A device for sorting quartz sand

A quartz sand sorting technology, applied in the field of quartz sand sorting, can solve problems such as low efficiency and long quartz sand production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is further described in detail through specific implementation methods:

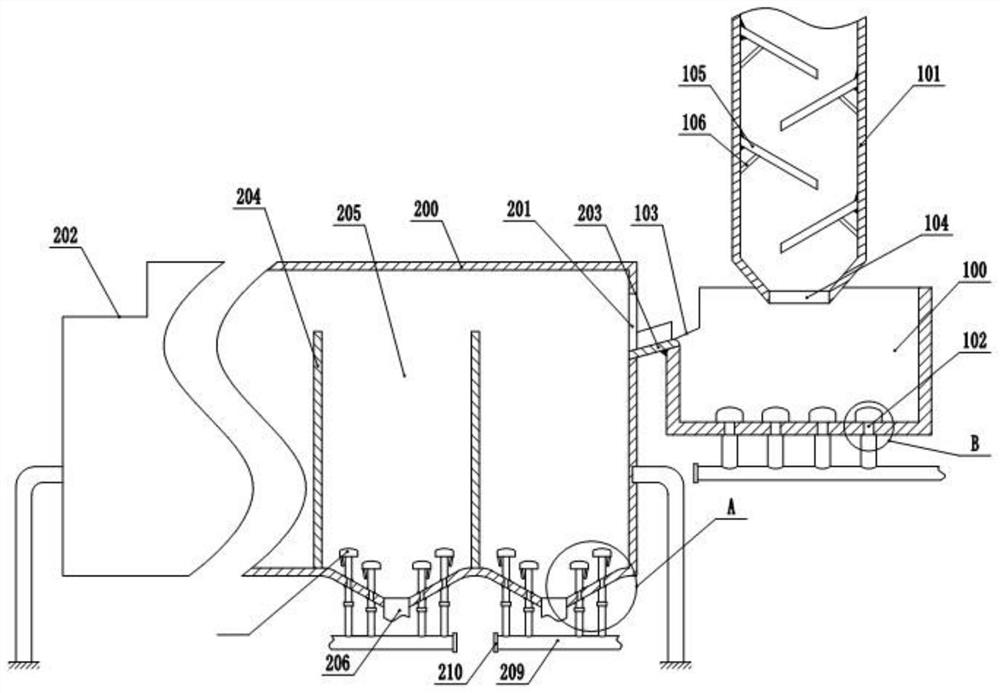

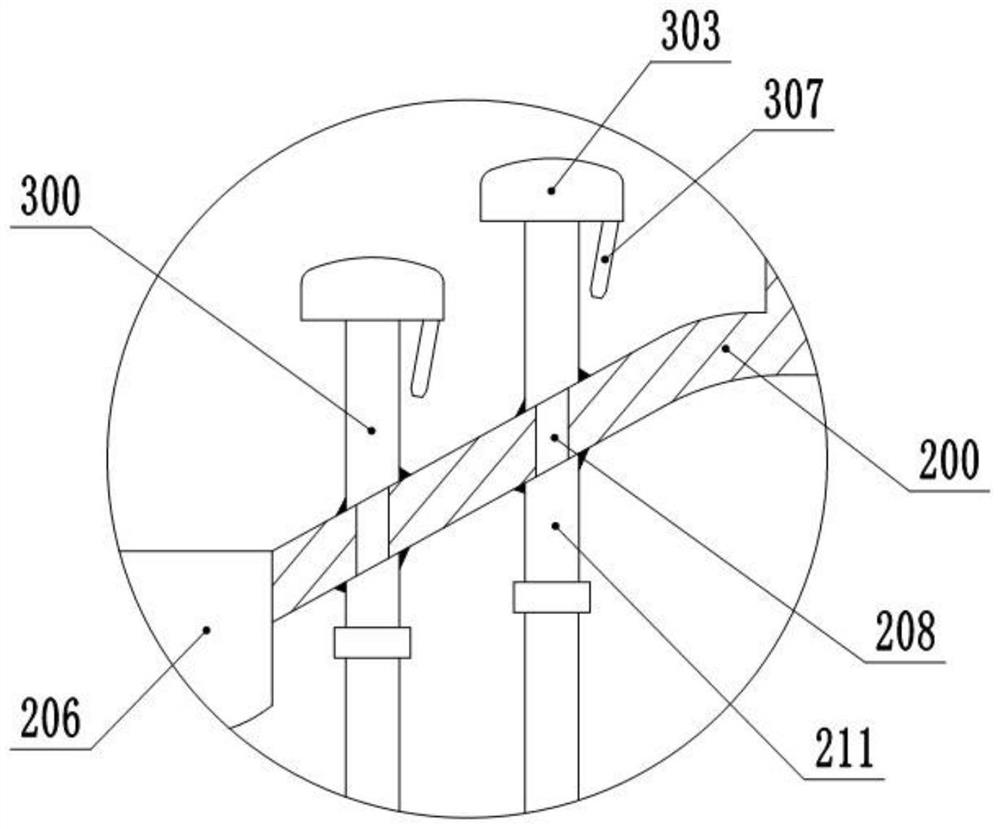

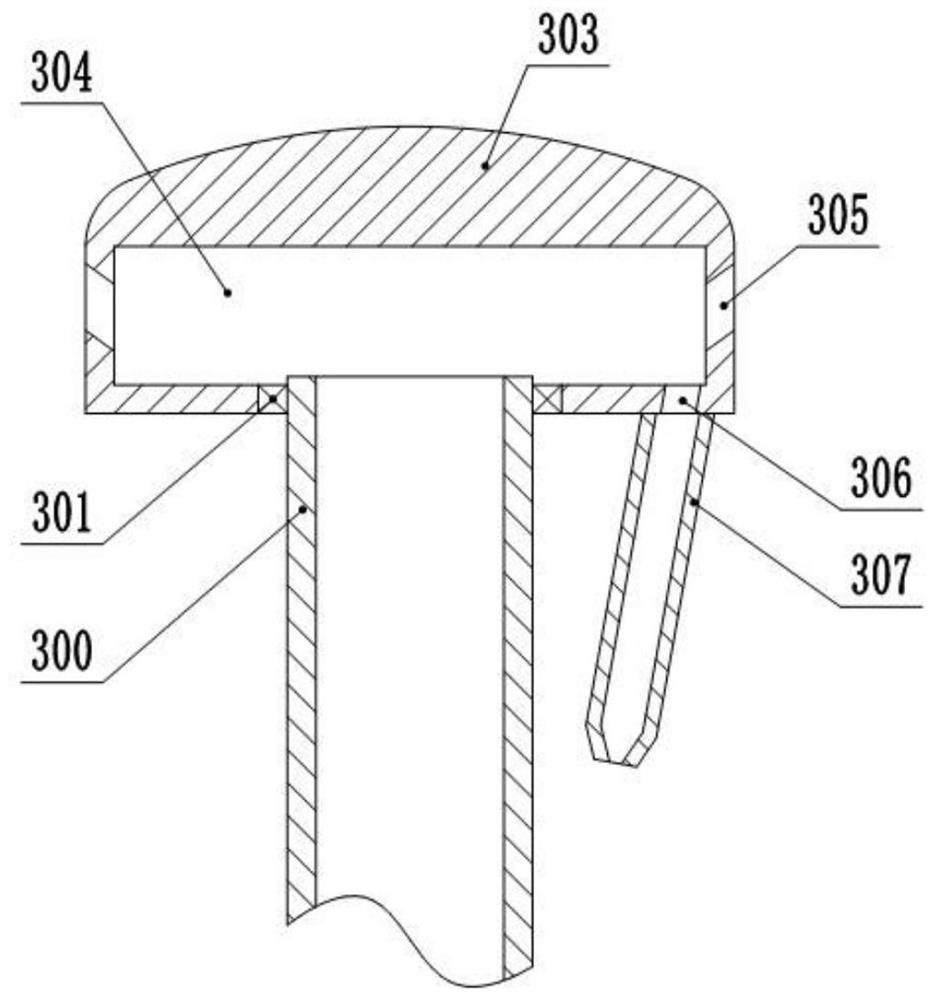

[0034] The reference signs in the accompanying drawings of the description include: mixing tank 100, feeding box 101, water injection port I 102, overflow gap 103, discharge port 104, buffer plate 105, support column 106, sorting box 200, sand inlet 201, Sand outlet 202, material guide plate 203, partition 204, sorting chamber 205, sand discharge pipe 206, water injection port II 208, multi-way pipe 209, end cover 210, connecting pipe 211, metal pipe 300, bearing 301, water spray Disk 303, water cavity 304, water spray hole 305, sand cleaning hole 306, sand cleaning pipe 307, water spray cover 400, water outlet hole 401.

[0035] The embodiment is basically as attached figure 1 Shown:

[0036]A device for sorting quartz sand, comprising a frame on which a feeding mechanism and a sorting box 200 are fixed, wherein the feeding mechanism includes a mixing tank 100 and a feeding box 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com