Patents

Literature

45results about How to "The average gear ratio is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

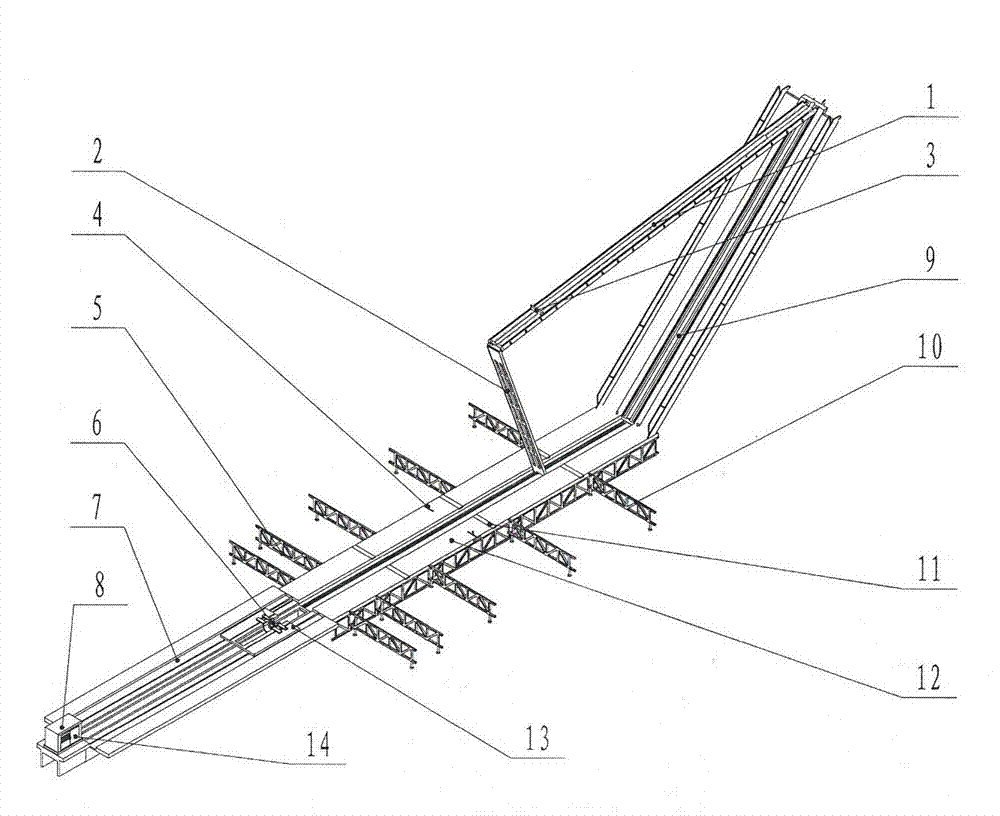

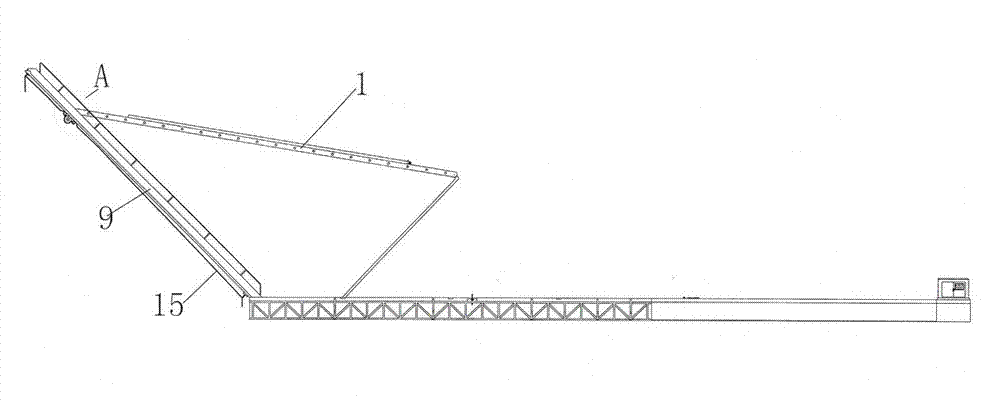

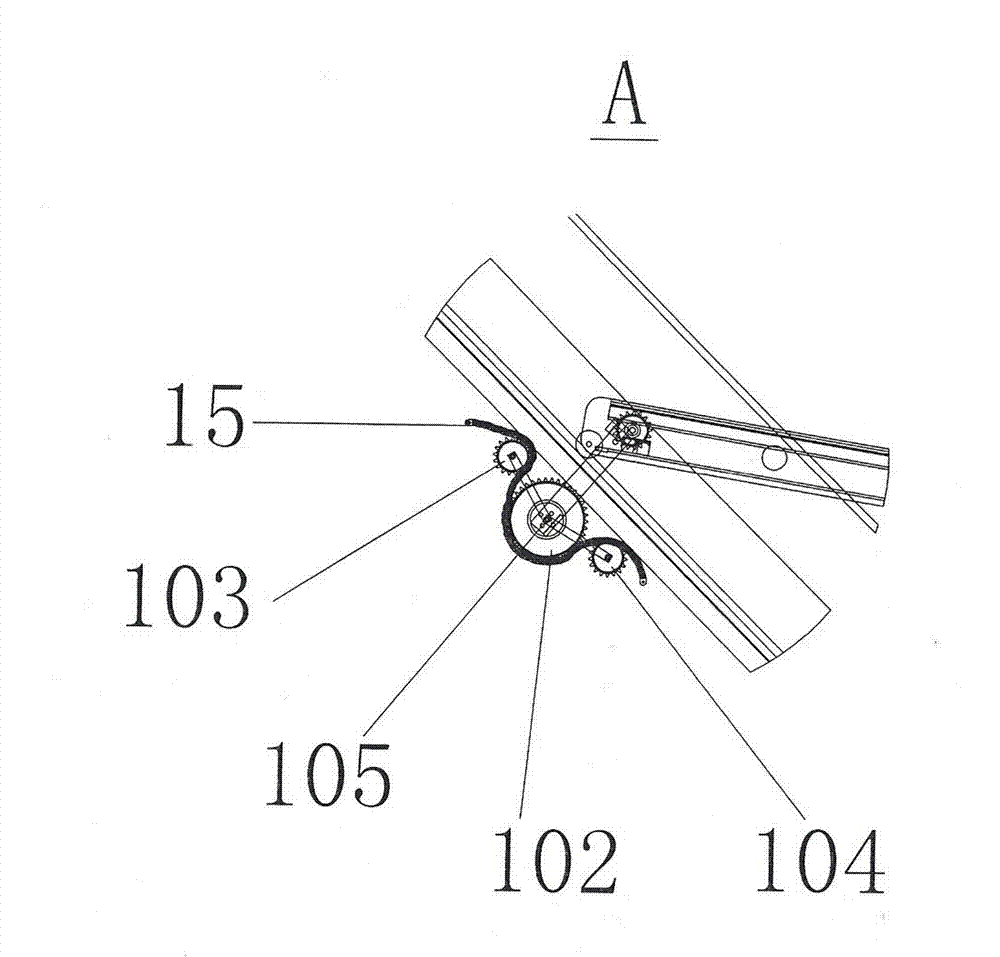

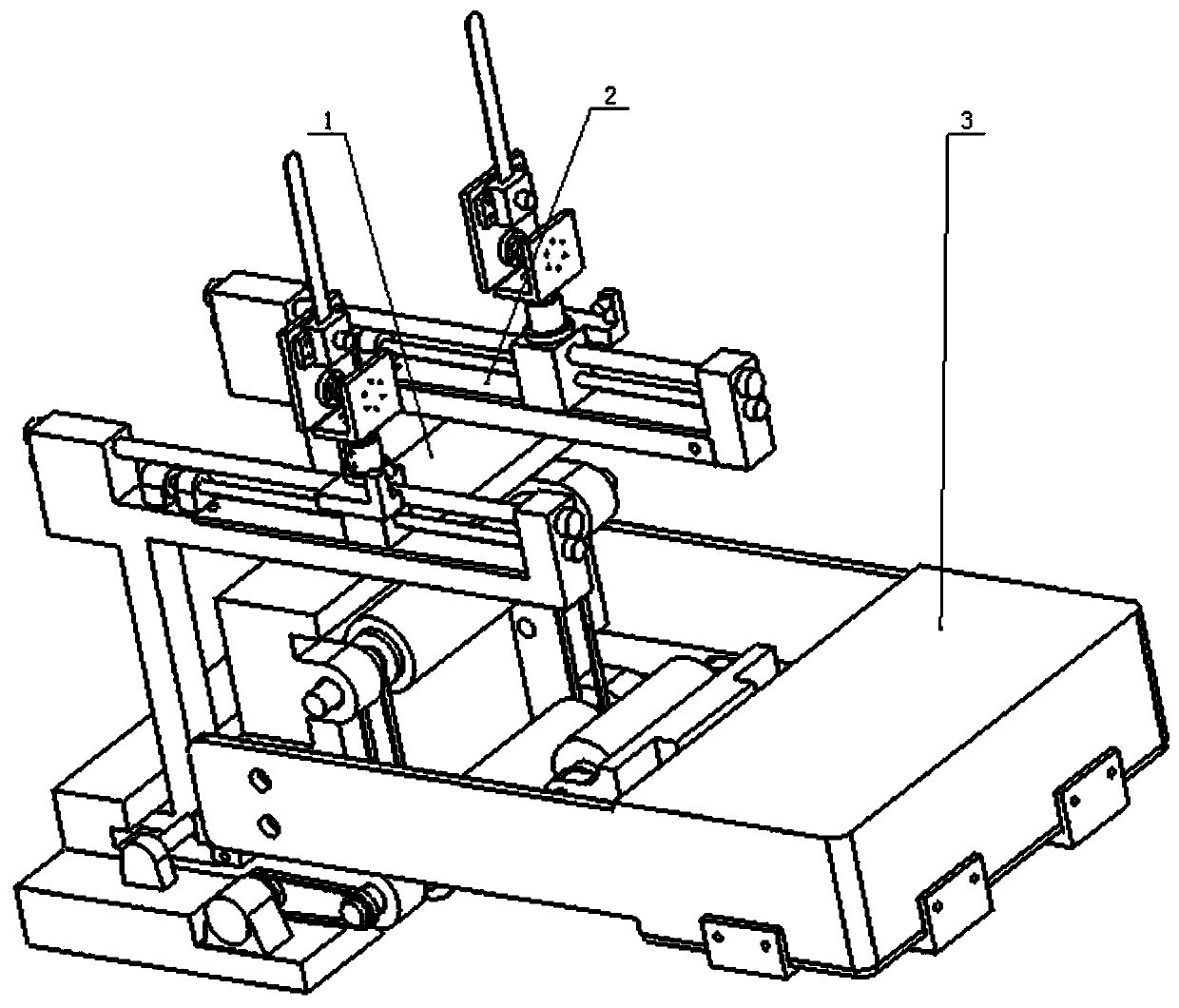

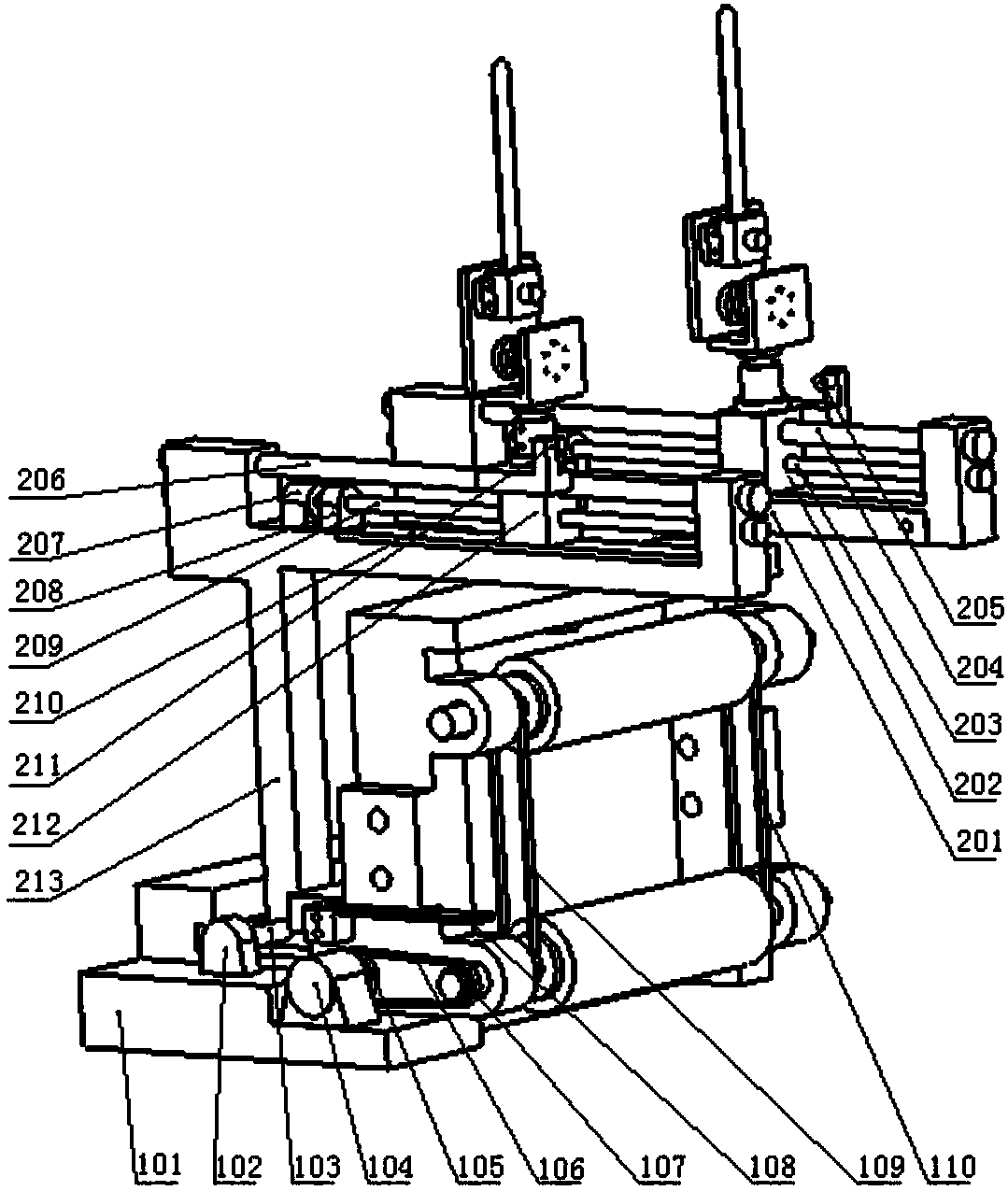

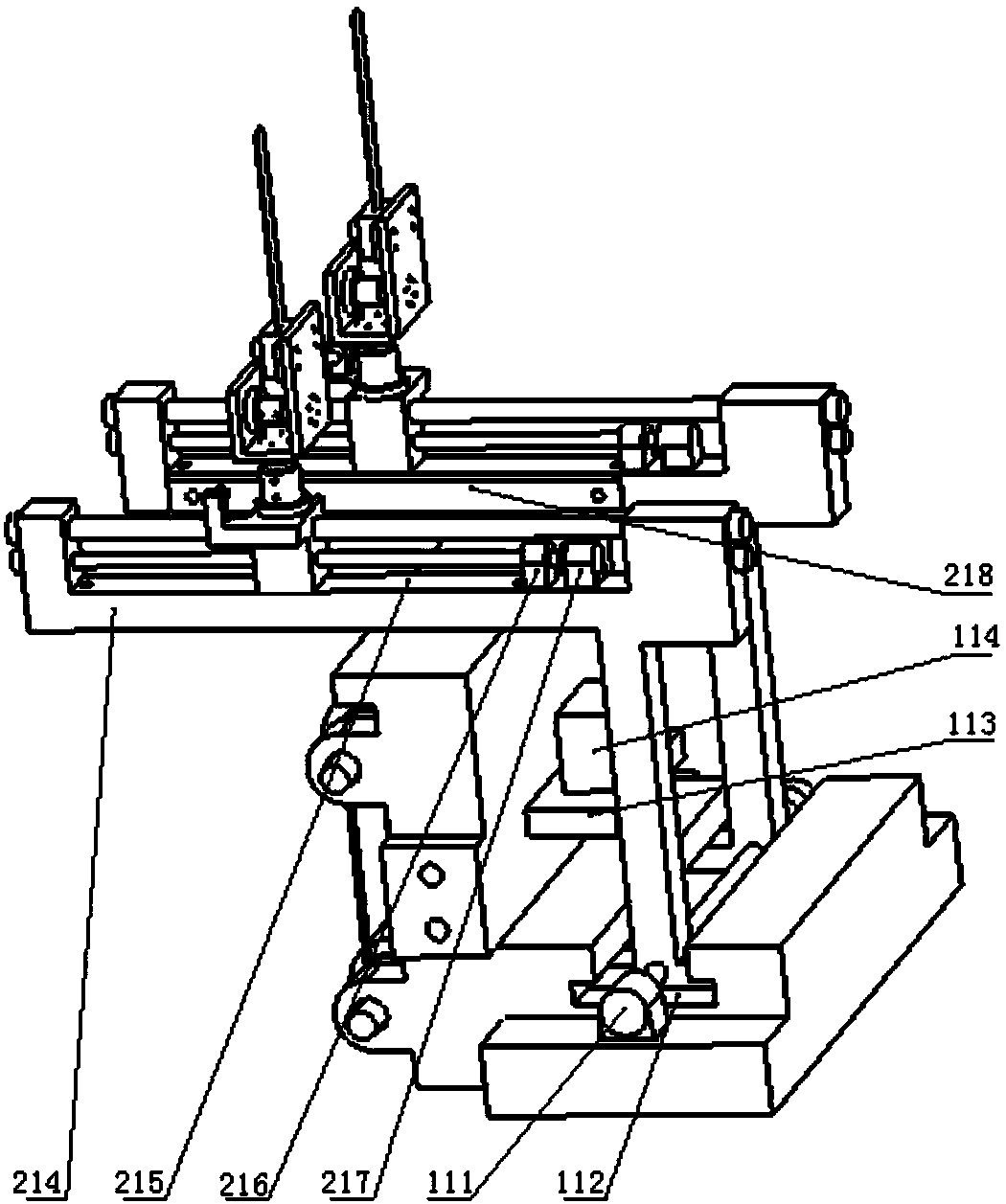

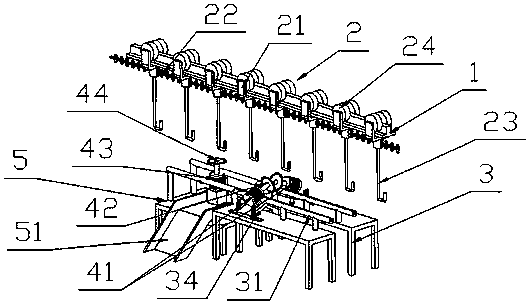

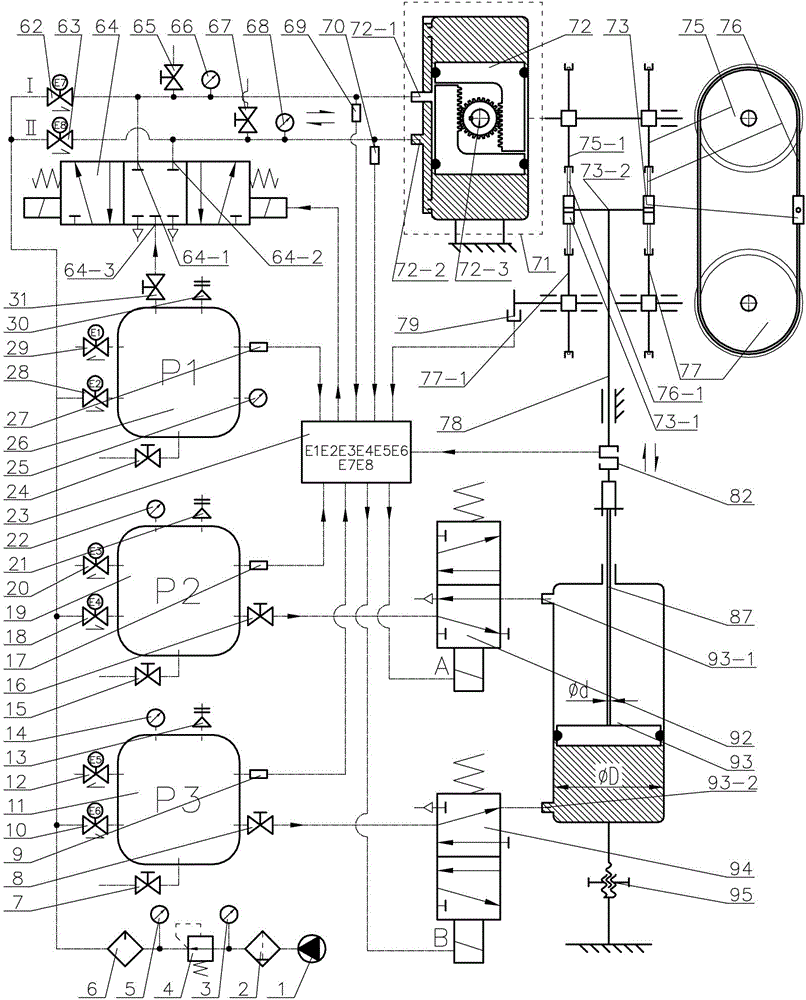

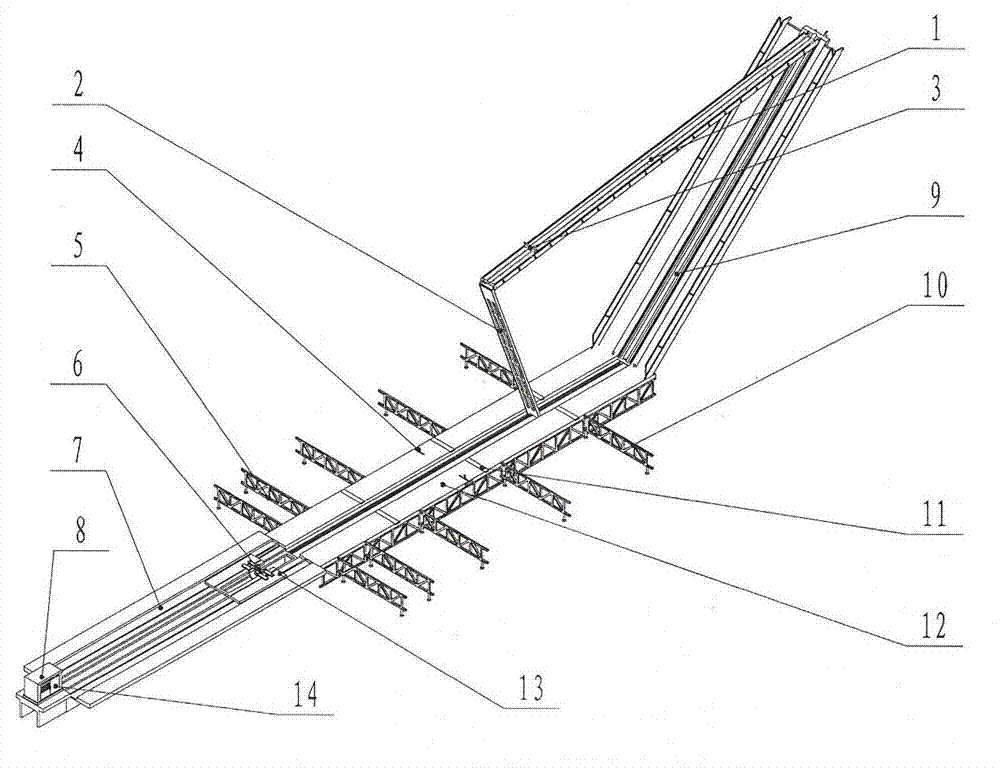

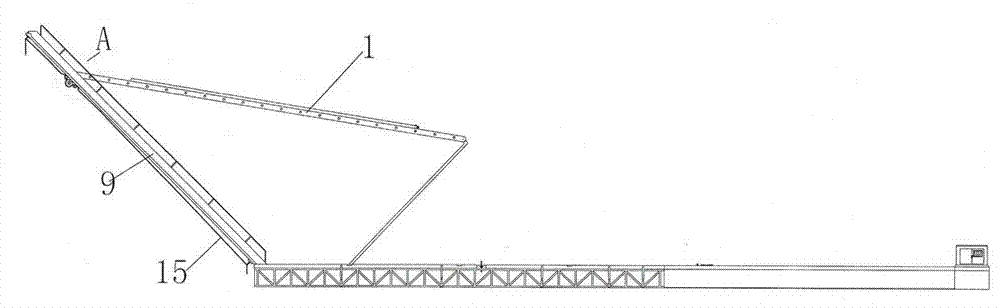

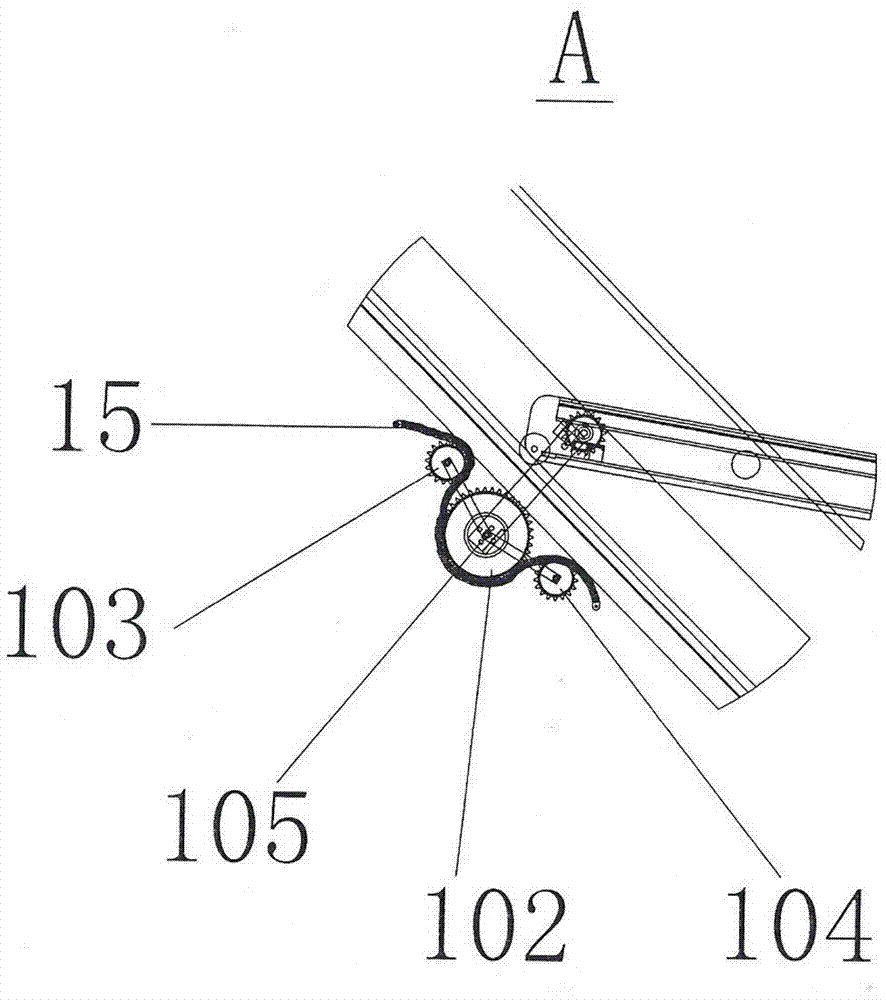

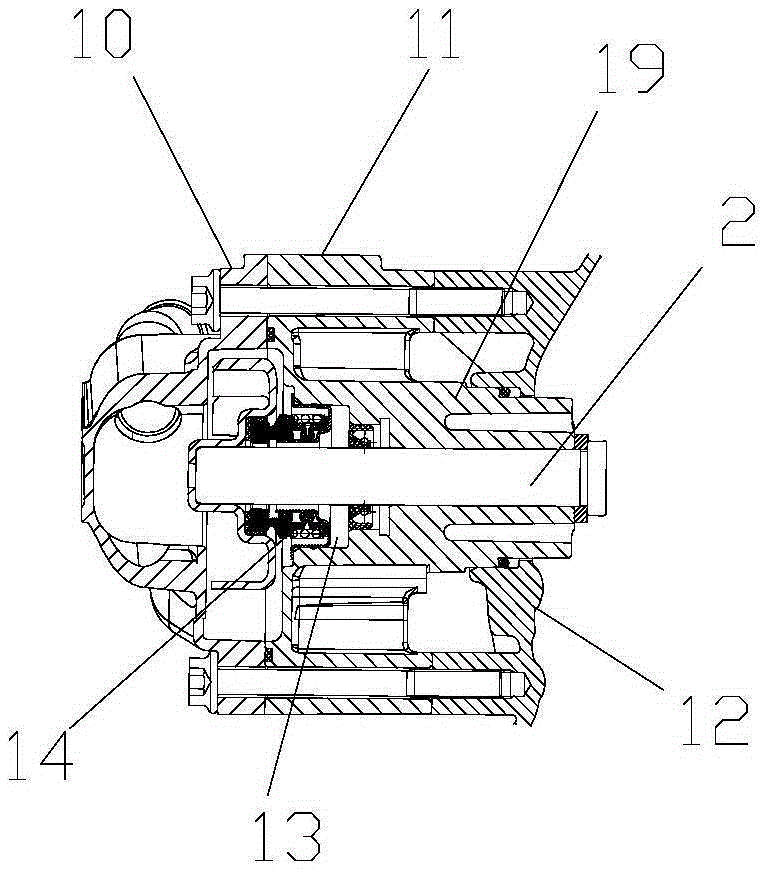

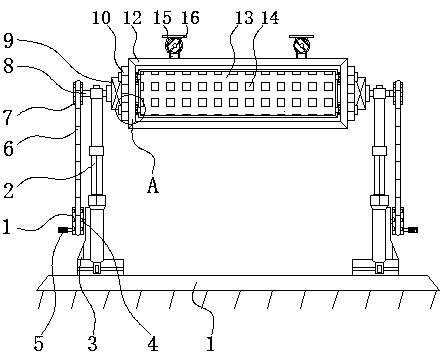

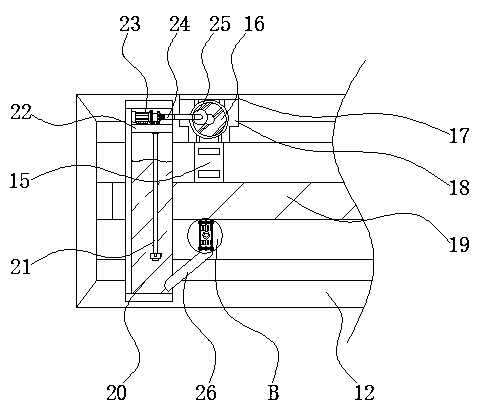

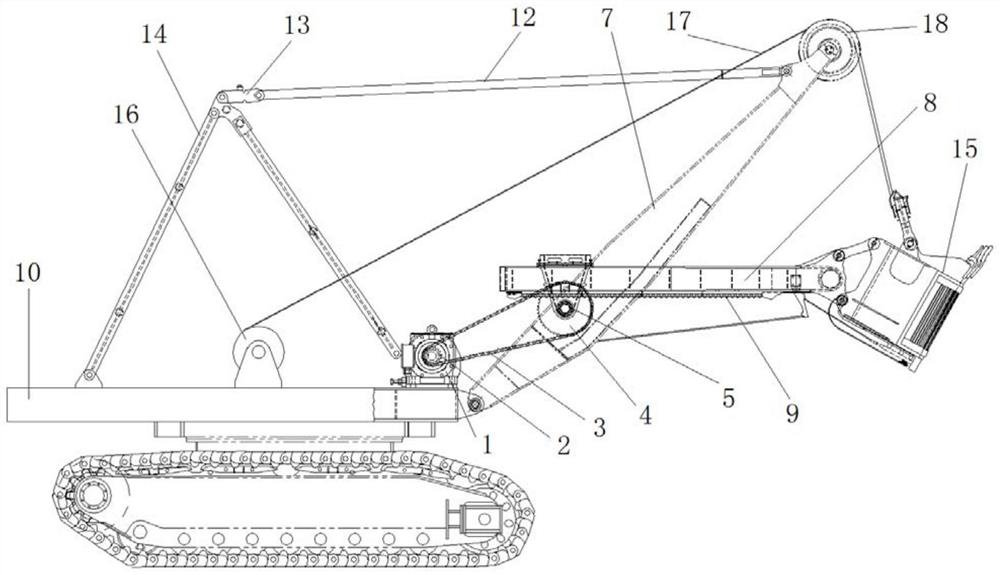

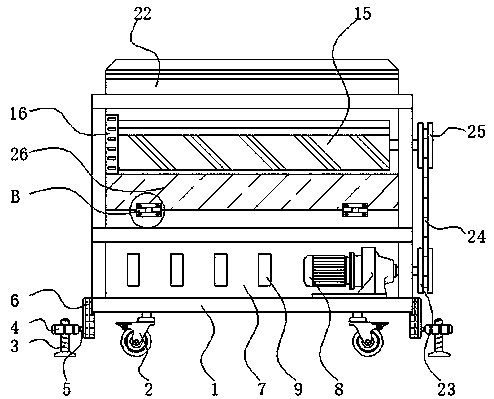

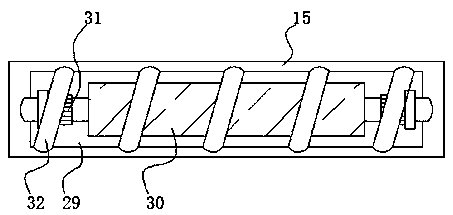

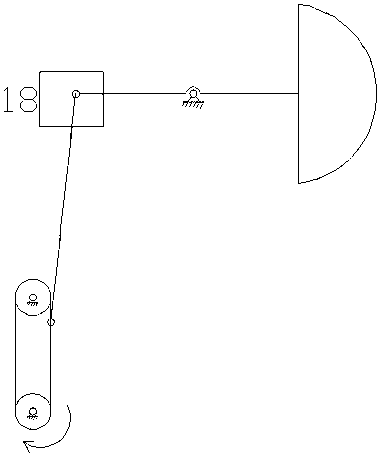

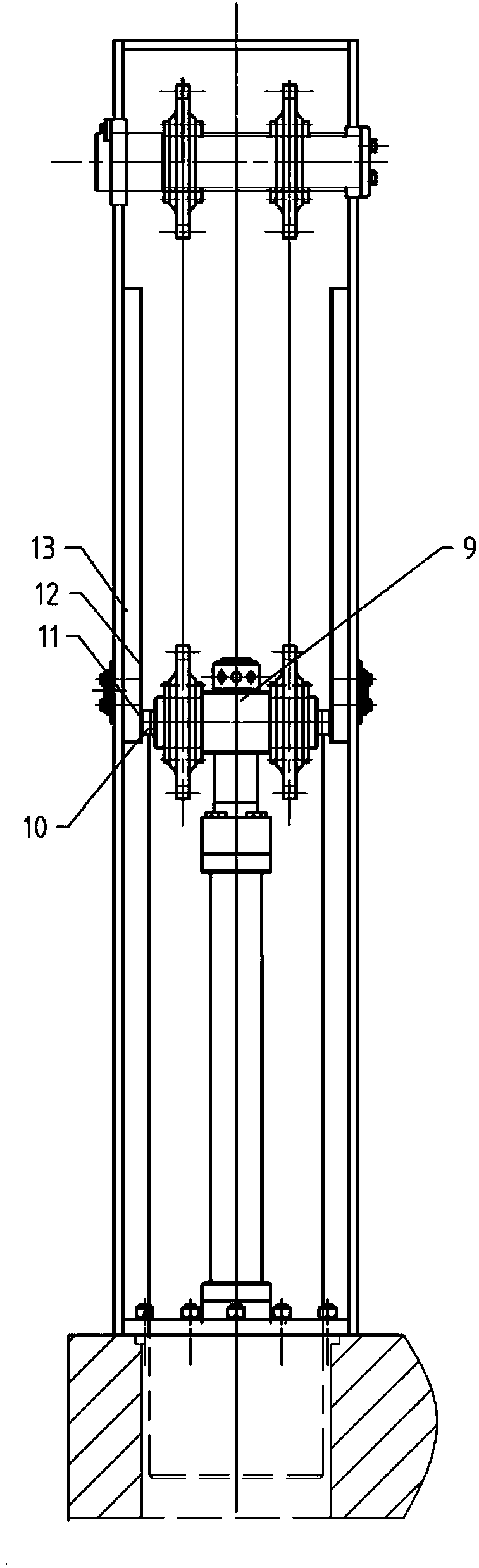

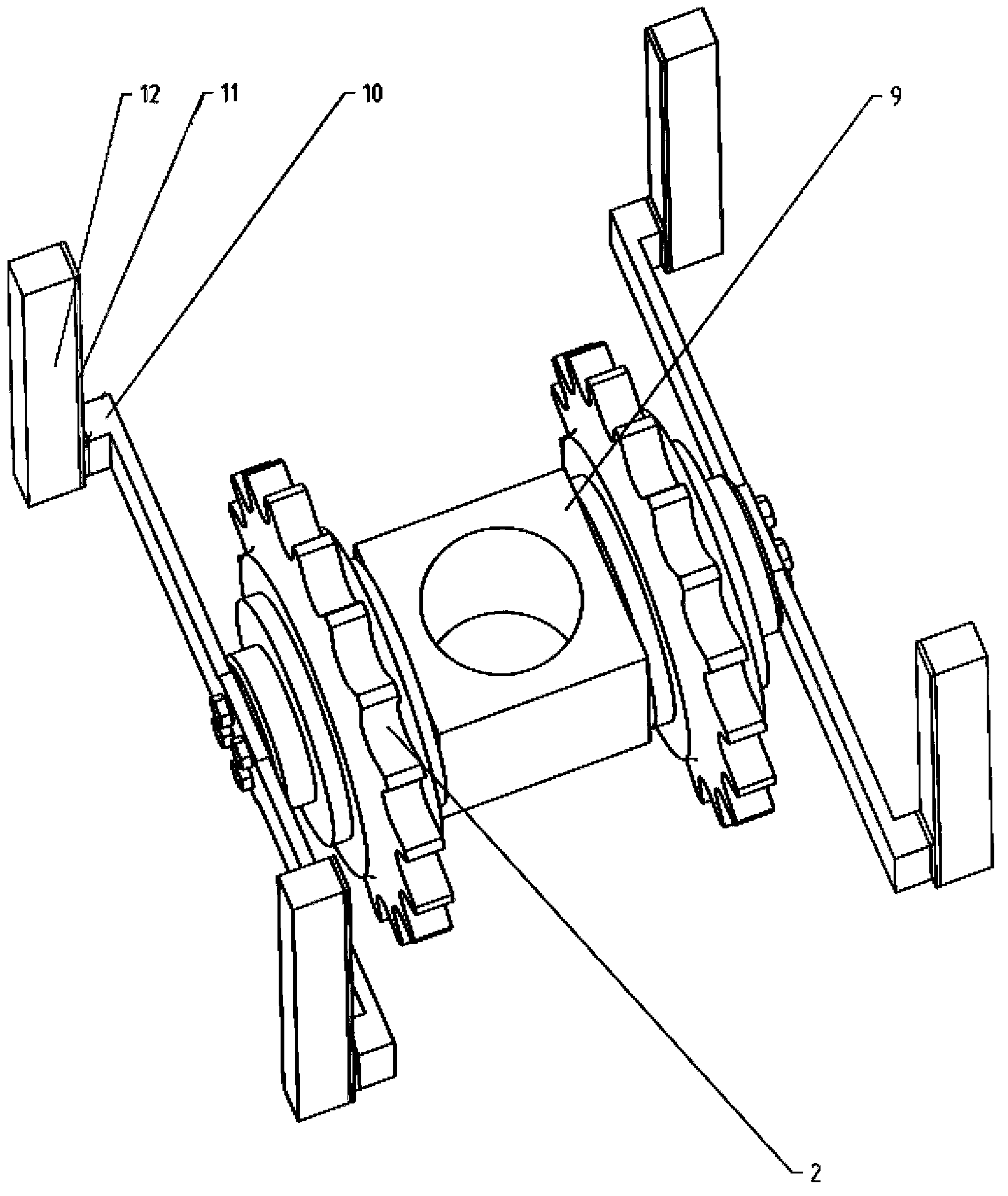

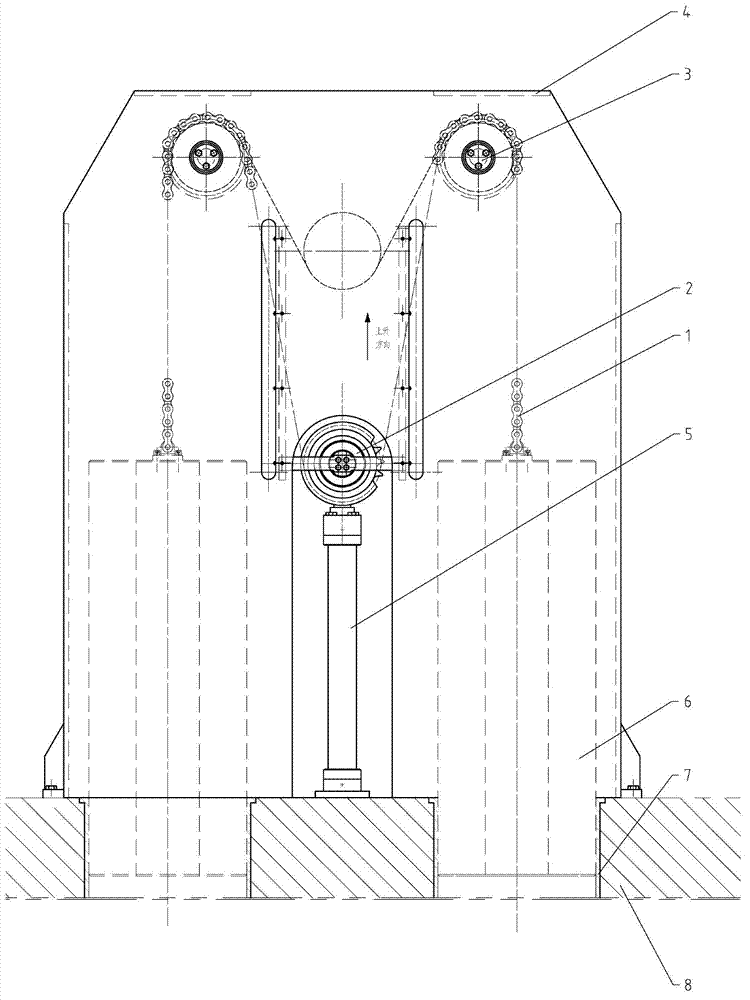

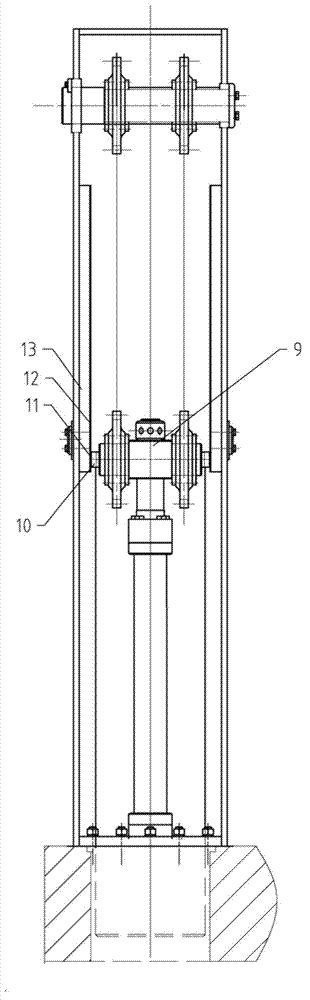

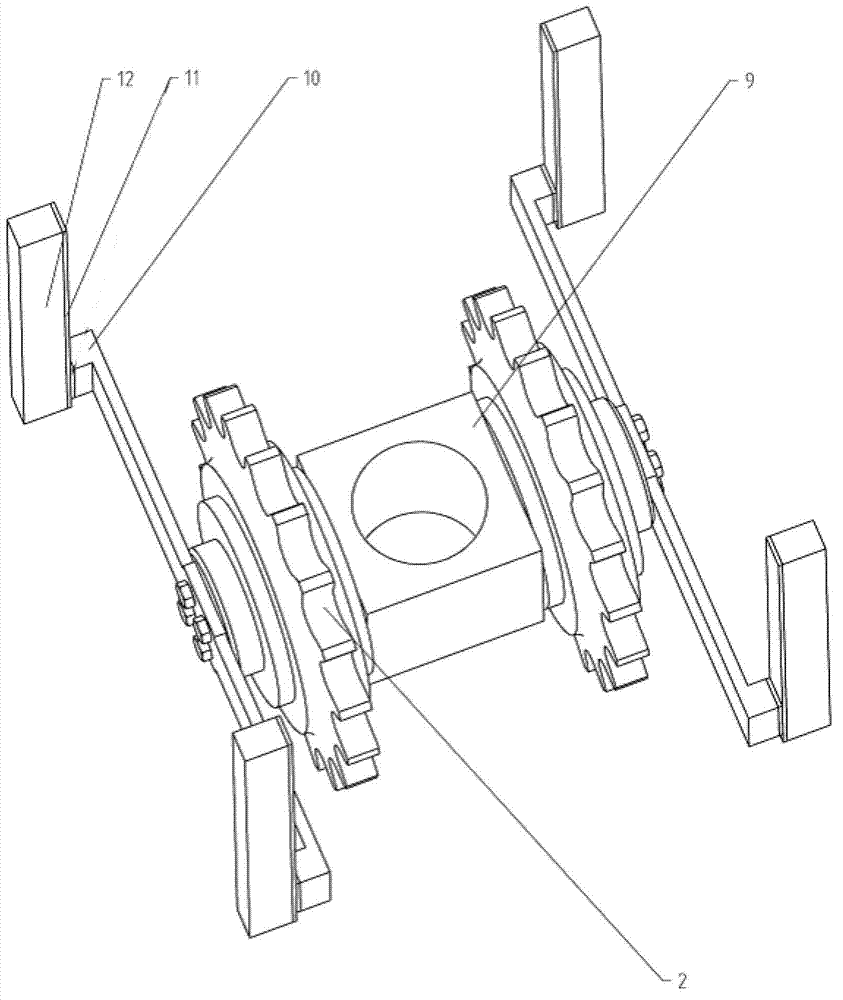

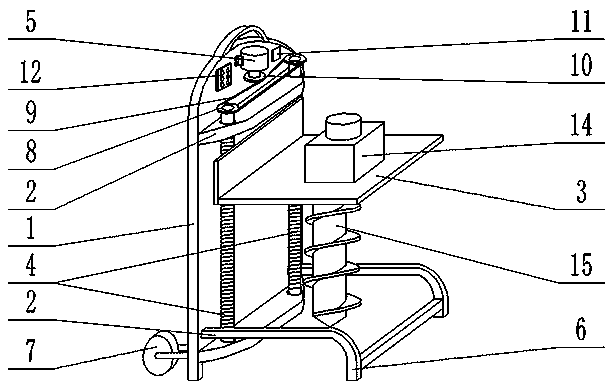

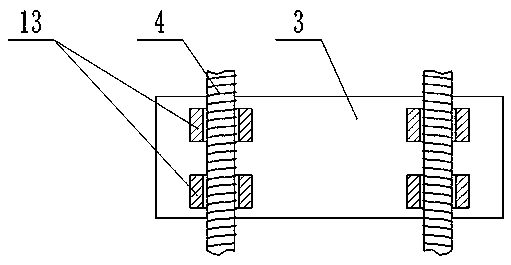

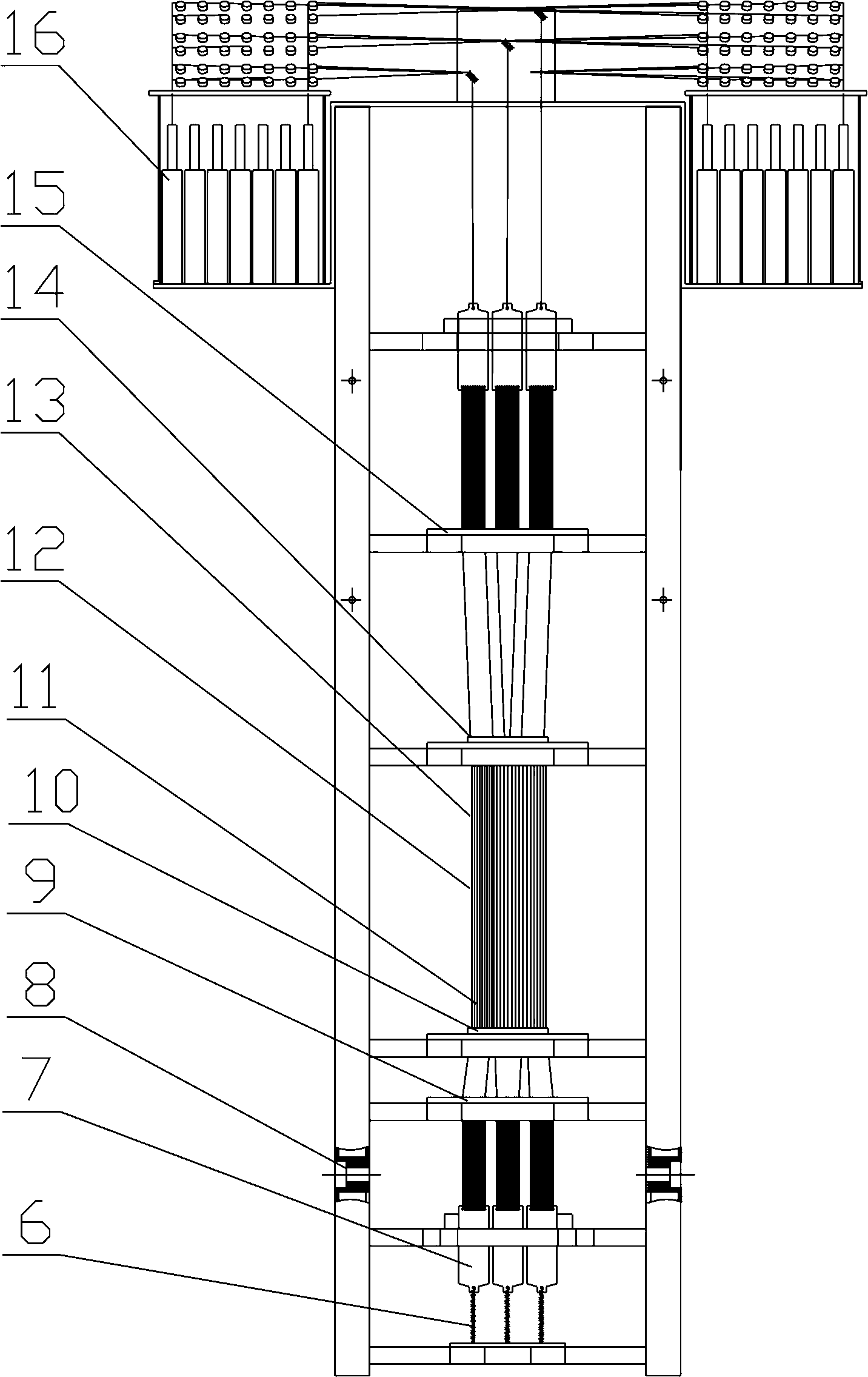

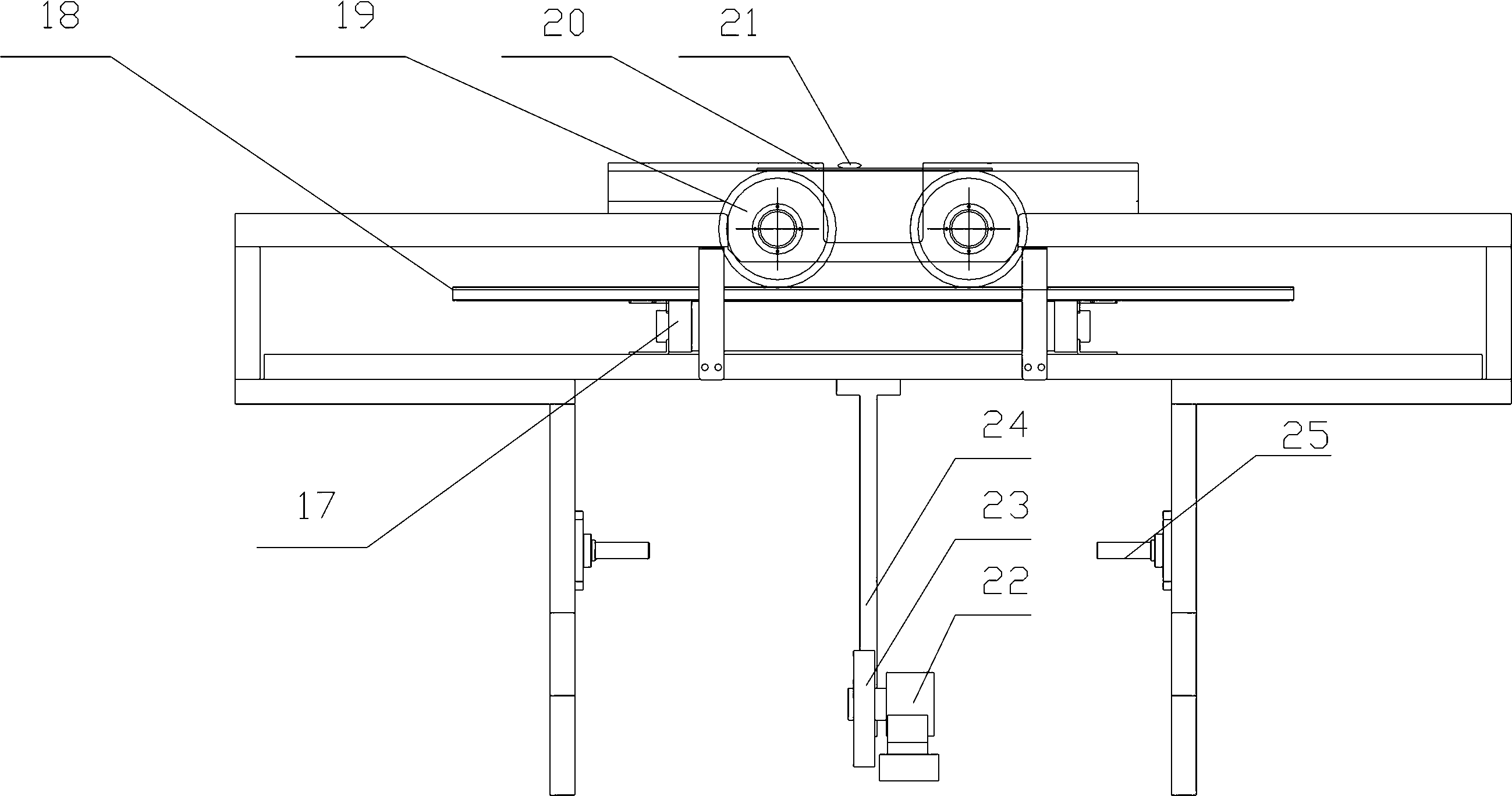

Intelligent full-hydraulic power catwalk

InactiveCN102787813AReduce labor intensityThe average gear ratio is accurateDrilling rodsDrilling casingsEngineeringDrilling system

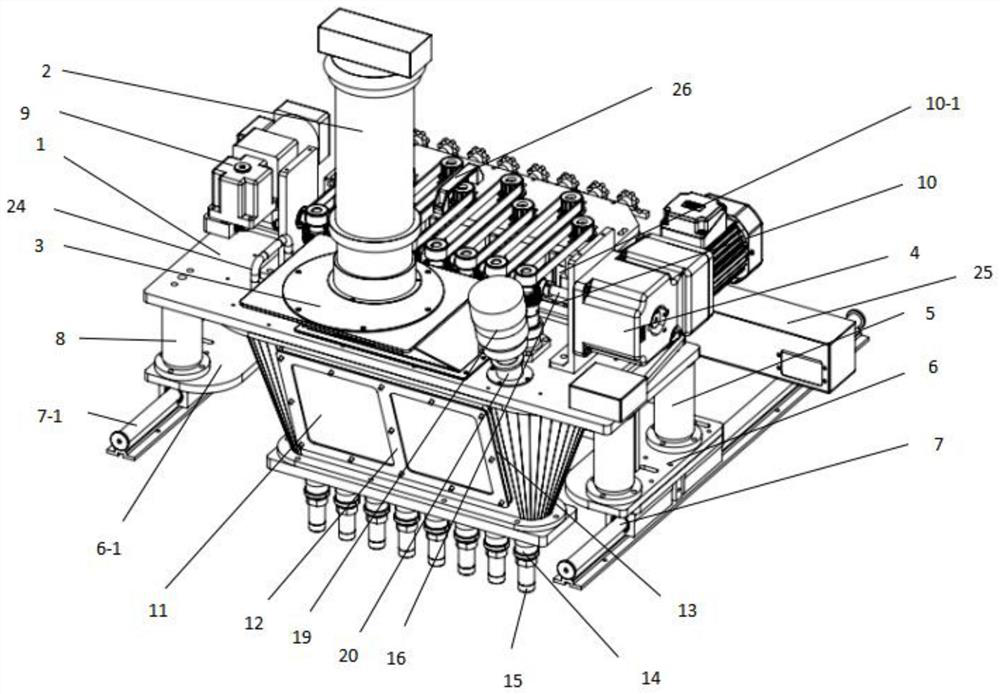

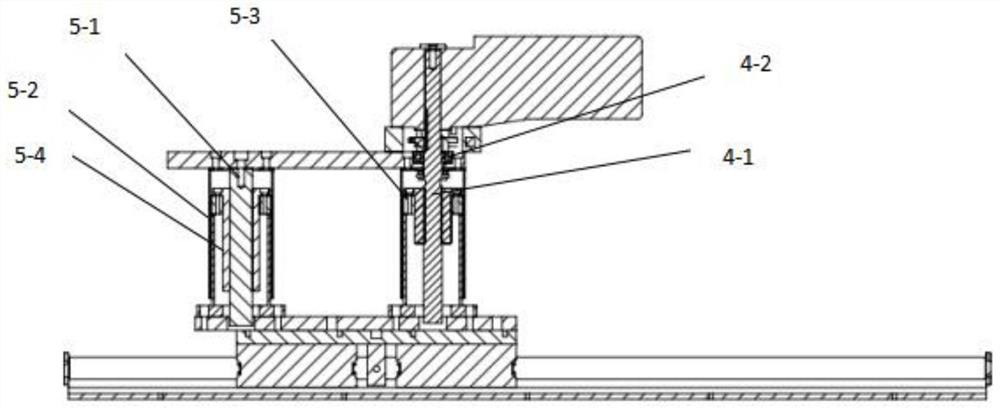

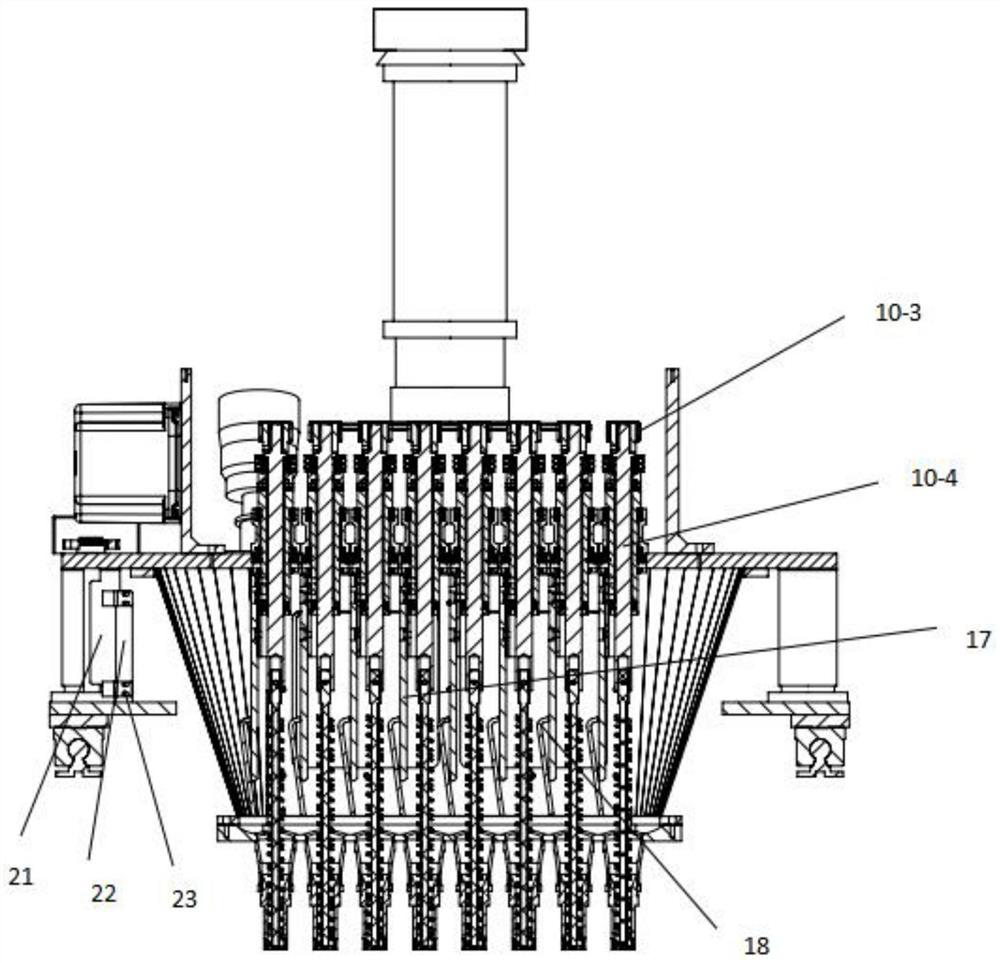

The invention discloses an intelligent full-hydraulic power catwalk which comprises a supporting arm, a lifting leg, a pulley, a drill rod positioning mechanism, a plurality of active outriggers, a twisting machine, a twisting machine sliding rail, a control box, a ramp, outriggers, an overturning plate, a foundation support, a waterpower decoring device and a hydraulic station. The ramp is connected with the foundation support via a bolt, the twisting machine and the twisting machine sliding rail are mounted on one side of the foundation support, the waterpower decoring device is mounted on the twisting machine, the drill rod positioning mechanism and the overturning plate are arranged on the foundation support, the pulley is arranged on the supporting arm, the active outriggers are arranged on two sides of the foundation support, the hydraulic station supplies power to a system, and operation of the system is control by the control box. By the aid of the intelligent full-hydraulic power catwalk, processes including joint and throw rod connecting, hole bottom power connecting and disconnecting and water power rock coring can be integrated, twisting and water power decoring can be automatically finished without removal of a drill rod, technical requirements for drilling deep well coring are met, construction fields are greatly reduced, labor intensity is lowered, and working efficiency of a drilling system is improved. Since the power catwalk is fully hydraulically controlled, stepless speed change can be realized, transmission mechanism is simplified, and adaptability and reliability of the power catwalk are improved.

Owner:JILIN UNIV

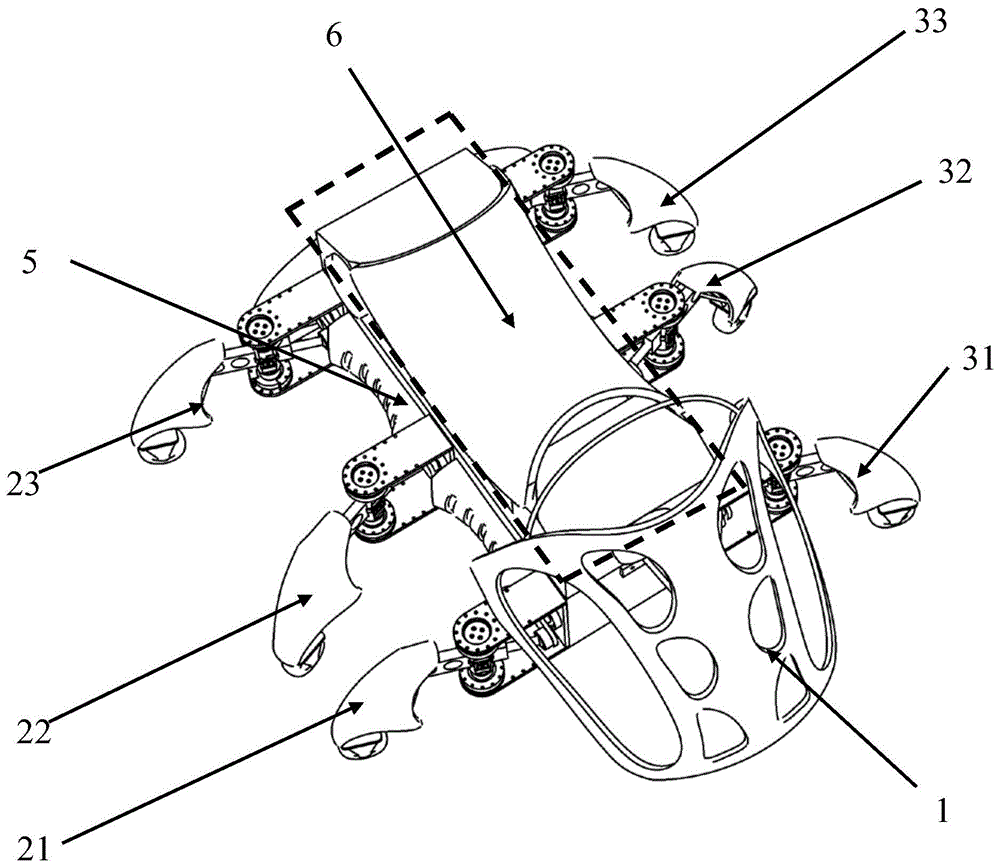

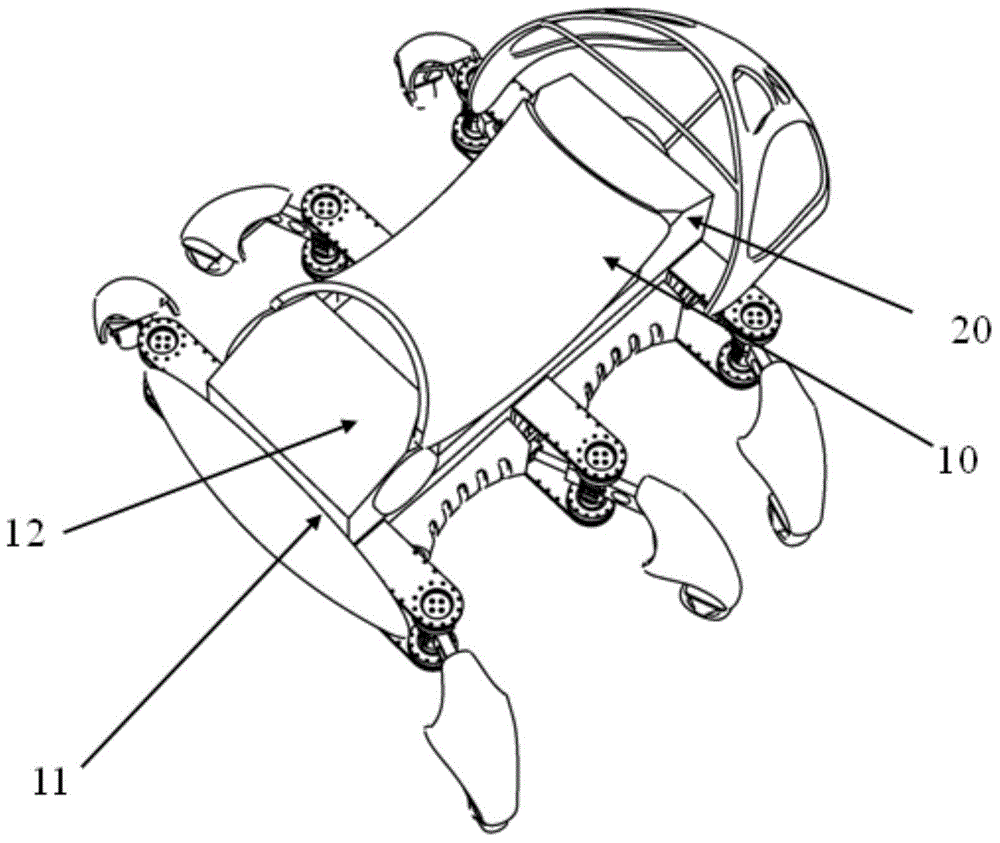

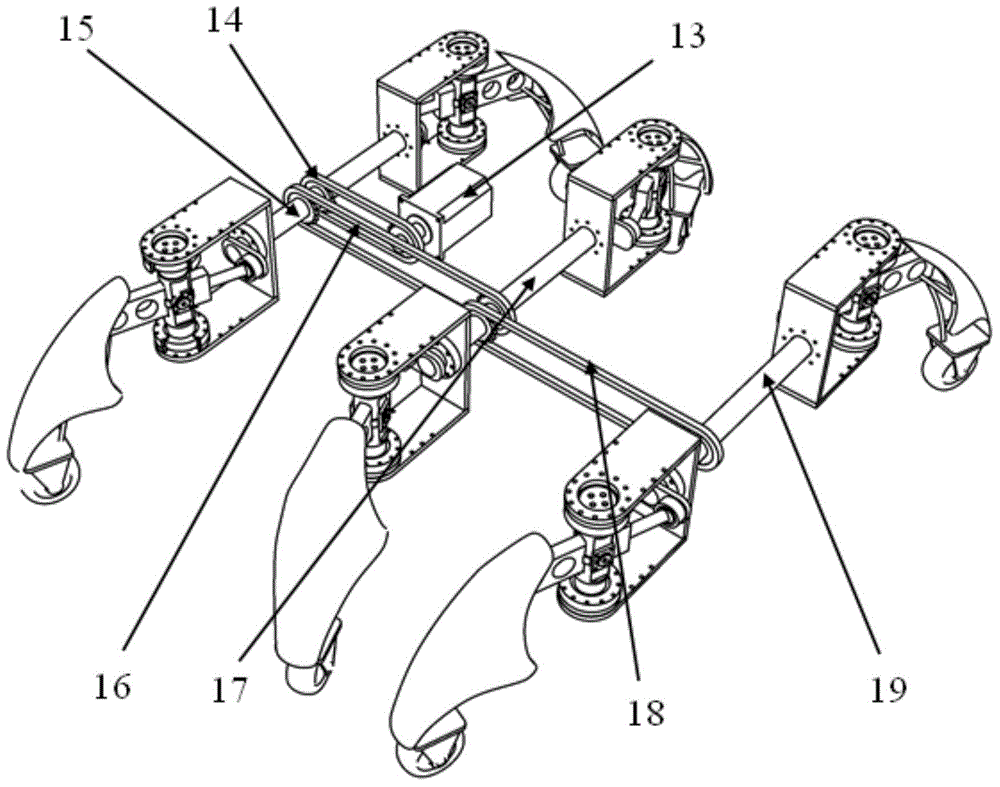

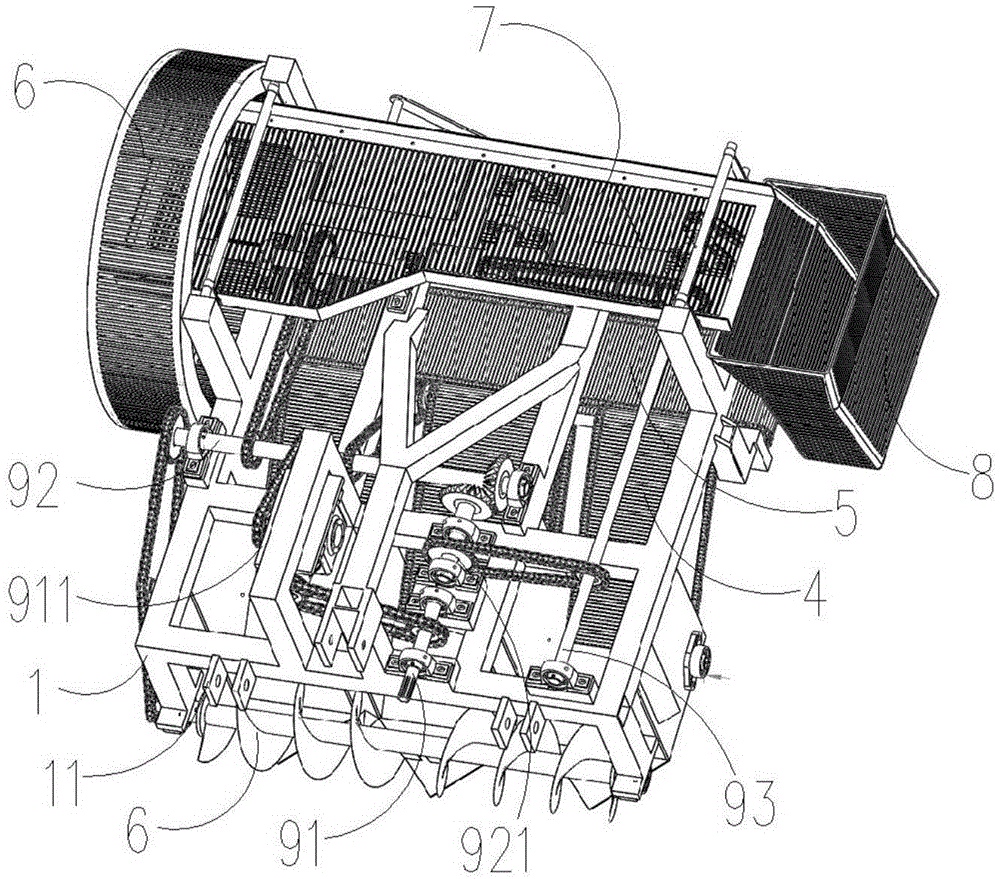

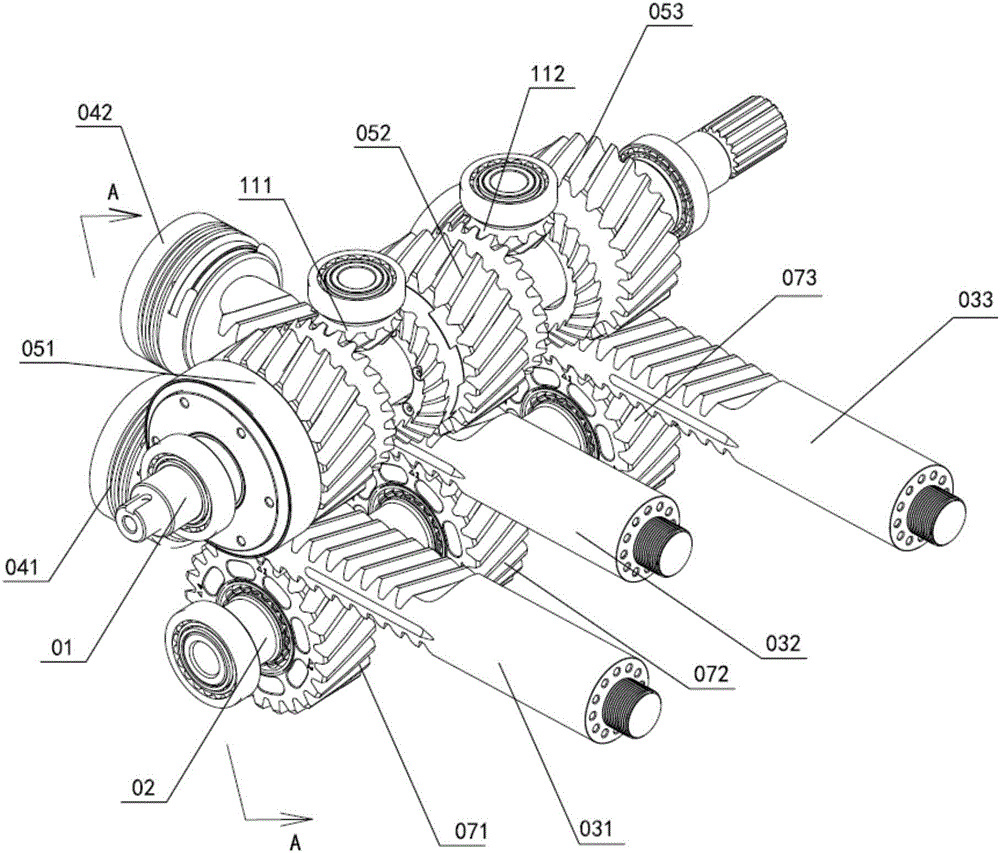

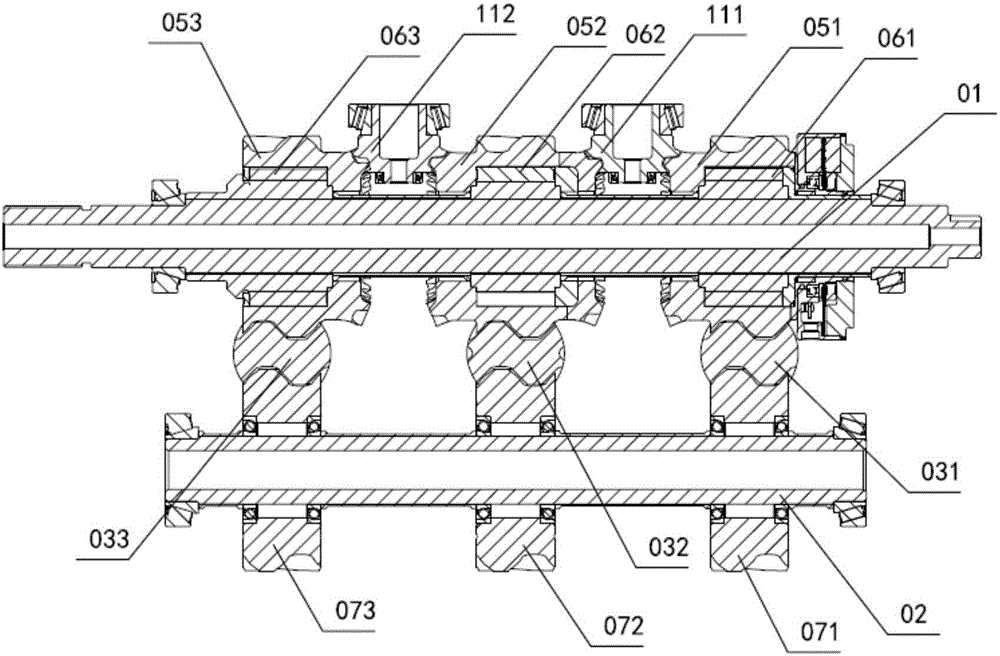

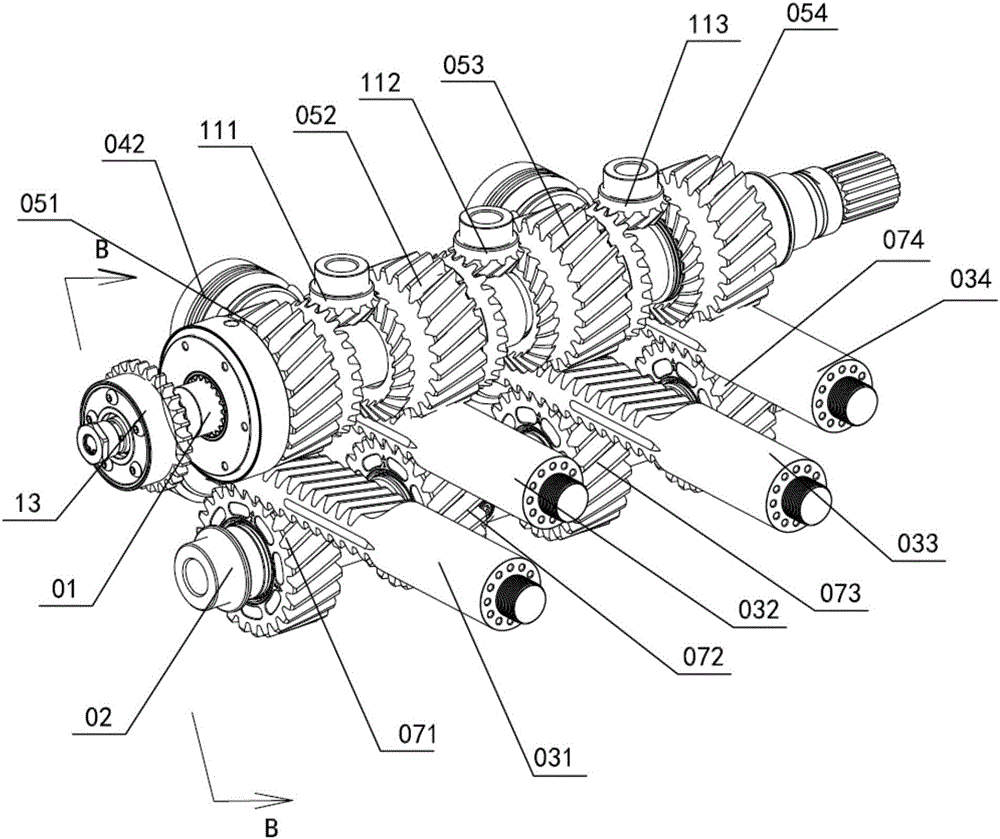

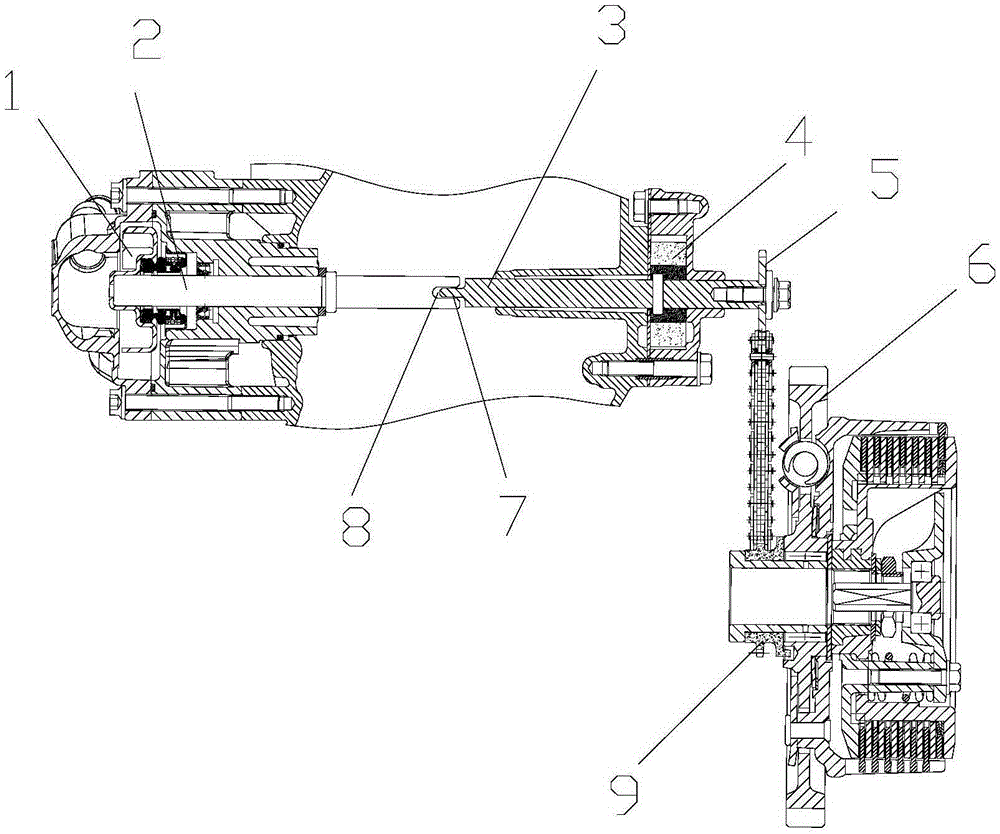

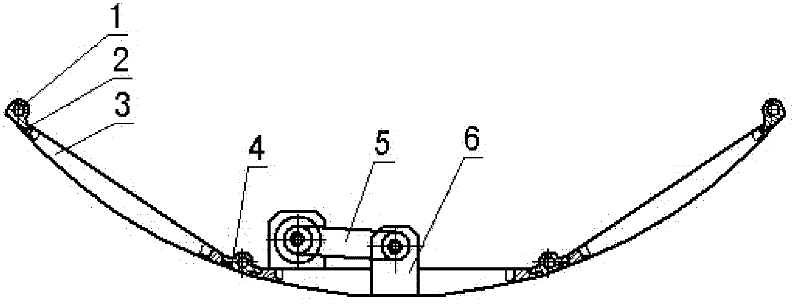

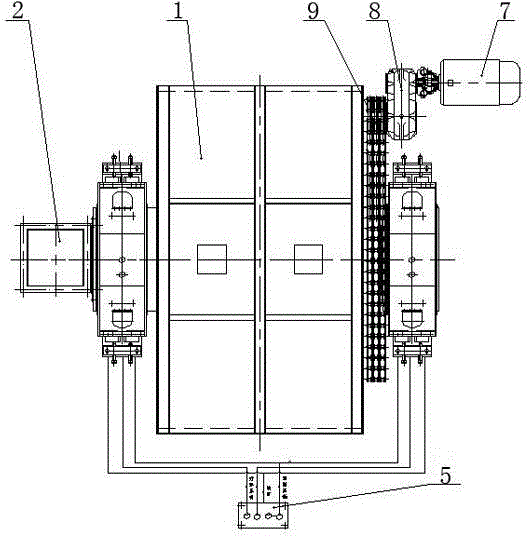

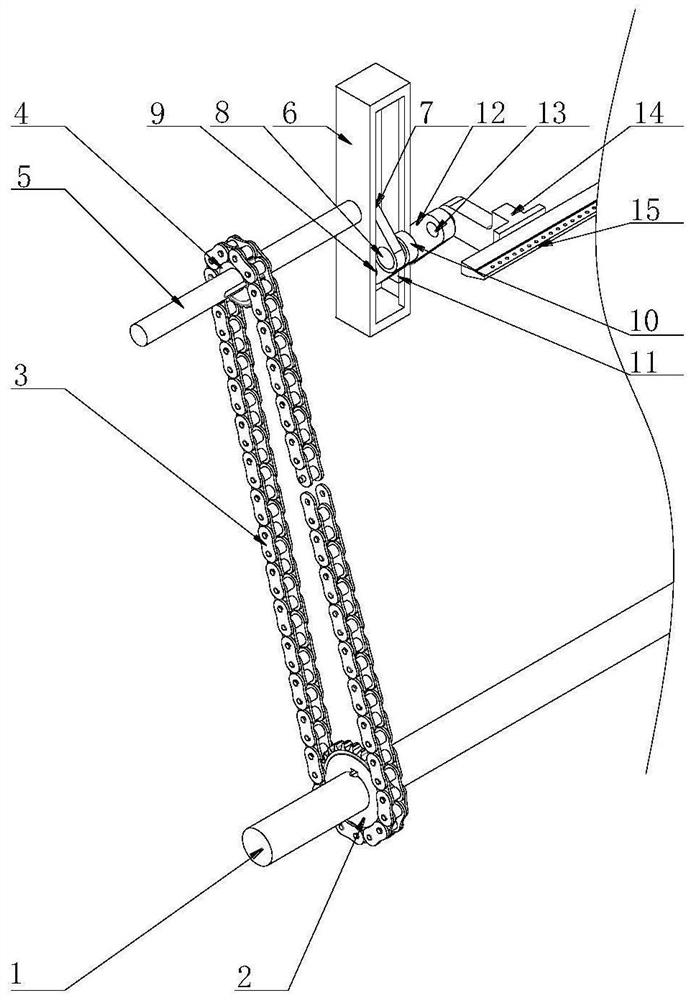

Hexapod robot

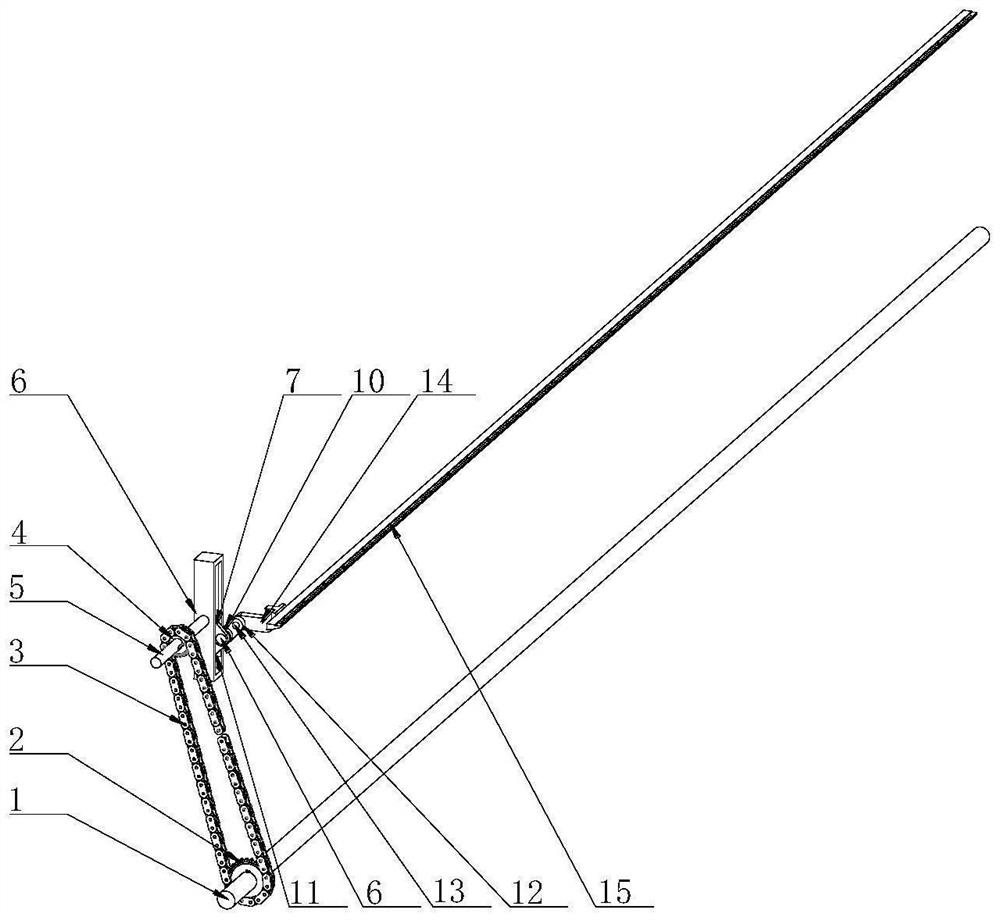

The invention discloses a hexapod robot. The robot comprises a head part, a body, a driving device, a transmission system and six mechanical legs. The hexapod robot is characterized in that the six mechanical legs are reversely and symmetrically mounted on both sides of the long edge of the body, and adopt the completely same structures; the driving device and the transmission system are arrayed at the inner part of the body; the driving device performs driving through a servo motor, and the transmission system performs transmission through sprocket chains; three output rods are also arranged at the inner part of the body, and the two mechanical legs are reversely and symmetrically mounted on both sides of each output rod; the six mechanical legs are divided into three groups, and the three groups of output rods are connected in a transmission manner by adopting the sprocket chains; the servo motor of the driving device designed at the inner part of the body simultaneously drives the six mechanical legs to move.

Owner:SHAANXI JIULI ROBOT MFG

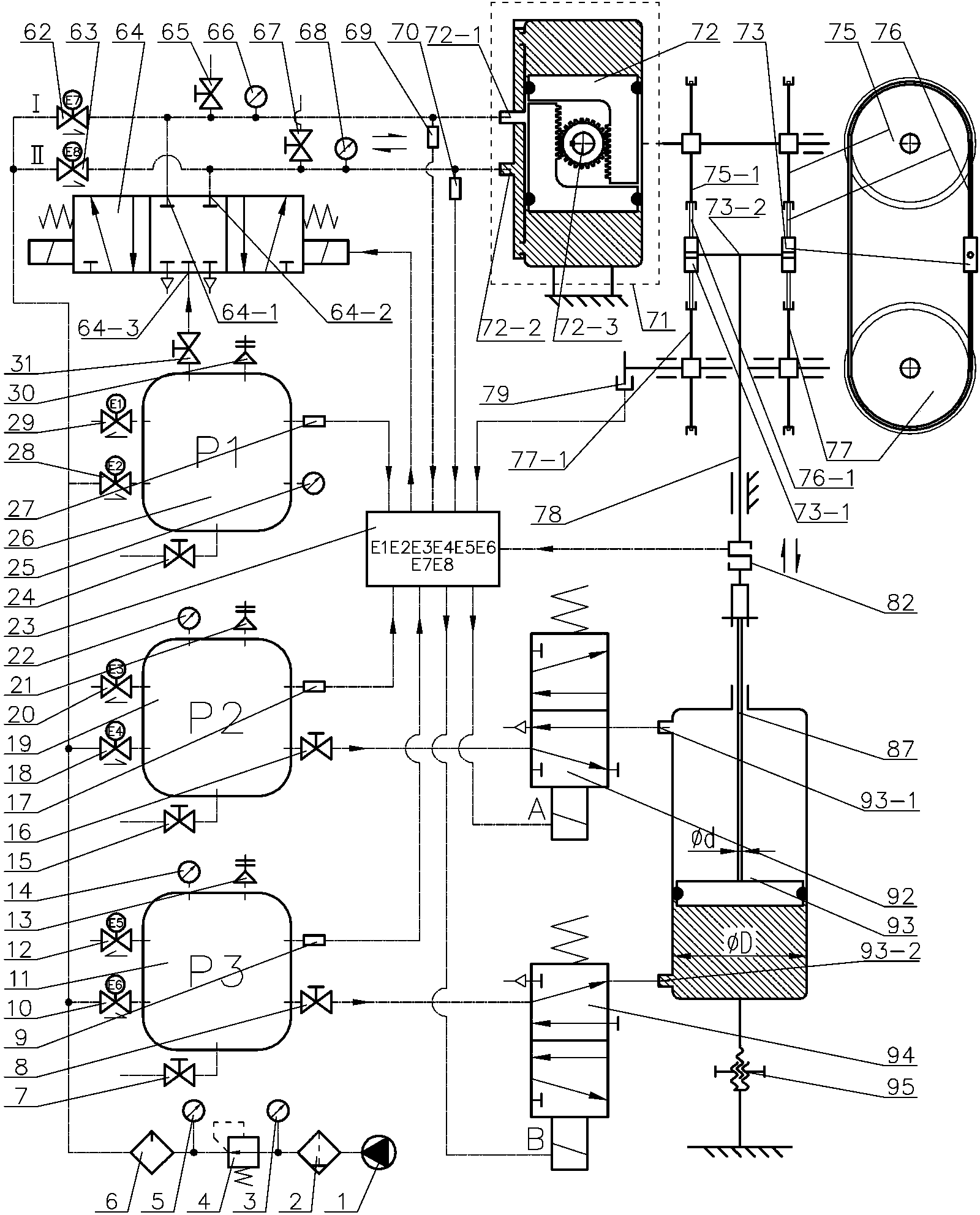

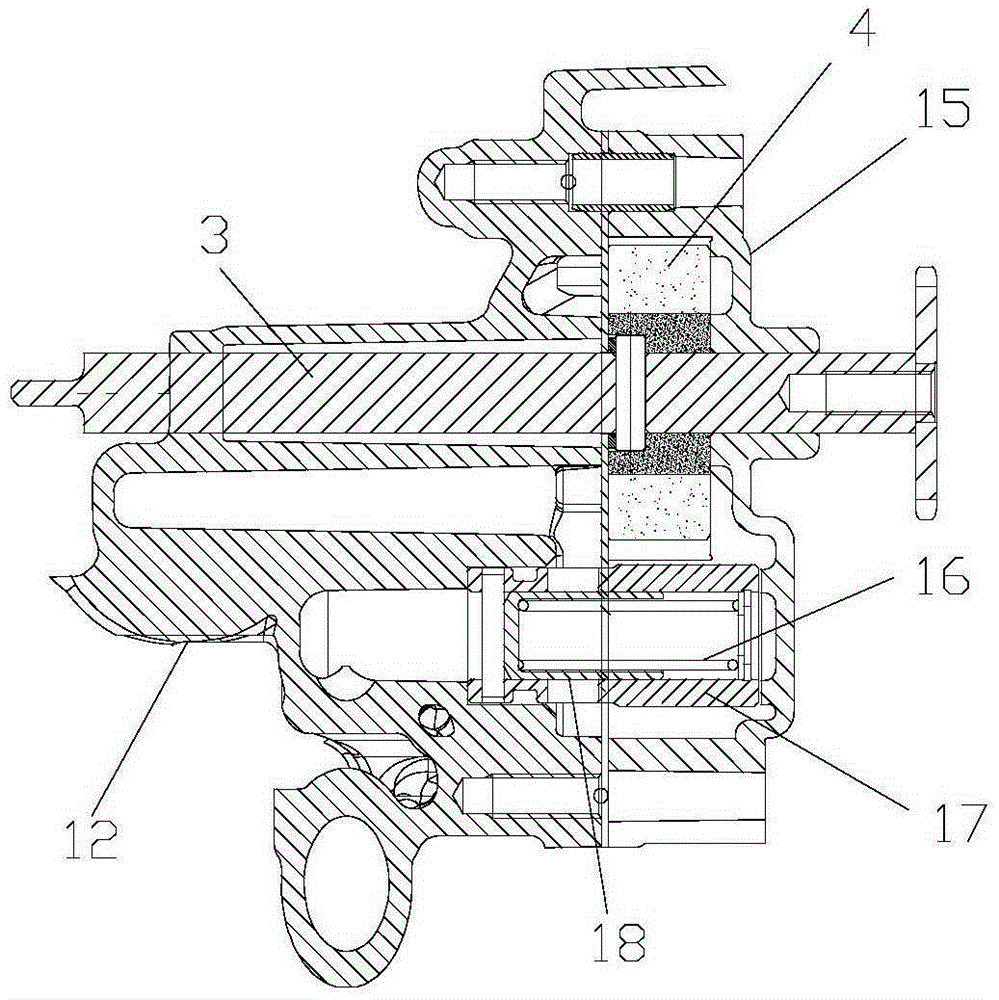

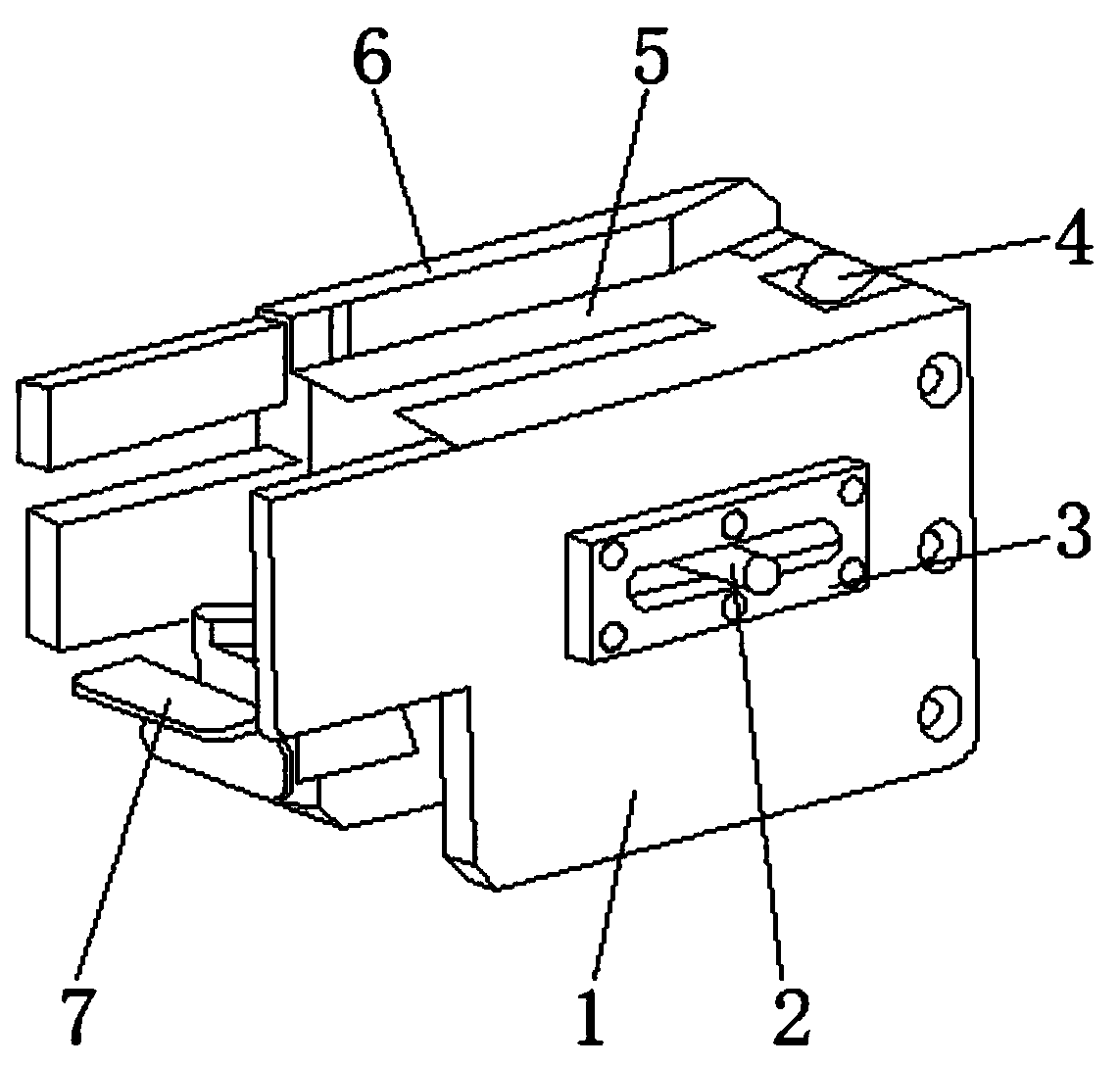

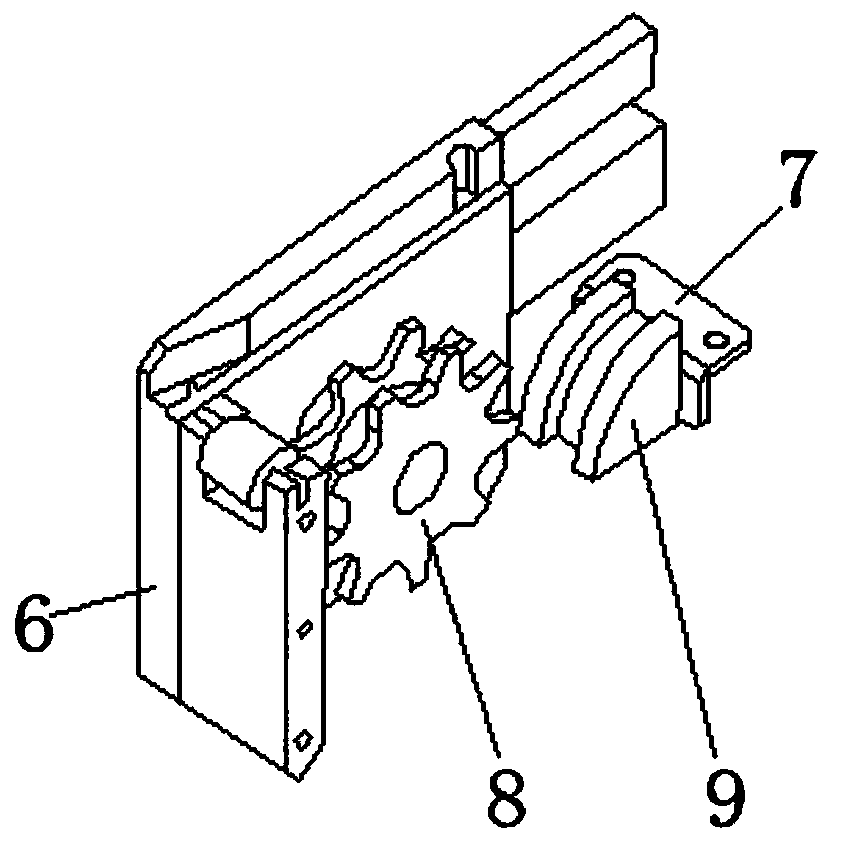

Method for testing rotary valve pneumatic actuator

InactiveCN103411763ASimple structureReduce maintenance costsMachine part testingMeasurement of fluid loss/gain rateRotary valveLife test

The invention relates to a method for testing a rotary valve pneumatic actuator. The method for testing the rotary valve pneumatic actuator can be used for precisely testing a single-acting rotary valve pneumatic actuator and a double-acting rotary valve pneumatic actuator. The method is used for carrying out no-load test detection, seal test detection, strength test detection, load test detection and action life test detection on the double-acting rotary valve pneumatic actuator and the single-acting rotary valve pneumatic actuator.

Owner:QUALITY INSPECTING CENT OF PUMP & VALVE PROD OF ZHEJIANG PROVINCE

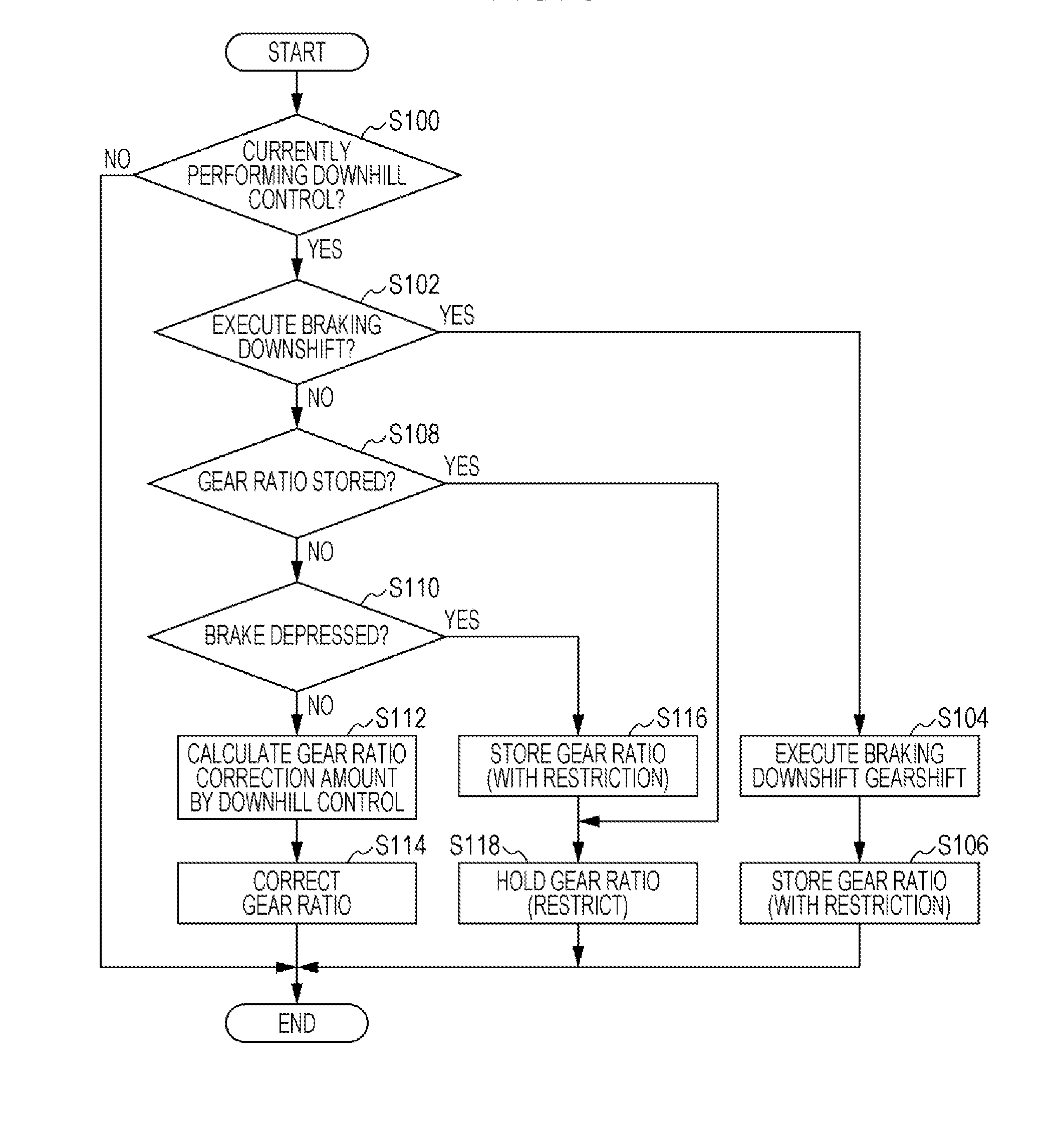

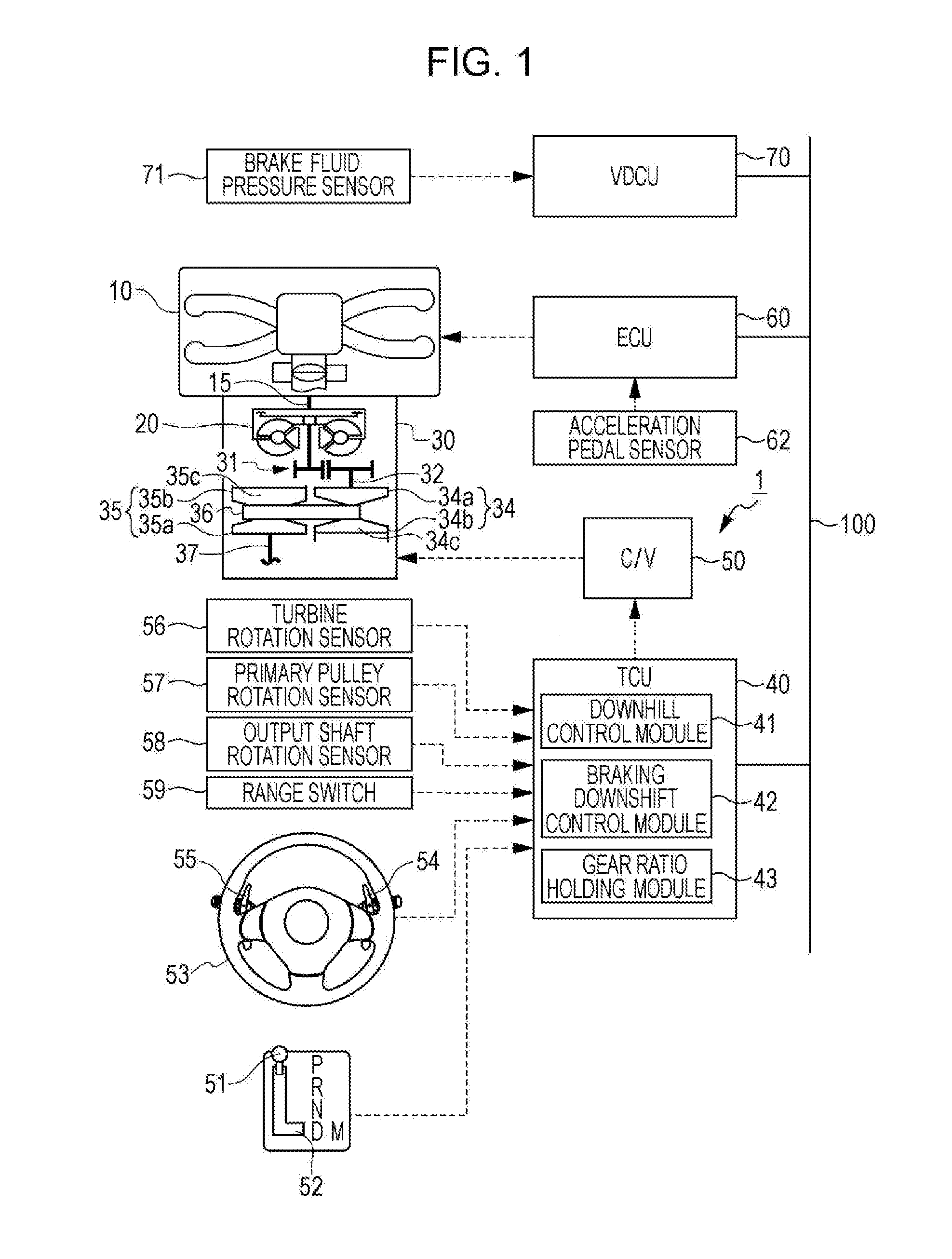

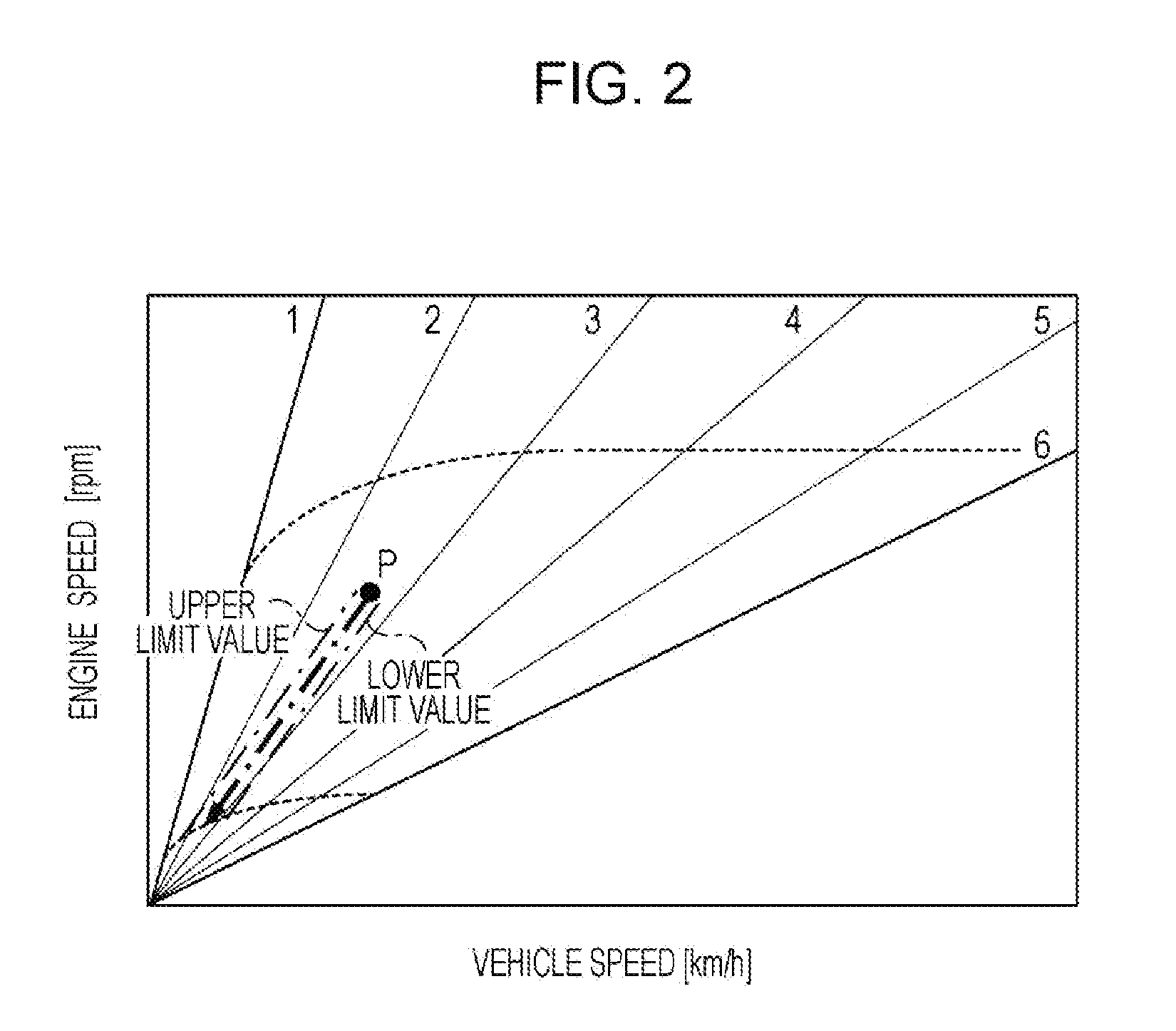

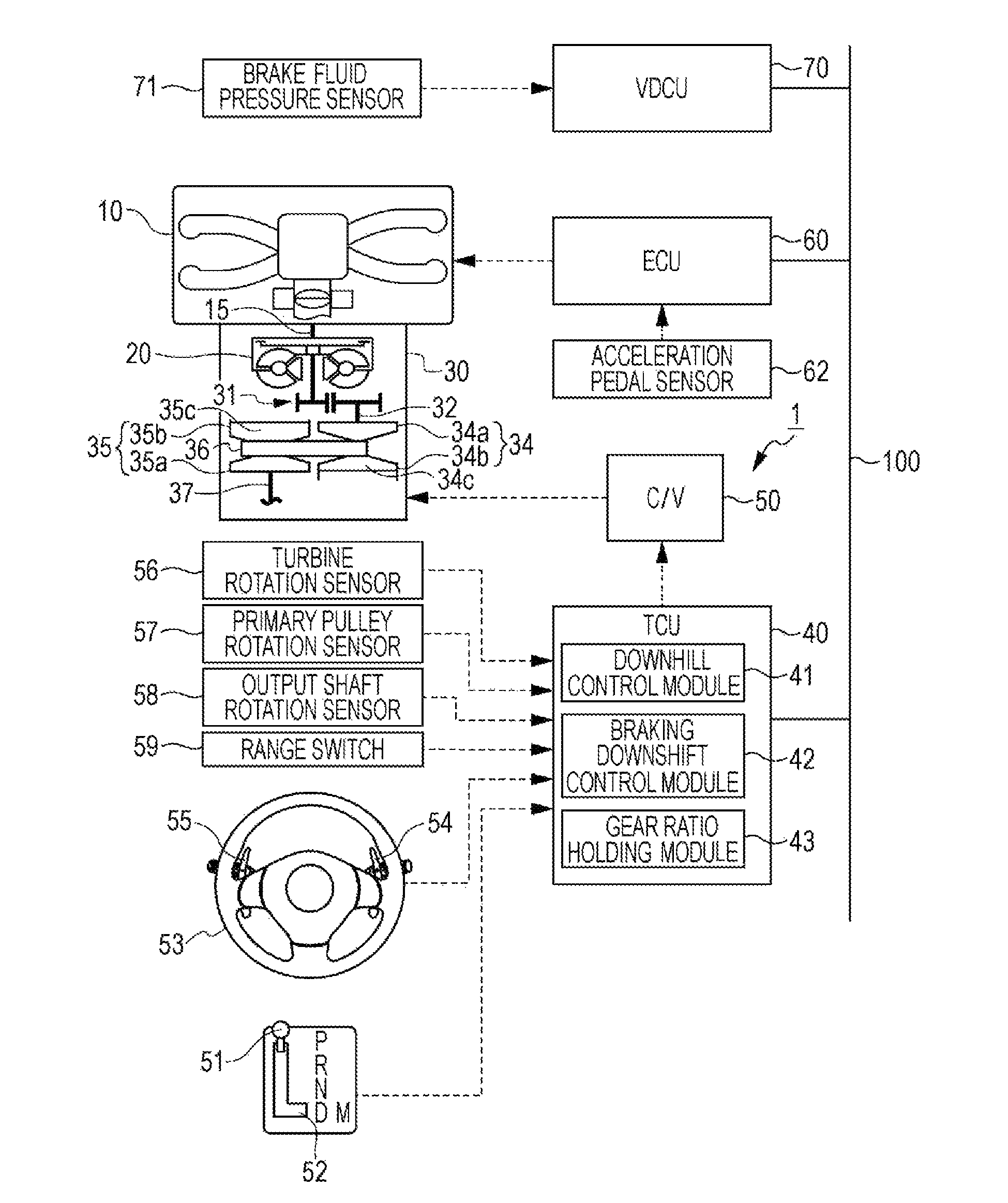

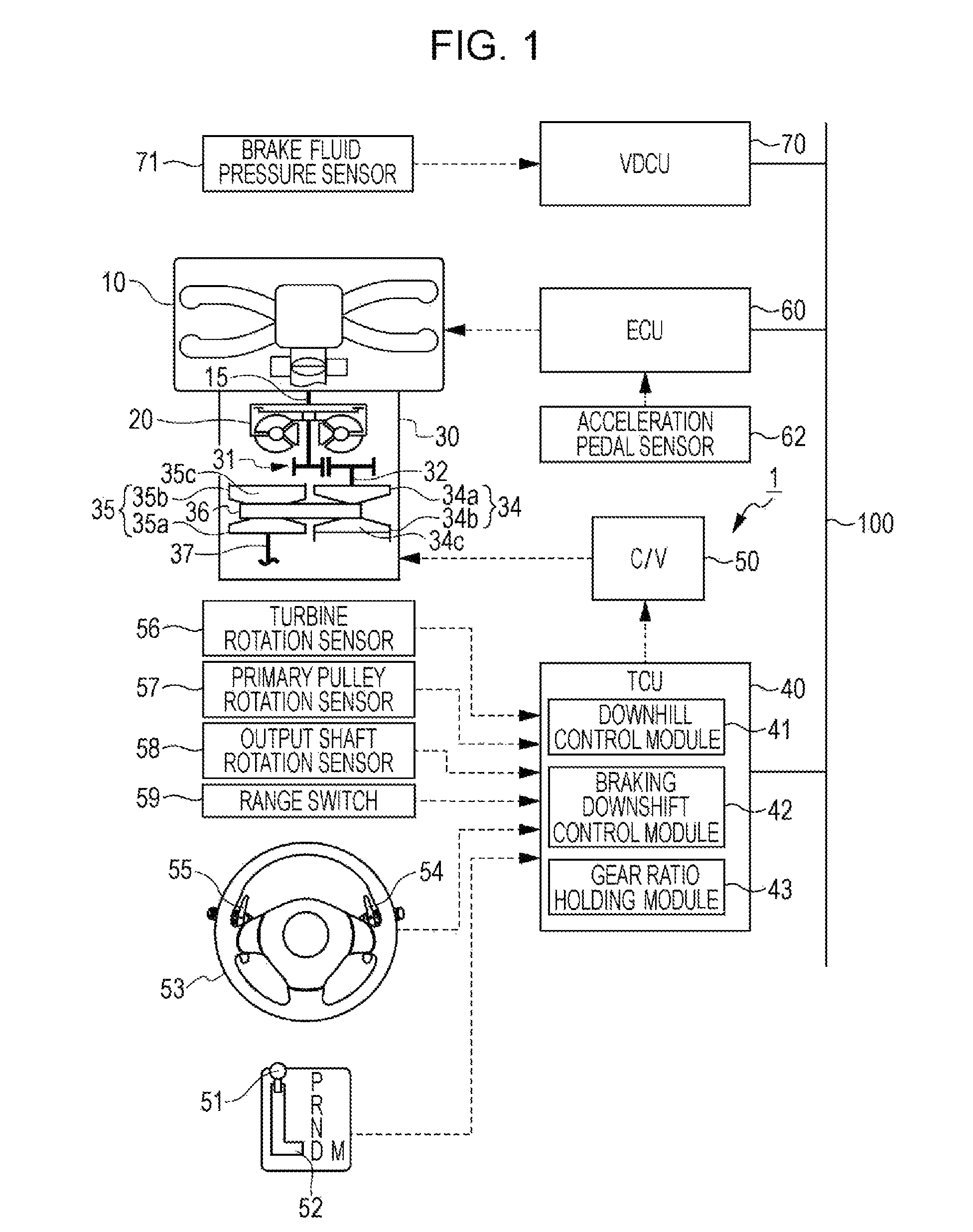

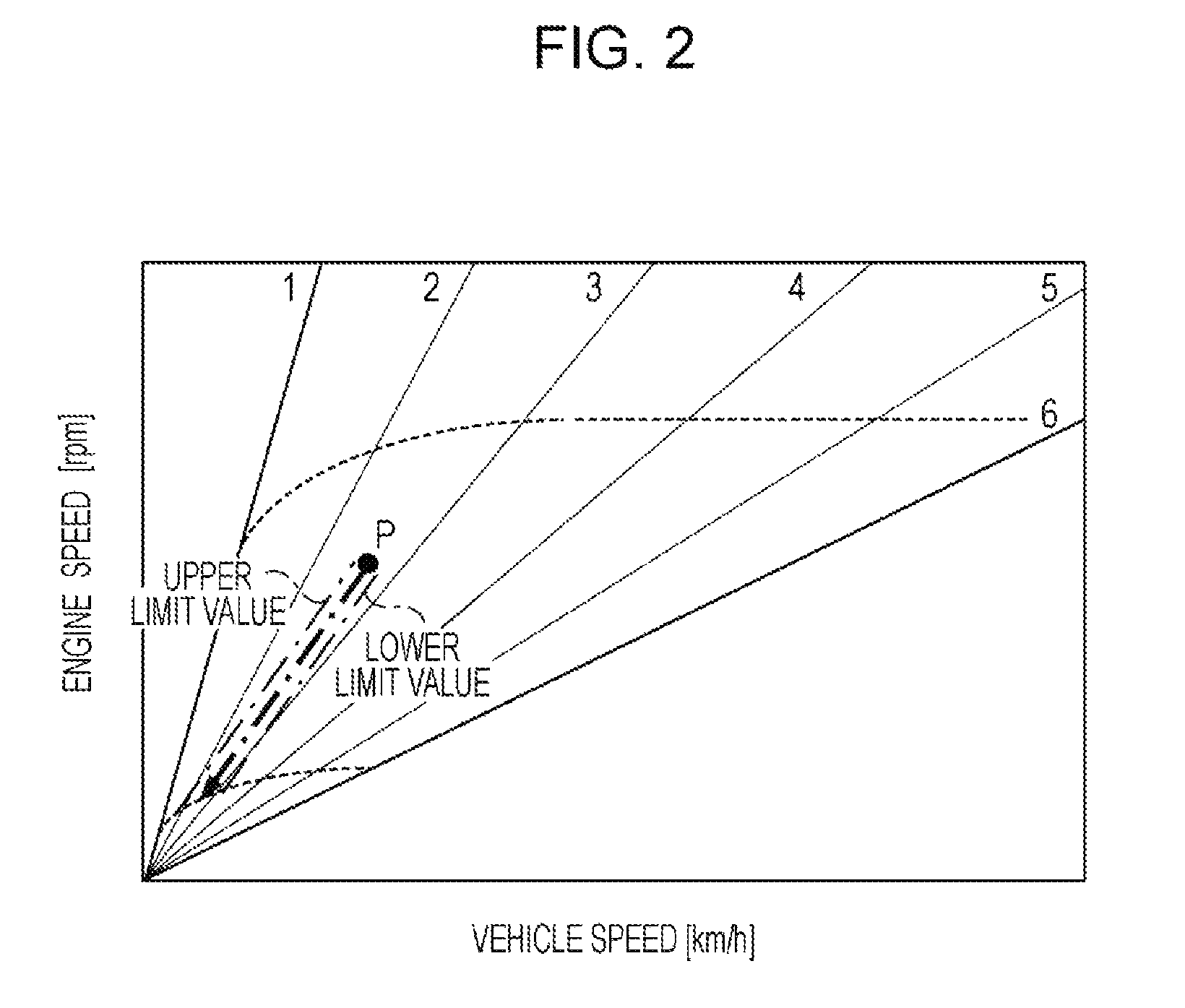

Shift Control Device for Continuously Variable Transmission

ActiveUS20150198240A1Prevented from feelingThe average gear ratio is accurateDigital data processing detailsGearing controlEngineeringControl theory

A shift control device for a continuously variable transmission includes a downhill control module that executes downhill control in which a gear ratio of the continuously variable transmission is corrected to a low side during driving downhill, and a gear ratio holding module that, in the case where a braking operation is detected while downhill control is executed, the gear ratio of the continuously variable transmission is held at the gear ratio at the time when the braking operation is started.

Owner:SUBARU CORP

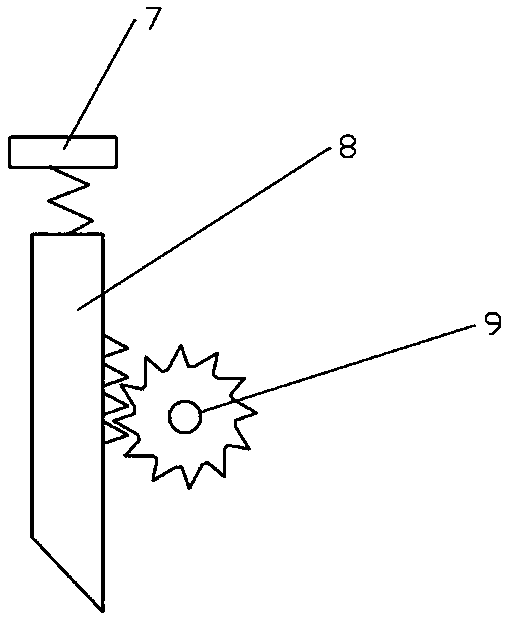

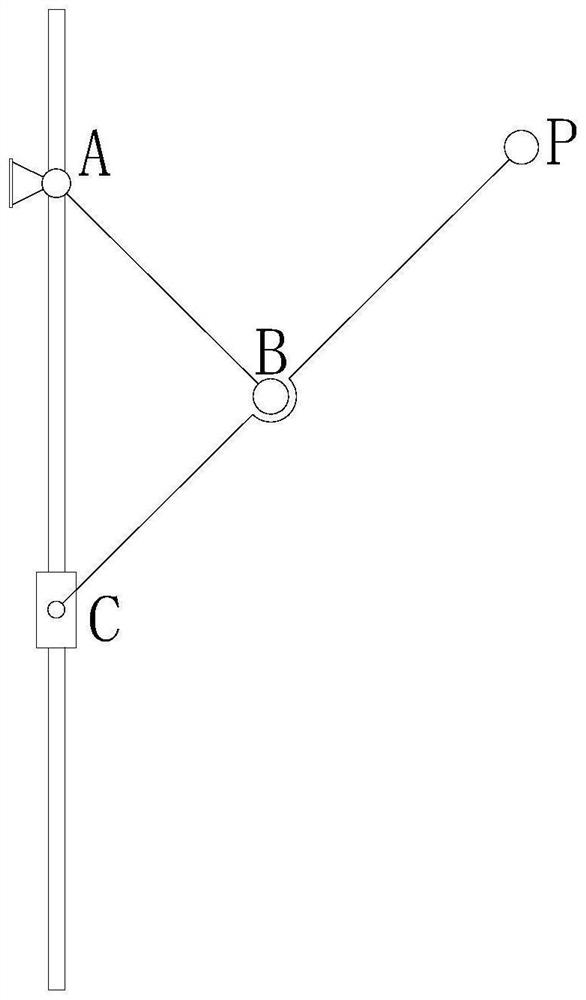

Intelligent automatic branches pruning device

InactiveCN107926332AImprove pruning efficiencyImprove versatilityCuttersMotor driven pruning sawsAgricultural engineeringPruning

The invention discloses an intelligent automatic branch pruning device, which is composed of a climbing mechanism, a pruning mechanism and a pressing mechanism, and is characterized in that a pruning mechanism is installed on the climbing mechanism, and a pressing mechanism is installed on the climbing mechanism . The advantage is that the intelligent automatic branch pruning device can replace manual branch pruning, which improves the efficiency of branch pruning and reduces the labor intensity of garden workers. Moreover, the device can realize the pruning of tree branches of different thicknesses. Different, the intelligent automatic branch pruning device can automatically adjust the internal spacing to meet the pruning work for trees of different thicknesses, avoiding the difficulty that the same branch pruning device cannot complete the job due to different tree thicknesses, improving the versatility of the branch pruning device, reducing pruning costs.

Owner:李洪龙

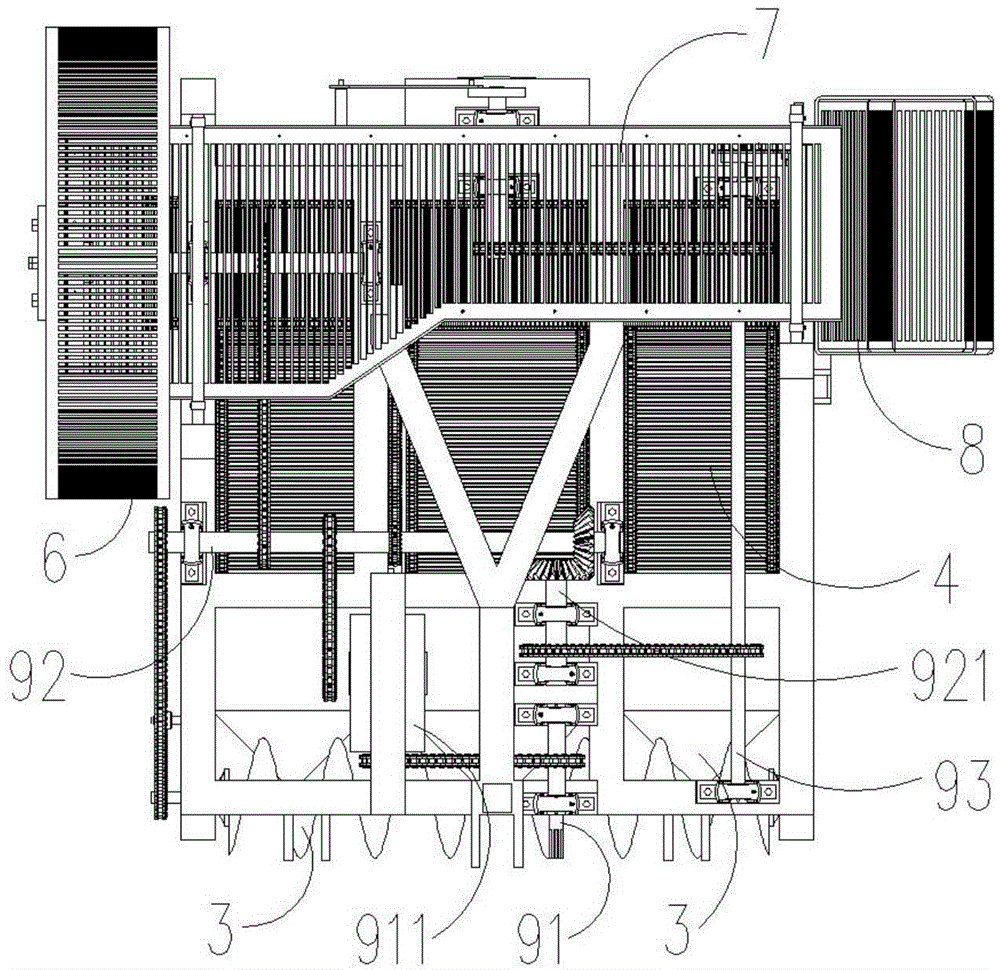

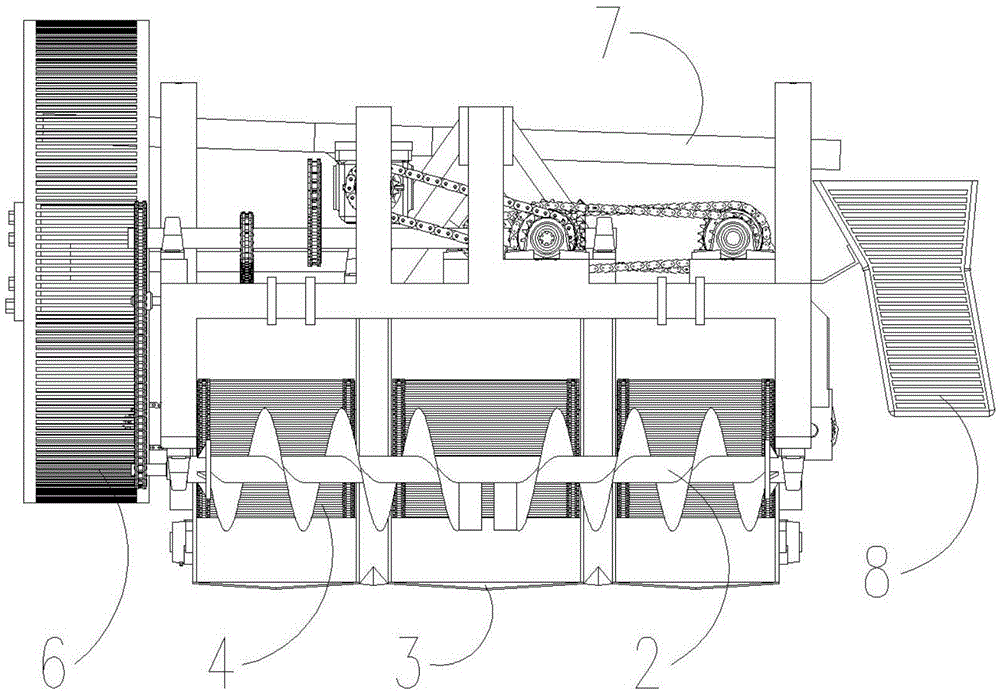

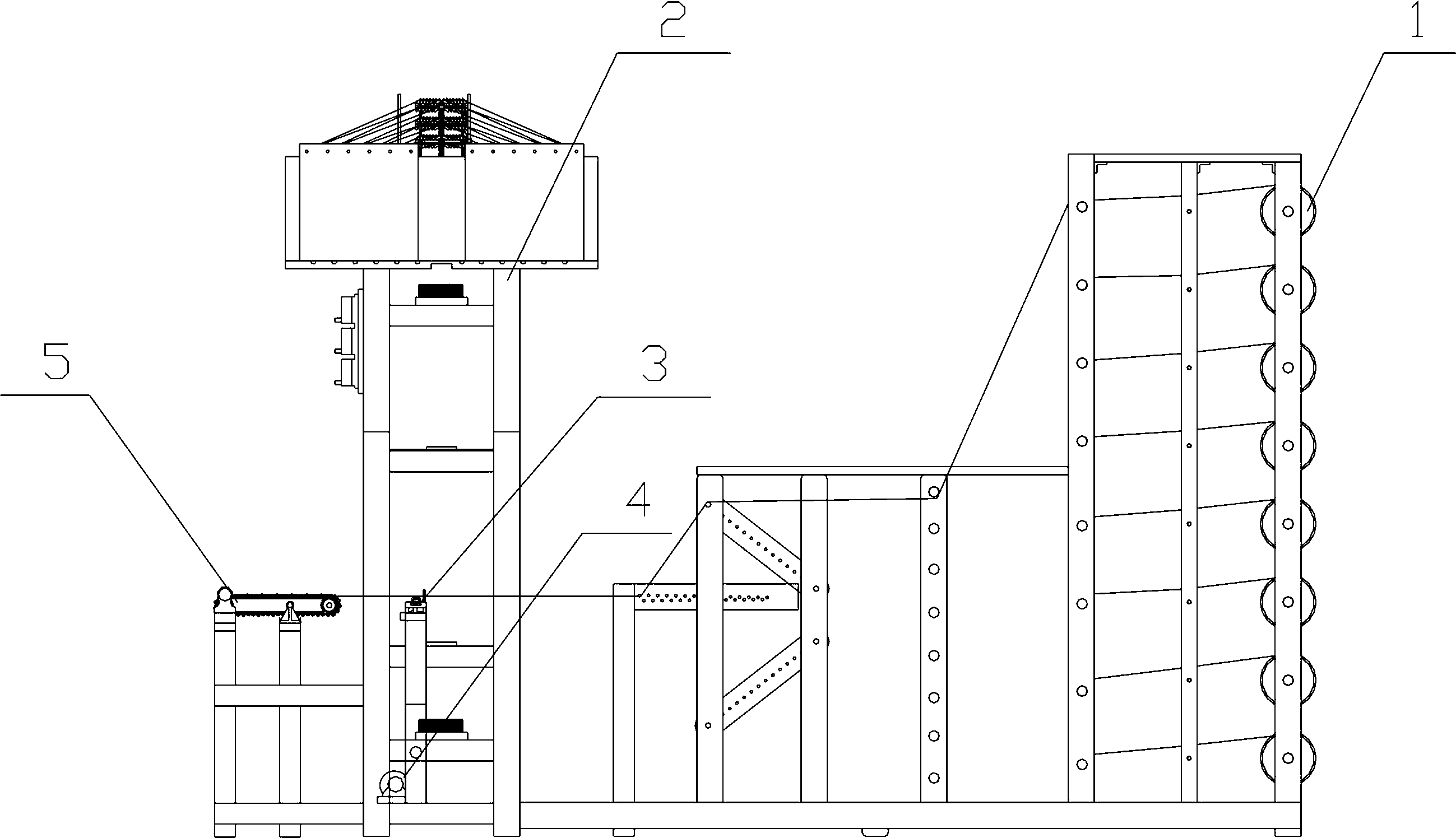

Chinese artichoke stalk-breaking harvester

InactiveCN105612903AAvoid congestionThe average gear ratio is accurateDiggersEngineeringPlant Tubers

A Chinese artichoke stalk-breaking harvester comprises a frame, a soil breaking tool, a penetrate-harvesting beveled spade, a primary stalk-soil conveying and separating device, a secondary stalk-soil transverse conveying and separating device, a drum-type tuber lift, a tertiary vibratory tuber screening device, a tuber collecting and boxing device and a transmission system; the soil breaking tool, the penetrate-harvesting beveled spade, the primary stalk-soil conveying and separating device, the secondary stalk-soil conveying and separating device, the drum-type tuber lift, the tertiary vibratory tuber screening device, the tuber collecting and boxing device and the transmission system are mounted on the frame, other devices are mounted according to a conveying process sequentially from front to rear, from top to bottom. The Chinese artichoke stalk-breaking harvester has the advantages that this harvester can perform operations at a time, such as stalk breaking and soil breaking, digging, conveying, separating, screening and collecting; the dig-out rate is high, the defective rate is low, and surface soil of planting land is never destructed; this harvester can run and operate stably at controllable rate without blockage problem; the multiple separations provide good separation effect.

Owner:NINGXIA UNIVERSITY

Automatic duck shell cutting device

The invention provides an automatic duck shell cutting device and belongs to the technical field of food processing. The technical scheme of the automatic duck shell cutting device is as follows: theutomatic duck shell cutting device comprises a cross beam arranged on a ceiling, the cross beam is provided with a driving mechanism, and the lower part of the driving mechanism is provided with a workbench and a control console, and both the workbench and the control console are provided with cutting mechanism. The automatic duck shell cutting device has the beneficial effects that manual operation cost is saved, a duck meat splashing phenomenon caused by manual cutting is avoided, the labor efficiency is high, the cutting quality is reliable, duck neck joints are free from injury, the problem that the duck neck joints are not uniform in length is solved, and the bone spur rate of duck necks is reduced.

Owner:东阿六和绿佳食品有限公司

Shift control device for continuously variable transmission

ActiveUS9429229B2Prevented from feelingThe average gear ratio is accurateDigital data processing detailsGearing controlEngineeringControl theory

A shift control device for a continuously variable transmission includes a downhill control module that executes downhill control in which a gear ratio of the continuously variable transmission is corrected to a low side during driving downhill, and a gear ratio holding module that, in the case where a braking operation is detected while downhill control is executed, the gear ratio of the continuously variable transmission is held at the gear ratio at the time when the braking operation is started.

Owner:SUBARU CORP

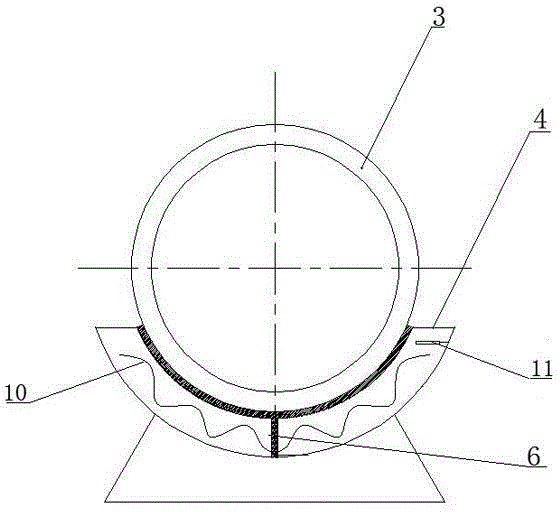

Test device for rotary valve pneumatic actuator

InactiveCN103411762BSimple structureHigh transmission powerMachine part testingMeasurement of fluid loss/gain rateControl systemClosed loop

The invention relates to a testing device for a rotary valve pneumatic actuator. The testing device for the rotary valve pneumatic actuator can respectively carry out no-load tests, load tests, seal tests, strength tests and action life tests on a single-action rotary valve pneumatic actuator and a double-action rotary valve pneumatic actuator, the device is overall a digitized closed-loop control system, the rotary valve pneumatic actuator which is long in service life and stable is tested, testing precision is high, stability is high, testing is convenient, detection speed is high, and the whole testing device is simple in structure and low in maintenance cost.

Owner:QUALITY INSPECTING CENT OF PUMP & VALVE PROD OF ZHEJIANG PROVINCE

Series connection non-crankshaft engine transmission mechanism and engine with series connection non-crankshaft engine transmission mechanism

The invention discloses a series connection non-crankshaft engine transmission mechanism which comprises a power shaft and an auxiliary shaft. At least two air cylinder piston rods are arranged between the power shaft and the auxiliary shaft. Air cylinder pistons are arranged at the end heads of the same ends of the air cylinder piston rods correspondingly. One side of each air cylinder piston rod is engaged with a main gear which is arranged on the power shaft in a sleeving manner through a one-way clutch. The combining directions of the one-way clutches are the same. The other side of each air cylinder piston rod is rotationally connected with the auxiliary shaft through a guiding mechanism. Every two adjacent two main gears are in transmission connection through a reverse transmission mechanism. When one air cylinder piston rod acts, the corresponding main gear rotates, and when the combining directions of the one-way clutches are the same, the main gears corresponding to the power shaft enable the power shaft to rotate to output power through the corresponding one-way clutches. Meanwhile, transmission and reversing of power needed by the stroke of the corresponding air cylinder piston rods are achieved by every adjacent two main gears through the corresponding reverse transmission mechanisms. The transmission mechanism belongs to a free piston type, and therefore a variable compression ratio function is achieved.

Owner:朱晓明

Intelligent full-hydraulic power catwalk

InactiveCN102787813BReduce labor intensityThe average gear ratio is accurateDrilling rodsDrilling casingsRock coreEngineering

The invention discloses an intelligent full-hydraulic power catwalk which comprises a supporting arm, a lifting leg, a pulley, a drill rod positioning mechanism, a plurality of active outriggers, a twisting machine, a twisting machine sliding rail, a control box, a ramp, outriggers, an overturning plate, a foundation support, a waterpower decoring device and a hydraulic station. The ramp is connected with the foundation support via a bolt, the twisting machine and the twisting machine sliding rail are mounted on one side of the foundation support, the waterpower decoring device is mounted on the twisting machine, the drill rod positioning mechanism and the overturning plate are arranged on the foundation support, the pulley is arranged on the supporting arm, the active outriggers are arranged on two sides of the foundation support, the hydraulic station supplies power to a system, and operation of the system is control by the control box. By the aid of the intelligent full-hydraulic power catwalk, processes including joint and throw rod connecting, hole bottom power connecting and disconnecting and water power rock coring can be integrated, twisting and water power decoring can be automatically finished without removal of a drill rod, technical requirements for drilling deep well coring are met, construction fields are greatly reduced, labor intensity is lowered, and working efficiency of a drilling system is improved. Since the power catwalk is fully hydraulically controlled, stepless speed change can be realized, transmission mechanism is simplified, and adaptability and reliability of the power catwalk are improved.

Owner:JILIN UNIV

Linkage type pumping system and engine thereof

InactiveCN105386869ASimple structureImprove reliabilityMachines/enginesPressure lubrication with lubrication pumpEngine powerLinkage concept

The invention discloses a linkage type pumping system. The linkage type pumping system comprises an oil pump and a water pump driven by an engine. The oil pump comprises an oil pump rotor. The water pump comprises a water pump rotor. The oil pump rotor and the water pump rotor are matched in a linkage mode. The linkage type pumping system only needs one transmission mechanism to drive the oil pump and the water pump to rotate together, therefore the structure compactness of the engine is improved, power loss of the engine is reduced, and the output power of the engine is effectively improved.

Owner:CHONGQING LONCIN ENGINE

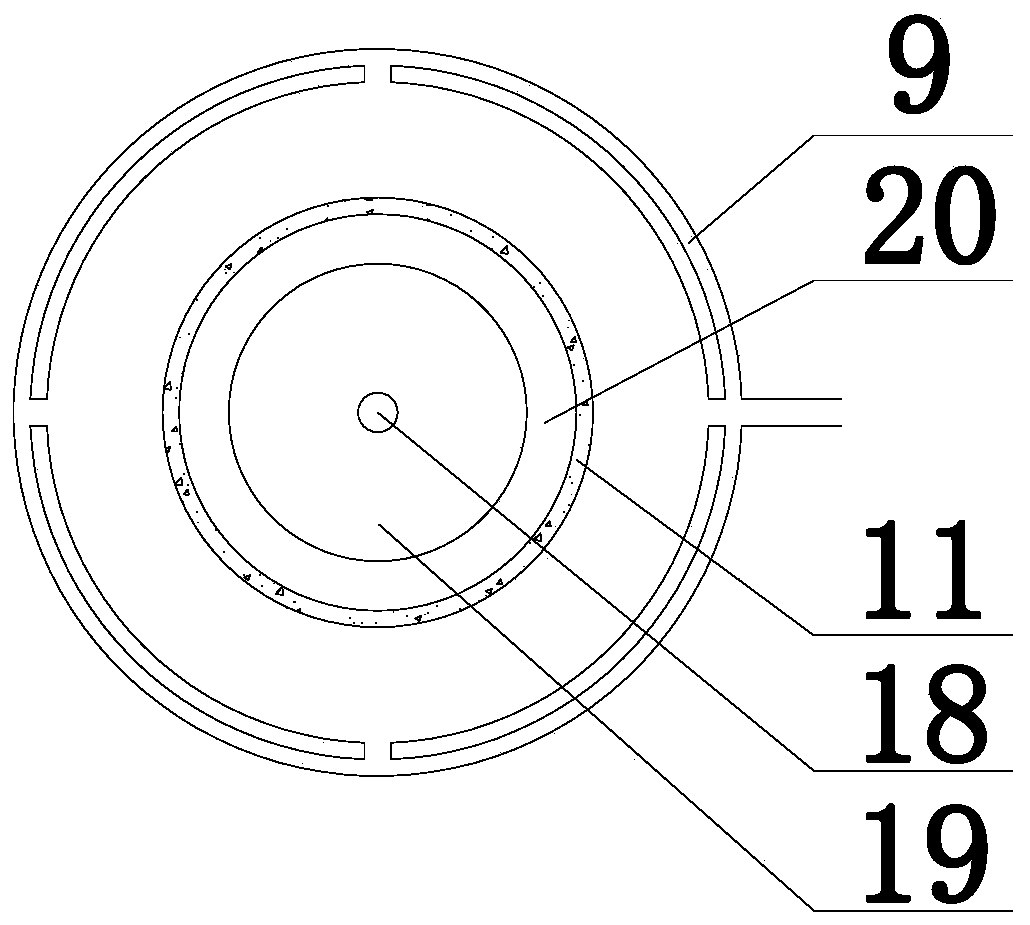

Lighting equipment with monitoring function for rotating machine under radiation environment

InactiveCN109442294ABarrier deliveryWon't burnLighting support devicesLighting elementsLight equipmentPunching

The invention discloses lighting equipment with a monitoring function for a rotating machine under a radiation environment. The lighting equipment comprises a substrate, driven gears and an outer shell. First hydraulic rods are installed on the substrate. The first hydraulic rods and extending blocks are formed in a punching manner. The left side of each drive gear is provided with a handle, the right side of each driven gear is connected with a rotating shaft. The surface of the left end of each thermal baffle is fixedly provided with a screw. The rear part of the outer shell is fixedly provided with a back plate. A liquid storage tank is internally provided with a water inlet pipe. According to the lighting equipment with the monitoring function for the rotating machine under the radiation environment, by means of the first hydraulic rods, the outer shell, the thermal baffles and a light emitting diode, the first hydraulic rods extend and retract to drive the outer shell to adjust the position in the vertical direction, and therefore the equipment is driven to ascend or descend; and after the outer shell descends, the interior of the outer shell can be washed, or parts in the outer shell can be maintained or changed, and steps needed for washing, maintaining or changing the equipment are simplified.

Owner:DONGGUAN UNIV OF TECH

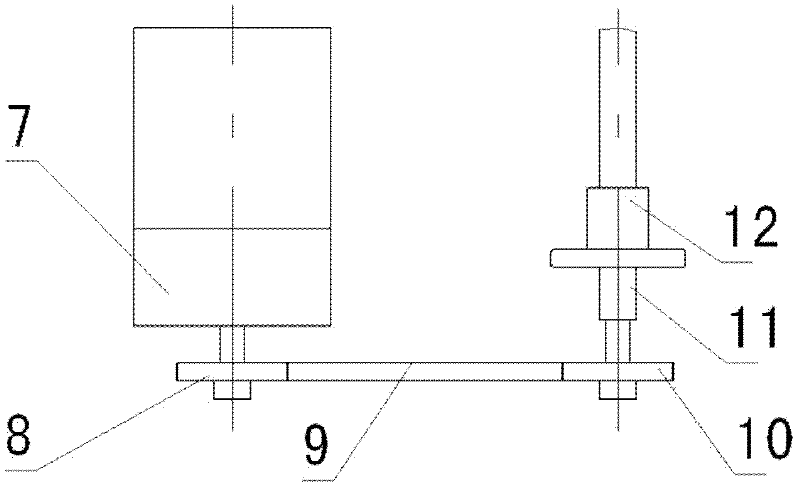

Linkage type compact optical window protection cover

ActiveCN102565985AThe average gear ratio is accurateHigh transmission efficiencyMountingsSynchronismAgricultural engineering

The invention relates to the field of aerial cameras, in particular to a linkage type compact optical window protection cover in the aerial camera. A protection cover mechanism mainly comprises a guide shaft, a transmission device, a ball screw, a single-side straight-line bearing, a double-side straight-line bearing and a connecting plate. The linkage type compact optical window protection cover has the technical schemes that the ball screw is driven to rotate by a chain wheel, and the rotary movement is converted into straight-line movement by a screw; a plurality of the optical window protection covers are connected by the dustproof and self-lubricating single-side straight-line bearing and the dustproof and self-lubricating double-side straight-line bearing, thereby realizing the linkage of the protection covers. The linkage type compact optical window protection cover has the advantages that due to the chain transmission design, the average transmission ratio is accurate, the transmission efficiency is high, the structural size is more compact, and the linkage type compact optical window protection cover is suitable for a high-altitude low-temperature environment; with the adoption of the chain-transmission and self-lubricating straight-line bearings, the synchronism of the movement of the protection covers is realized, and the reliability of the movement of the mechanism is enhanced; the design of the optical window protection cover is realized in a limited size range, and the safety of the optical window protection cover is ensured. The linkage type compact optical window protection cover has the greatest characteristics of compact structure, flexibility in use, safety and reliability.

Owner:YUSENSE INFORMATION TECH & EQUIP QINGDAO INC

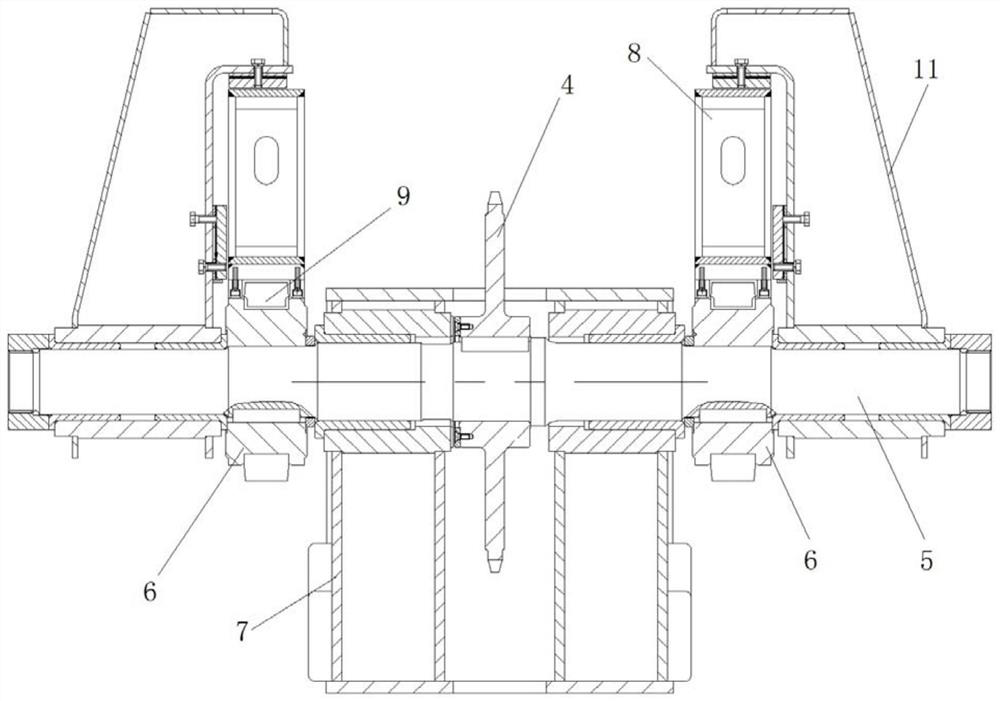

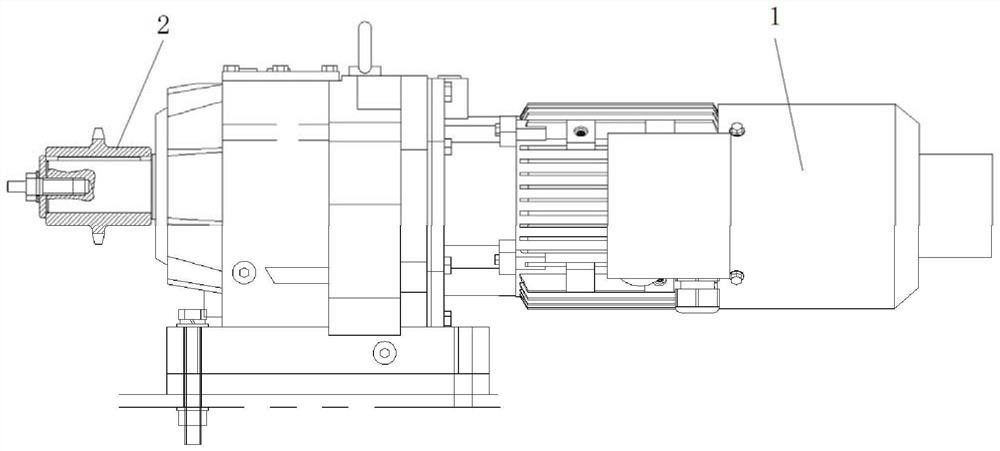

Mining excavator pushing and pressing device and mining excavator

ActiveCN112627260AReduce tensionSmall sizeMechanical machines/dredgersFriction gearingsGear wheelElectric machinery

The invention discloses a mining excavator pushing and pressing device and a mining excavator. The pushing and pressing device comprises a coaxial gear motor, a first chain wheel, a chain, a second chain wheel, a pushing and pressing shaft and a pushing and pressing gear, wherein the coaxial gear motor is fixedly installed on the mining excavator, the first chain wheel is installed at the output end of the coaxial gear motor and is in transmission connection with the second chain wheel through the chain, the second chain wheel is installed on the pushing and pressing shaft, the pushing and pressing shaft is installed on a cargo boom of the mining excavator, the pushing and pressing gear is installed on the pushing and pressing shaft, and the pushing and pressing gear meshes with a rack on a bucket rod of the mining excavator. According to the mining excavator pushing and pressing device and the mining excavator, by arranging the coaxial gear motor, the structure can be simplified, and the occupied space can be reduced, meanwhile, a chain transmission mode is adopted, higher buffering and vibration reduction performance and transmission efficiency are achieved, the average transmission ratio is accurate, the structure size is more compact, the occupied space is small, and maintenance is convenient.

Owner:TAIYUAN HEAVY IND

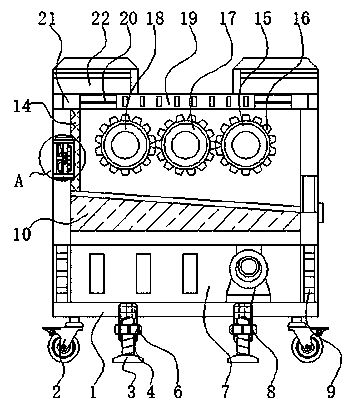

Three-roller grinding machine with cooling system for removing peculiar smell function of chemical industry

InactiveCN109365045AImprove stabilityPlace stableGrain treatmentsChemical industryElectric machinery

The invention discloses a three-roller grinding machine with a cooling system for removing peculiar smell function of chemical industry, relates to the technical field of material grinding and processing equipment, in particular to a three-roller grinding machine with a cooling system for removing peculiar smell function of the chemical industry. The three-roller grinding machine with the coolingsystem for removing the peculiar smell function comprises a shell, a bottom plate and a blocking block, wherein the bottom plate is arranged in the center of the inner part of the shell, the blockingblock is located at the top end of the shell, a universal wheel is connected below the shell, a fixing block is arranged above a rotating shaft, and a motor chamber is arranged at the bottom end of the interior of the shell. According to the three-roller grinding machine with the cooling system for removing peculiar smell function of the chemical industry, the ground raw materials fall on the bottom plate under the action of gravity, then the ground raw materials pass through the inclined bottom plate, so that the raw material slides to the right end of the bottom plate, then a baffle is rotated through hinges, so that the ground raw materials can be taken out, the structure is simple, and the ground raw materials can be taken out without a complicated structure.

Owner:谭崴

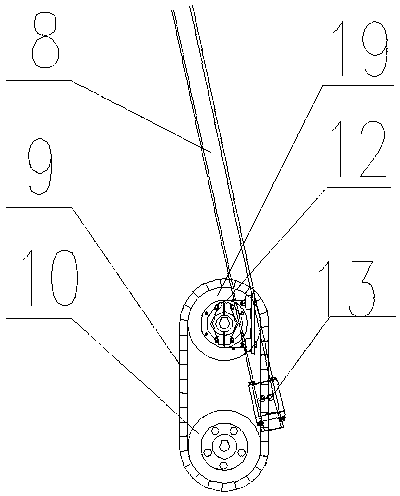

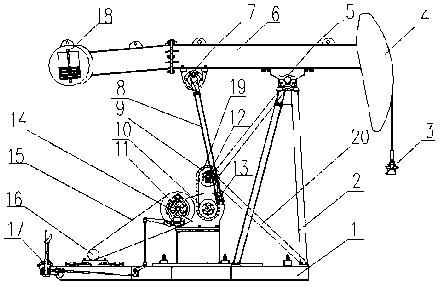

Chain driving reversing device and method of beam-pumping unit

InactiveCN102996747AReduce shockGood balance of movementGearingFluid removalGear wheelControl engineering

The invention relates to a chain driving reversing device and method of a beam-pumping unit. The technical scheme is that a main transmission gear is installed on an output shaft of a reducer box, and a driven gear is installed right above the driving gear through a driven gear shaft, a driven gear bearing base and a driven gear fixing support, wherein the driven gear bearing base is installed right in the middle of the driven gear shaft, a part of the driven gear fixing support is fixed on a support, another part of the driven gear fixing support is fixed on a base, the main driving gear is connected with the driven gear through a transmission chain, special chain links are arranged on the transmission chain, and a special chain link is connected with a connection rod through a fixing bolt on the special chain link fixing device. The chain driving reversing device and method has the advantages that compared with the beam-pumping unit of the same type with the beam-pumping unit of an installation chain transmission reversing device, the loading effect is reduced, the energy saving effect is remarkable, the transmission ratio of the chain transmission reversing device is larger than 1 and can reach as high as 4-7, and compared with a conventional beam-pumping unit, low frequency of stroke can be achieved easily.

Owner:孙继辉 +1

Chain drive screening pulverizer

InactiveCN104525334AReduced coplanarity requirementsIncrease the gapGrain treatmentsReduction driveGear wheel

The invention relates to a chain drive screening pulverizer, which comprises a cylinder, a feeding mechanism, a discharging mechanism, a hollow shaft, a hollow shaft supporting mechanism and a transmission mechanism, wherein the supporting mechanism comprises a static pressure main bearing and a high and low-pressure lubrication station, and the transmission mechanism comprises a motor, a speed reducer and a cranked link chain; the output end of the motor is connected with the input end of the speed reducer through a hydraulic coupling, and one end of the cranked link chain is connected with the output end of the speed reducer; the other end of the cranked link chain is connected with the cylinder, and the motor drives the cylinder to rotate through the cranked link chain. The chain drive screening pulverizer provided by the invention adopts chain drive, and the chain drive is meshed drive with an intermediate flexible part, and has the characteristics of belt drive and gear drive; the chain drive does not need a large initial pull force, so the pressure on a shaft is small; the chain drive can realize large-center-distance drive like the belt drive, and is much lighter than the gear drive.

Owner:洛阳宇航重工科技股份有限公司

Screening device for wood strips

The invention discloses a screening device for wood strips, and belongs to the field of wood processing. The screening device comprises a machine frame, a material storage box and a track, wherein thematerial storage box comprises a material inlet formed in the upper part of the material storage box and a material outlet formed in the bottom part of the material storage box; the track is arrangedbelow the material storage box; a pressing plate and a cutting machine are further connected to the machine frame, and a material collecting box is further arranged below the cutting machine; and a feeding pipe further communicates with the material collecting box, and a spiral rod is arranged in the feeding pipe. According to the screening device, the length of the strips can be screened and processed before the wood strips enter a plate splicing process, so that the strips with different lengths are prevented from entering a plate splicing machine.

Owner:重庆市长寿区美全家具有限公司

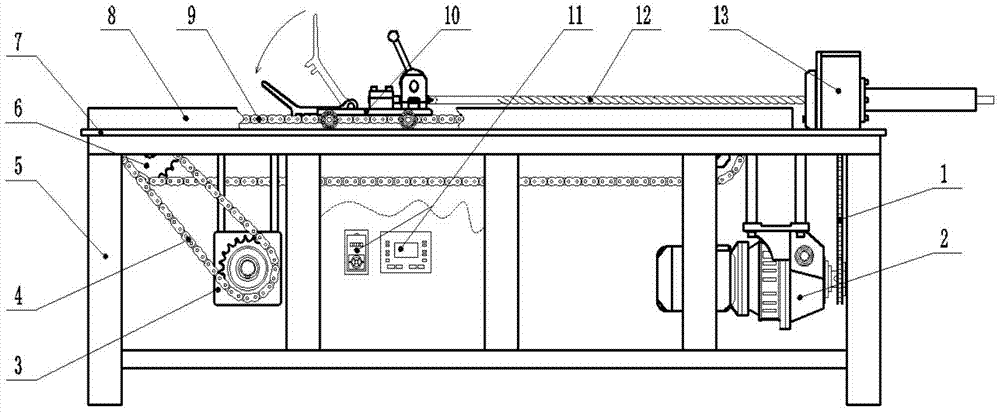

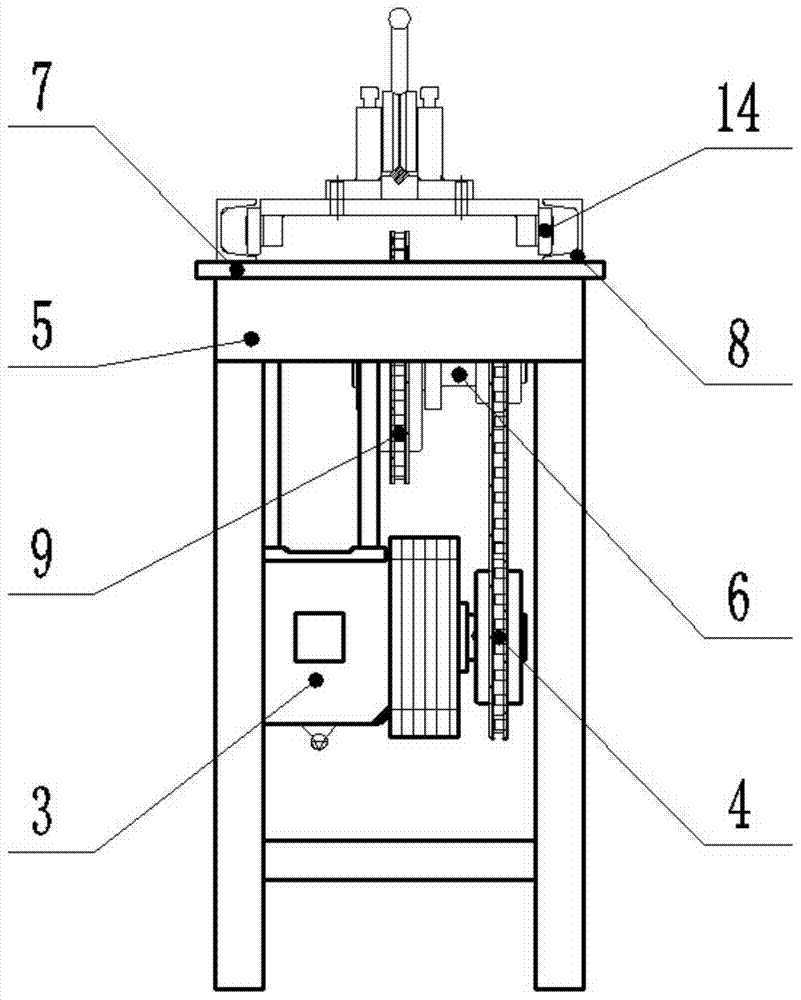

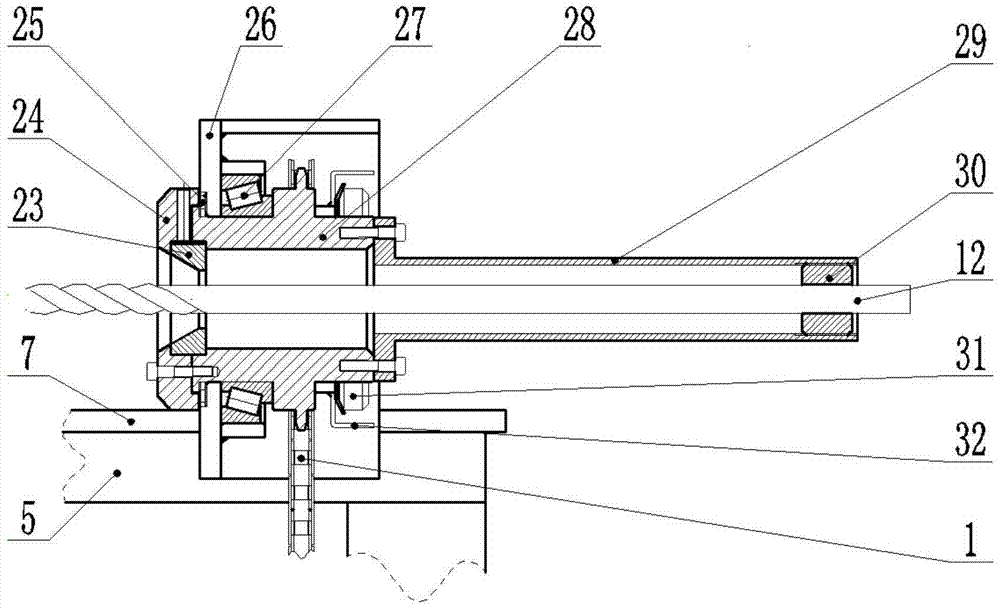

A tube drawing machine

The invention relates to a pipe-pulling pattern-twisting machine. The pipe-pulling pattern-twisting machine comprises a platform frame, a platform frame panel, two sets of transmission chains, a traction mechanism, a pattern-twisting mechanism, a driving motor and a control panel. The traction mechanism and the pattern-twisting mechanism are located on the platform frame panel. The driving motor is installed inside the platform frame. One set of motor chain power device is responsible for twisting patterns, and the other set of motor chain power device is responsible for pulling pipes. Manufacturing of the patterns is completed through optimized procedures. The procedures are controlled to be ungraded, the machine can be made to operate well and stably, and all kinds of patterns can be manufactured. Pattern-twisting machining of various kinds of blank pipes can be achieved through one set of the device, multiple sets of molds do not need to be prepared, the application amount of mold materials is decreased, and the working efficiency is improved.

Owner:陈立佳

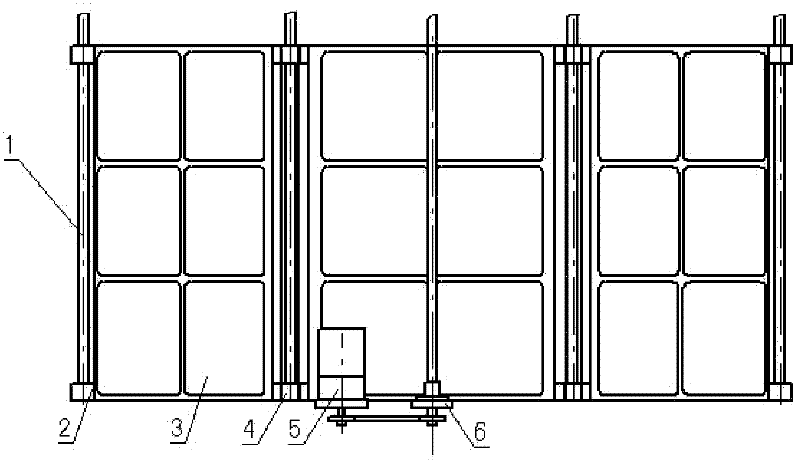

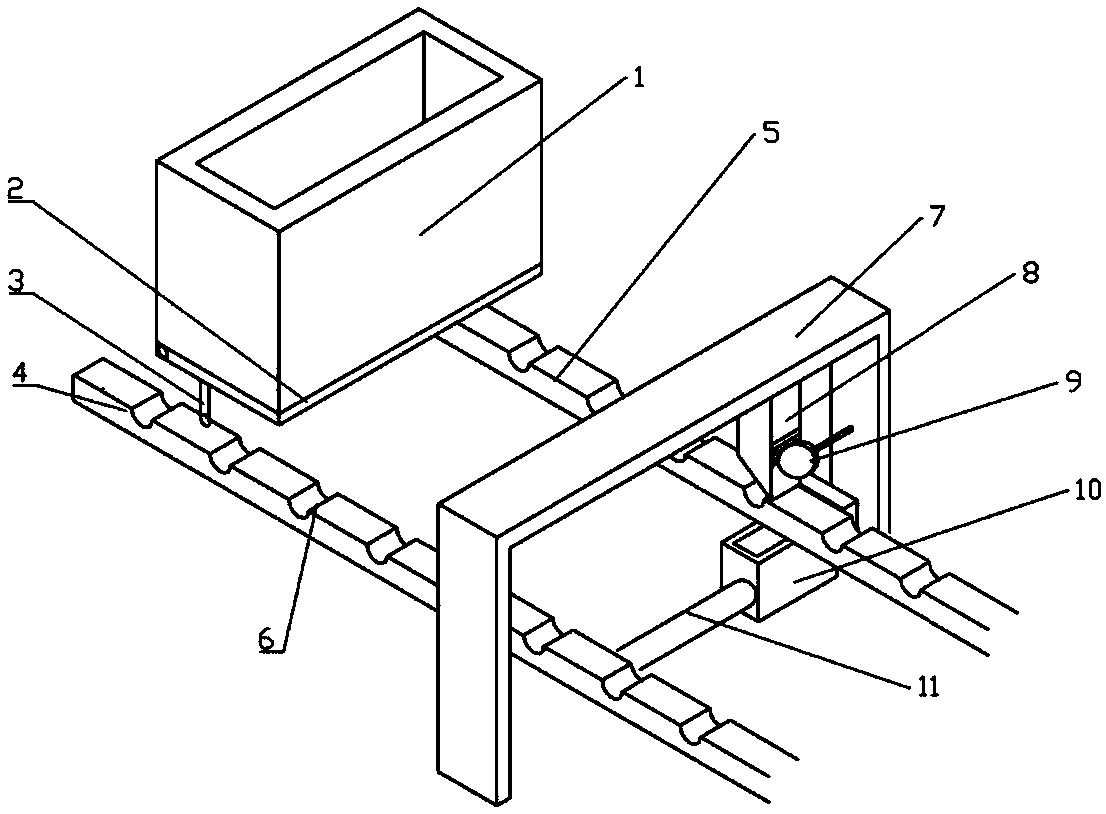

Full-automatic stretching machine

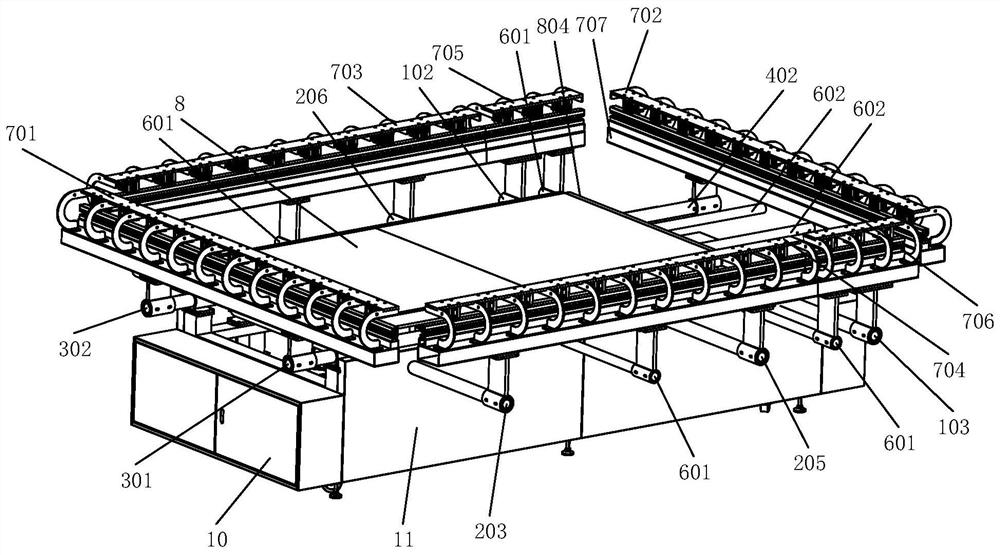

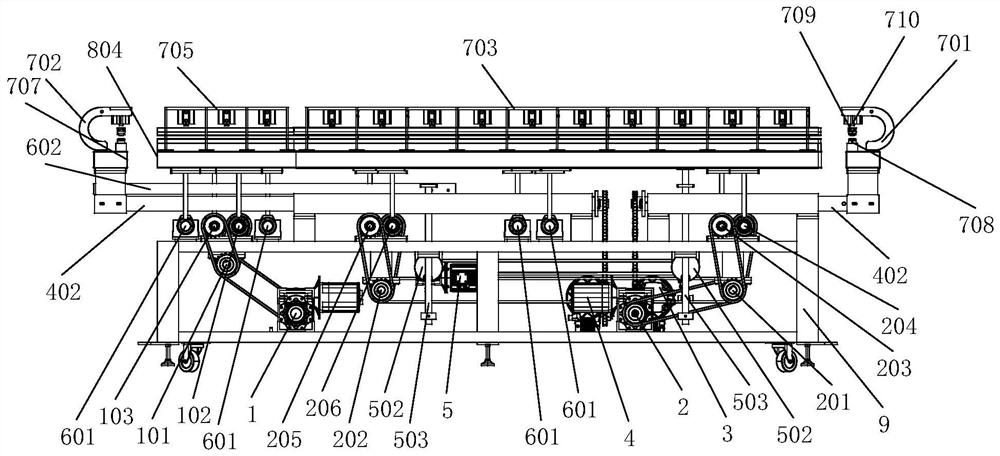

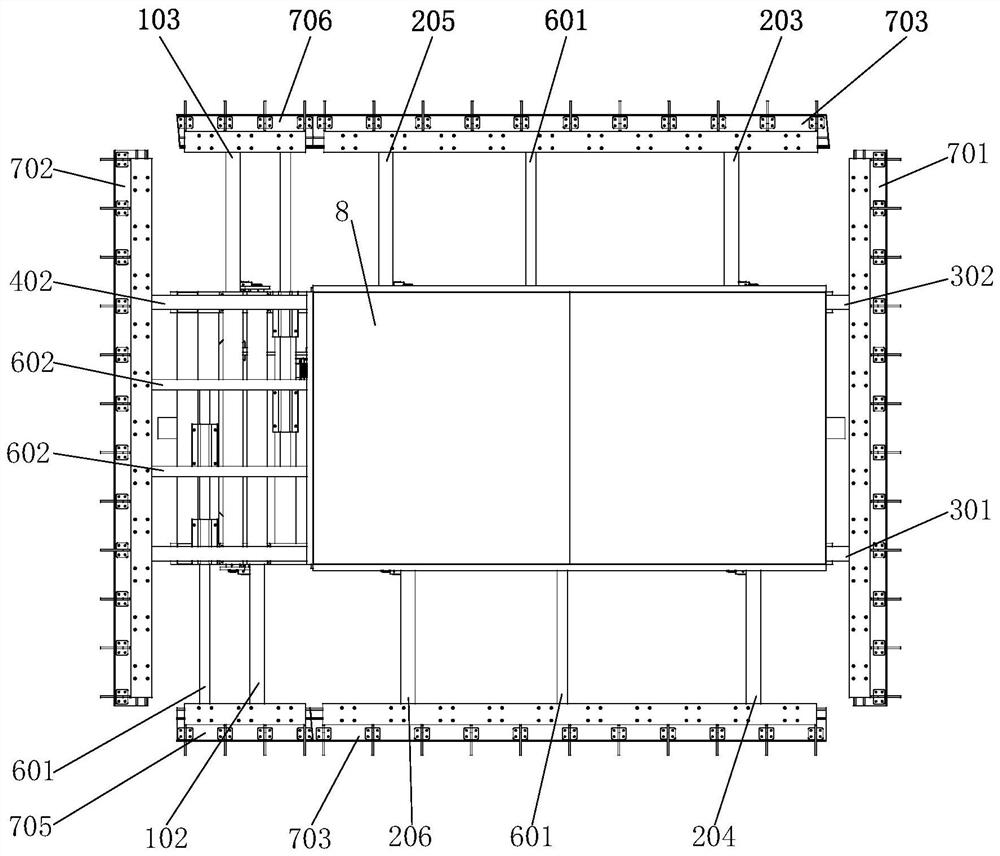

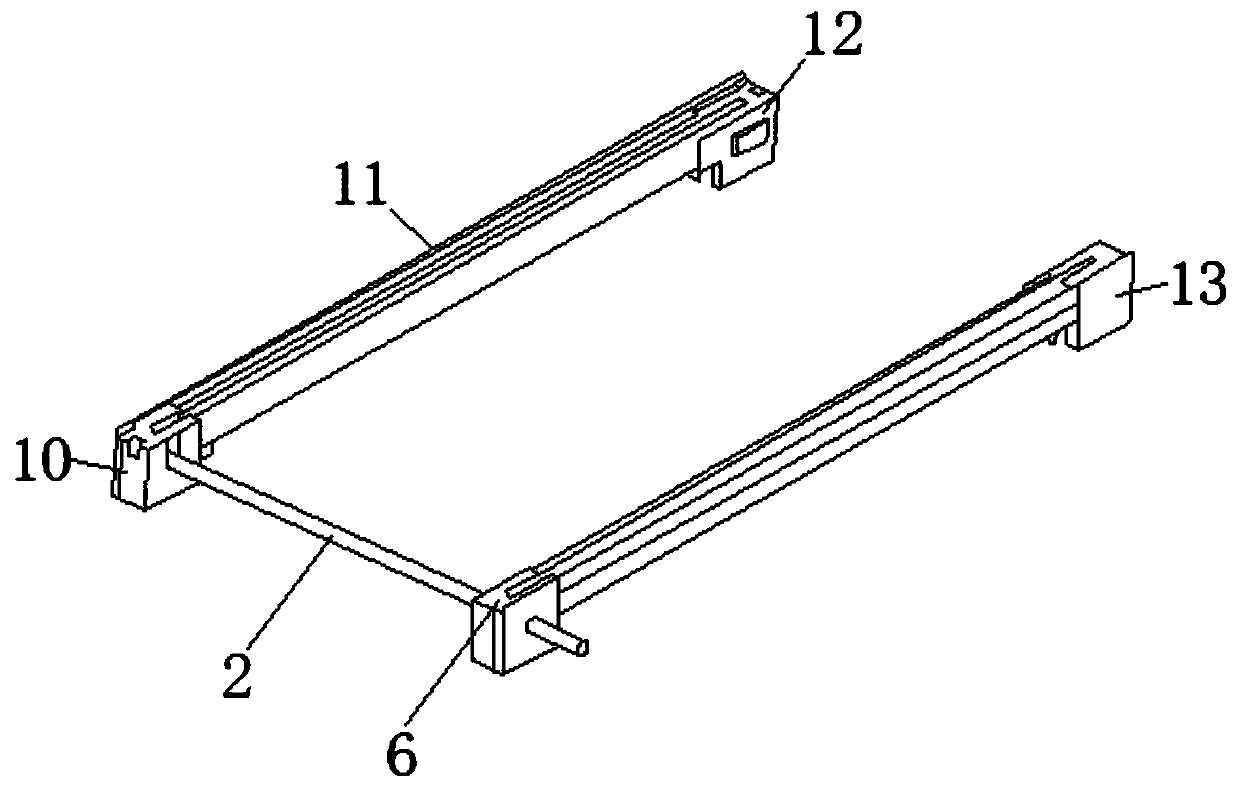

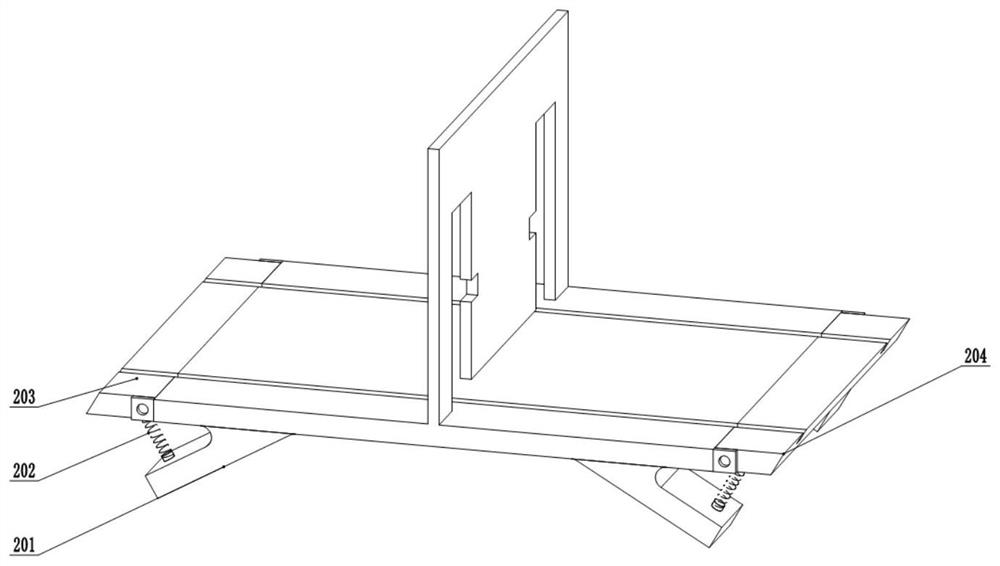

PendingCN113510994AThe average gear ratio is accurateLow costForme preparationDrive shaftControl engineering

The invention discloses a full-automatic stretching machine. The full-automatic stretching machine comprises a first clamping device, a second clamping device, a third clamping device and a fourth clamping device; a third driving shaft and a third driving shaft driven rod can jointly control the first clamping device to be far away from or close to one short edge of a bottom rack, and a fourth driving shaft and a fourth driving shaft driven rod can jointly control the second clamping device to be far away from or close to the other short edge of the bottom rack; and a second driving shaft second driven rod and a second driving shaft fourth driven rod can jointly control the fourth clamping device to be far away from or close to one long side of the bottom rack, and a second driving shaft third driven rod and a second driving shaft fifth driven rod can jointly control the third clamping device to be far away from or close to the other long edge of the bottom rack. According to the full-automatic stretching machine, automatic adjustment of tensioning devices at four sides can be completed through chain transmission, chain transmission is suitable for long-distance transmission, and the cost is low while the accurate average transmission ratio is kept.

Owner:英辉(大厂)自动化技术有限公司

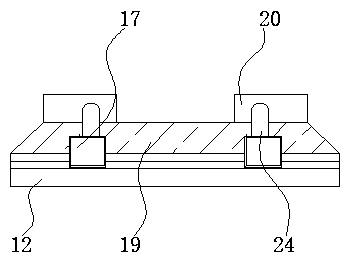

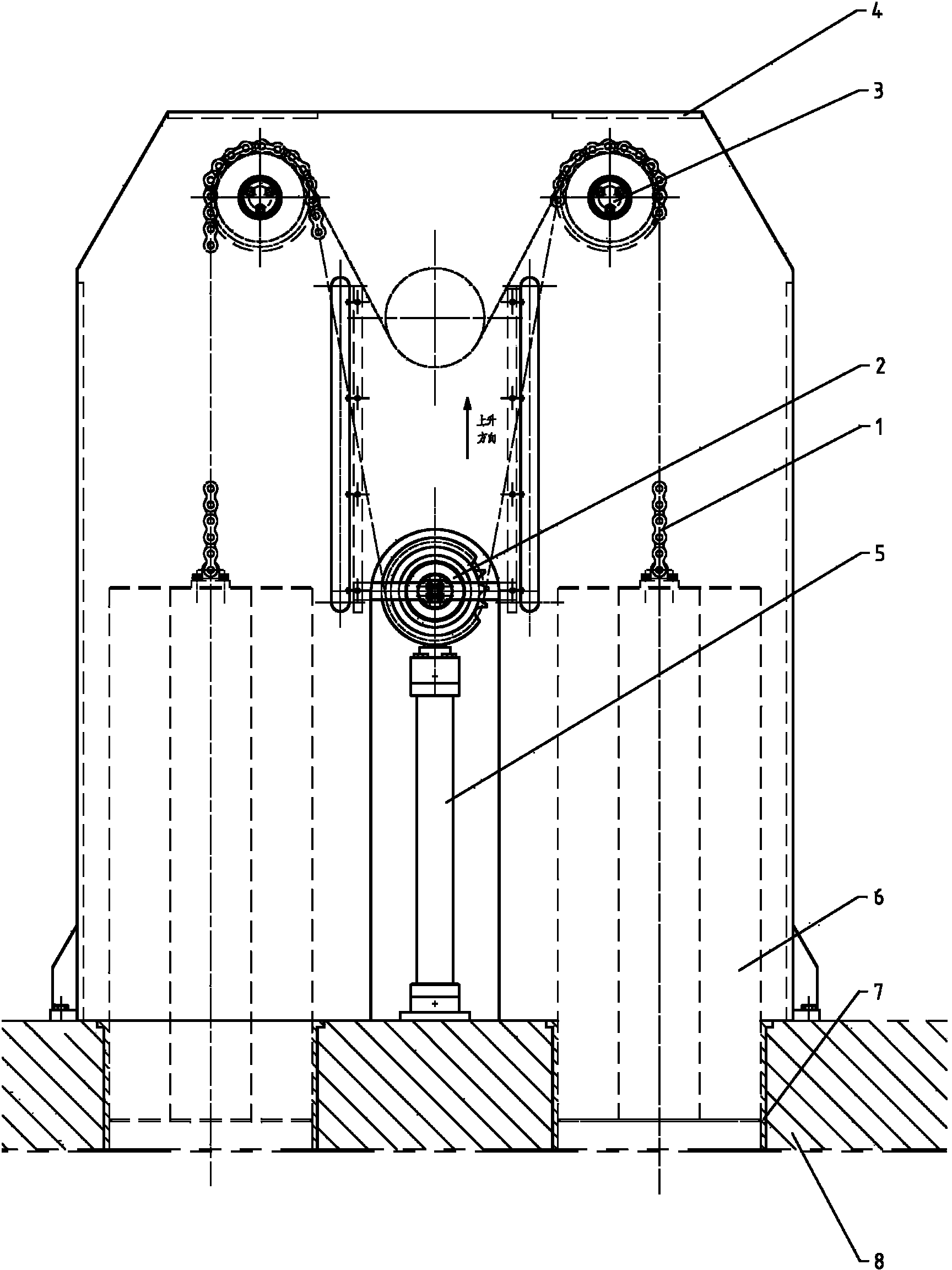

Stretcher leveler chain drive lifting pin mechanism with guiding

ActiveCN103028633BImprove work efficiencyThe average gear ratio is accurateHydraulic cylinderSlide plate

The invention discloses a stretcher leveler chain drive lifting pin mechanism with guiding. The stretcher leveler chain drive lifting pin mechanism with the guiding comprises a hanging bracket, a bolt cylinder, compression columns, a crosshead, lifting pins, two roller chains, two fixed chain wheels, two moving chain wheels, a chain wheel guide rail, copper sliding plates and hanging bracket guide rails, wherein the two fixed chain wheels are respectively and fixedly arranged at both sides of the crosshead; the two moving chain wheels are arranged on the hanging bracket above the fixed chain wheels through a chain wheel shaft; one ends of the two roller chains are respectively and fixedly arranged on the two fixed chain wheels; the other ends of two the roller chains respectively bypass the moving chain wheels to be respectively connected onto the lifting pins; the chain wheel guide rails are respectively and fixedly arranged at the outer sides of the fixed chain wheels; the hanging bracket guide rails are respectively arranged on pillars of the hanging bracket; the copper sliding plates are arranged on surfaces of the hanging bracket guide rails; and the chain wheel guide rails are respectively abutted with the copper sliding plates on the surfaces of the hanging bracket guide rails. The stretcher leveler chain drive lifting pin mechanism with the guiding has the beneficial effects that elastic sliding or slipping does not occur during chain drive, so that the average drive ratio is stable and accurate, and the synchronism and the work efficiency of the movement of every lifting pin can be improved; the deflection of a piston rod is avoided; the service life of the hydraulic cylinder is prolonged; and chain drive tension is low, so that pressure acting on the chain wheel shaft is also low.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

Novel transmission mechanism for triple speed chain

The invention belongs to the technical field of speed chain assembly line transmission, and particularly relates to a novel transmission mechanism for a triple speed chain. The novel transmission mechanism comprises an inner side plate, a guiding transition wheel and an outer side plate, a tensioning guiding block is arranged on the surface of the front end of the inner side plate, a protection plate is arranged on the left side of the guiding transition wheel, a chain guiding block is mounted in front of the outer side plate, a transmission chain wheel is arranged on the surface of the back of the inner side plate, a fixing plate is arranged on the right side of the tensioning guiding block, a guiding track is connected to the right side of the fixing plate, and a first mounting plate isarranged on the right side of a second mounting plate. According to the novel transmission mechanism for the triple speed chain, the inner side plate and the outer side plate provide protection for aninternal transmission chain, the situation that an external medium is clamped in the transmission chain, consequently, normal operation of the transmission chain is affected, and normal work of a whole assembly line is affected is prevented, stability of the mechanism is improved, the protection plate protects the conveyed chain against manual accidental injure during moving, and safety of the mechanism is improved.

Owner:深圳市奥图机电设备有限公司

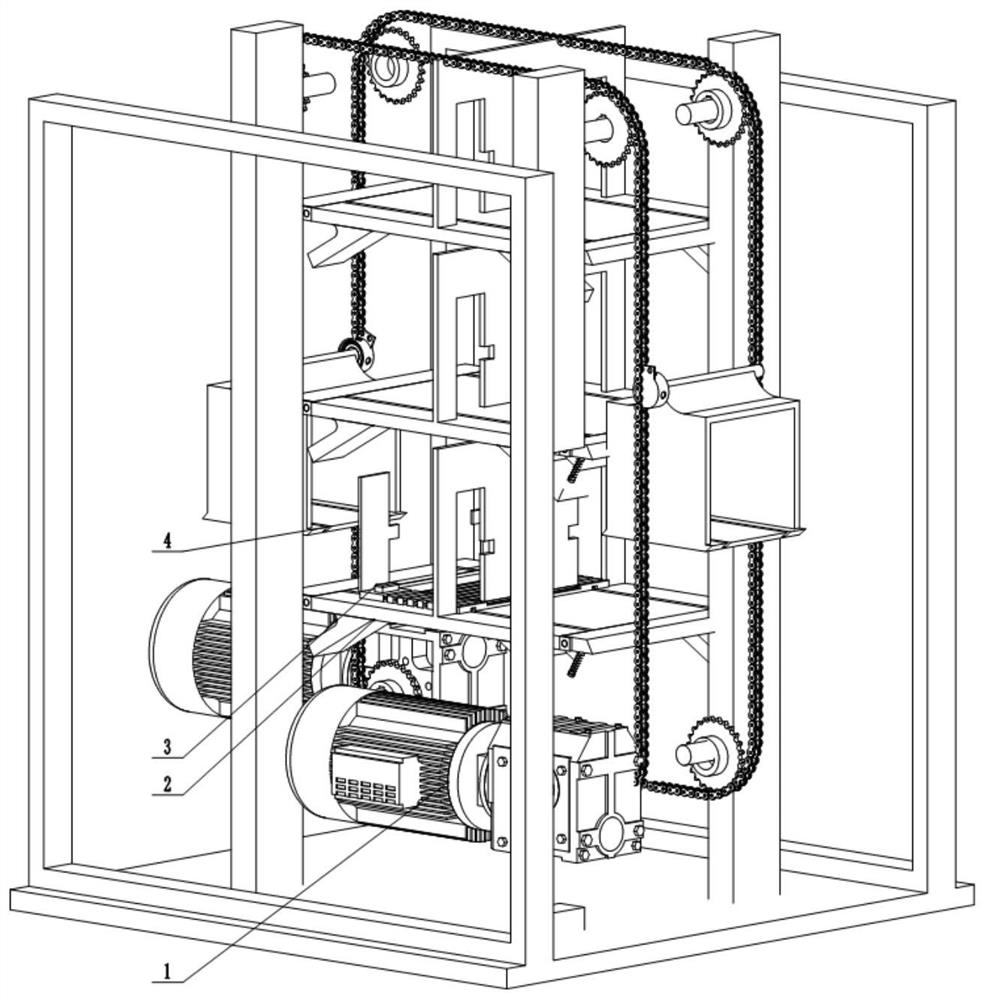

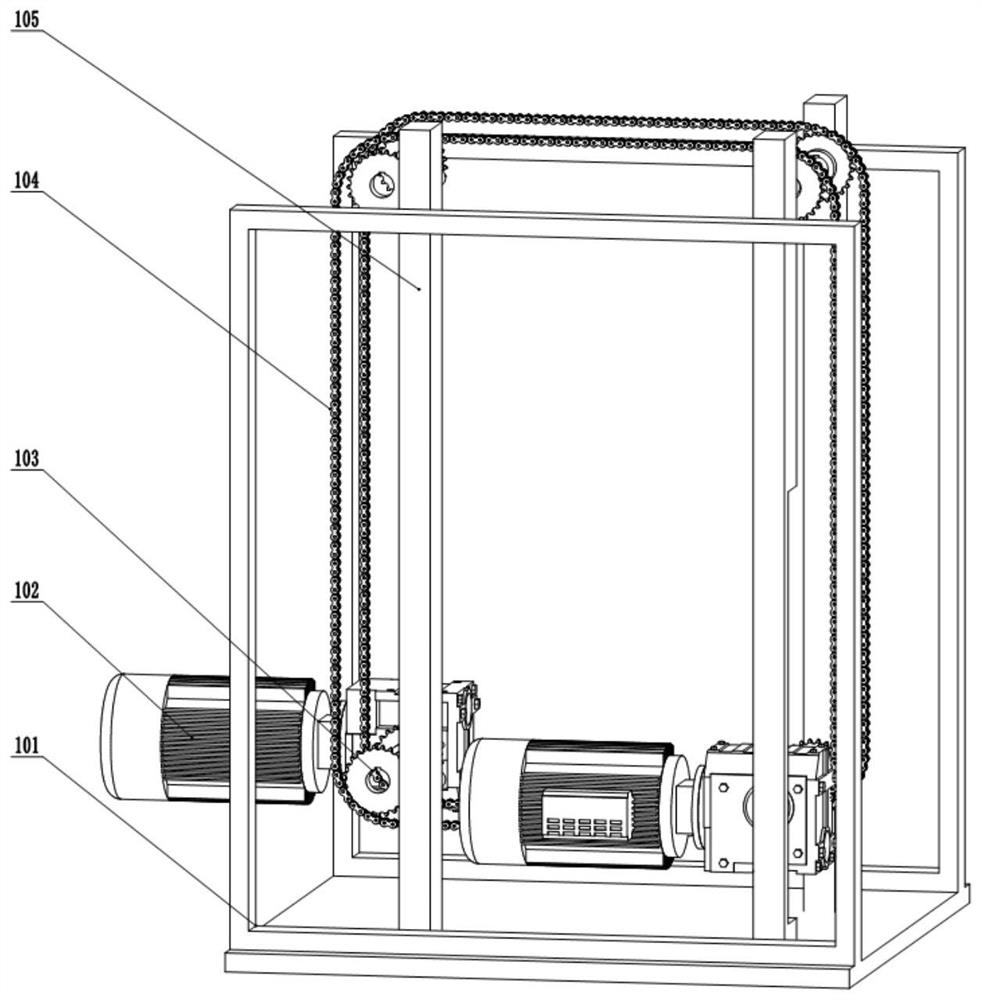

A chain type recyclable stacking device

ActiveCN112678387BReasonable designThe average gear ratio is accurateLifting framesStorage devicesControl engineeringChain type

The invention discloses a chain-type circular stacking device, which comprises a chain driving device, an object-carrying device, an object-carrying flexible trolley device, and an object-carrying car device. The beneficial effects of the present invention are: using the chain drive, the average transmission ratio is accurate, the work is reliable, the efficiency is high, the transmission power is large, and the load capacity is strong; the use of the chain drive device to cooperate with the transport device can realize the cycle of uninterrupted storage of goods, such as It can realize the separation of the load-carrying engineering vehicle and the lifting car, and connect with the loading platform through the connecting track to complete the cargo transportation action of the load-carrying engineering vehicle; the uninterrupted warehouse storage improves work efficiency, and the operation is simple, reducing the number of people operating on the post, creating Higher efficiency; the flexible trolley passes through the track, reducing unnecessary rigid impact; most of the parts are common parts, which are easy to replace and match after damage, so the service life is longer.

Owner:HIT SMART FACTORY CO LTD

Multi-column back sealing powder packaging machine discharging mechanism

The invention discloses a multi-column back sealing powder packaging machine discharging mechanism. The discharging mechanism comprises a discharging mechanism body connected with a feeding port through a vacuum machine flange, wherein a first guide rail and a second guide rail which can slide up and down are mounted on the two sides of the discharging mechanism body, and two guide columns are arranged in the first guide rail and the second guide rail; the first guide rail is connected with a horizontally-arranged first slide rail through a first connecting plate, the second guide rail is connected with a second slide rail through a second connecting plate, powder head wire groove plates are arranged on the first guide rail and the second guide rail, a tuning fork is arranged on one side of the feeding port, and an exhaust pipe is arranged on the other side of the feeding port; a first right-angle hollow motor, a second right-angle hollow motor and a plurality of servo motors are arranged on the discharging mechanism body, the servo motors are connected with a servo reducer, and the lower portion of the discharging mechanism body is connected with an outlet connector. According to the mechanism, packaging mechanization can be achieved in the operation process, full-automatic production can be achieved, the discharging quantity can be metered according to the number of turns of rotation of a screw arranged internally, and meanwhile the mechanism has the advantages of being convenient to disassemble and easy to clean.

Owner:广州和易包装设备有限公司

Moving device of yarn pushing mechanism and adjusting method

ActiveCN114855350AImprove reliabilityStable structureWarp knittingTextile disintegration and recoveryControl engineeringSprocket

The invention discloses a motion device of a yarn pushing mechanism, which comprises a driving input shaft, the driving input shaft is in key connection with a driving chain wheel, the driving chain wheel is in meshed connection with a driven chain wheel through a chain, the driven chain wheel is in key connection with a driven input shaft, the driven input shaft is provided with a guide rail frame, and the driven input shaft penetrates through the guide rail frame and is rotationally connected with a driving shaft; one end of the driving shaft is rotationally connected with a first yarn pushing rod through a first pin shaft, the bottom end of the first yarn pushing rod is rotationally connected with a second pin shaft, the second pin shaft is rotationally connected with a sliding block, the sliding block is fixedly connected with a second yarn pushing rod through a pin shaft, the driving chain wheel is installed on a main shaft of the warp knitting machine, and the driven chain wheel is directly connected with the yarn pushing part. Power is directly transmitted to the input shaft of the yarn pushing part from the main shaft of the warp knitting machine through the driving chain wheel and the driven chain wheel, and compared with an existing plane multi-connecting-rod mechanism, the structure for transmitting the power is simple in structural composition, small in number of needed parts, reliable in work, small in loss, high in efficiency, large in transmission power and high in overload capacity.

Owner:丹阳市益讯机械有限公司

Stretcher leveler chain drive lifting pin mechanism with guiding

ActiveCN103028633AImprove work efficiencyThe average gear ratio is accurateHydraulic cylinderEngineering

The invention discloses a stretcher leveler chain drive lifting pin mechanism with guiding. The stretcher leveler chain drive lifting pin mechanism with the guiding comprises a hanging bracket, a bolt cylinder, compression columns, a crosshead, lifting pins, two roller chains, two fixed chain wheels, two moving chain wheels, a chain wheel guide rail, copper sliding plates and hanging bracket guide rails, wherein the two fixed chain wheels are respectively and fixedly arranged at both sides of the crosshead; the two moving chain wheels are arranged on the hanging bracket above the fixed chain wheels through a chain wheel shaft; one ends of the two roller chains are respectively and fixedly arranged on the two fixed chain wheels; the other ends of two the roller chains respectively bypass the moving chain wheels to be respectively connected onto the lifting pins; the chain wheel guide rails are respectively and fixedly arranged at the outer sides of the fixed chain wheels; the hanging bracket guide rails are respectively arranged on pillars of the hanging bracket; the copper sliding plates are arranged on surfaces of the hanging bracket guide rails; and the chain wheel guide rails are respectively abutted with the copper sliding plates on the surfaces of the hanging bracket guide rails. The stretcher leveler chain drive lifting pin mechanism with the guiding has the beneficial effects that elastic sliding or slipping does not occur during chain drive, so that the average drive ratio is stable and accurate, and the synchronism and the work efficiency of the movement of every lifting pin can be improved; the deflection of a piston rod is avoided; the service life of the hydraulic cylinder is prolonged; and chain drive tension is low, so that pressure acting on the chain wheel shaft is also low.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

Tree pit digging machine

InactiveCN109348782AEasy to moveReduce labor intensityPlantingFurrow making/coveringEngineeringTar pit

The invention discloses a tree pit digging machine, which is characterized by comprising a side protection supporting plate, pressure bearing seats, a movable seat, spiral transmission rods, a stepping motor, supporting legs and movable wheels, wherein a group of the pressure bearing seats symmetrically arranged on one side of each the supporting leg are arranged on the side protection supportingplate; a group of the spiral transmission rod are arranged between the pressure bearing seats through bearing seats; one end of each the spiral transmission rod penetrates through the pressure bearingseats, and driven gears are arranged at the end part; the driven gears are connected through a chain; a driving gear is arranged at the center; the driving gear meshes with the chain, and is arrangedon the output end of the stepping motor in a sleeved manner; the movable seat is arranged on the spiral transmission rods; internal thread sleeves are arranged on one surface of the movable seat which is vertical to the ground and corresponds to the spiral transmission rods; the internal thread sleeves are respectively arranged at four corners of the surface of the movable seat vertical to the ground; a diesel engine is arranged on one surface of the movable seat horizontal to the ground; and a drill bit is mounted on the output end of the diesel engine. The machine has the advantages of simple operation, convenient maintenance, reliability and durability, easy starting and high efficiency.

Owner:黄忠越

Multilayered fabric weaving machine

InactiveCN102888698BImprove performanceSimple structureJacquardsLoomsStructural engineeringMechanical engineering

The invention discloses a multilayered fabric weaving machine. The multilayered fabric weaving machine comprising a let-off mechanism, a shedding mechanism, a weft insertion mechanism, a beating-up mechanism, and a rolling mechanism, wherein the shedding mechanism comprises a shedding frame; a plurality of shedding cylinders, a plurality of upper connecting plates, an upper amplifying plate, an upper mesh plate, a harness wire, a lower mesh plate, a lower amplifying plate, a plurality of lower connecting plates are arranged on the shedding frame; every shedding cylinder is connected with the corresponding upper connecting plates; the lower end of every lower connecting plate is provided with a returning spring; and the lower end of the returning spring is fixed at the bottom end of the shedding frame. After being connected with harness cords respectively, the upper end and lower end of every harness wire are respectively crossed through the upper mesh plate and lower mesh plate, the upper amplifying plate and the lower amplifying plate through the harness cords, then every group of harness cords are connected with the corresponding connecting plate; through the direct connection between the harness cords and the harness wires, the space limit caused by a heald frame in the traditional weaving machine is avoided; thereby weaving of the multilayered fabric is realized under a certain opening.

Owner:成都渝锦股权投资基金管理有限公司

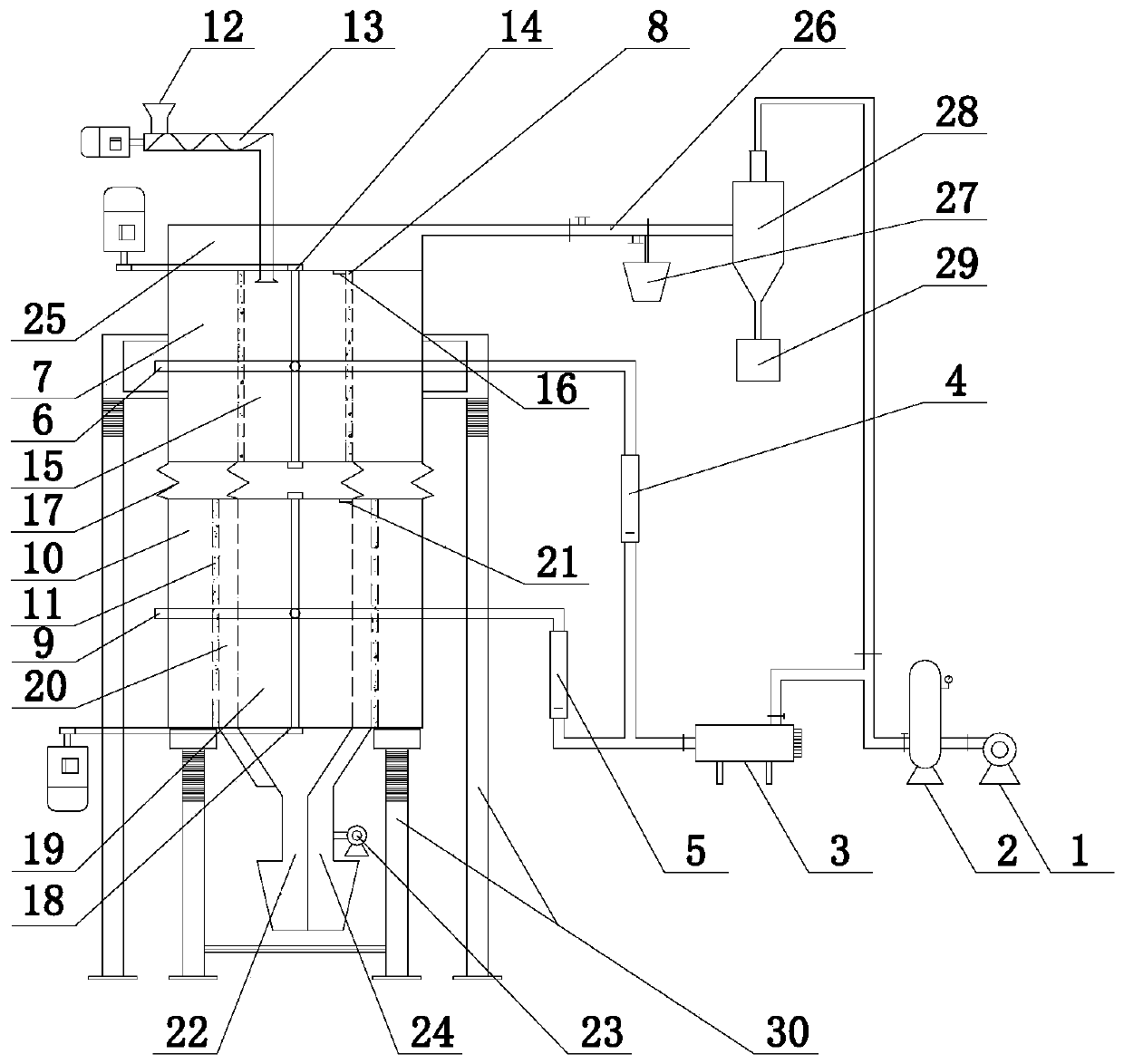

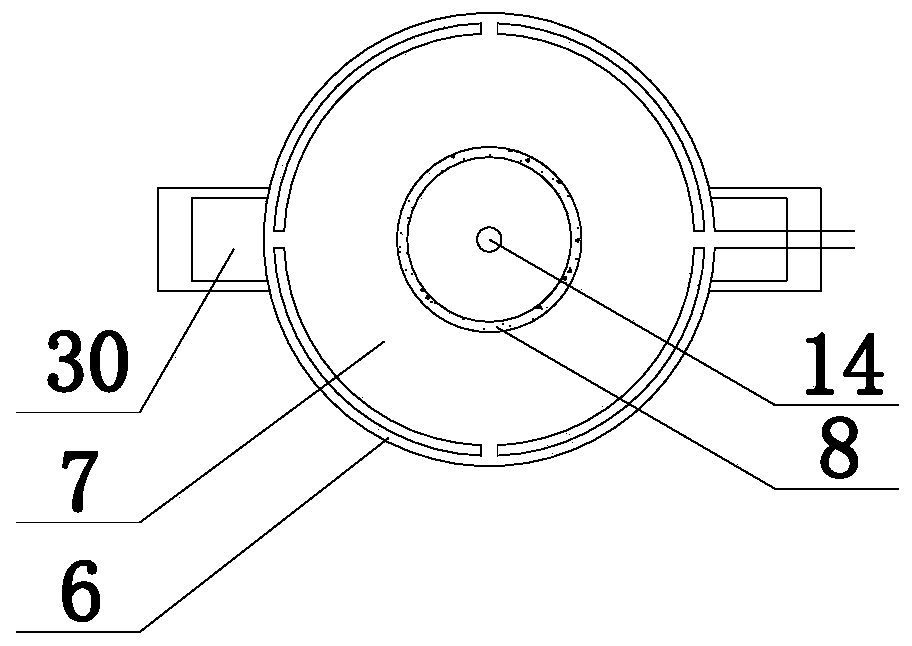

A centrifugal fluidized bed drying and sorting system and drying and sorting method

ActiveCN110068200BAchieve sorting effectReduce backmixing rateGas current separationDrying solid materials with heatFluidized bed dryingAir volume

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com