A dry quality upgrading system and method for dry sorting minerals

A sorting and drying technology, applied in the direction of drying solid materials, drying gas arrangement, drying, etc., can solve the problems of small processing capacity, high energy consumption, poor continuity, etc., and achieve the effect of ensuring stability and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

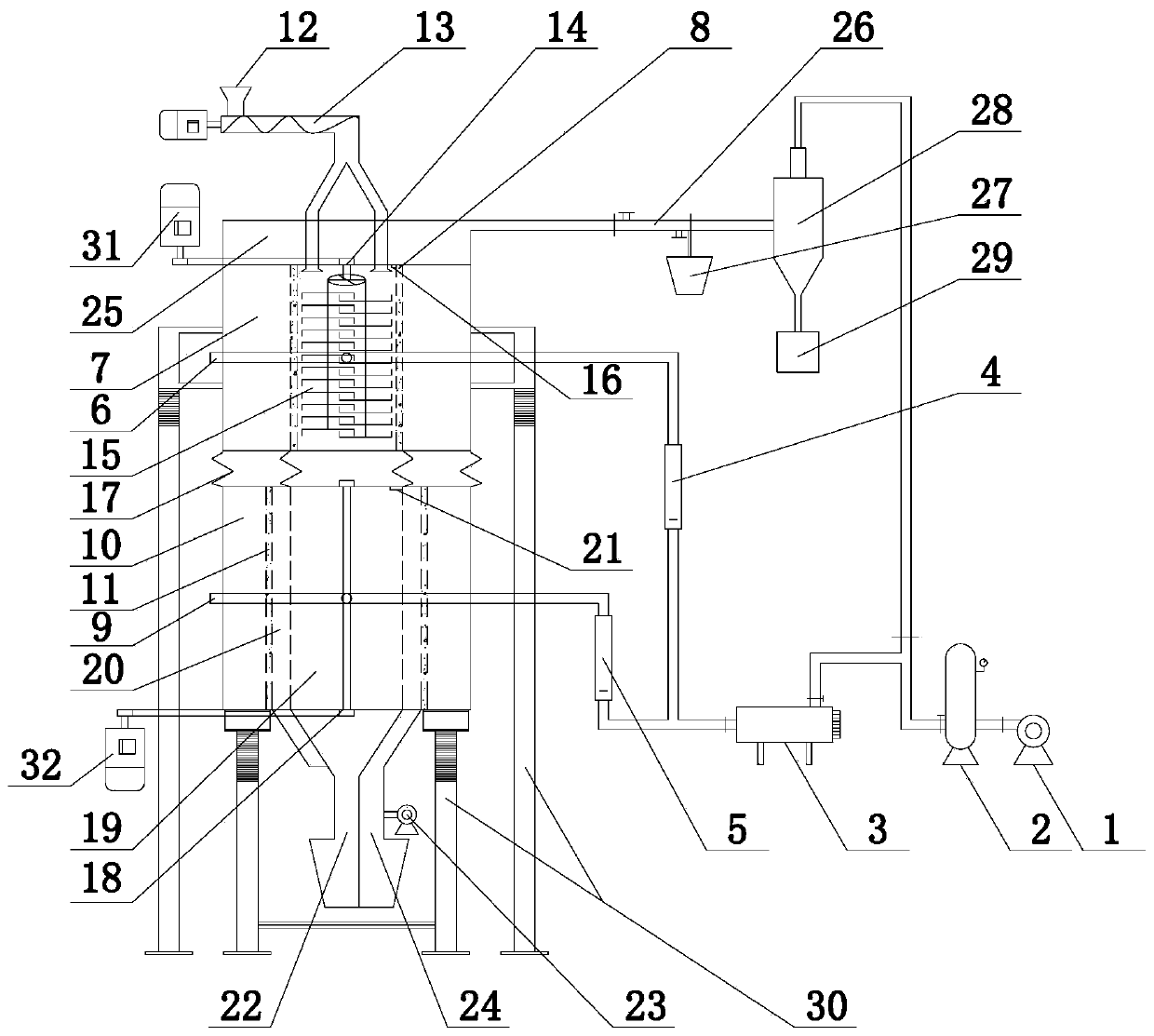

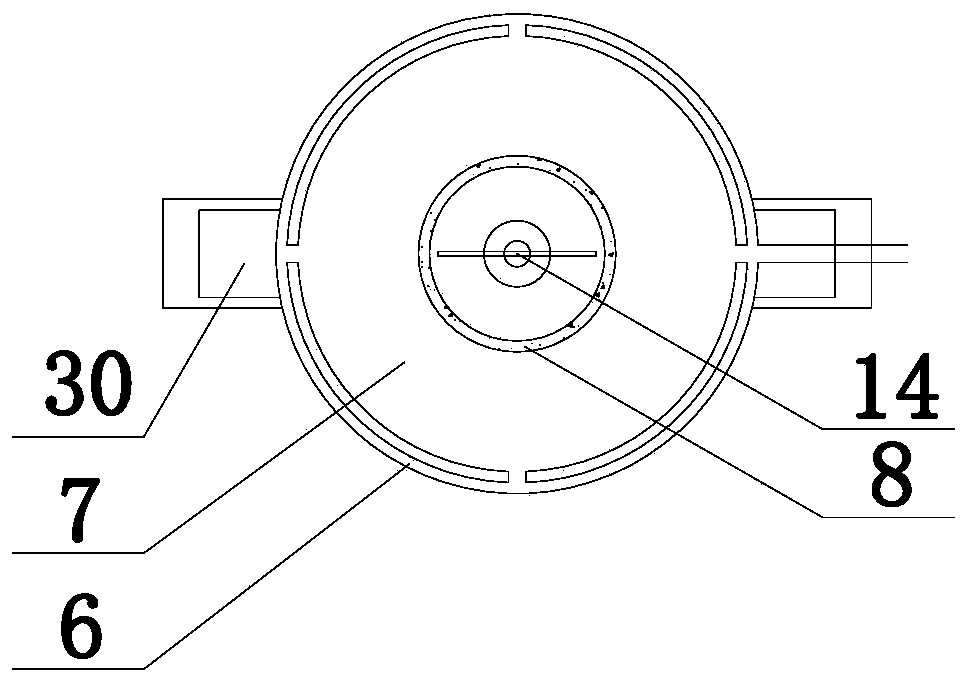

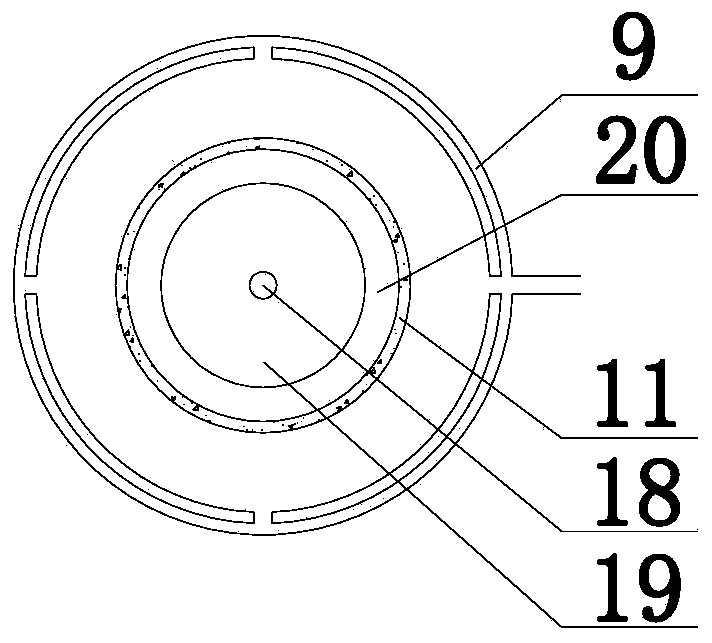

[0036] In one aspect, the invention discloses a dry upgrading system for dry sorting minerals, such as Figure 1 to Figure 5 As shown, the dry upgrading system includes a pre-drying unit and a drying and sorting unit, the pre-drying unit is arranged above the drying and sorting unit; the pre-drying unit includes a first air distribution chamber 7 and a first air distribution chamber 7 provided with a plurality of first holes. An air distribution cylinder 8; the first air distribution cylinder 8 is provided with a stirring device 15; the drying and sorting unit comprises a drum 19, a second air distribution cylinder 11, a second air distribution chamber 10 and a mandrel 18, and the drum 19 and The area between the second air distribution cylinder 11 is an interlayer area 20 , and a plurality of second holes are provided on the rotating drum 19 and the second air distribution cylinder 11 .

[0037] Specifically, such as figure 1 As shown, the pre-drying unit is a pre-drying sti...

Embodiment 2

[0069] The present invention also provides a dry upgrading method for dry sorting minerals, which specifically includes the following steps:

[0070] S1. Start the blower 1 to store gas in the air bag 2. The gas from the air outlet of the air bag 2 generates high-temperature hot air through the air heater 3. By controlling the first flow meter and the first regulating valve 4 and the second flow meter and the second flow meter Two regulating valves 5, and then control the air volume of hot air supplied to the first air distribution chamber 7 and the second air distribution chamber 10 by the first annular air supply pipe 6 and the second annular air supply pipe 9; wherein, the first air distribution chamber The hot air in the chamber 7 enters the first air distribution cylinder 8 through the first hole; the hot air in the second air distribution chamber 10 enters the drum 19 through the second air distribution cylinder 11 and the interlayer area 20. At this time, the first The ...

Embodiment 3

[0074] This example is dry sorting of fine-grained lignite, using the dry upgrading system for dry sorting minerals provided in Example 1 and the dry upgrading method for dry sorting minerals provided in Example 2 , and its specific implementation process is as follows:

[0075] Lignite with a particle size of 1-6mm, a moisture content of 38.6%, and an ash content of 31.29% is selected for dry separation. Expected requirements for dry separation: the ash content of clean coal is less than 15%, the yield is higher than 70%, and the moisture is less than 10%.

[0076] Turn on the blower 1 and blow a large amount of wind into the air bag 2. After the pressure gauge value reaches 0.4MPa, turn off the blower 1, open the air outlet of the air bag 2, and the air enters the air heater 3. Set the heating temperature to 110°C. Control the first flow meter and the first regulating valve 4 and the second flow meter and the second regulating valve 5, so that the hot air enters the first a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com