Moving device of yarn pushing mechanism and adjusting method

A motion device and active technology, applied in textiles and papermaking, knitting, warp knitting, etc., can solve problems such as complex structure of plane linkage mechanism, complex structure design, complex motion requirements, etc., and achieve accurate and reliable calculation results and high transmission power Large, wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] The existing warp knitting machine has the disadvantages of numerous driving components, complex mechanism composition and large space occupied by the connecting rod box.

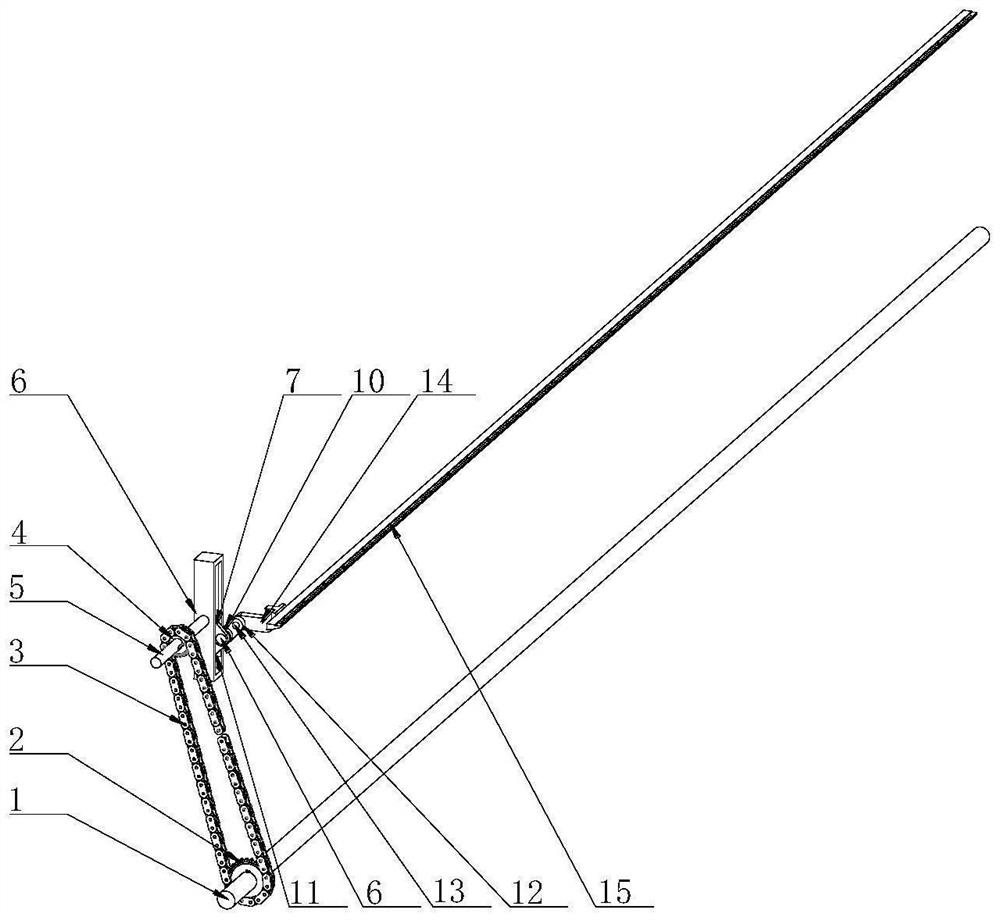

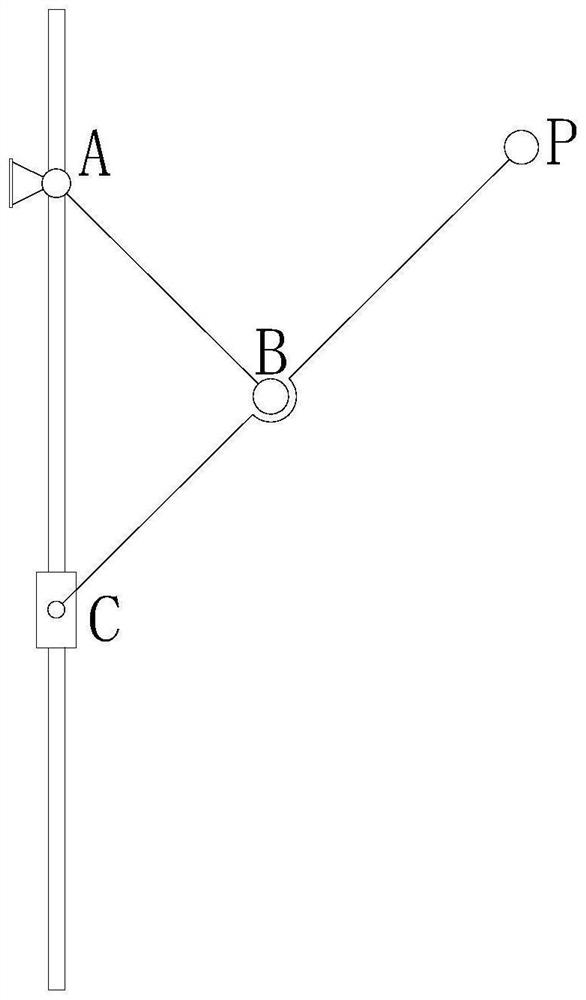

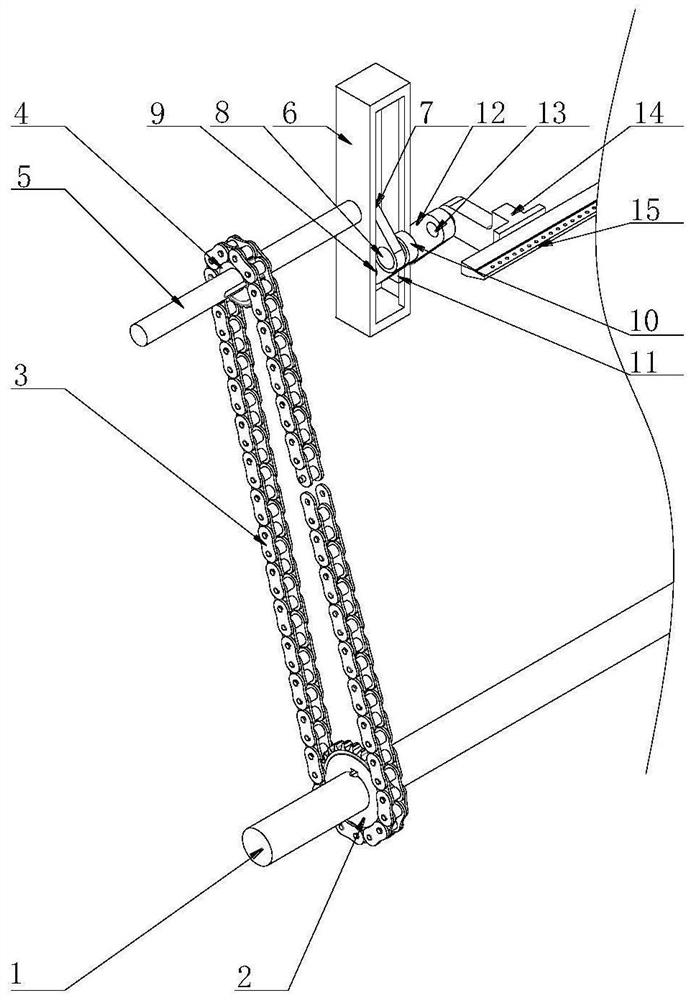

[0016] see Figure 1-3 , this embodiment provides a movement device for a yarn pushing mechanism, including an active input shaft 1, the active input shaft 1 is keyed to a drive sprocket 2, and the drive sprocket 2 is connected by a flat key, which can be easily disassembled and assembled. Well, the driving sprocket 2 is meshed with the driven sprocket 4 through the chain 3, the driven sprocket 4 is keyed to the driven input shaft 5, the driven input shaft 5 is provided with a guide rail frame 6, and the guide rail frame 6 is fixed on the operating table. On one side, the guide rail frame 6 is provided with three grooves, which can provide a limiting effect on the driven input shaft 5 and the first yarn pushing rod 10 respectively. The driven input shaft 5 is rotatably connected with the drive shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com