A tube drawing machine

A flower machine and machine head technology, applied in the field of tube drawing and twisting machine, to achieve the effect of strong overload capacity, strong operability and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

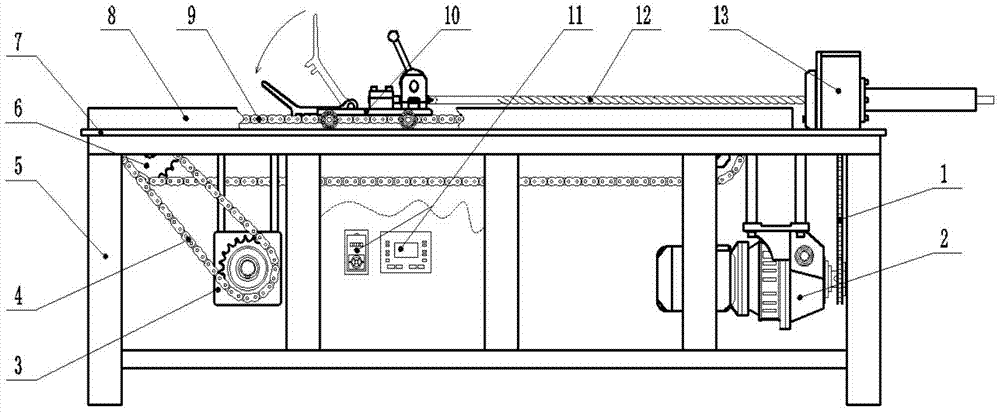

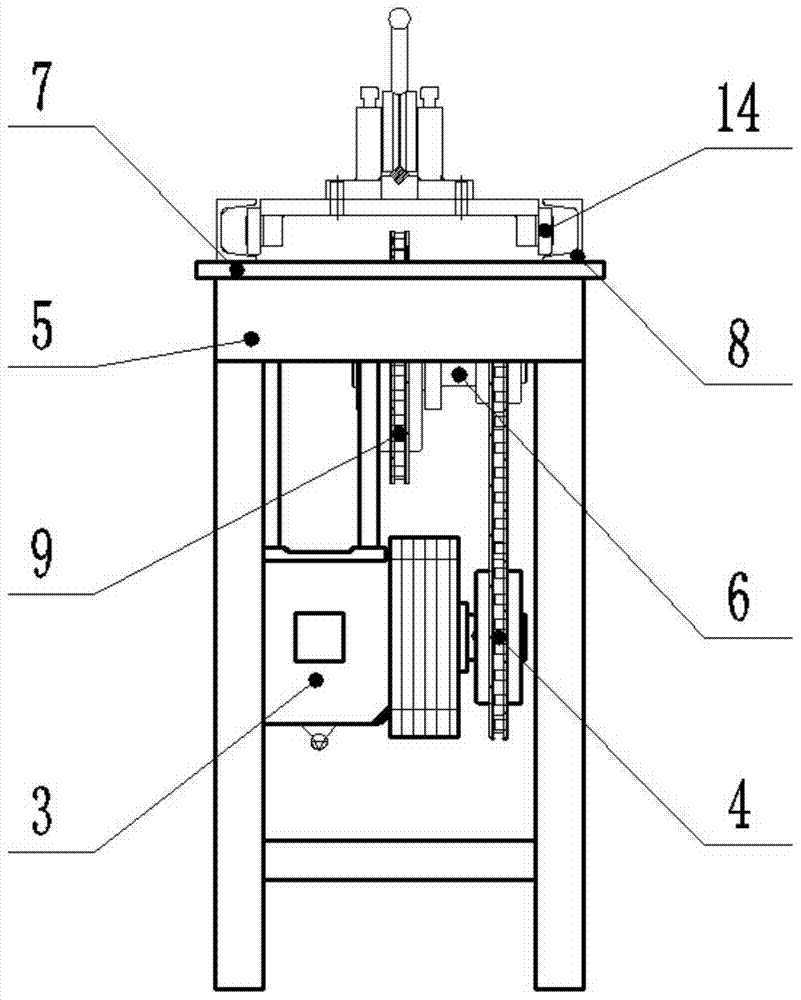

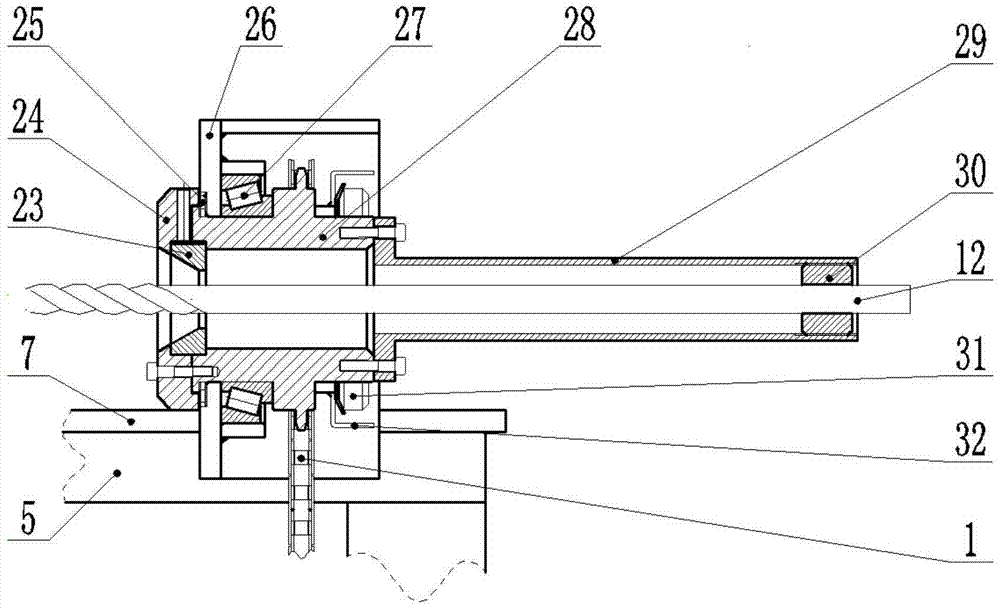

[0028] see Figure 1 to Figure 6 , a tube twisting machine of the present invention, which includes a frame part, a feed twisting part, a control part and a material tube traction part, and the frame part includes a stand 5 and a stand panel 7, and the stand Panel 7 is fixed on the stand 5, and above described stand panel 7 is provided with feed twisting machine head 13, workpiece 12, traction trolley 10, rolling chain three 9 and slide rail 8 from right to left, and described stand The lower right side of the panel 7 is provided with a rolling chain one 1 and a transmission motor one 2 connected to the feeding screw head 13, and the lower left side of the stand panel 7 is provided with a transmission motor two connected with the driven gear set 6 of the wrench. 3. Rolling chain two 4; the traction trolley 10 moves back and forth in the slide r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com