Stretcher leveler chain drive lifting pin mechanism with guiding

A technology of a straightening machine chain and a transmission mechanism, applied in the field of forging equipment, can solve the problems of easy slippage, different lifting heights, great danger, etc., and achieve the effects of reducing movement asynchrony, improving work efficiency, and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with drawings and embodiments.

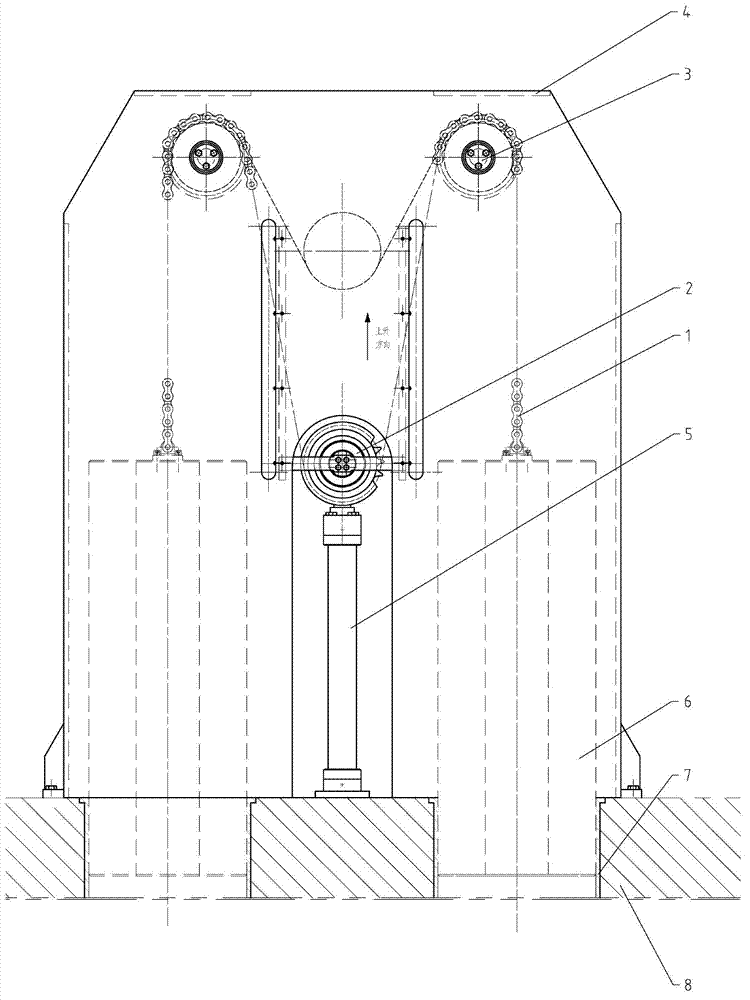

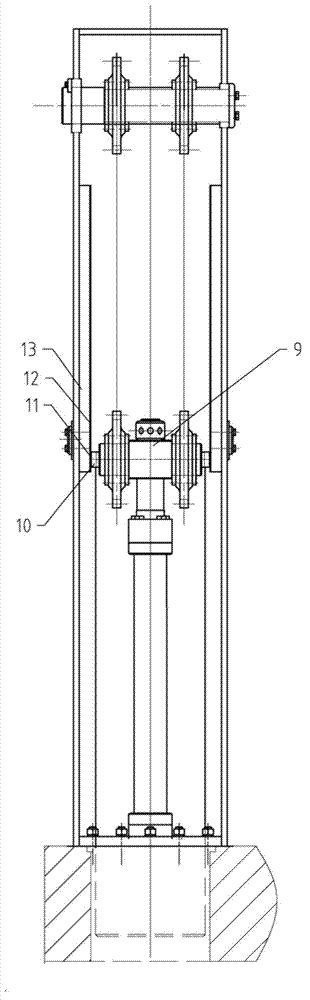

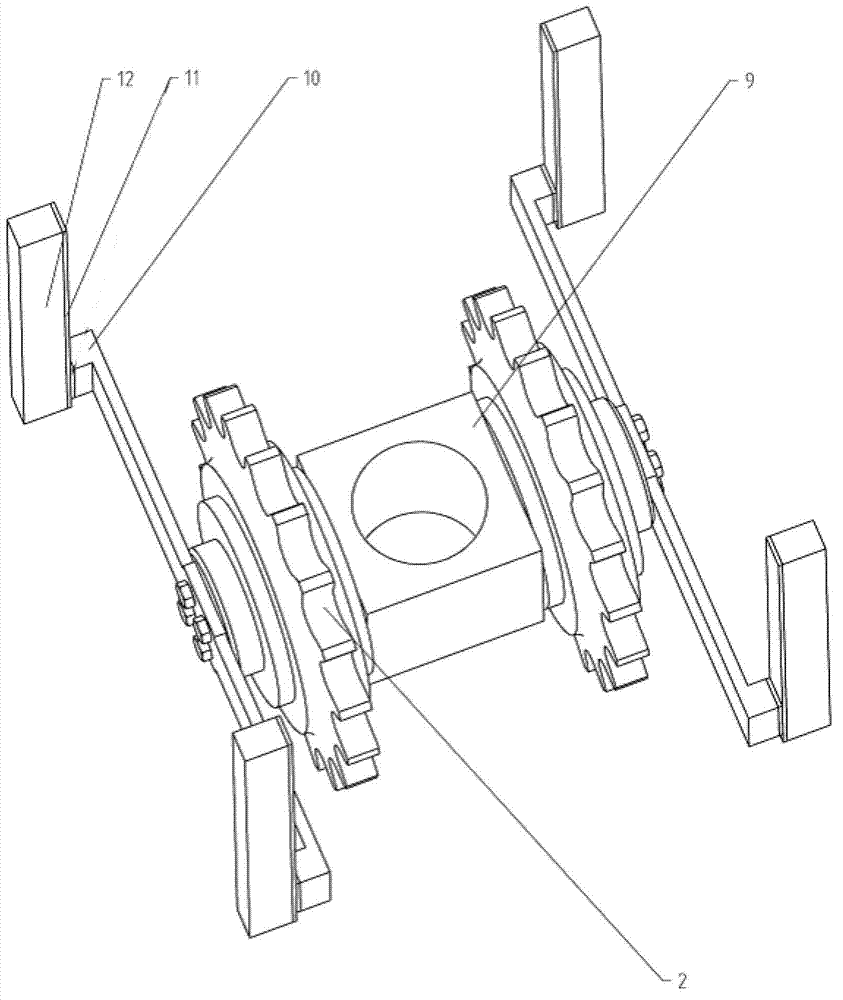

[0017] Tension leveler chain drive pin lifting mechanism with guide, including hanger, pin cylinder, compression column, crosshead, lifting pin, roller chain, fixed sprocket, moving sprocket, sprocket guide rail, copper slide plate and hanger The frame guide rail, the bolt cylinder is fixed on the compression column, the crosshead is connected to the bolt cylinder, the two fixed sprockets are fixedly installed on both sides of the crosshead, the inner side of the fixed pulley is connected to the crosshead, and the two fixed sprockets are respectively located on the bolt cylinder On both sides, the fixed sprocket does not rotate, and the two moving sprockets are installed on the hanger above the fixed sprocket through the shaft. One end of the roller chain is fixed on the fixed sprocket, and the other end is connected to the lifting pin around the moving sprocket. The wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com