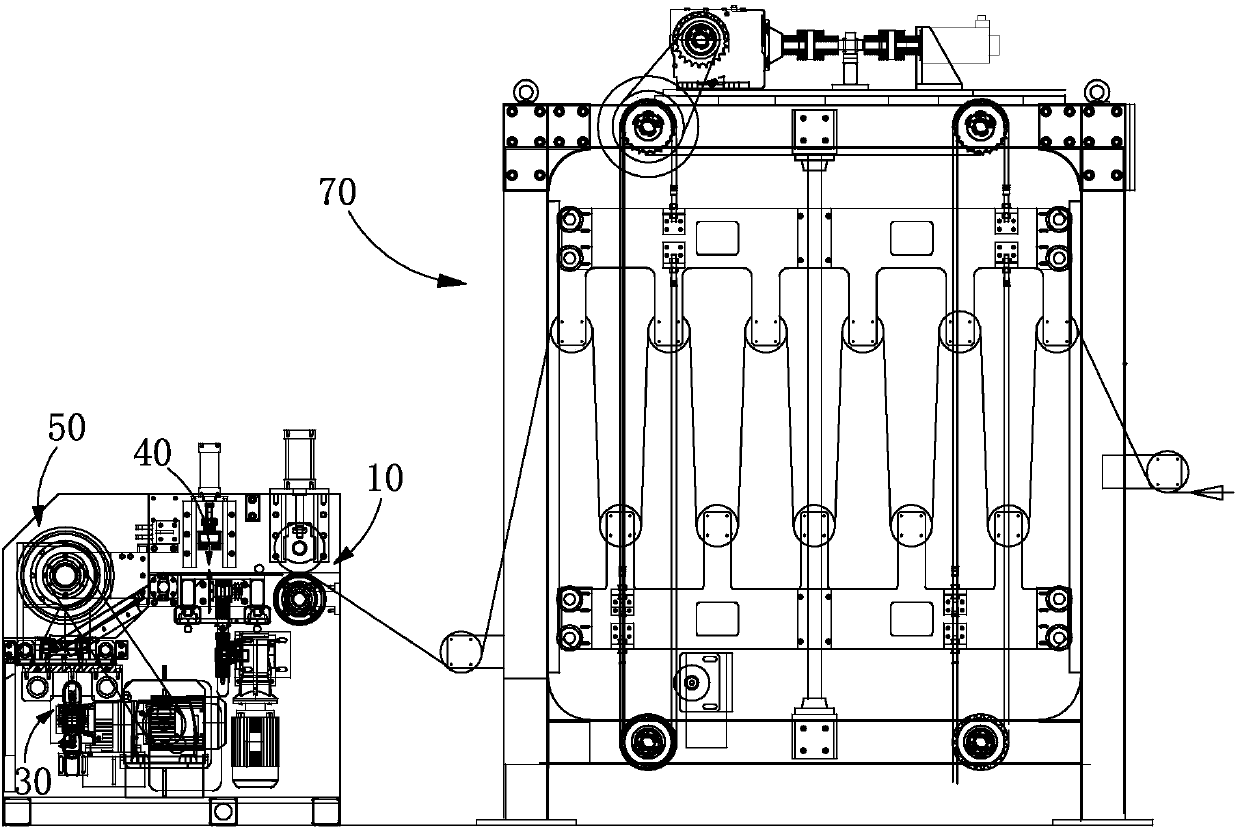

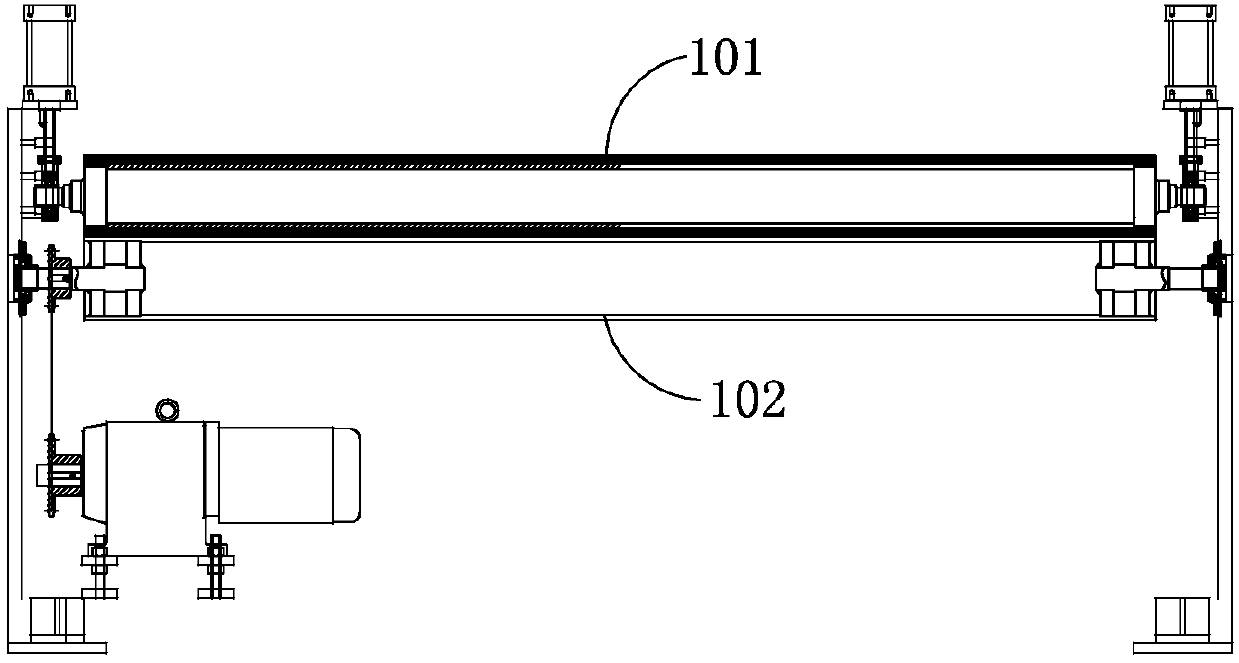

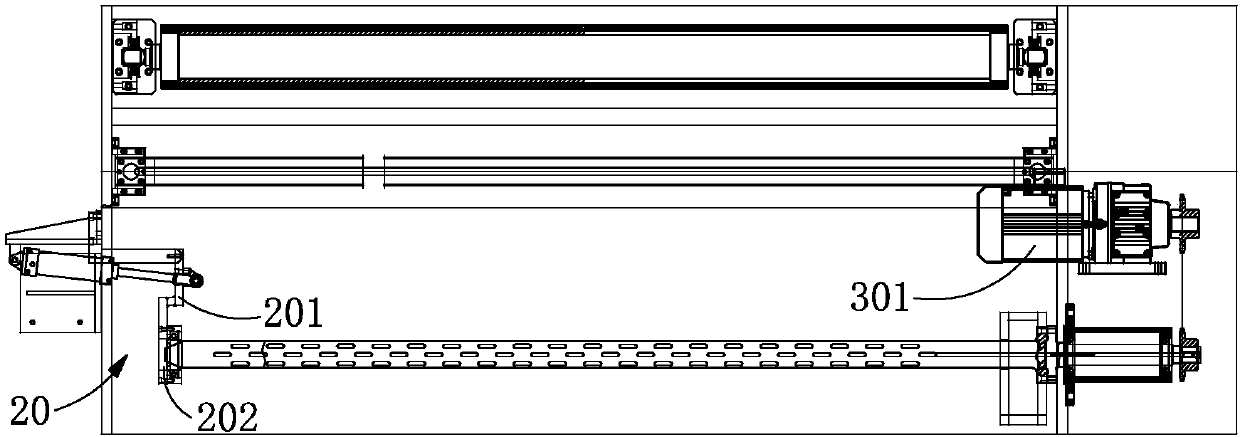

Small-rolling-diameter full-automatic winding device

ActiveCN106115322ANot easy to stretchGuaranteed product performanceWebs handlingEngineeringMaterial storage

The invention discloses a small-rolling-diameter full-automatic winding device. The small-rolling-diameter full-automatic winding device comprises a traction mechanism, a gas expansion shaft auxiliary tight jacking mechanism, a winding mechanism, an automatic cutting mechanism, an automatic unwinding mechanism, an automatic conveying and conveying mechanism and a material storage mechanism, wherein the traction mechanism, the gas expansion shaft auxiliary tight jacking mechanism, the winding mechanism, the automatic cutting mechanism, the automatic unwinding mechanism, the automatic conveying and conveying mechanism and the material storage mechanism are sequentially arranged on a rack. The winding, cutting, unwinding and weighing mechanisms of the small-rolling-diameter full-automatic winding device all achieve automation, by adjusting, controlling and feeding back the tensile force of a sheet, the winding tension degree is adjusted through a winding motor, the sheet winding tension is constant tension, and the product performance is guaranteed; and meanwhile, the unwinding mechanism is designed at the position of the center of a current winding shaft, the wound sheet can be fast unwound, in the unwinding process, the material storage mechanism stores the sheet at the same time, the material storage mechanism performs discharging on the sheet when winding is started, it is guaranteed that a product is not prone to stretching, the product performance is improved, and the wound sheet is weighed and subjected to labeling. The whole device structure effectively improves the production line efficiency, time is saved, operation is convenient, the effect is remarkable, and the labor cost is greatly saved.

Owner:SUZHOU JWELL MACHINERY

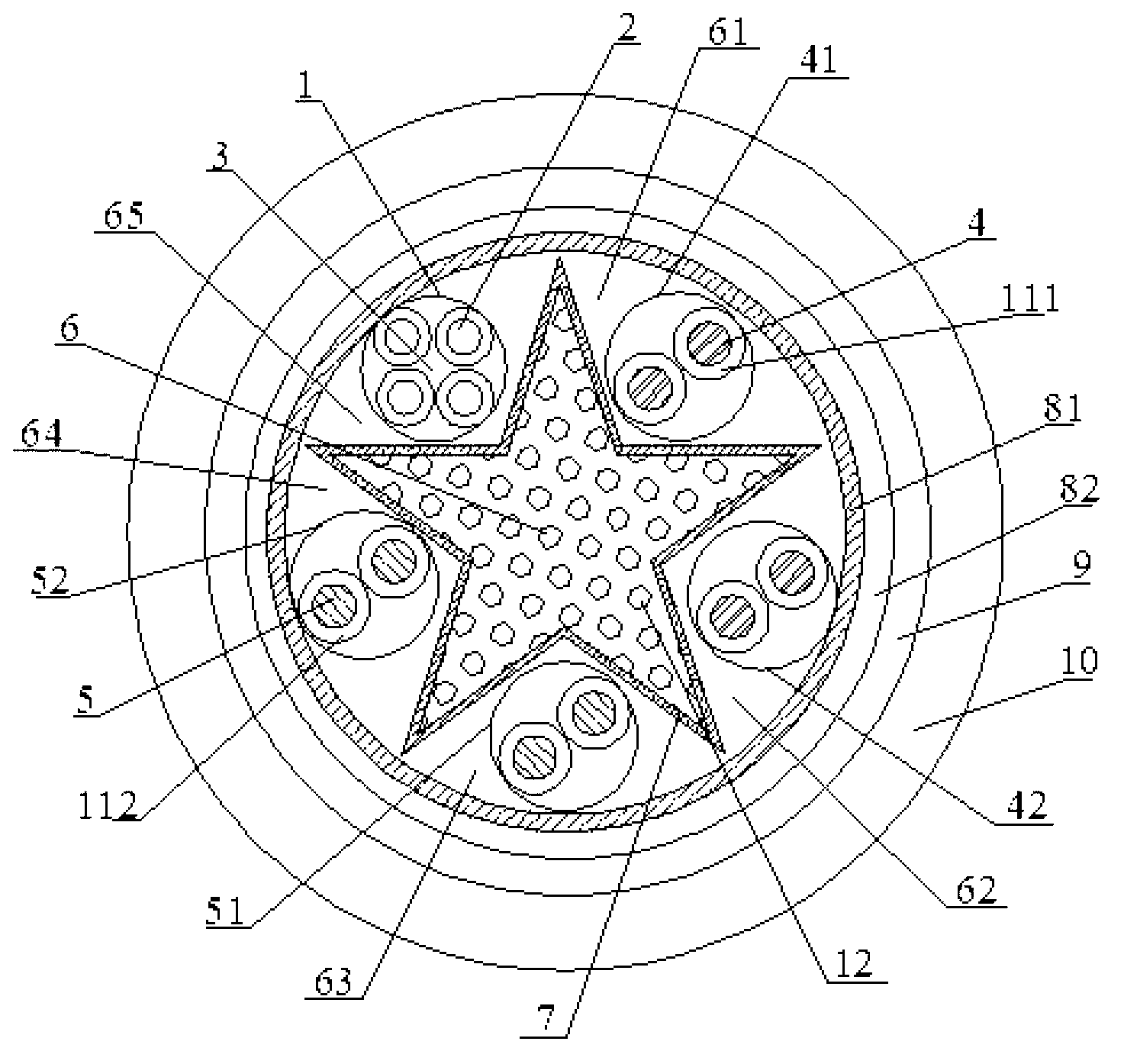

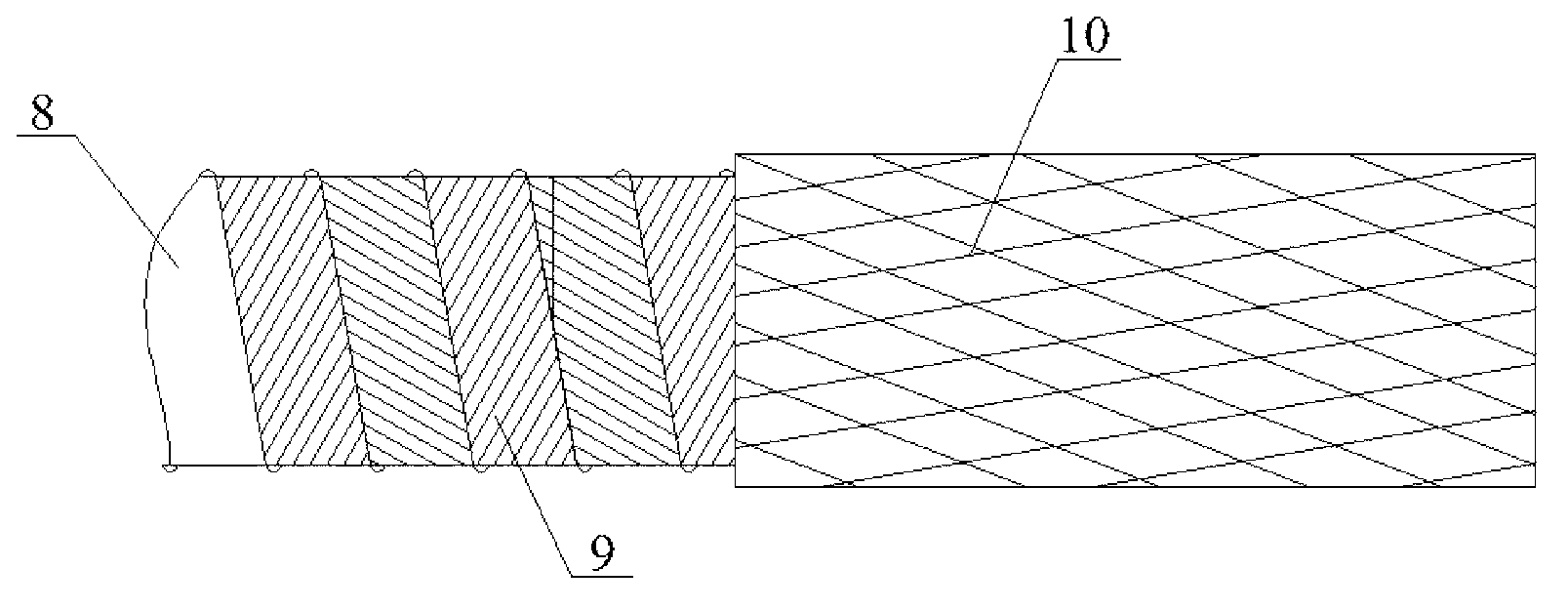

Photoelectrical composite data cable of star structure

ActiveCN103258586AImprove return lossImprove impedance characteristicsInsulated cablesInsulated conductorsDielectricCopper conductor

The invention discloses a photoelectrical composite data cable of a star structure. The photoelectrical composite data cable comprises an optical fiber unit, a first communication stranded wire pair, a second communication stranded wire pair, a first electric stranded wire pair, a second electric stranded wire pair and a pentagonal start framework. Four first copper conductors wrapped with insulating layers are stranded into the first communication stranded wire pair and a second communication stranded wire pair in a pairwise stranded mode for information communication. Four second copper conductors wrapped with insulating layers are stranded to form the first electric stranded wire pair and the second electric stranded wire pair in a pairwise stranded mode for electricity transmission. A metal layer is coated on the surface of the pentagonal start framework, and an aluminum layer of an aluminum foil layer is arranged on the inner side so that the aluminum layer can be in electric contact with the metal layer of the pentagonal start framework. A steel wire is tightly wrapped on the outer surface of the aluminum foil layer to form an armor layer, and a plurality of air holes are formed in the pentagonal start framework. The dielectric constant of the pentagonal start framework is larger than 0.1 and smaller than 2.3. By means of the photoelectrical composite data cable, communication cable allowance of crosstalk indicators is effectively improved by 1%, and even allowance of loss is improved by 1dB. Stability of characteristic impedance is increased by 1.5%, and meanwhile external electromagnetic interference is effectively prevented from entering the cable and internal signals are prevented from radiating out.

Owner:JIANGSU HENGTONG WIRE & CABLE TECH

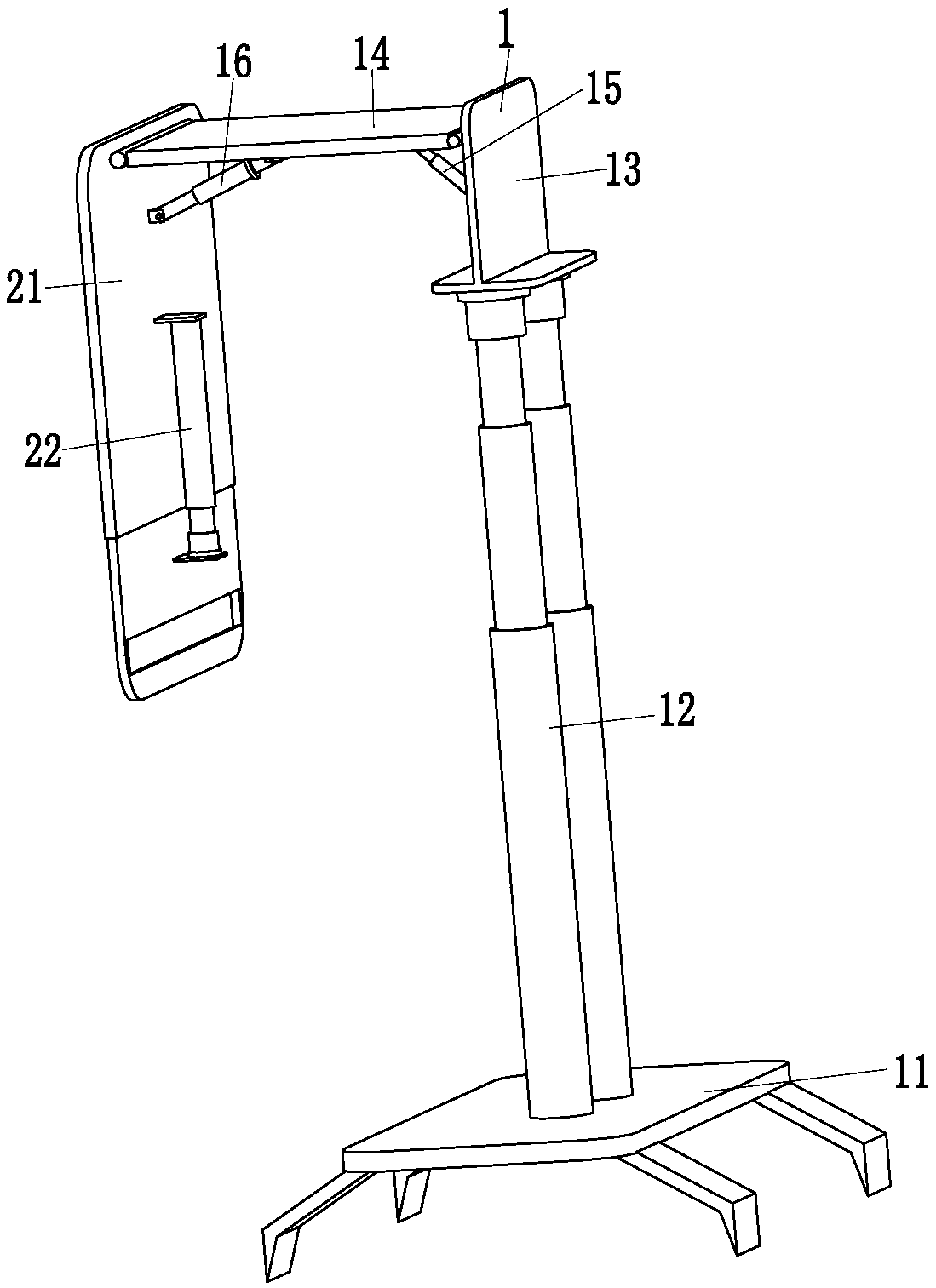

Construction robot for environment-friendly wall decorations

The invention relates to a construction robot for environment-friendly wall decorations, which comprises an adjusting device, a telescopic device, a connecting plate, a cutting device, a dual-purposedevice and a shearing device, wherein the telescopic device is installed on the front side of the upper end of the adjusting device, and the shearing device is installed at the lower end of the telescopic device, the connecting plate is installed at the front end of the telescopic device, the shearing device is installed at the upper end of the connecting plate, and the dual-purpose device is installed at the lower end of the connecting plate. The invention can solve the existing problems: in case of seaming anti-mold wallpapers, personnel are required to push the excess paper material betweenthe two wallpapers into a convex shape by means of a ruler, and then cut the paper material with a cutter, and a plurality of people are needed to cooperate; in case of cutting, a manual cutting is not flush, and the cutting is not complete, and the wallpapers may be pulled and damaged or stretched due to personnel not pressing the wallpapers stable; and in case of cutting the redundant wallpaperat the skirting line, as the skirting line is too low, the personnel will have difficulties to cut even the personnel bend down, thereby resulting in a long time consumption, a large labor intensityand a low efficiency etc.

Owner:浙江金果知识产权有限公司

Composite film material for manufacturing liquid package sealing tape and preparation method thereof

InactiveCN106183294ANot easy to stretchNot easy to cutLamination ancillary operationsSynthetic resin layered productsLow-density polyethylenePolyester

The invention belongs to the field of sealing materials, and in particular relates to a composite film material used for making liquid packaging sealing strips. The invention comprises a double-sided corona biaxially stretched polyester film layer, wherein one side of the double-sided corona biaxially stretched polyester film layer is sequentially compounded with a first metallocene polyethylene resin film layer, a first low-density polyethylene resin film layer, the second metallocene polyethylene resin film layer, the other side of the double-sided corona biaxially stretched polyester film layer is sequentially compounded with the third metallocene polyethylene resin film layer, the second low density polyethylene resin film layer , the fourth metallocene polyethylene resin film layer. The strip-shaped sealing strip prepared from the composite film material of the present invention is not easy to stretch and cut off during use, and has strong peel strength, good low-temperature heat-sealability, smoothness and medium resistance. Composite film materials provide domestic manufacturers with more choices about sealing strips for liquid aseptic liquid packaging.

Owner:程淋

Inner plastic bag folding and lengthening device

ActiveCN102673013AAvoid breakingThe need to realize fully airtight packagingContainer making machineryEngineeringPendulum

The invention discloses an inner plastic bag folding and lengthening device, which comprises a first air shaft. The first air shaft passes through the central core drum of an outer paper roll and is placed on an outer paper support, a first servo motor is mounted under the outer paper support, an outer paper tension controller is mounted at the paper position of the outer paper support, a second air shaft passes through the central core drum of a rolled drum-like plastic inner bag and is placed on the drum-like plastic inner bag support, a second servo motor is mounted under the drum-like plastic inner bag support, a drum-like plastic inner bag tension controller is mounted at the paper position of the drum-like plastic inner bag support, an upper pendulum shaft is mounted on a vertical wallboard, one end of a first strip-shaped tooth is fixed on the upper pendulum shaft, and the first strip-shaped tooth is engaged with a first gear. The inventive folding and lengthening device increases the total volume of the drum-like plastic inner bag, and avoids breakage of the inner plastic bag after filling.

Owner:SHANGHAI AILU PACKAGE

High-strength antirust bolt

The invention discloses a high-strength antirust bolt which comprises the following components in percentage by mass: 0.001-0.02% of terbium, 0.0003-0.005% of nickel, 0.13-0.7% of strontium, 20-70ppm of zirconium, 50-100ppm of iridium, 60-120ppm of platinum, 0.00005-0.0009% of niobium, 30-90ppm of molybdenum, 2.5-7.8% of metalloid element and the balance of iron. The high-strength antirust bolt has the advantages of high tensile strength and fatigue resistance, and can be easily lengthened, pulled apart, slipped or abraded; the bolt operating in a moist atmosphere or corrosion atmosphere environment can resist rust and corrosion; and the bolt can be used repeatedly, thereby reducing the waste of resources and saving the cost.

Owner:褚介平

High-strength high-conductivity enameled copper alloy wire

InactiveCN103117116AImprove stabilityResistivity ControlInsulated cablesMetal/alloy conductorsHigh pressureThermal shock

The invention discloses a high-strength high-conductivity enameled copper alloy wire which comprises a conductor layer and an insulated layer wrapped outside the conductor layer. The conductor layer is a copper alloy wire which is made of an alloy material of cooper and magnesium or copper and silver or copper, chromium and zirconium. The high-strength high-conductivity enameled copper alloy wire does not soften in a high-temperature environment, and does not deform or neck down when subjected to high-pressure thermal shock. The enameled wire cannot be lengthened during a winding process of electrical equipment. Therefore, the fact that resistivity of the enameled wire can be controlled is ensured, and high stability of the electrical equipment is obtained.

Owner:ZHEJIANG HONGLEI COPPER CO LTD +1

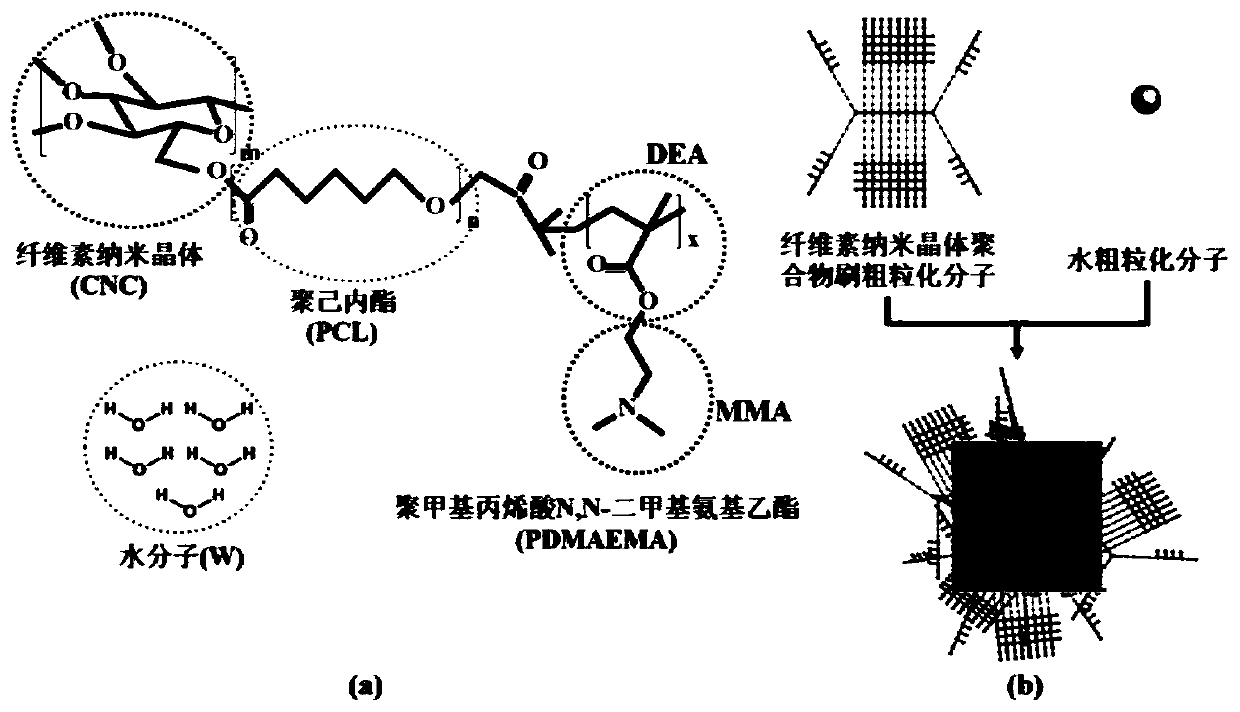

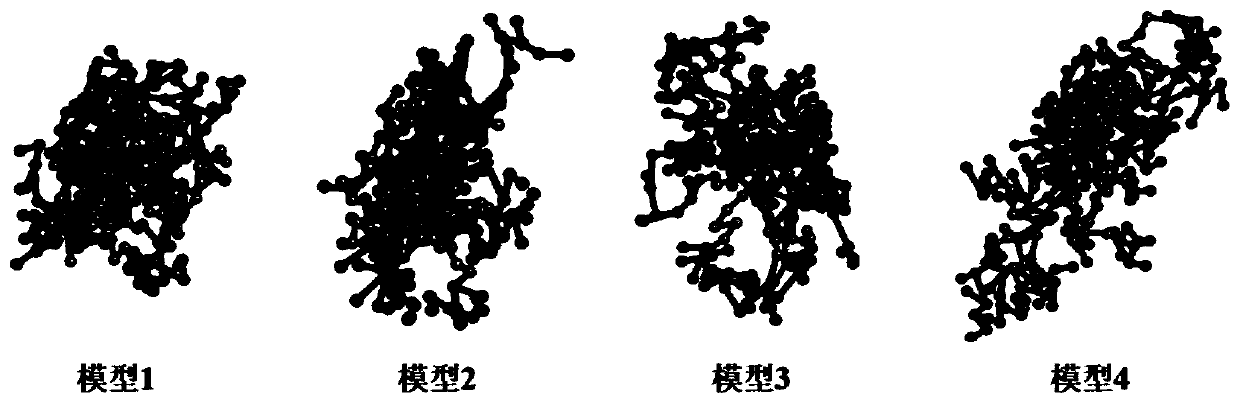

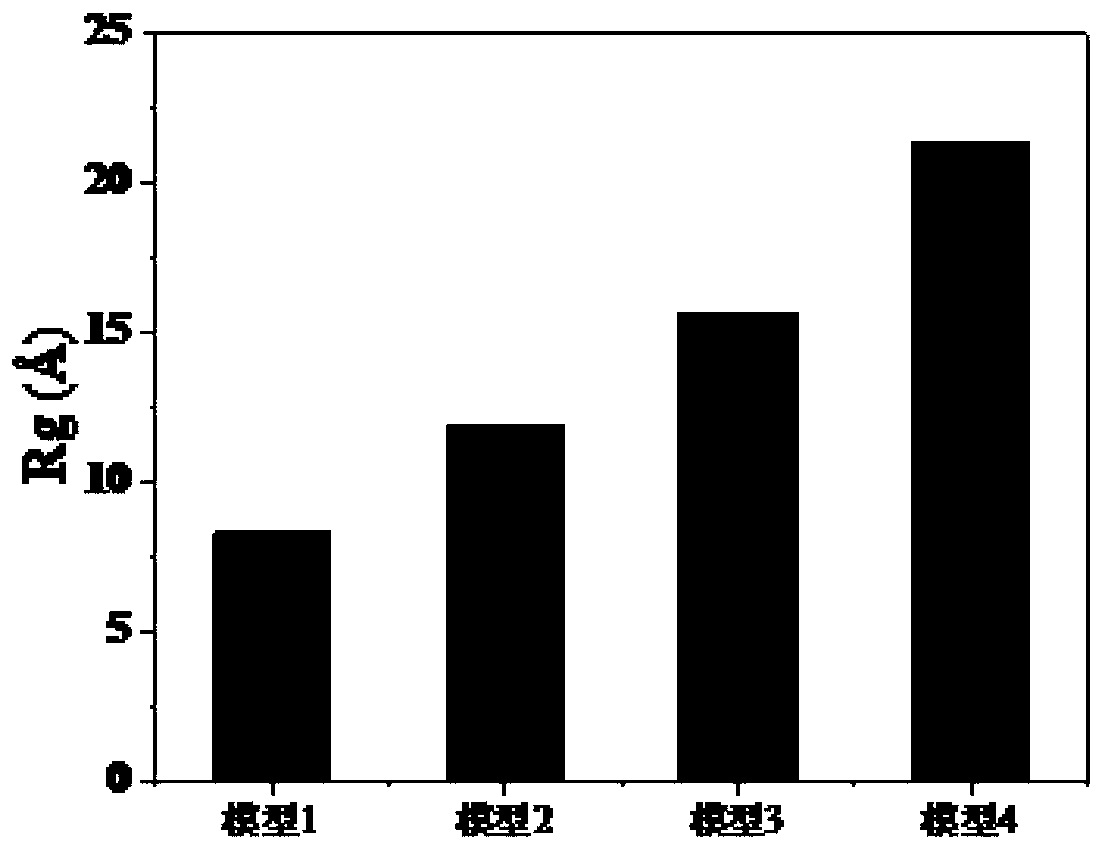

Method for simulating self-assembly behavior of rigid segmented block copolymer solution

ActiveCN110767273ASolve the problem of uncontrollable rigidityNot easy to stretchSustainable transportationComputational materials sciencePolymer scienceChemical physics

The invention discloses a method for simulating the self-assembly behavior of rigid segmented block copolymer solution. The method is characterized in that rigidity of a segmented block is controlledby fixing a bond angle of the rigid segmented block of the rigid segmented block copolymer and adjusting elastic constants of bonds and a bond angle, so a self-assembly microstructure of rigid polymermolecules in solution is simulated. The method comprises steps of firstly, constructing an initial model of rigid polymer solution through Matrials Studio software; secondly, calculating a repulsiveforce parameter between beads in the rigid polymer molecular solution according to the solubility parameter; then, fixing the rigid segmented block bond angle, adjusting the elastic constants of the bonds and the bond angle so as to endow the polymer segmented block with rigid characteristics, and lastly, carrying out the dynamic relaxation process of the initial configuration of the rigid polymersolution to obtain a self-assembled structure of rigid polymer molecules. The method is advantaged in that rigidity of the intramolecular bonds of the polymer can be accurately controlled, and guidance and theoretical basis are provided for regulation and control of the self-assembly structure of the polymer.

Owner:SOUTH CHINA UNIV OF TECH

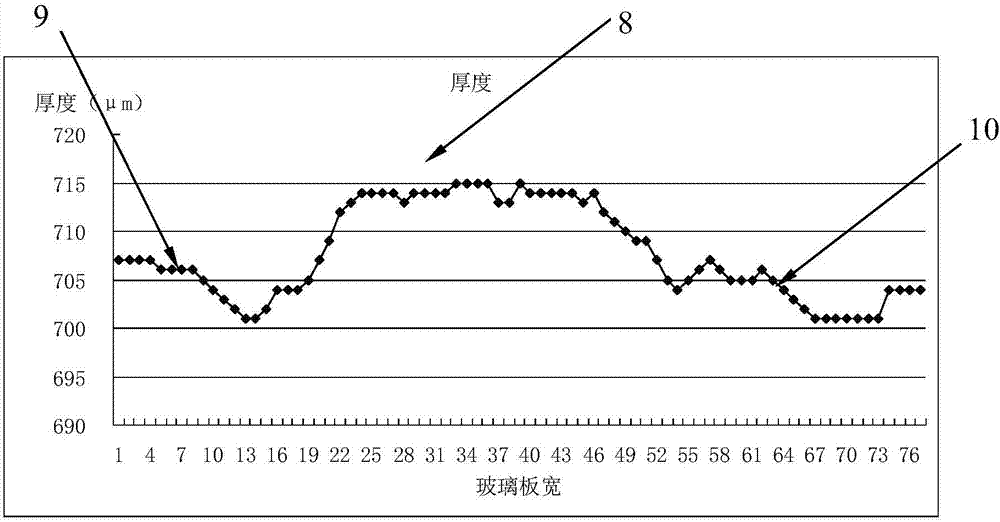

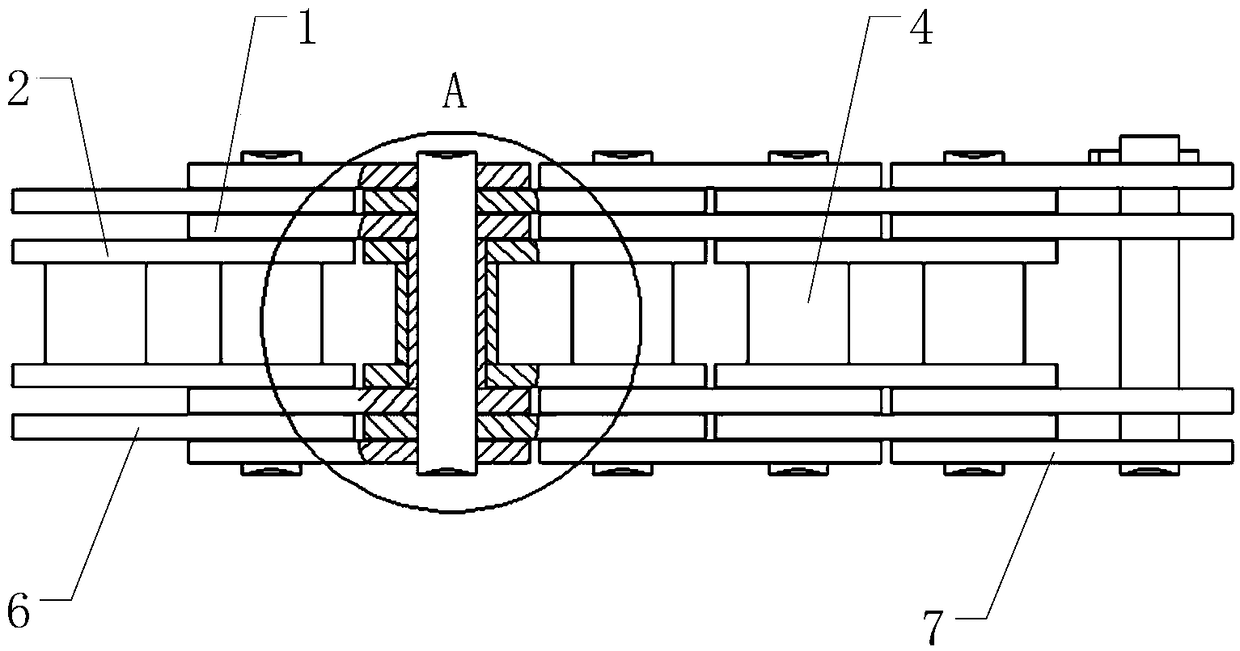

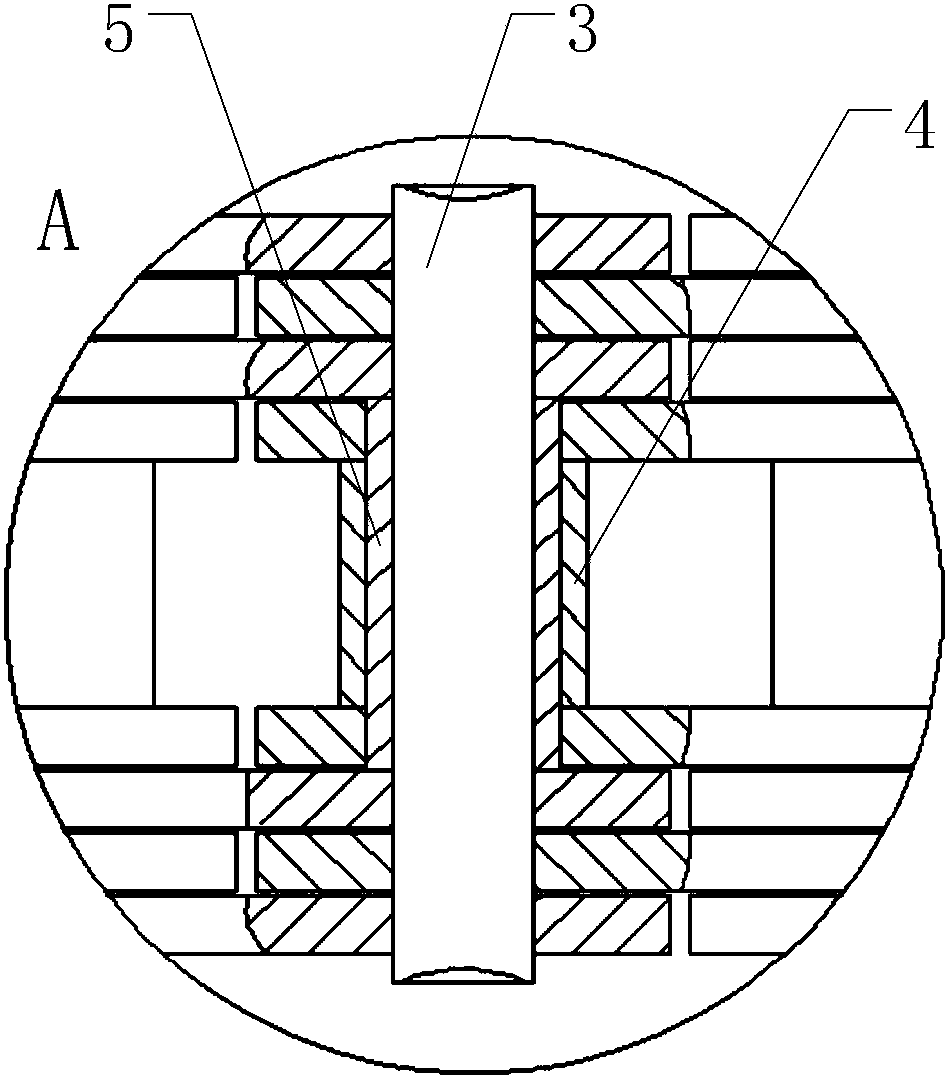

Forming equipment capable of adjusting glass substrate thickness distribution uniformity and method for adjusting glass substrate thickness distribution uniformity by adopting forming equipment

InactiveCN107365058AAdjust thickness distribution uniformityThickness distribution uniformity adjustmentGlass forming apparatusEngineeringGlass sheet

The invention provides forming equipment capable of adjusting glass substrate thickness distribution uniformity and a method for adjusting the glass substrate thickness distribution uniformity by adopting the forming equipment and belongs to the field of manufacturing of glass substrates. Cooling sockets are formed in the side wall of the forming equipment and are located between an overflow groove and a traction roll assembly of the forming equipment; the forming equipment further comprises cooling insert pipes which are of enclosed hollow-out pipes, tail ends of the cooling insert pipes are connected with coolant outlet pipelines, and coolant sleeves are arranged in the cooling insert pipes; tail ends of the coolant sleeves are fixed to the tail ends of the cooling insert pipes and are connected with coolant inlet pipelines; front ends of the coolant sleeves are communicated with front end of the cooling insert pipes; the cooling insert pipes can be inserted in the cooling sockets to be matched with the same, and the distance between parts of the cooling insert pipes, extending to the forming equipment and a glass substrate is 3-15cm. By the arrangement, the glass substrate thickness distribution uniformity can be adjusted, thinner places on the glass substrate can be thickened, and thicker places on the glass substrate can be thinned.

Owner:RAINBOW (HEFEI) LIQUID CRYSTAL GLASS CO LTD

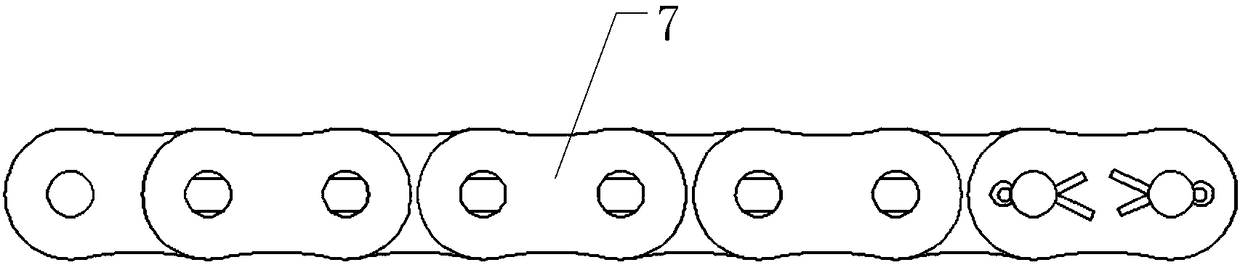

Roller chain and chain transmission system

PendingCN108317221AImprove carrying capacityImprove fatigue resistanceChain linksDriving chainsEngineeringRoller chain

The invention relates to the technical field of transmission components, in particular to a roller chain and a chain transmission system. The roller chain comprises outer chain plates, inner chain plates, pin shafts, rollers, sleeves, first reinforcing plates and second reinforcing plates. The two ends of each sleeve are fixed to the two corresponding inner chain plates arranged oppositely. The pin shafts are sleeved with the corresponding sleeves. The two ends of each pin shaft are connected with the corresponding outer chain plate and the corresponding inner chain plate. The sleeves are sleeved with the corresponding rollers. The first reinforcing plates are arranged on the sides, far away from the inner chain plates, of the corresponding outer chain plates. The first reinforcing platesconnect the two adjacent pin shafts. The second reinforcing plates are arranged on the side, far away from the outer chain plates, of the first reinforcing plates. The second reinforcing plates connect the two adjacent pin shafts. The chain transmission system comprises the roller chain. The roller chain and the chain transmission system are provided for solving the technical problems that a chainis small in bearing capacity and poor in anti-fatigue performance and wear-resisting property in the prior art.

Owner:SUZHOU UNIVERSAL GRP TECH CO LTD

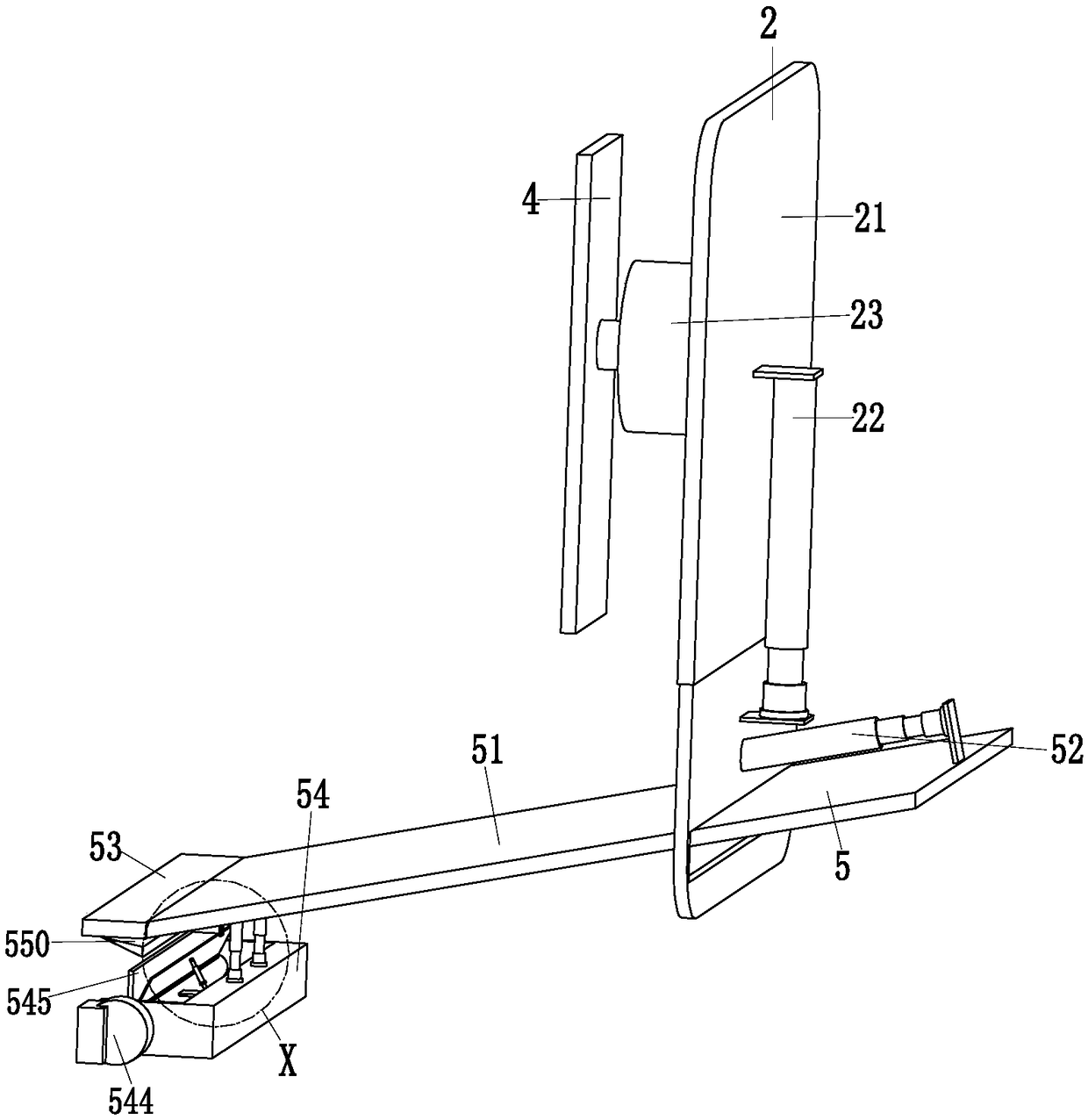

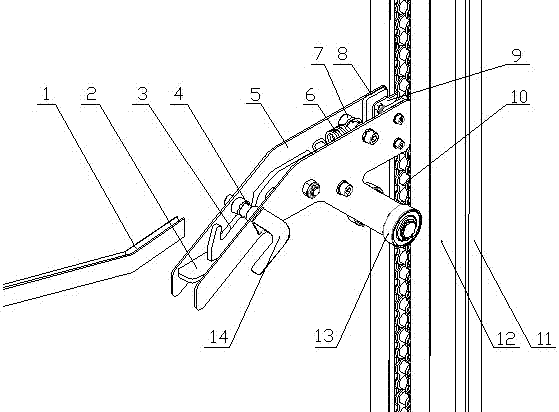

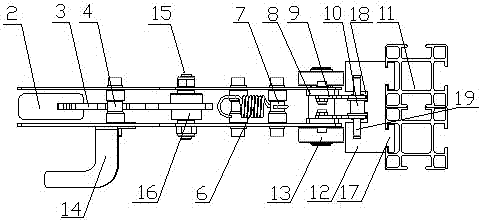

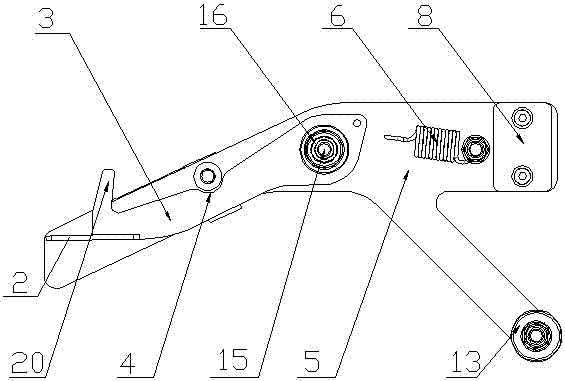

Steel wrapper feed frame device

InactiveCN105253688ANot easy to stretchSimple and fast operationArticle deliveryWebs handlingEngineeringMechanical engineering

Owner:HAINING RUICHUANG MACHINERY TECH

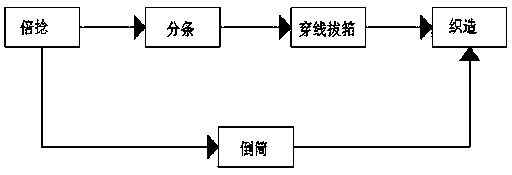

Production technology of crepe jacquard gold and silver fabric

The invention discloses a production technology of a crepe jacquard gold and silver fabric. The production technology includes warp yarn treatment and weaving, the temperature of a weaving workshop is25-26 DEG C, the humidity is 65-70%, the speed is 520 r / min, the rear beam height is 4 cm, the angle is 75 degrees, the loom tension of an upper weaving shaft is 600-670 kg*g, the loom tension of a lower weaving shaft is 250-300 kg*g, there is one 30# water pump, two 90# water pumps and two 40# nozzles, the water spraying angle is 85-90 degrees, the angle between water and waste edge yarn is 220-230 degrees, the angle between yarn and waste edge yarn is 240-255 degrees, the contact angle between the yarn and a reed is 280-295 degrees, and the leveling angle is 345 degrees. On the basis of digestion, absorption and improvement of equipment, the problem that warp is easy to break in the weaving process, the initial modulus of adopted metallic yarn is high, and the metallic yarn is not easyto stretch. Through optimization of the weaving process, the warp breakage rate is reduced, the weaving efficiency is improved, and the anti-wrinkle and non-ironing novel fabric with comfortable handfeeling and fine, smooth and soft texture is developed.

Owner:JIANGSU DESHUN TEXTILES

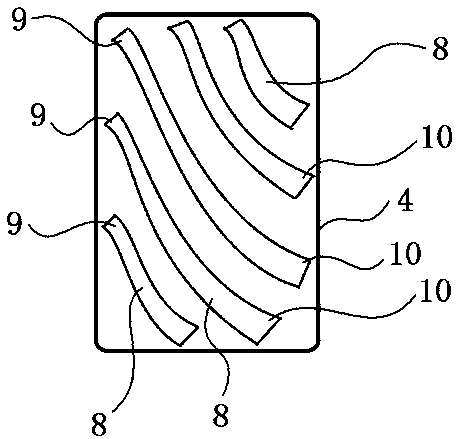

Section-color bamboo joint filament fabric

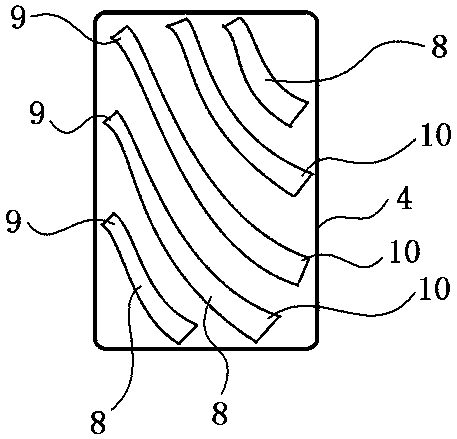

ActiveCN107815775AIncrease the degree of reinforcementOvercoming effect is not goodFibre typesFilament/thread formingYarnAirflow

Provided is a section-color bamboo joint filament fabric. The fabric is made by adopting section-color bamboo joint filaments. A making method of the section-color bamboo joint filament fabric comprises the making steps of section-color bamboo joint filament preparation, yarn spinning, weaving and after finishing. A cylindrical wall of a spinning and cooling cover housing for making section-colorbamboo joint filaments is provided with a plurality of breathable hollow-out portions, laterally-blown cooling airflow penetrates through the spinning and cooling cover housing through the multiple breathable hollow-out portions to enter the spinning and cooling cover housing and cool spun filaments; the multiple breathable hollow-out portions surround the cylindrical spinning and cooling cover housing and are arranged in spiral line shapes, the starting ends of the breathable hollow-out portions are greater than their tail ends in width, and linear change is formed from the widths of the starting ends of the breathable hollow-out portions to the widths of the tail ends of breathable hollow-out portions in the directions of the spiral lines of the breathable hollow-out portions; the cooledspun filaments are changed to a semi-solidified state. The spun filaments located in other positions in the spinning and cooling cover housing are not fully cooled by the laterally-blown cooling airflow and are still in a sticky-elastic state.

Owner:杭州佳泰纺织品有限公司

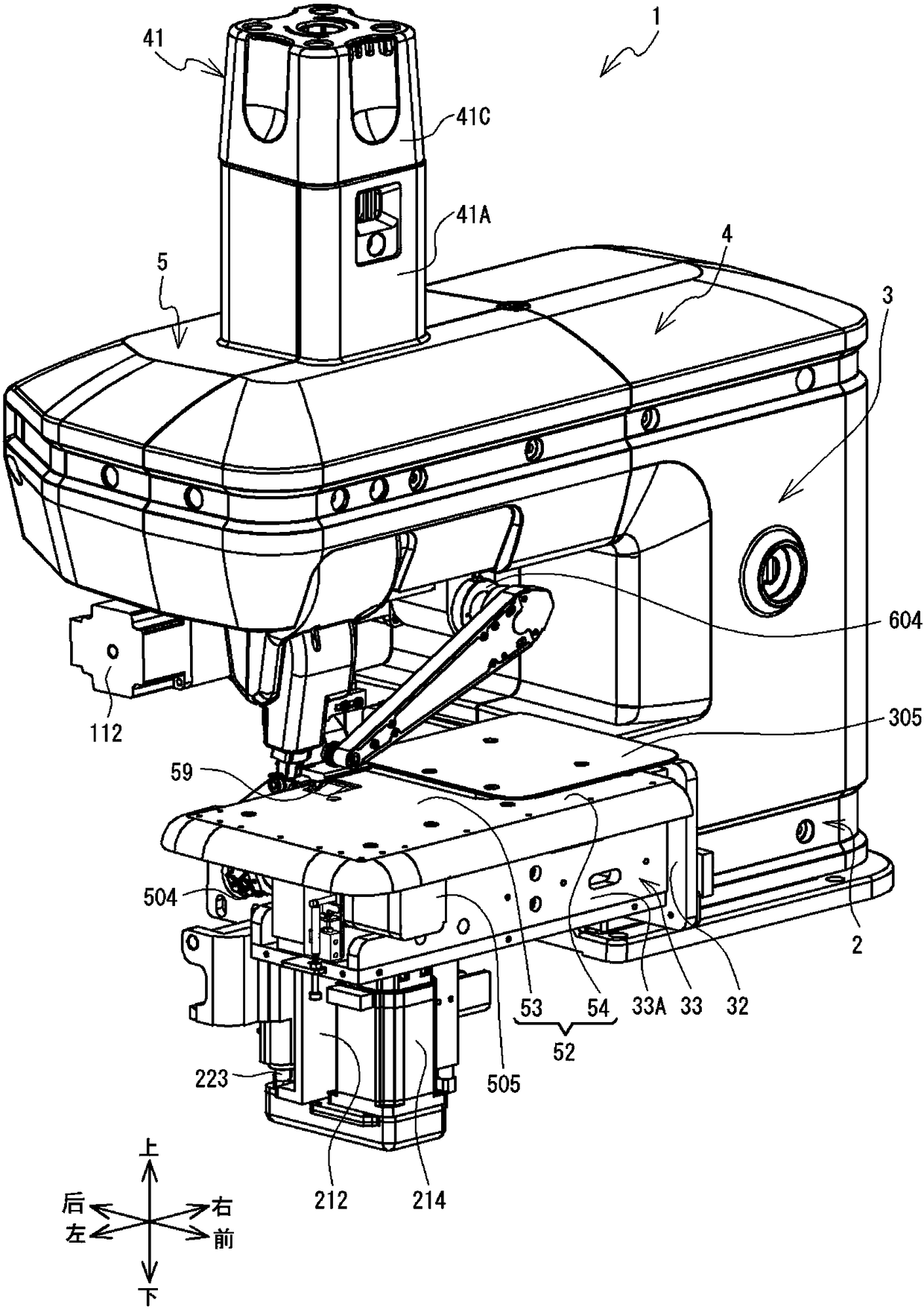

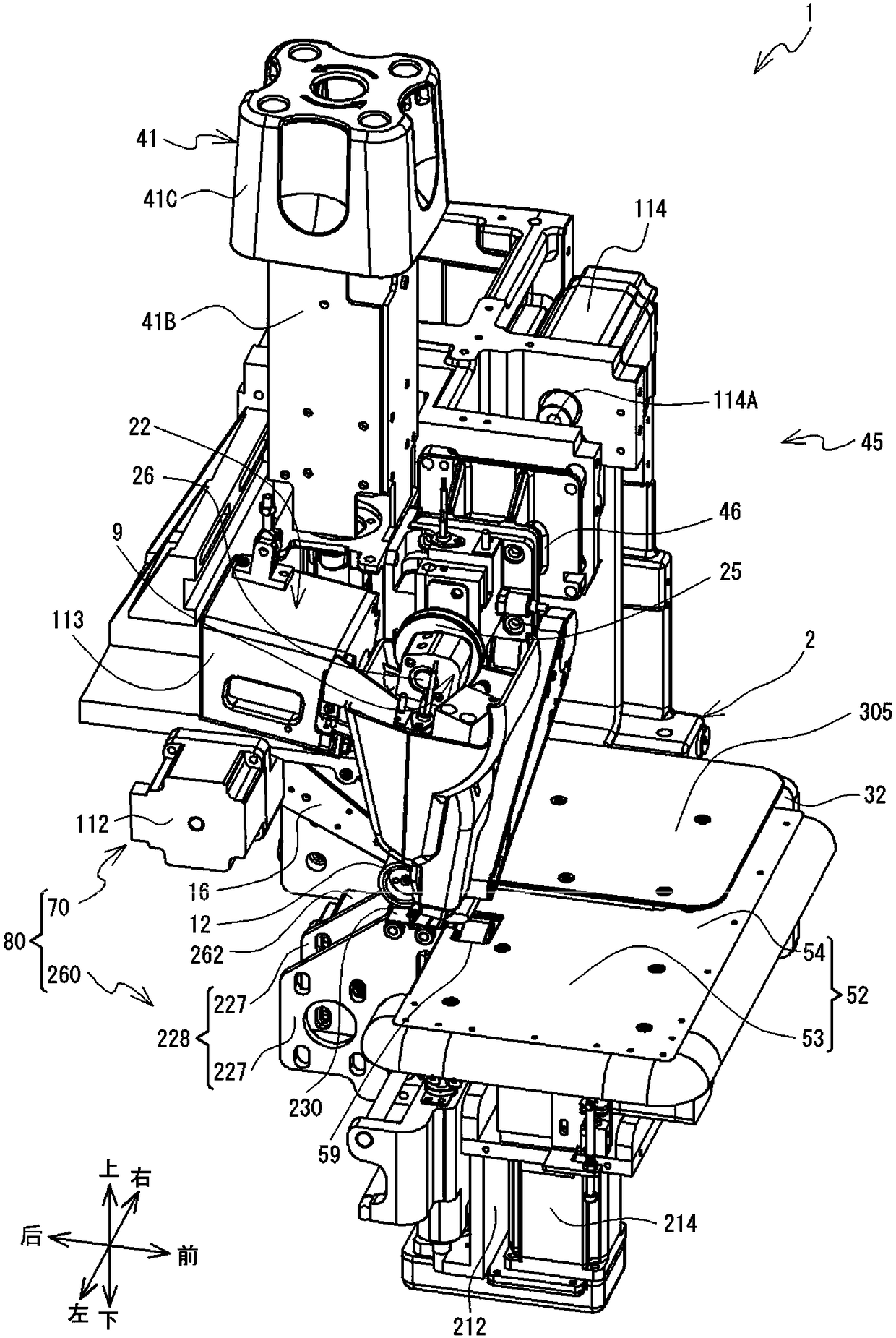

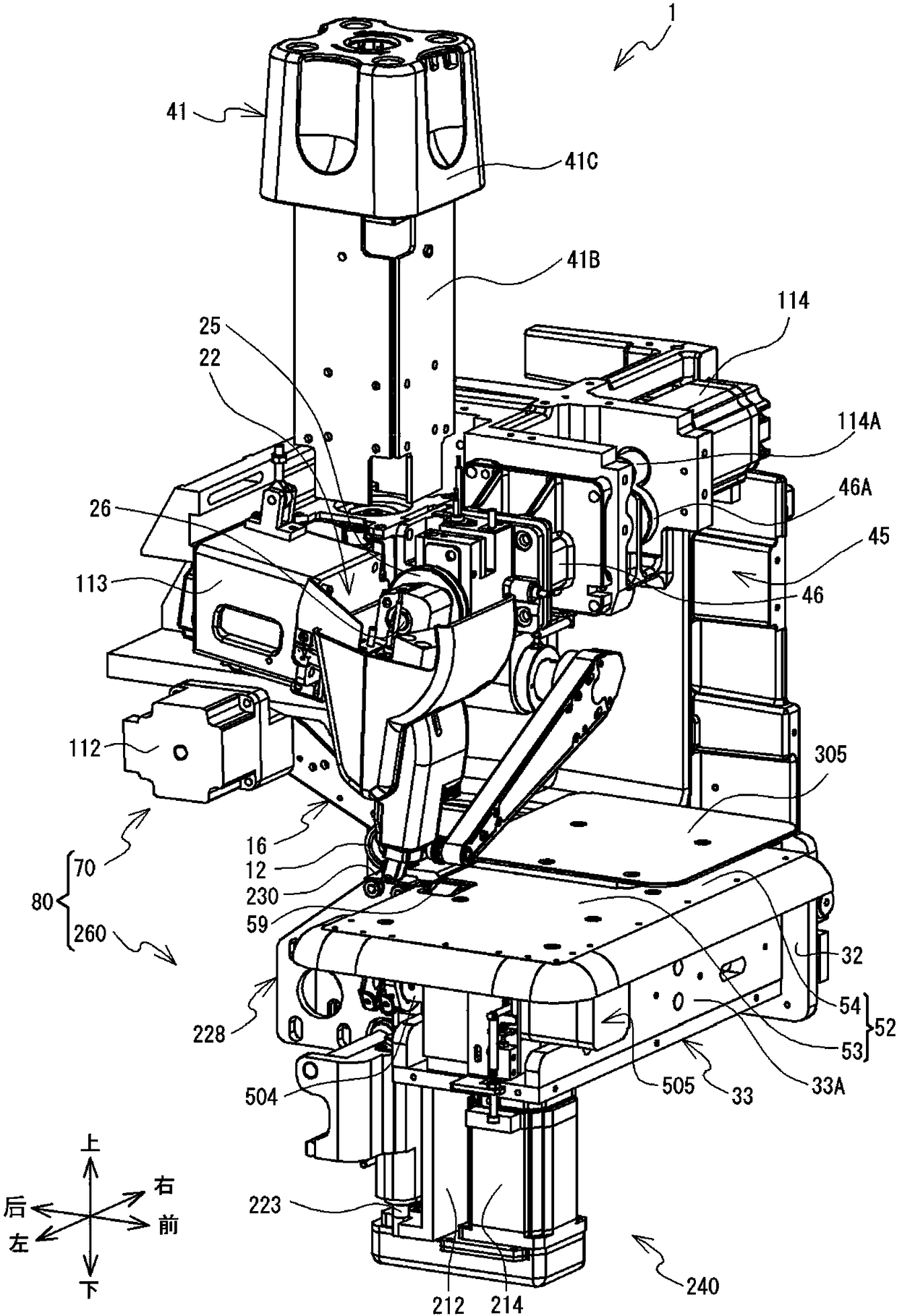

Bonding device

ActiveCN108685240ANot easy to stretchNot easy to produce unevennessSeaming textilesClothes making applicancesSheet materialEngineering

Owner:BROTHER KOGYO KK

Agricultural anti-bird net with random colors

ActiveCN107747154ANatural occasional color effectGood at repelling birdsFibre typesProtective fabricsYarnAfter treatment

The invention relates to an agricultural anti-bird net with random colors. The anti-bird net is prepared in the mode that segment color bamboo joint cellosilk is adopted and spun. Preparation of the segment color anti-bird net comprises the steps of preparation of the segment color bamboo joint cellosilk, yarn spinning, weaving and after treatment. A plurality of air permeable hollowed-out parts are formed in the cylinder wall of a spinning cooling cover shell which is used for preparing the segment color bamboo joint cellosilk, and cooling air flow of lateral blowing air runs through the spinning cooling cover shell through the air permeable hollowed-out parts, enters the spinning cooling cover shell and conducts cooling on spun filament; the air permeable hollowed-out parts surround thecylindrical spinning cooling cover shell and are arranged in a spiral line-shaped mode, the widths of the initial ends of the air permeable hollowed-out parts are larger than the widths of the tail ends of the air permeable hollowed-out parts, and the widths from the initial ends to the tail ends of the air permeable hollowed-out parts are changed in a linear mode in the directions of spiral linesof the air permeable hollowed-out parts; cooled spun filament strips are changed into a semi-solidified state; the spun filament which is located in the spinning cooling shell cover and is located atthe other positions cannot be sufficiently cooled by the cooling air flow of the lateral blowing air, and is still in a sticking and elastic state.

Owner:景宁畲族自治县牧风工艺品厂

Logistics turning transfer system

PendingCN107055058AGood movement stabilityGuaranteed stabilityConveyor partsTransfer systemEngineering

The invention discloses a logistics turning transfer system. The problems that an existing transfer system is complicated in structure, turning stability of goods is poor and a drive chain can be stretched easily are solved. The logistics turning transfer system is used for being arranged between a vertical conveying device and a transverse conveying device and comprises a plurality of goods conveying racks. The vertical conveying device comprises a stand column. A drive chain is arranged on the periphery of the stand column. The inner ends of the goods conveying racks are fixed to the drive chain. A hinged rod is hinged to the goods conveying racks. A movable clamping opening used for clamping goods hooks is formed between the hinged rod and the goods conveying racks. A reset spring is arranged between the hinged rod and the goods conveying racks. The free end of the hinged rod stretches into the outer ends of the goods conveying racks. A bearing rod is obliquely arranged at a goods inlet of the transverse conveying device, stretches into the goods conveying racks and is used for stopping the hinged rod on the goods conveying racks moved in place, so that goods enter the bearing rod from the goods conveying racks.

Owner:INA INTELLIGENT TECH (ZHEJIANG) CO LTD

Assembled box-shaped mobile house and processing method thereof

The invention discloses an assembled box-shaped mobile house and relates to the related technical field of mobile house installation. The assembled box-shaped mobile house comprises a first frame, a second frame, a first butt joint box and a second butt joint box, wherein a first installation groove and a second installation groove are respectively formed in the first frame and the second frame, the first butt joint box is fixedly installed in the first installation groove, and the second butt joint box is fixedly installed in the second installation groove. The invention also discloses a processing method of the assembled box-shaped mobile house. The processing method comprises the following steps of A, material selection; B, cold rolling; C, splicing; D, cutting; E, punching; F, fixing;G, grooving; H, butt joint; I, completion of processing. The first butt joint box and the second butt joint box are fixed through the first frame and the second frame, and the distance between the first frame and the second frame can be adjusted through the matched arrangement of connecting rods and telescopic grooves.

Owner:苏州霍森新型智能集装箱科技有限公司

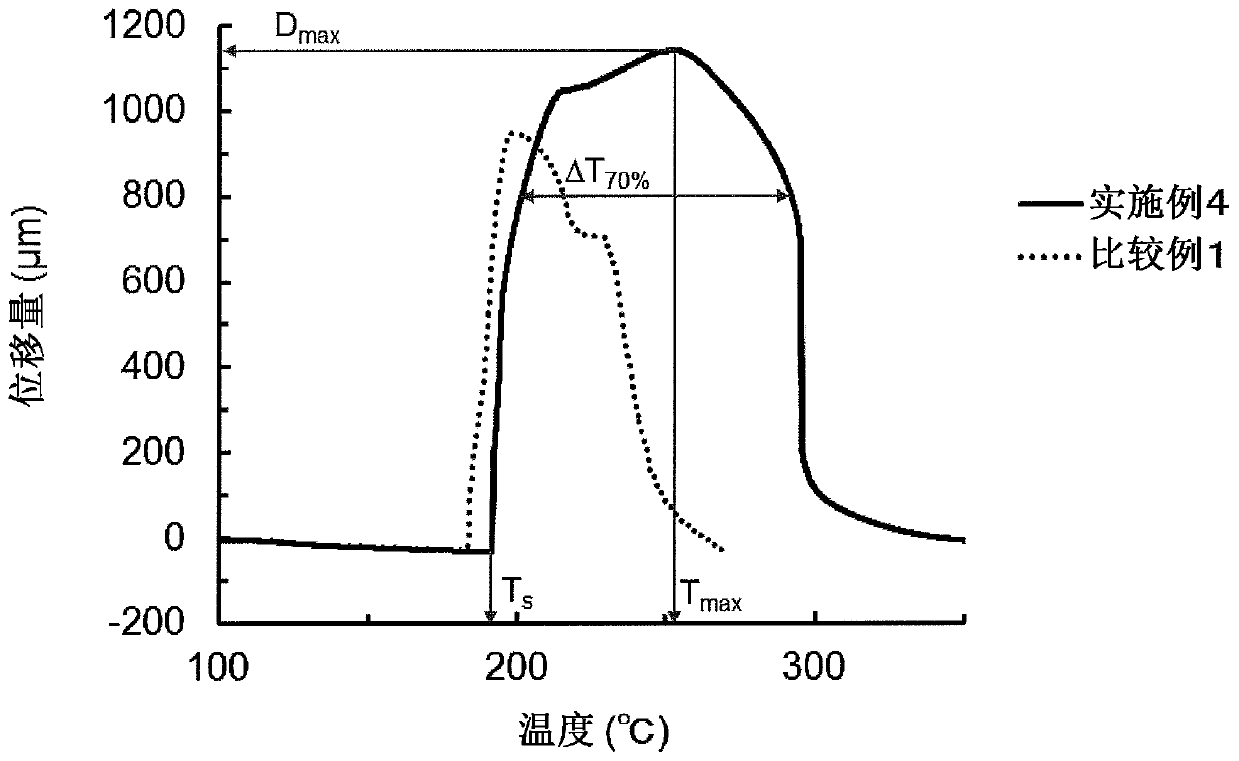

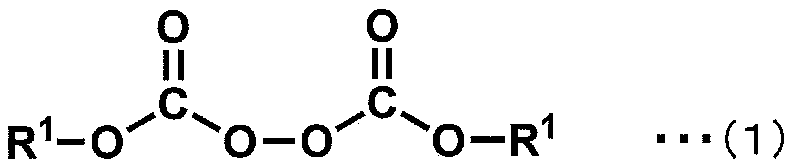

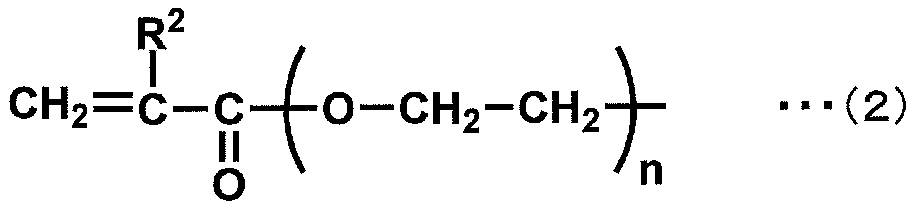

Heat-expandable microcapsules, production method therefor, and foamed molded article

ActiveCN111051462AEasy to manufactureAvoid breakingOther chemical processesMicroballoon preparationPolymer chemistryCarbon atom

Heat-expandable microcapsules each having a core / shell structure which comprises a core and a shell, wherein the core comprises a volatile substance and the shell comprises a polymer, the polymer being obtained by reacting a monomer mixture with organic peroxide represented by general formula (1). The heat-expandable microcapsules of the present invention have such excellent heat resistance that ayielding phenomenon can be inhibited in a wide temperature range and have a high expansion ratio. (In formula (1), the R1 moieties each independently represent a C2-12 unsaturated hydrocarbon group,the unsaturated hydrocarbon group being optionally separated by one or more of -CO-O-, -O-CO-, and -O-.)

Owner:NIPPON OIL & FATS CO LTD

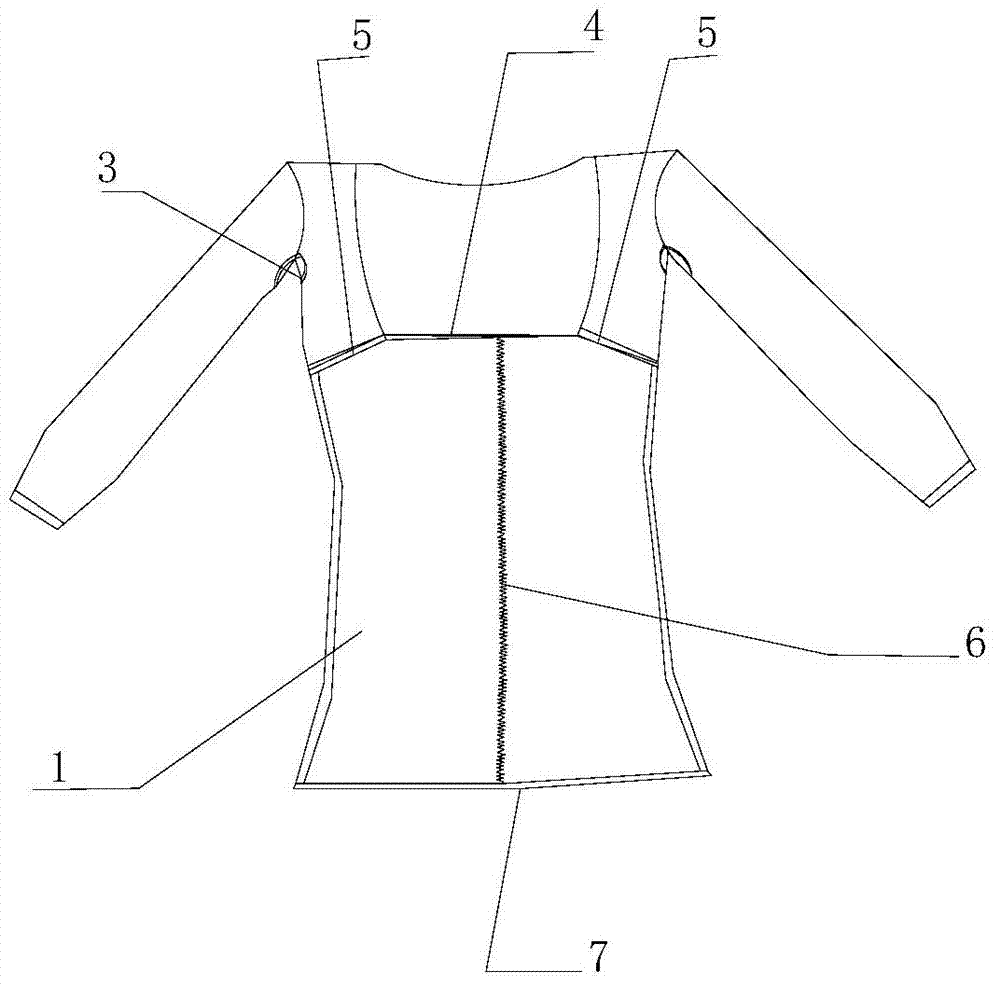

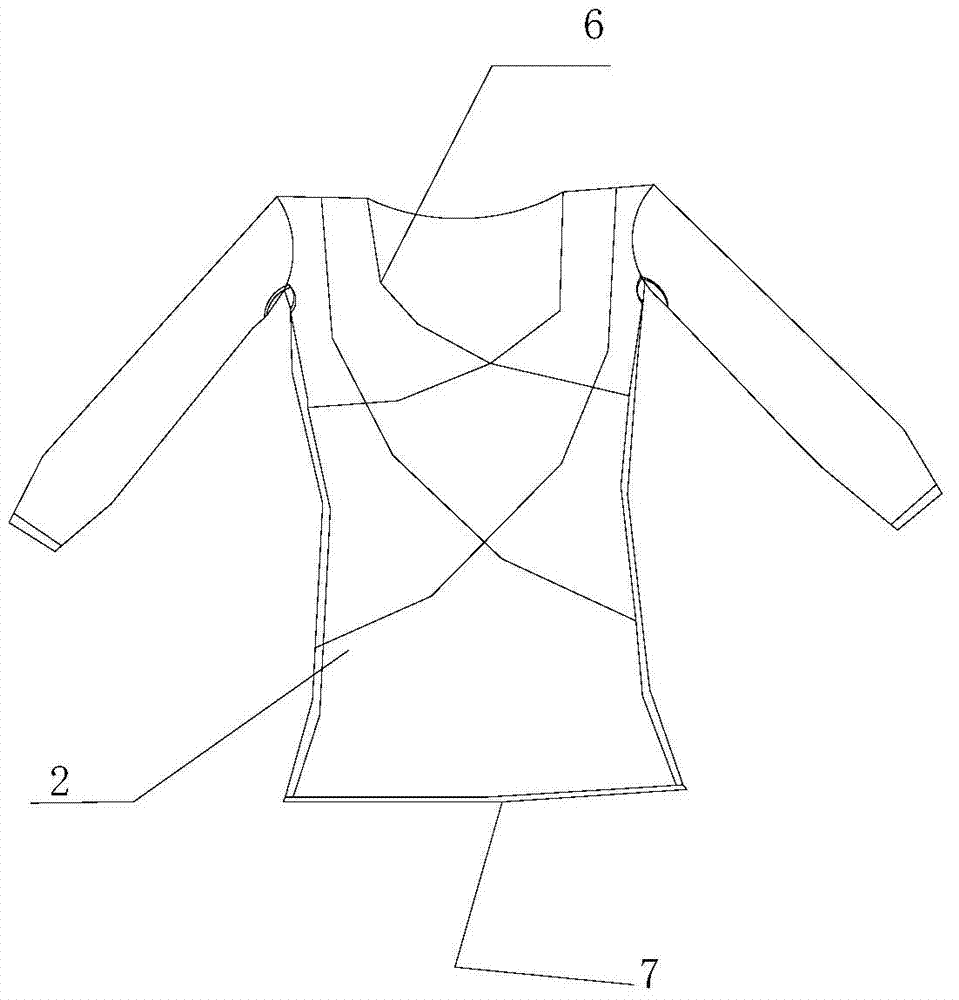

Shaping and warm keeping underwear capable of being worn outside

InactiveCN104705816AEfficient removalGood form stabilityProtective garmentSpecial outerwear garmentsMechanical engineeringAccessory breast

The invention discloses shaping and warm keeping underwear capable of being worn outside. The shaping and warm keeping underwear capable of being worn outside comprises a shaping and warm keeping underwear body which comprises a front piece and a back piece. A warm keeping woolen layer is arranged on the inner layer of the shaping and warm keeping underwear body and is made of thickened hot woolen fabrics. Openings are formed in the underarm parts of the shaping and warm keeping underwear body. A breast supporting device is arranged at the position, below the breast of a user, of the front piece, and accessory breast tightening devices are arranged at the ends of the breast supporting device along the underarm parts. The shaping and warm keeping underwear achieves shaping through elastic cloth. The openings in the underarm parts solve the problem of uplift of sleeves, the arms can move freely without the constraint feeling, and ventilating and sweat discharging are achieved; the breast supporting device and the accessory breast tightening devices can improve the shaping effect, and fat cannot deviate. The user can have a brand new feeling on the skin, warm keeping, body building and shaping are achieved, a proud chest line is enhanced, a waist curve is tightened, a back line is corrected, and warm keeping becomes fashionable.

Owner:CHANGZHOU LONGDAO E COMMERCE

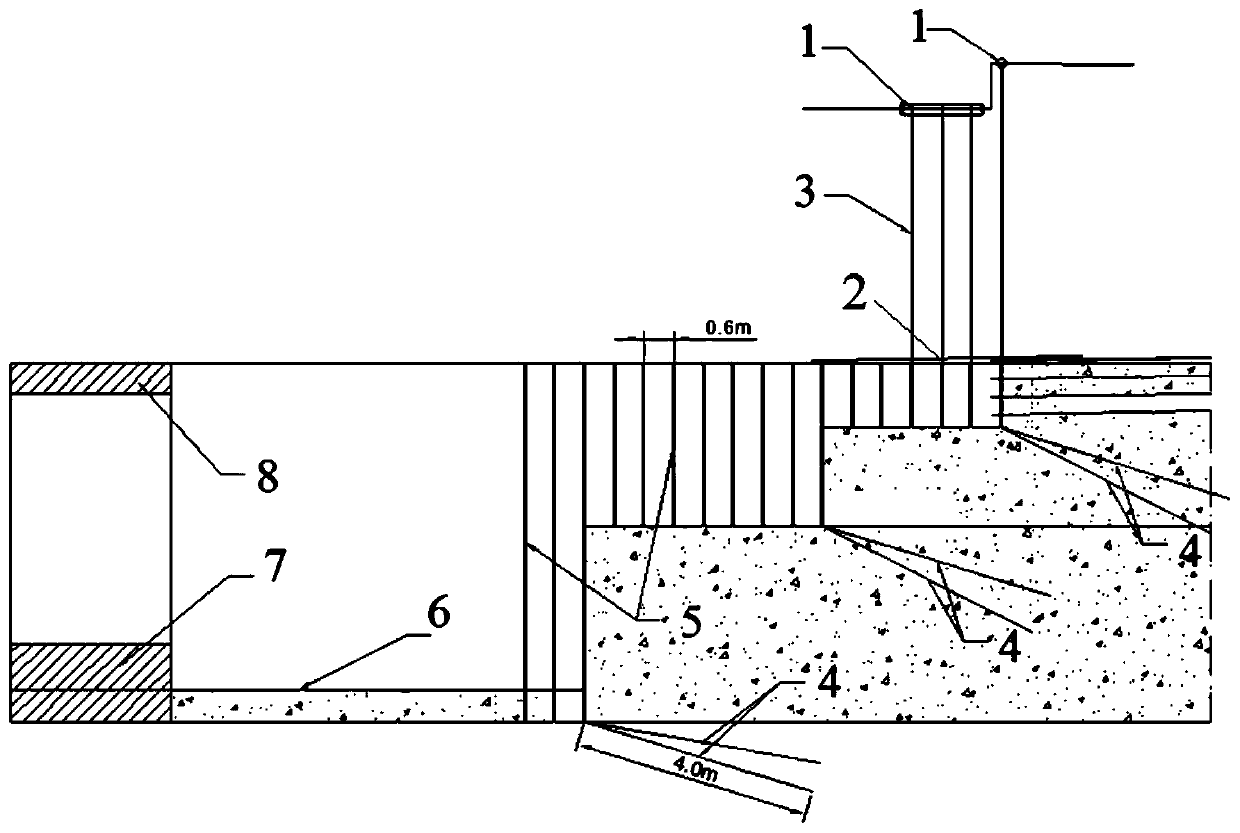

Method for enabling tunnel to safely pass through shallow-buried ditch weak surrounding rock

ActiveCN111577295AEasy to operateEasy constructionUnderground chambersTunnel liningDrainage tubesPipe

The invention discloses a method for enabling a tunnel to safely pass through shallow-buried ditch weak surrounding rock. The method includes the following steps that (1) stream water is blocked through damming in the upstream position of a stream above the shallow-buried weak surrounding rock, a water drainage pipe is arranged, and impervious concrete is paved at the bottom of the stream; (2) a plurality of ground surface steel pipes are arranged on the impervious concrete in the length direction of the tunnel, multiple groups of drilling holes penetrating through the shallow-buried weak surrounding rock are formed along each ground surface steel pipe, and a steel strand penetrates through one drilling hole of each group of the drilling holes; (3) after all the steel strands are locked firmly, all the drilling holes are filled with concrete, and the concrete is tamped densely; (4) advanced middle pipe sheds and advanced small ducts are arranged at the inner arch part of the tunnel, and grouting of the advanced small ducts is performed; (5) steps (1)-(4) are circulated sequentially in the construction direction of the tunnel until the tunnel passes through the shallow-buried weak surrounding rock. With the method, the construction safety when the tunnel passes through the shallow-buried weak surrounding rock is improved.

Owner:CHINA RAILWAY 18TH BUREAU GRP CO LTD +1

Small diameter automatic winding device

The invention discloses a small-rolling-diameter full-automatic winding device. The small-rolling-diameter full-automatic winding device comprises a traction mechanism, a gas expansion shaft auxiliary tight jacking mechanism, a winding mechanism, an automatic cutting mechanism, an automatic unwinding mechanism, an automatic conveying and conveying mechanism and a material storage mechanism, wherein the traction mechanism, the gas expansion shaft auxiliary tight jacking mechanism, the winding mechanism, the automatic cutting mechanism, the automatic unwinding mechanism, the automatic conveying and conveying mechanism and the material storage mechanism are sequentially arranged on a rack. The winding, cutting, unwinding and weighing mechanisms of the small-rolling-diameter full-automatic winding device all achieve automation, by adjusting, controlling and feeding back the tensile force of a sheet, the winding tension degree is adjusted through a winding motor, the sheet winding tension is constant tension, and the product performance is guaranteed; and meanwhile, the unwinding mechanism is designed at the position of the center of a current winding shaft, the wound sheet can be fast unwound, in the unwinding process, the material storage mechanism stores the sheet at the same time, the material storage mechanism performs discharging on the sheet when winding is started, it is guaranteed that a product is not prone to stretching, the product performance is improved, and the wound sheet is weighed and subjected to labeling. The whole device structure effectively improves the production line efficiency, time is saved, operation is convenient, the effect is remarkable, and the labor cost is greatly saved.

Owner:SUZHOU JWELL MACHINERY

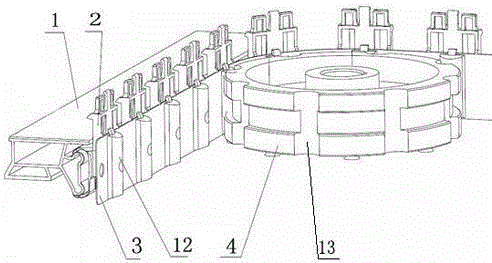

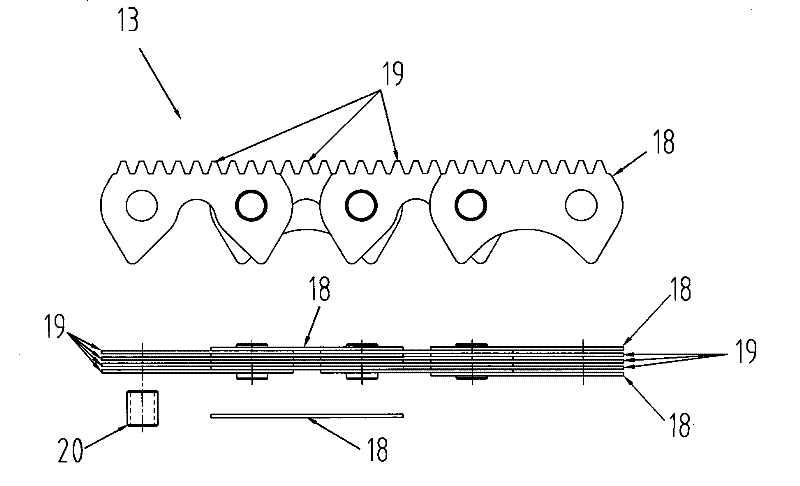

Collective doffing gear block steel belt guide mechanism of ring spinning frame

The invention relates to a collective doffing gear block steel belt guide mechanism of a ring spinning frame. Upper guide outer fringes and lower outer fringes are arranged on a steel belt guide rail, the upper guide outer fringes and the lower outer fringes are each of a circular-arc-shaped structure protruding outwards, each upper guide outer fringe is located over the corresponding lower guide outer fringe, each upper guide outer fringe and the corresponding guide outer fringe are integrally formed through a vertical ribbed plate, and each upper guide outer fringe and the corresponding lower guide outer fringe are coated with an upper guide buckle and a lower guide buckle in a slidable and matched mode respectively; a vertical long-strip structure is arranged on each protruding disc bracket, one side of a transmission steel belt is provided with an insertion slot, a transmission gear block shaped like a semicircular cylinder is arranged on the other side of each transmission steel belt, each insertion slot is installed on the corresponding long-strip structure in an inserted mode to fix the corresponding transmission steel belt to the corresponding protruding disc bracket, arc-shaped grooves are formed in the circumferential surface of a driving wheel, the gear blocks of the transmission steel belts are connected with the arc-shaped grooves, and the transmission steel belts are driven to conduct transmission through rotation of the driving wheel. By means of the collective doffing gear block steel belt guide mechanism of the ring spinning frame, high stability and reliability of a system can be guaranteed, and the highly automatic requirement of textile industry is met.

Owner:JINGWEI TEXTILE MASCH CO LTD

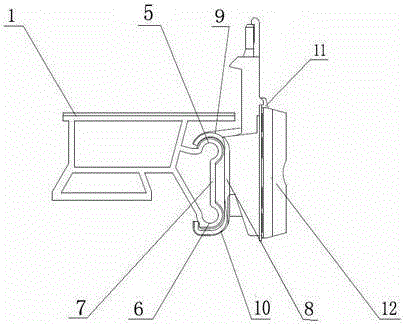

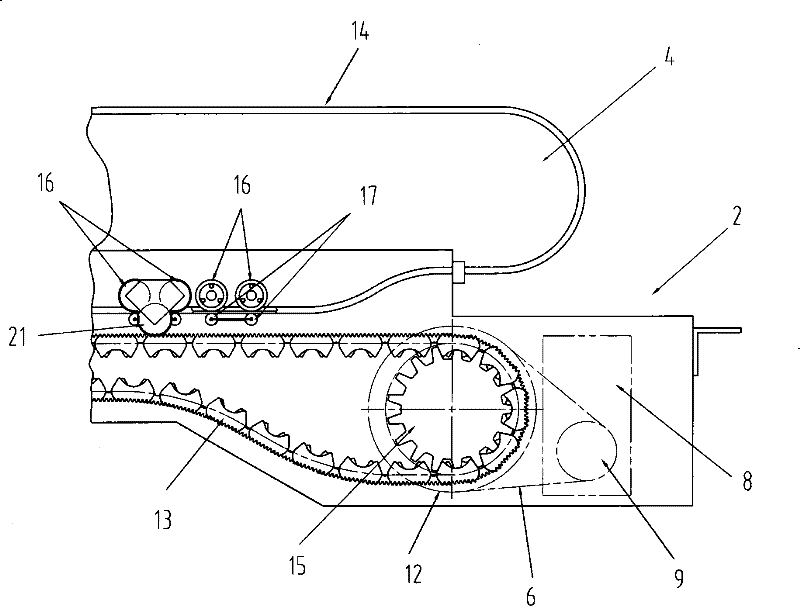

Passenger delivery device

The invention discloses a passenger deliver device which comprises a driving mechanism, a driving chain wheel driven by the driving mechanism and positioned at one end part, a petal chain wheel coaxially connected with the driving chain wheel, a tooth-shaped chain belt with large and small tooth profiles and a plurality of petals connected by the tooth-shaped chain belt. The petal chain wheel is engaged with the large teeth of the tooth-shaped chain belt to drive the tooth-shaped chain belt; the small teeth of the tooth-shaped chain belt drives a handrail belt driving device to enable a handrail belt to move synchronously in the direction of the petals. The passenger delivery device can meet the requirements of heavy-load and long-distance delivery of passengers.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

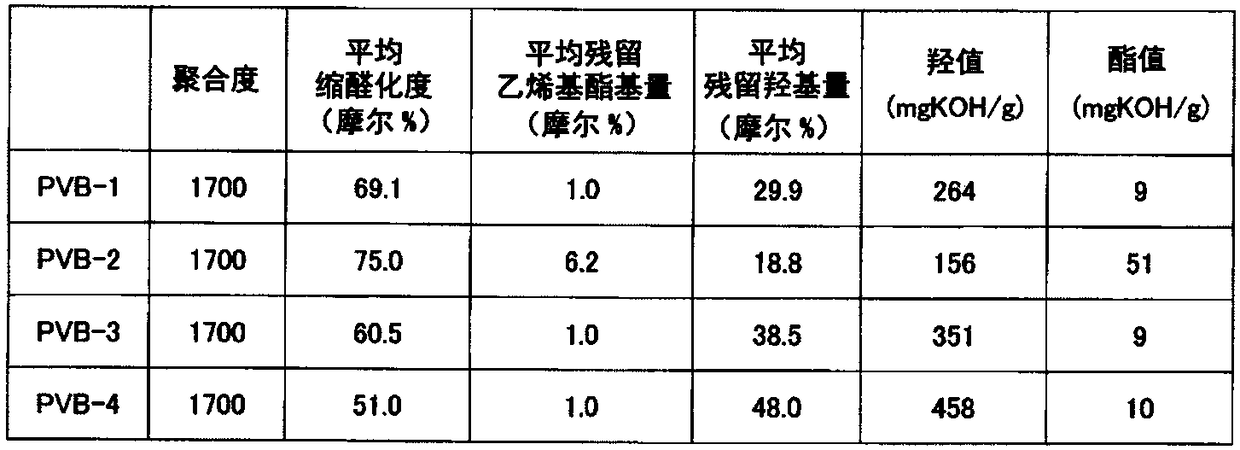

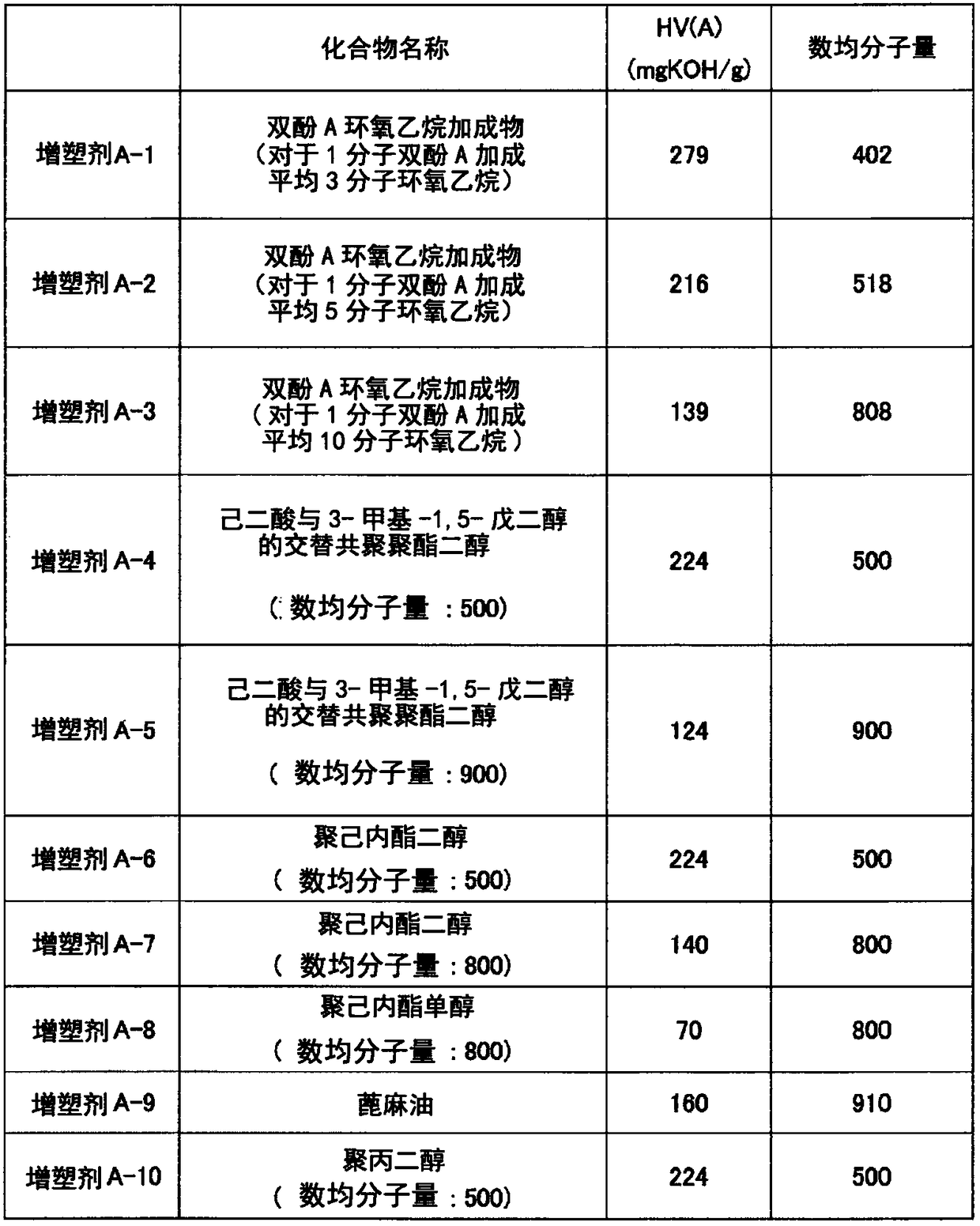

Laminate

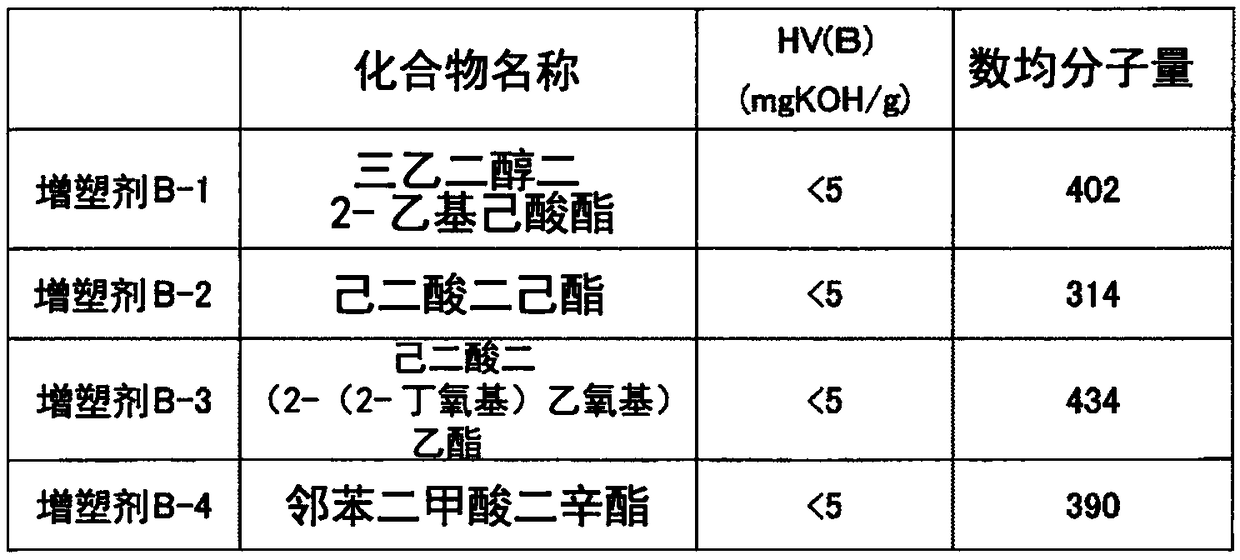

InactiveCN108602333AImprove securityNot self-adhesiveLayered product treatmentAdhesive articlesPolymer sciencePlasticizer

Owner:KURARAY CO LTD

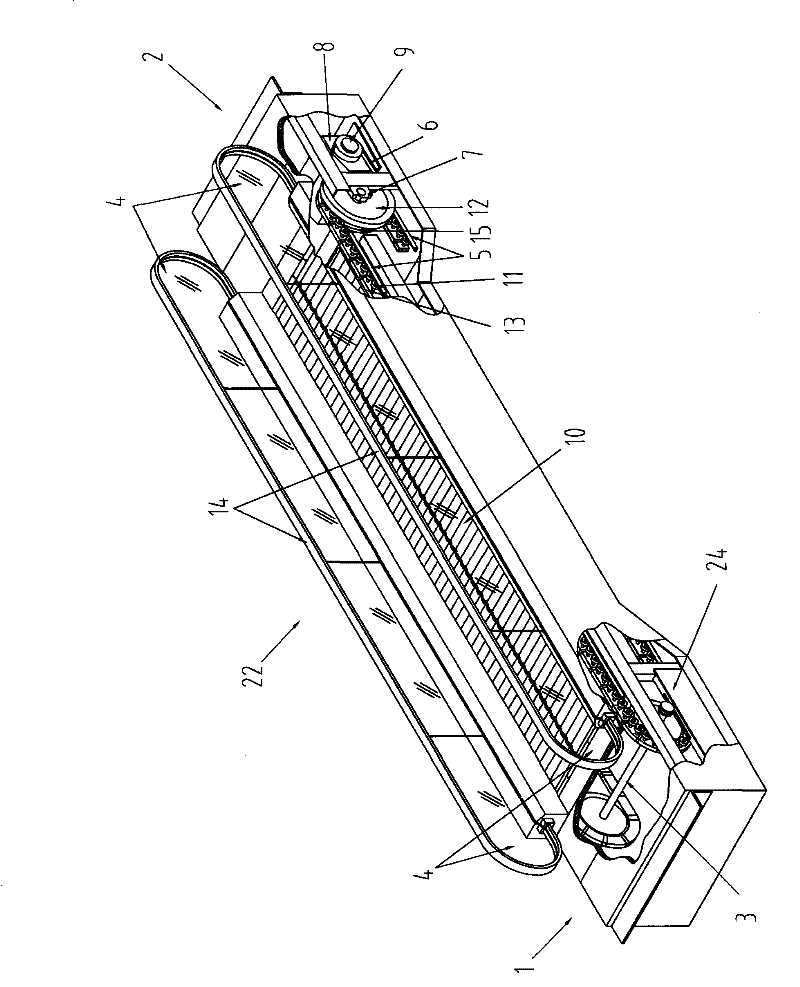

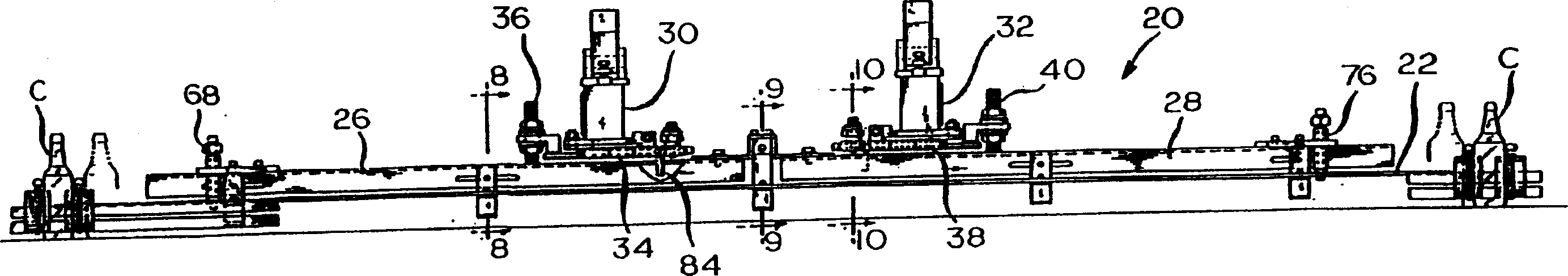

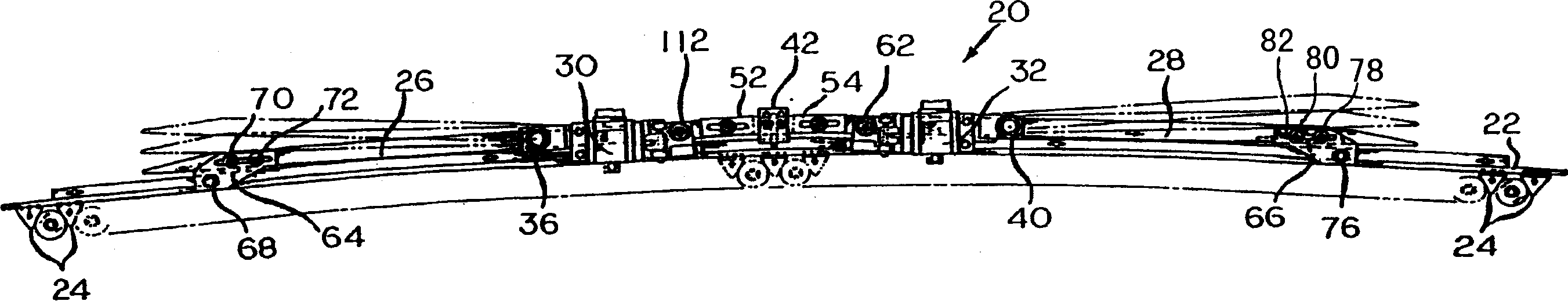

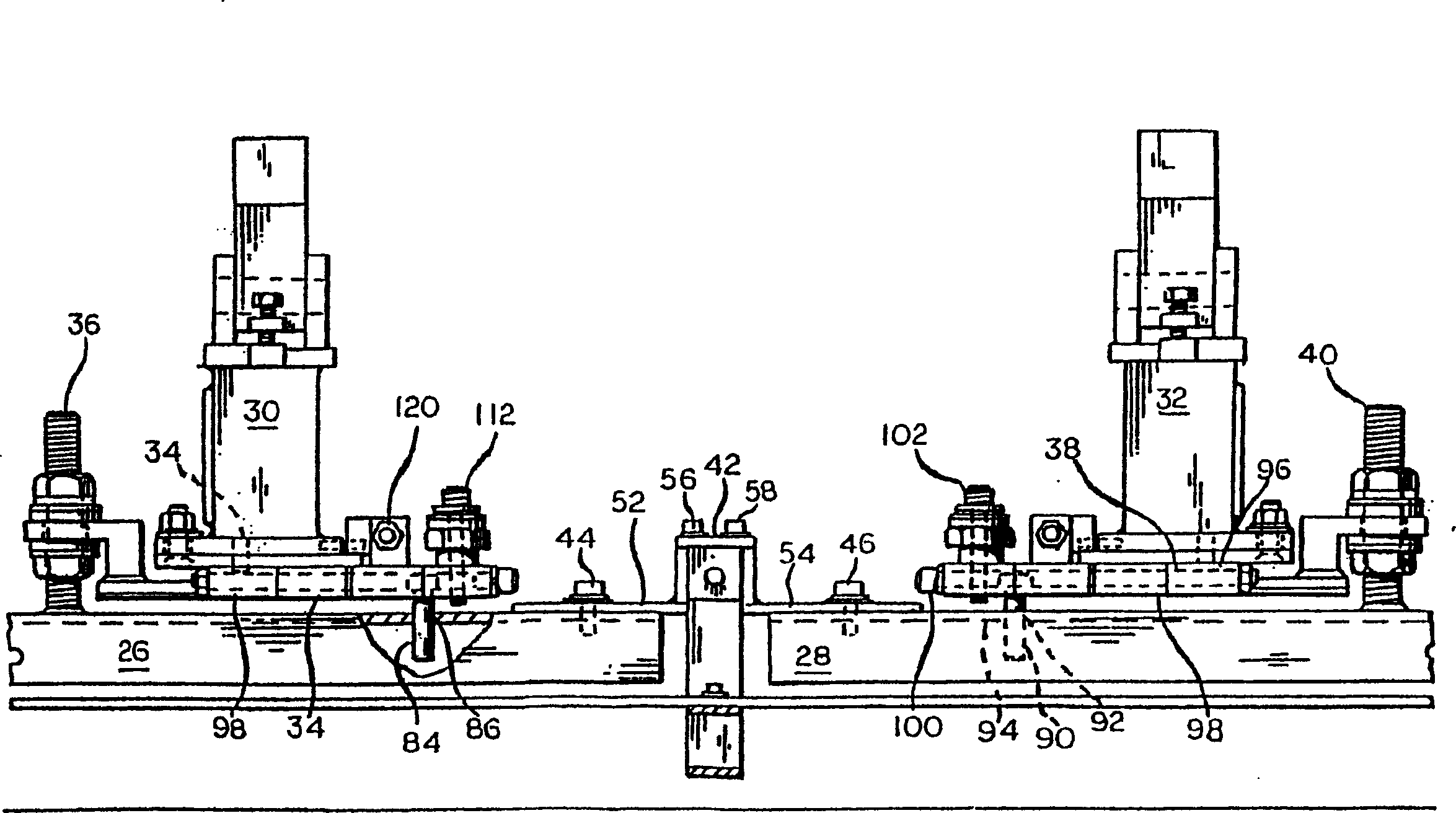

Push rod device of annealing furnace shovel loader

InactiveCN1190375CEasy to installNot easy to stretchConveyorsGlass transportation apparatusLinear arrayShovel

A pusher bar assembly (20) having a flexible, horizontally extending pocket bar (22) of sufficient longitudinal extent to push a linear array of glass containers on a cross-conveyer transversely of the cross-conveyor into an annealing lehr. The pocket bar, which engages the containers to be pushed, is disengageably secured to a pair of aligned horizontal pusher bars (26, 28), whose adjacent ends are spaced apart from one another. The pusher bars are secured, respectively, to first and second downwardly extending beams (30, 32).

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

Method for preparing low-toxicity BOPP adhesive tape

InactiveCN107400472ATransparent appearanceTransparent colorNon-macromolecular adhesive additivesFilm/foil adhesivesPolypropyleneConductor Coil

The invention discloses a method for preparing a low-toxicity BOPP adhesive tape. The method comprises the following operation steps: (1) performing extruding granulation on polypropylene resin, melamine cyanurate, colopholic acid, erucyl amide and titanium dioxide by an extruder to prepare master batches, and then making the master batches into a BOPP film; and (2) brushing the BOPP film with a prepared low-toxicity glue, and performing slitting and winding after the glue is completely dry to prepare an end product. The prepared low-toxicity BOPP adhesive tape is transparent in appearance, uniform in color, strong in bonding strength, resistant to piecing and good in tearing resistance, particularly, cannot give out pungent smells, is non-toxic and environment-friendly, and can be used in large scale in the food package industry.

Owner:阜南县力韦包装材料有限公司

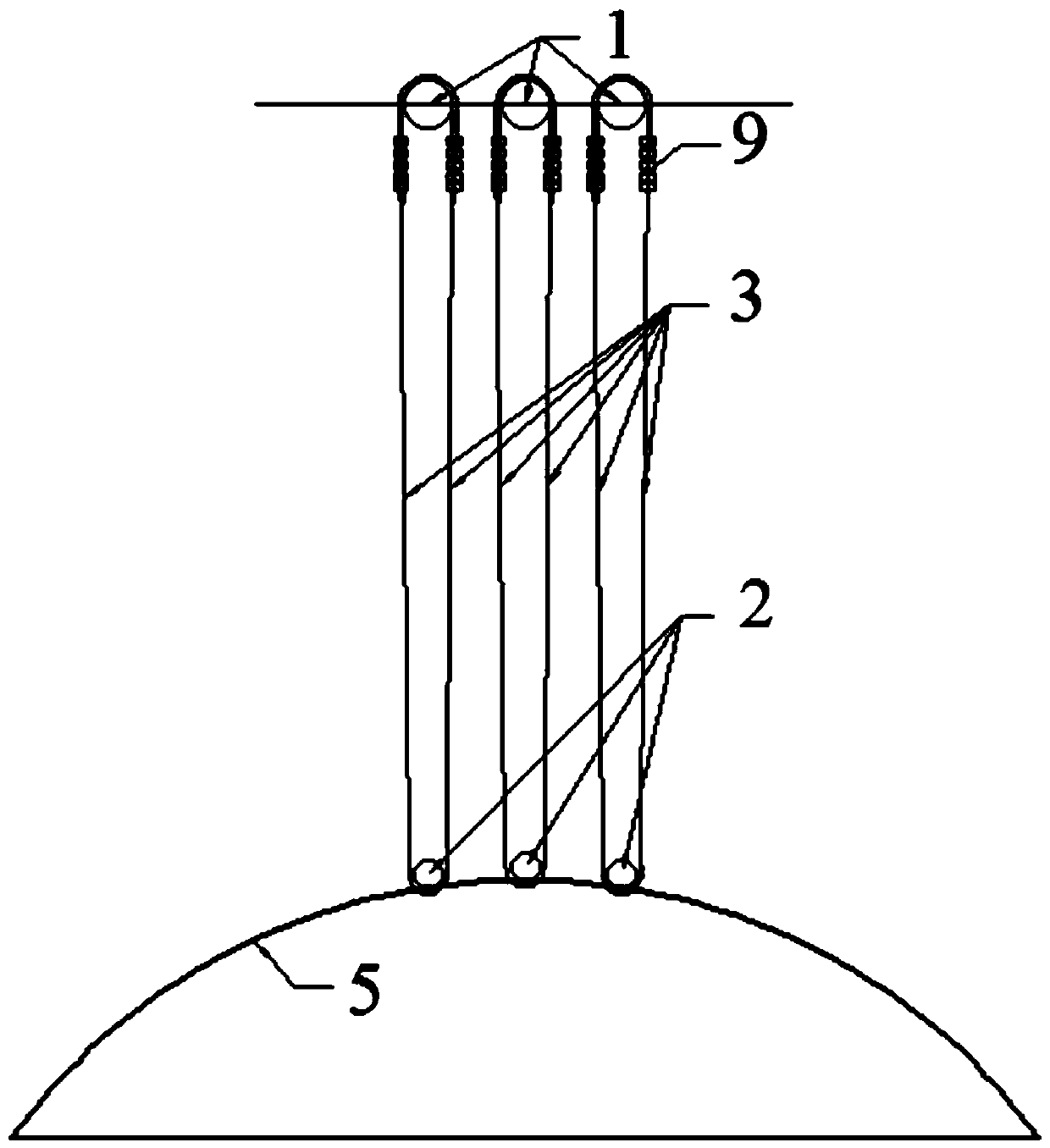

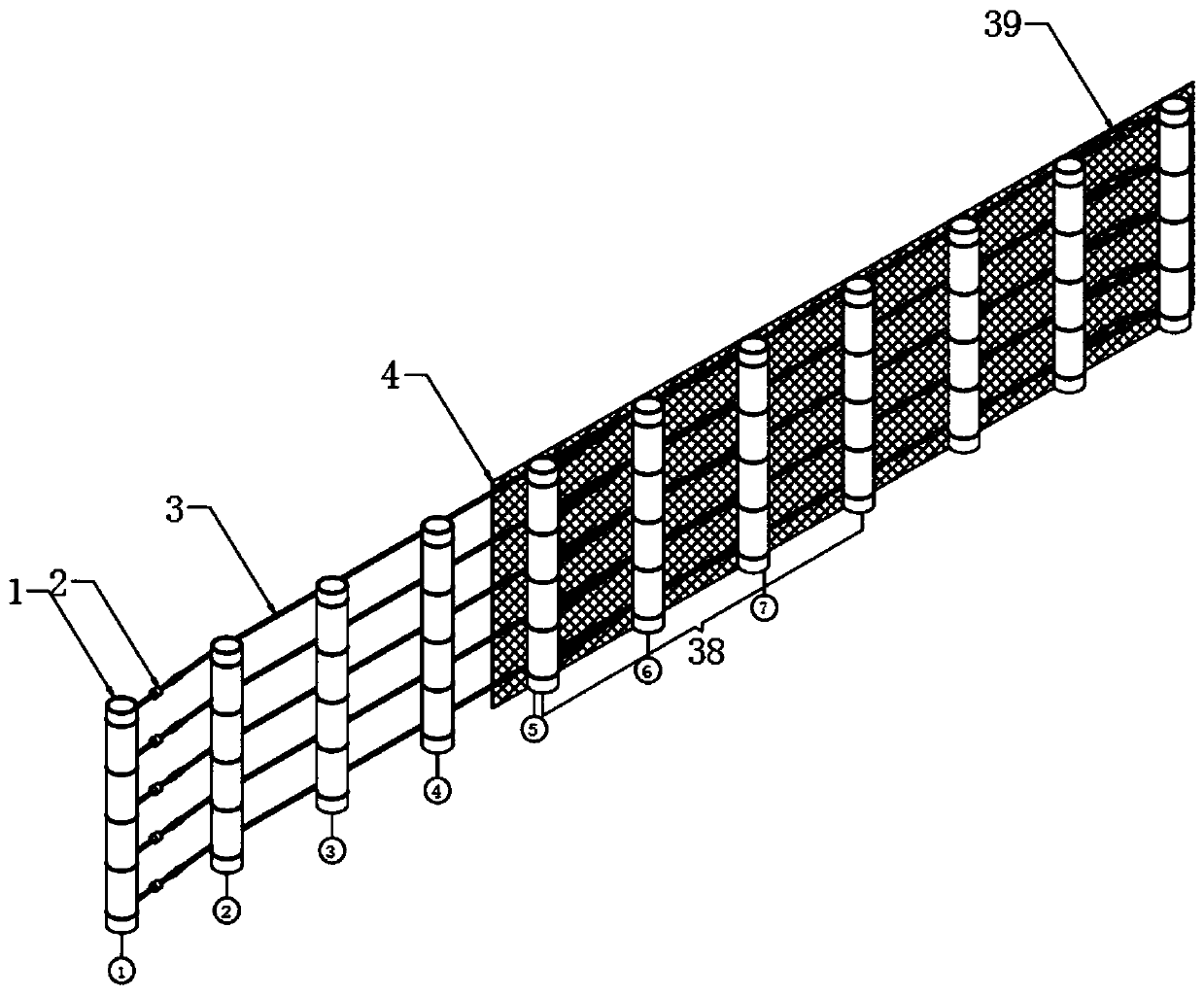

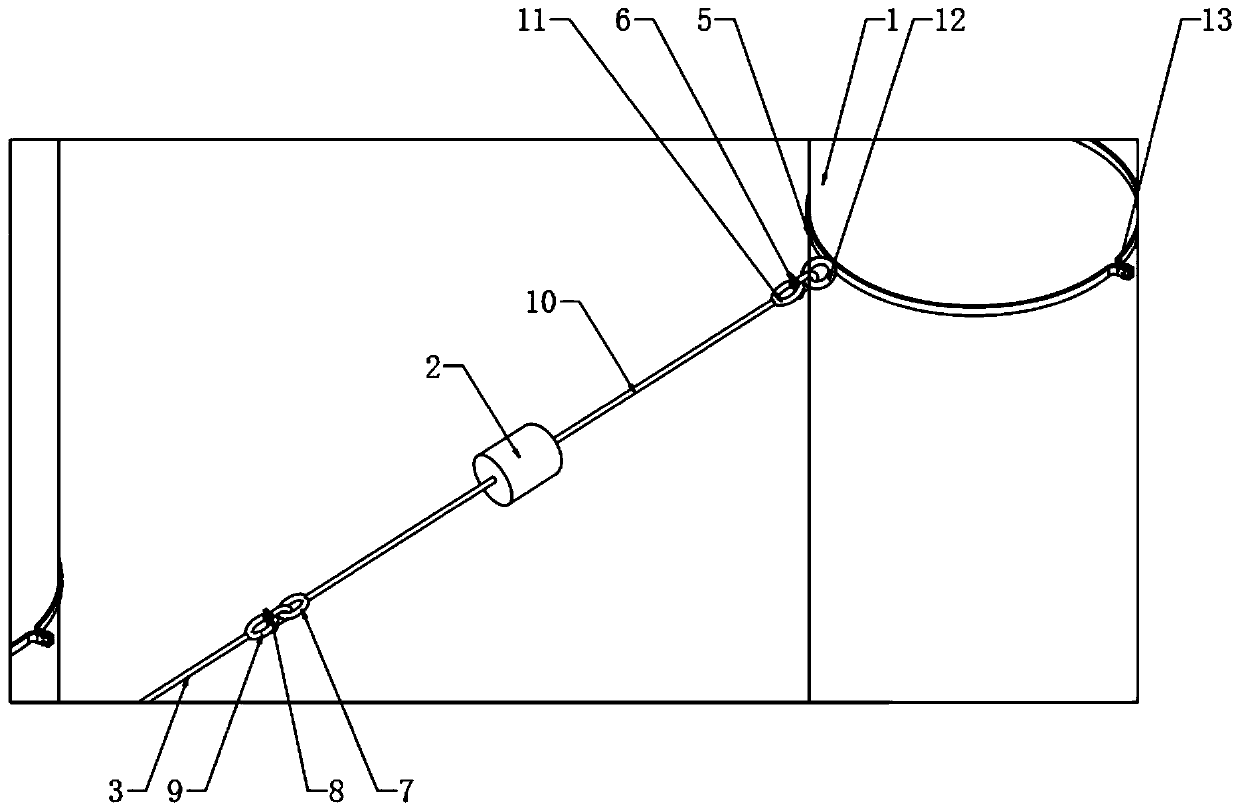

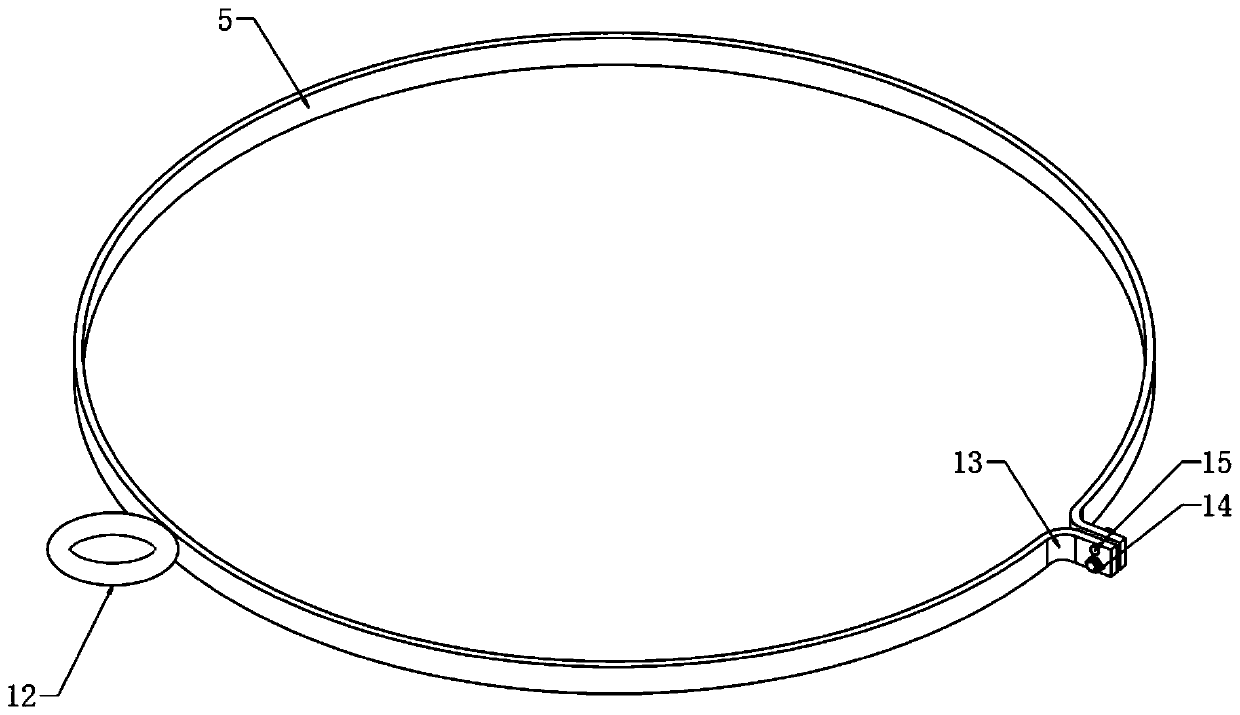

Netting strength supporting construction method based on fence breeding facility

ActiveCN111503221AAvoid deformationNot easy to stretchRopes and cables for vehicles/pulleyClimate change adaptationButt jointStress strength

The invention relates to the technical field of fence breeding facilities, in particular to a netting strength supporting construction method based on a fence breeding facility. The netting strength supporting construction method involves column piles, tighteners, steel wire ropes and a netting, multiple sets of tighteners are connected to one sides of the column piles, steel fixing clamping ringsare arranged at the joints of the exteriors of the column piles and the tighteners, a steel connecting clamping ring is arranged at the position, close to the lower end of the steel fixing clamping rings, outside the column piles, an adjusting steel is arranged in the middle of the tighteners, a connecting clamping ring is arranged at one end of the adjusting steel, a connecting ring shackle is connected to the end, away from the adjusting steel, of the connecting clamping ring, a pull ring is welded to the joint of the steel fixing clamping ring and the connecting ring shackle, butt joint plates are welded to one side of the steel fixing clamping ring and one side of the steel connecting clamping rings, a plurality of sets of bolt holes are formed in the butt joint plates, bolts are arranged in the bolt holes, a steel connecting ring is arranged at the end, away from the connecting clamping ring, of the adjusting steel, and a steel connecting shackle is connected to the end, away from the adjusting steel, of the steel connecting ring. The construction method is used for enhancing the stress strength of the netting and preventing the netting from being damaged due to uneven stress.

Owner:EAST CHINA SEA FISHERIES RES INST CHINESE ACAD OF FISHERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com