A centrifugal fluidized bed drying and sorting system and drying and sorting method

A fluidized bed drying and sorting system technology, applied in chemical instruments and methods, drying solid materials, drying gas layout, etc., can solve the problems of small processing capacity, inability to perform drying and sorting simultaneously, and high energy consumption. Guaranteed effect of stability and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

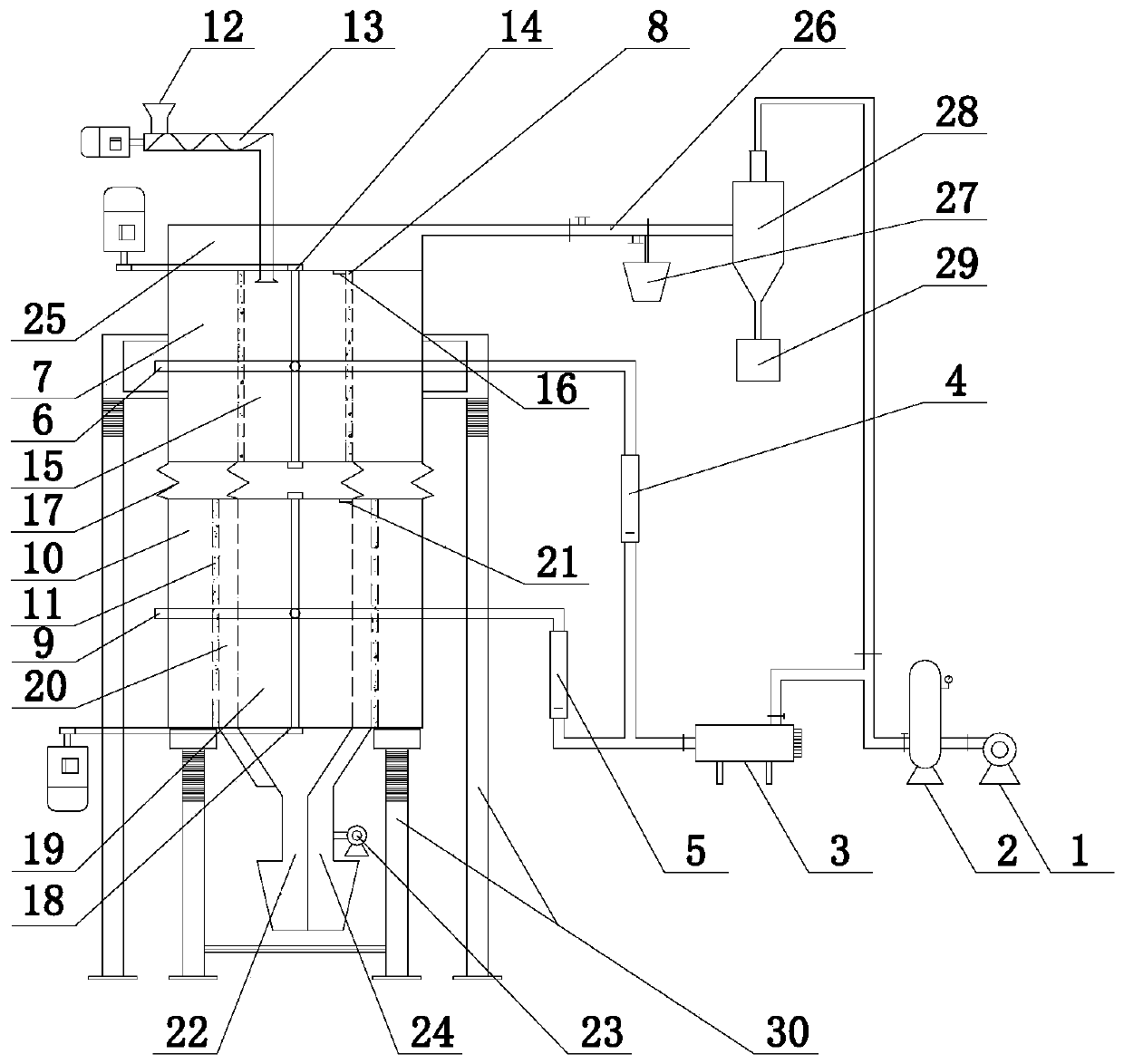

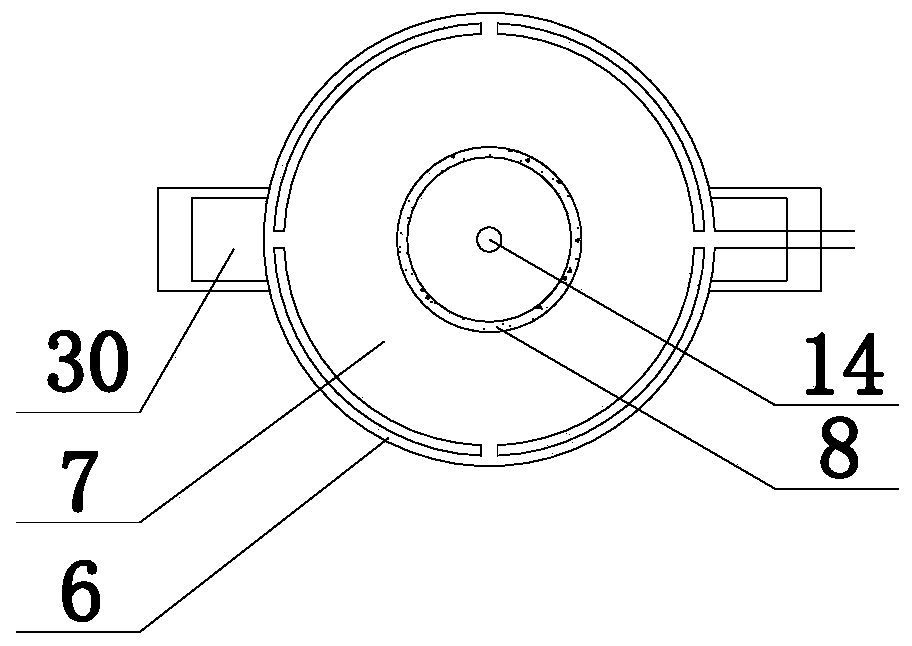

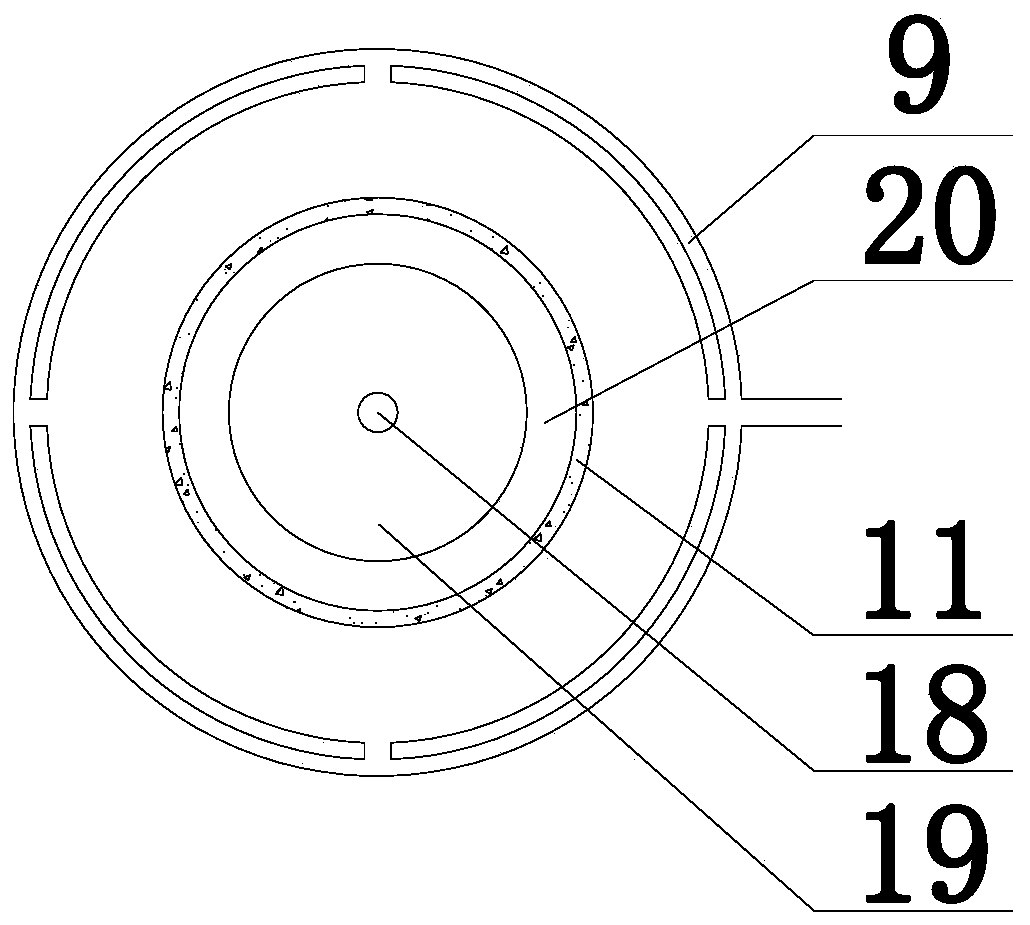

[0035] The invention discloses a centrifugal fluidized bed drying and sorting system, such as Figure 1 to Figure 3 As shown, it includes a pre-drying unit and a dry sorting unit; the pre-drying unit is arranged above the dry sorting unit; the pre-drying unit includes a first air distribution chamber 7, a first mandrel 14, and a first hole provided with a plurality of first holes. An air distribution tube 8, the first air distribution tube 8 includes a first drum 15; the drying and sorting unit includes a second drum 19, a second air distribution tube 11, a second air distribution chamber 10 and a second mandrel 18, The area between the second rotating drum 19 and the second air distribution tube 11 is the interlayer area 20. The second rotating drum 19 and the second air distribution tube 11 are provided with a plurality of second holes; the air volume of the first air distribution chamber 7 is greater than The air volume of the second air distribution chamber 10.

[0036] Speci...

Embodiment 2

[0059] The invention also provides a centrifugal fluidized bed drying and sorting method, which specifically includes the following processes:

[0060] Air supply means: start the blower 1 to store gas in the wind drum 2, and the gas from the exhaust port of the wind drum 2 generates high-temperature hot air through the air heater 3, and controls the first flow meter, the first regulating valve 4 and the second flow rate. The first air distribution chamber 7 and the second air distribution chamber 10 are supplied with hot air volume; among them, the hot air in the first air distribution chamber 7 enters the first rotation through the first air distribution tube 8 The materials are pre-dried in the drum 15; the hot air in the second air distribution chamber 10 enters the second drum 19 through the second air distribution cylinder 11 and the interlayer area 20, and the materials are dried and separated.

[0061] The centrifugal fluidized bed pre-drying means that the material is fed ...

Embodiment 3

[0065] This embodiment is the drying and sorting of fine-grained coal. The centrifugal fluidized bed drying and sorting system provided in Example 1 and the centrifugal fluidized bed drying and sorting method provided in Example 2 are used. The specific implementation process is as follows:

[0066] Lignite with a particle size of 1-6 mm, a moisture content of 38.6% and an ash content of 24.86% is selected for drying and sorting. The expected requirements for dry separation are: lignite concentrate ash content is less than 18%, yield is more than 75%, and moisture content is less than 13%.

[0067] Turn on blower 1 and blow a large amount of air into wind drum 2. After the pressure gauge value reaches 0.4 MPa, turn off blower 1, open the air outlet of wind drum 2, wind enters air heater 3, set heating temperature to 110 ℃, pass Control the first flow meter and the first regulating valve 4 and the second flow meter and the second regulating valve 5 so that the hot air enters the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com