Collective doffing gear block steel belt guide mechanism of ring spinning frame

A spinning frame and steel belt technology, applied in the direction of textiles and papermaking, etc., can solve the problems that the steel belt is not easy to elongate, the guiding effect is not good, and the positioning accuracy is low, so as to ensure high stability and reliability, stable transportation, The effect of fast delivery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

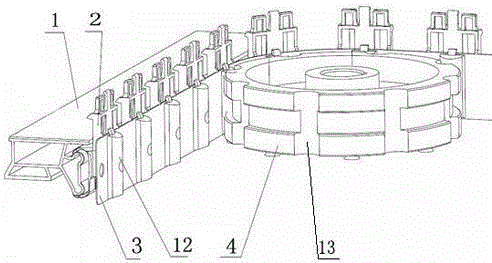

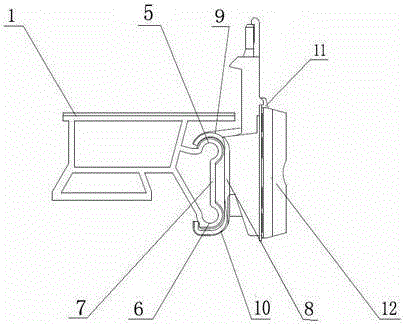

[0010] Such as figure 1 As shown, a ring spinning frame collective doffing gear steel belt guide mechanism, which includes a steel belt guide rail 1, a convex disc bracket 2, a transmission steel belt 3, and a driving wheel 4. The steel belt guide rail 1 is provided with an upper guide The outer edge 5 and the lower guide outer edge 6, the upper guide outer edge 5 and the lower guide outer edge 6 are circular arc structures protruding outward, the upper guide outer edge 5 is located directly above the lower guide outer edge 6, and the upper guide outer edge 5 is located directly above the lower guide outer edge 6. The outer edge 5 and the lower guide outer edge 6 are integrally formed by a vertical rib plate 7, and a "C"-shaped covering structure 8 is arranged on the convex plate bracket 2, and the two sides of the "C"-shaped covering structure 8 The ends are respectively an upper guide buckle 9 and a lower guide buckle 10 of a groove-shaped structure, and the upper guide buck...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com