Screening device for wood strips

A screening device and a technology for wood strips, which are applied to wood processing appliances, joining of wooden veneers, and manufacturing tools, etc., can solve the problems of uneven contours, inability to screen wood strips, and inconsistency in size, etc., to save energy, Smooth, length-accurate effects on and off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Further detailed explanation through specific implementation mode below:

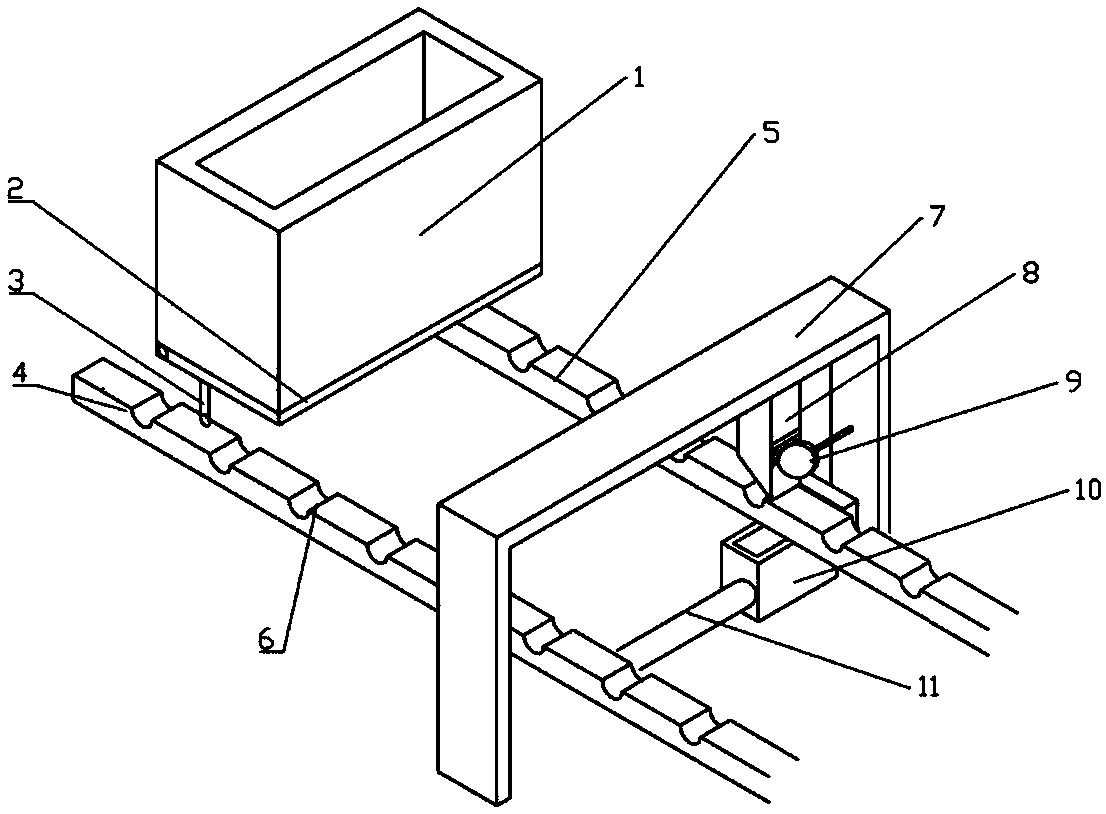

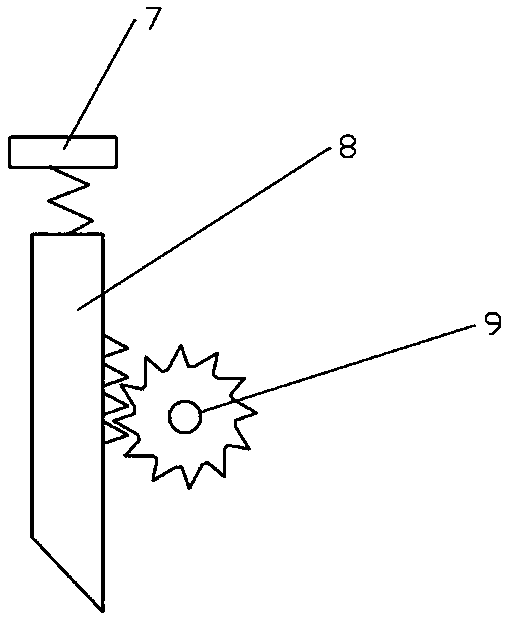

[0024] The reference signs in the drawings of the description include: storage box 1, bottom plate 2, connecting rod 3, first guide rail 4, second guide rail 5, placement groove 6, frame 7, pressure plate 8, gear 9, collection box 10 , Feeding pipe 11.

[0025] Such as figure 1 with figure 2 Shown, a kind of stick screening device comprises frame 7, material storage box 1 and track. The material storage box 1 includes a material inlet and a material outlet, the material inlet is at the top of the material storage box 1, and the material outlet is at the bottom of the material storage box 1; the bottom of the material storage box 1 is also provided with a bottom plate 2, and the bottom plate 2 is hinged On the material storage box 1, a chute is also provided on the bottom plate 2, and the bottom plate 2 rotates along the hinge to open and close the discharge port, and the track is below the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com