Patents

Literature

38results about How to "Work compact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

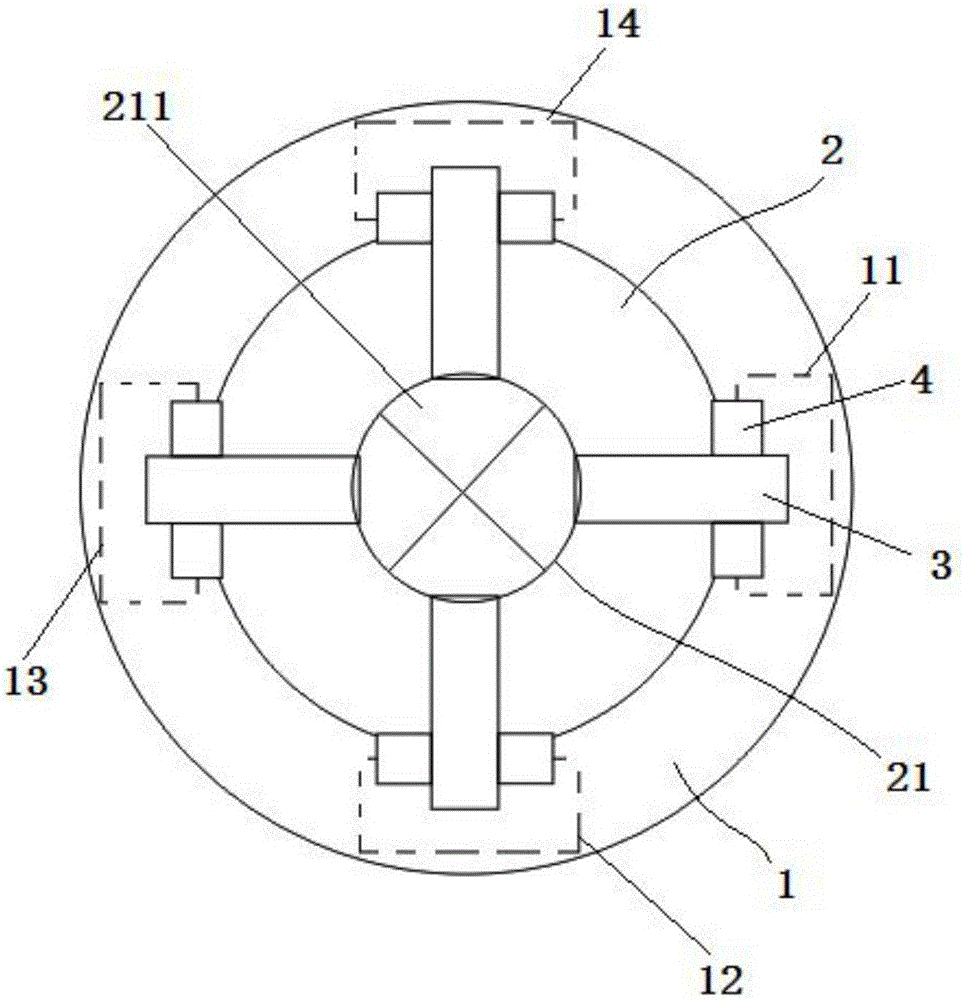

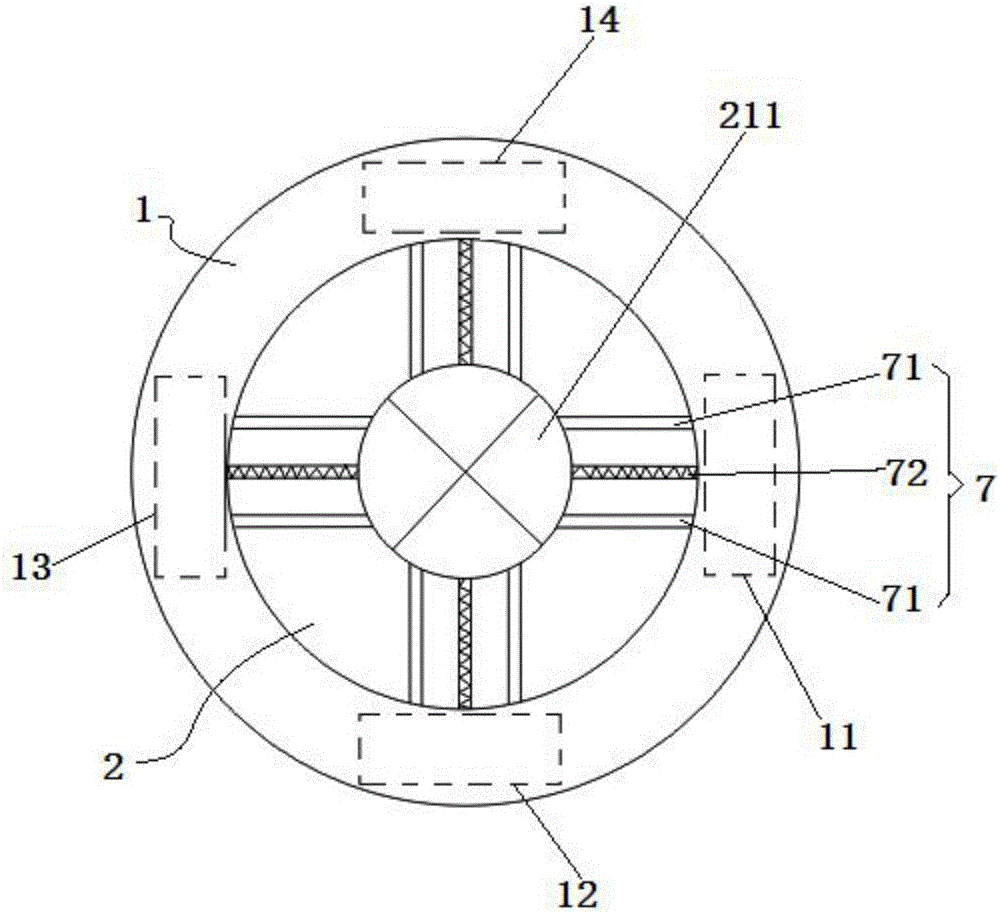

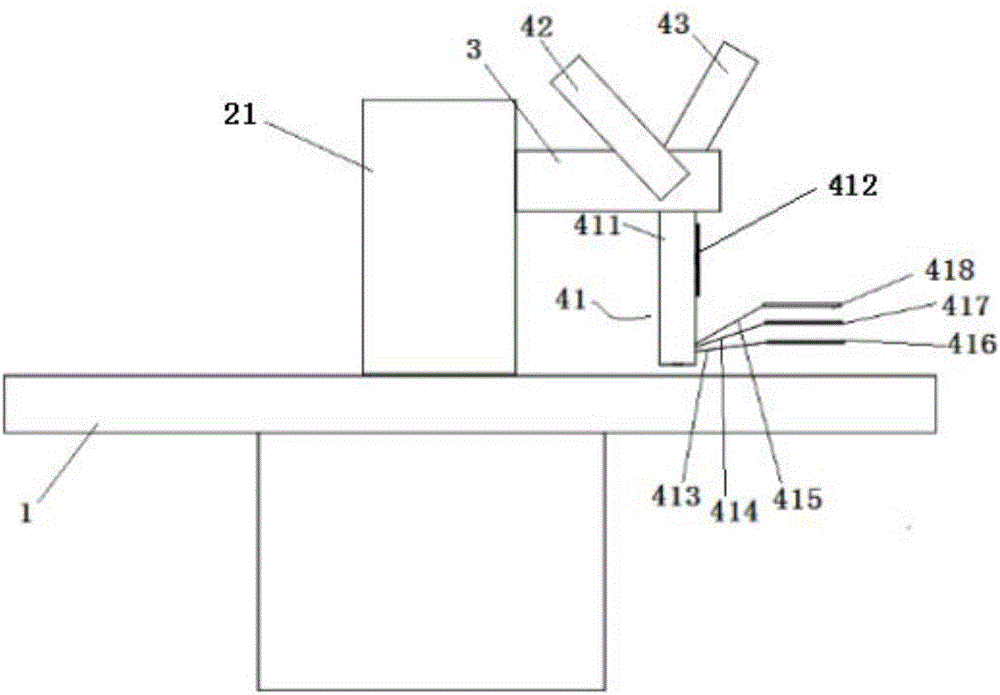

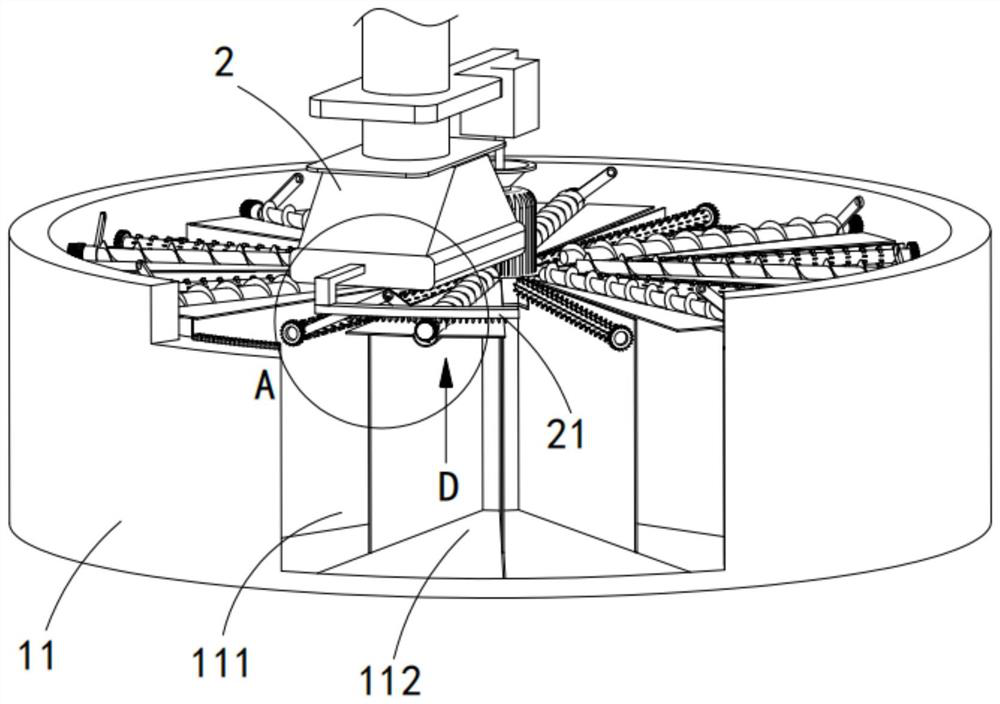

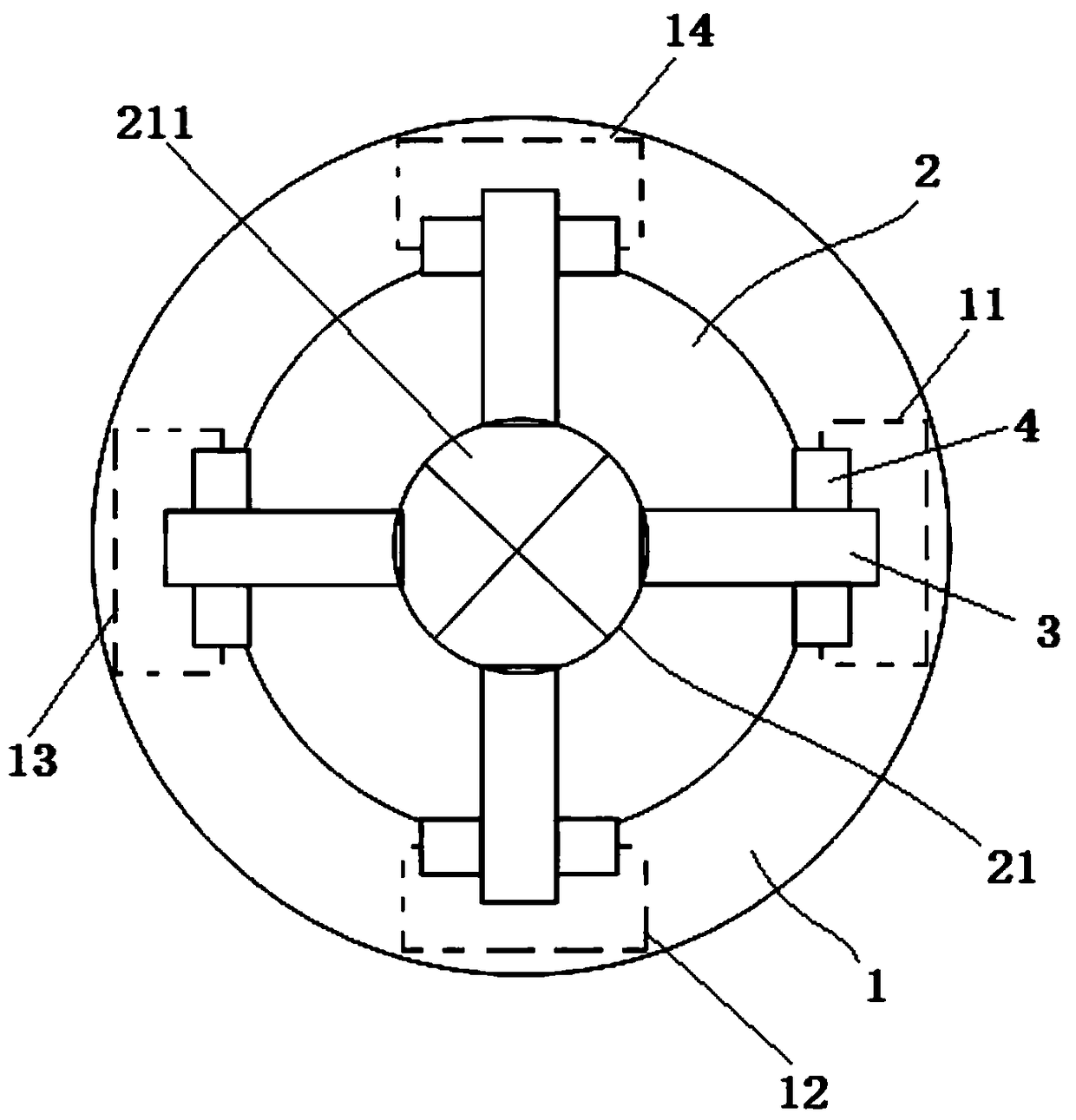

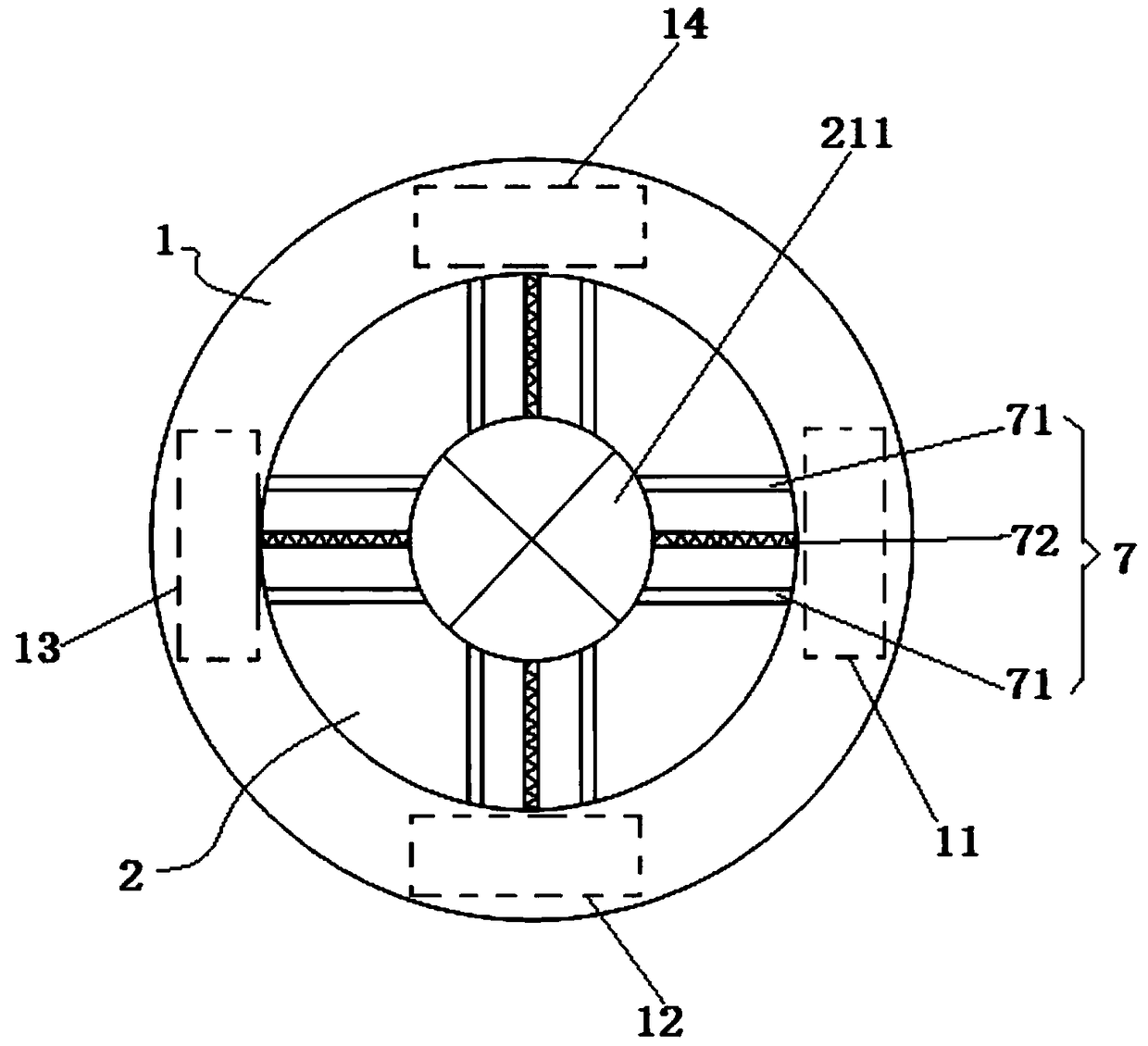

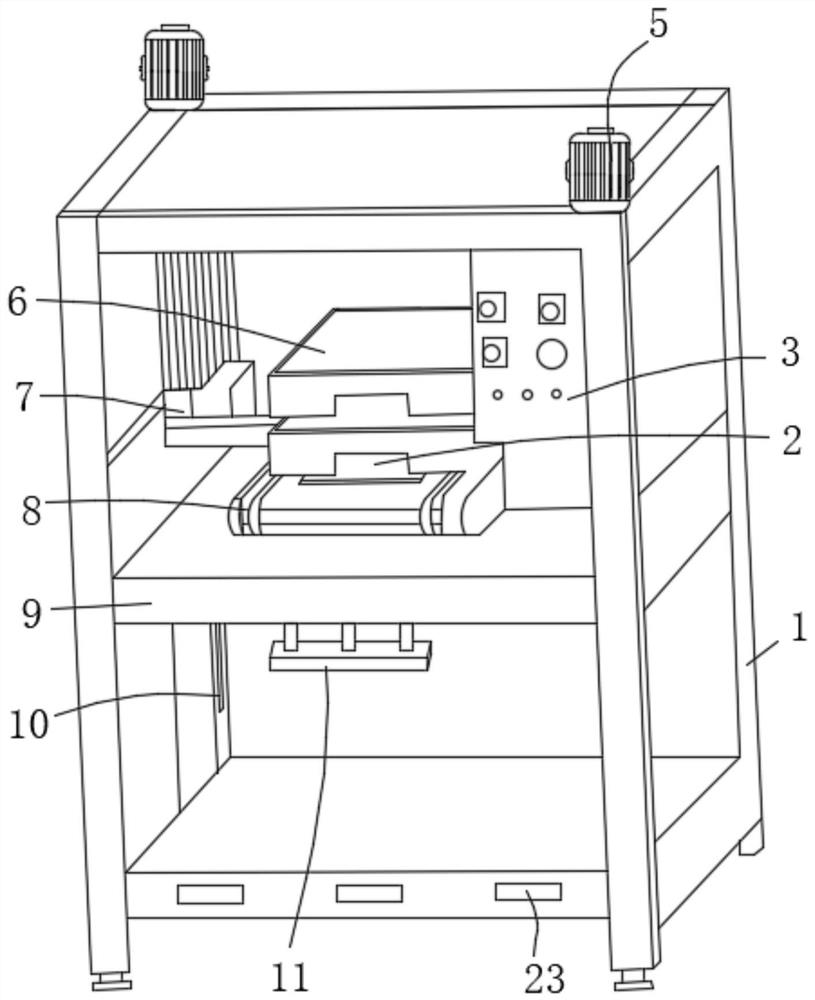

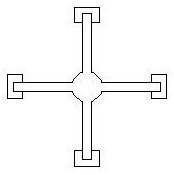

Multifunctional garment sewing machine

ActiveCN105887369AMeet different process requirementsImprove efficiencyWorkpiece carriersWork-feeding meansControl systemEngineering

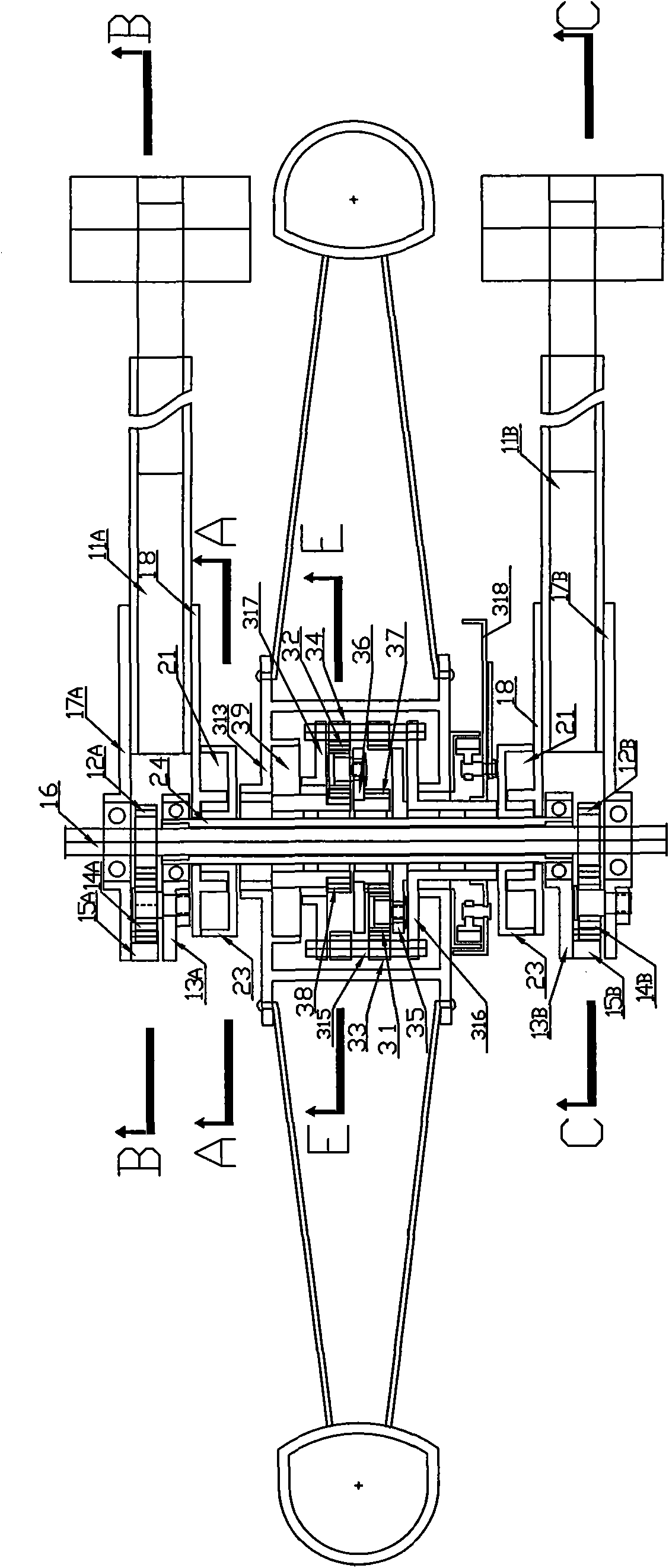

The invention discloses a multifunctional garment sewing machine which comprises a rack and a control system, wherein a worktable and a rotating mechanism are arranged on the rack; a plurality of working areas are formed in the worktable; the rotating mechanism comprises a rotating disc; the rotating disc is arranged in the middle of the worktable; a first rotating shaft which rotates along the rotating disc is longitudinally arranged on the rotating disc; the first rotating shaft is composed of a plurality of equally divided intervals; the number of the intervals is equal to that of the working areas; the bottom of each interval is connected with the rotating disc by virtue of a Y-axis transmission mechanism so as to realize Y-direction movement of the intervals on the rotating disc; a second rotating shaft is transversely arranged on each interval; a plurality of working groups with different using functions are arranged on the second rotating shaft; the plurality of working groups are respectively uniformly and fixedly distributed on the second rotating shaft by taking the second rotating shaft as an axis and are positioned just above the worktable; and function switching of the working groups is realized by virtue of rotation of the second rotating shaft. According to the invention, the rotating mechanism is combined with the plurality of working groups, so that function selection diversity and automatic operation are realized.

Owner:南京润泽华针纺织科技发展有限公司

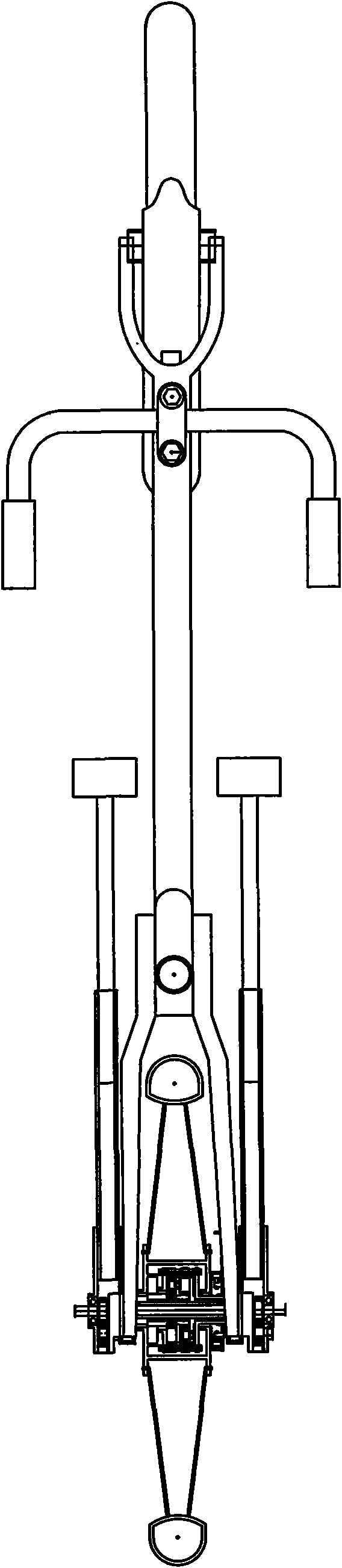

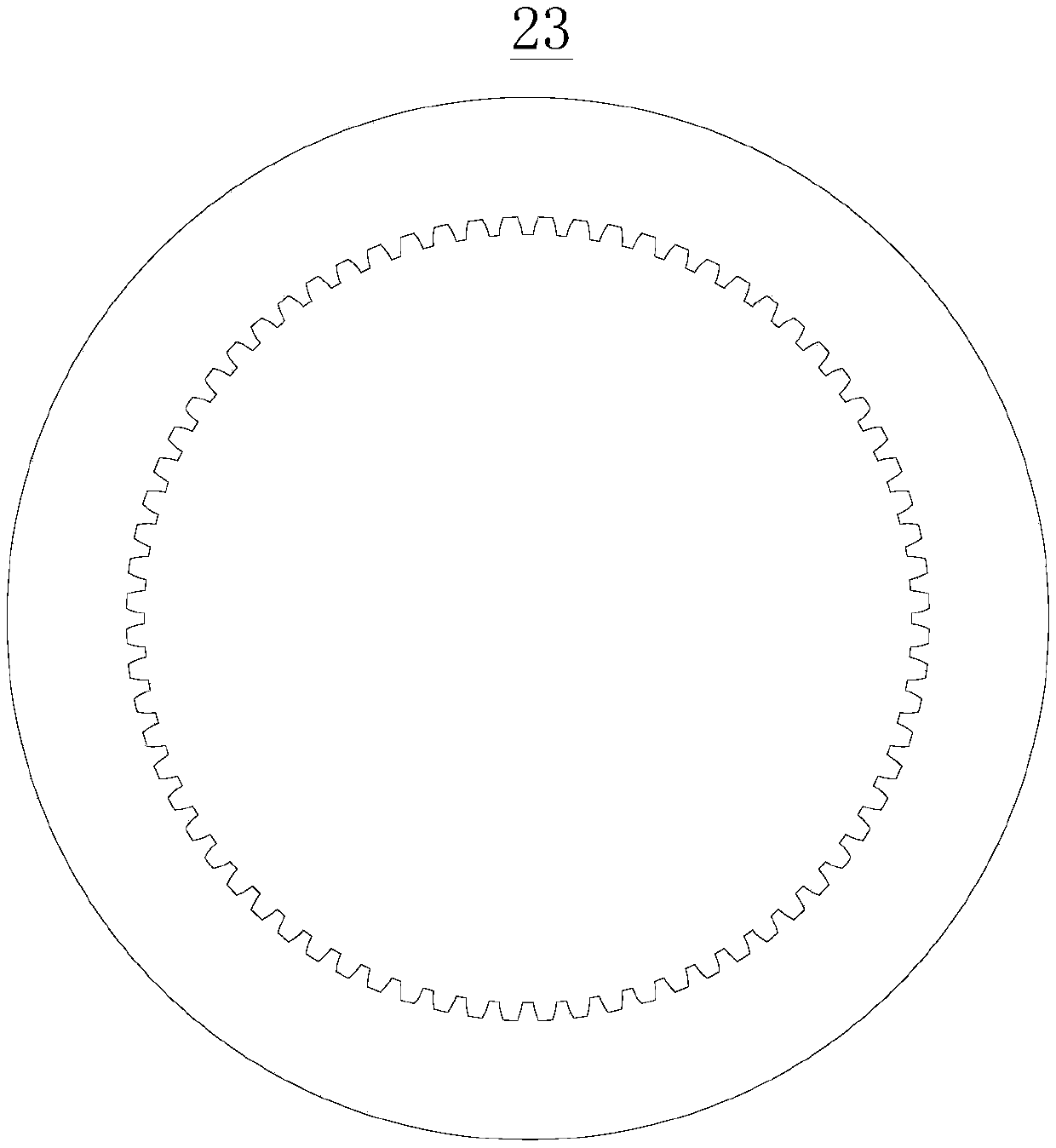

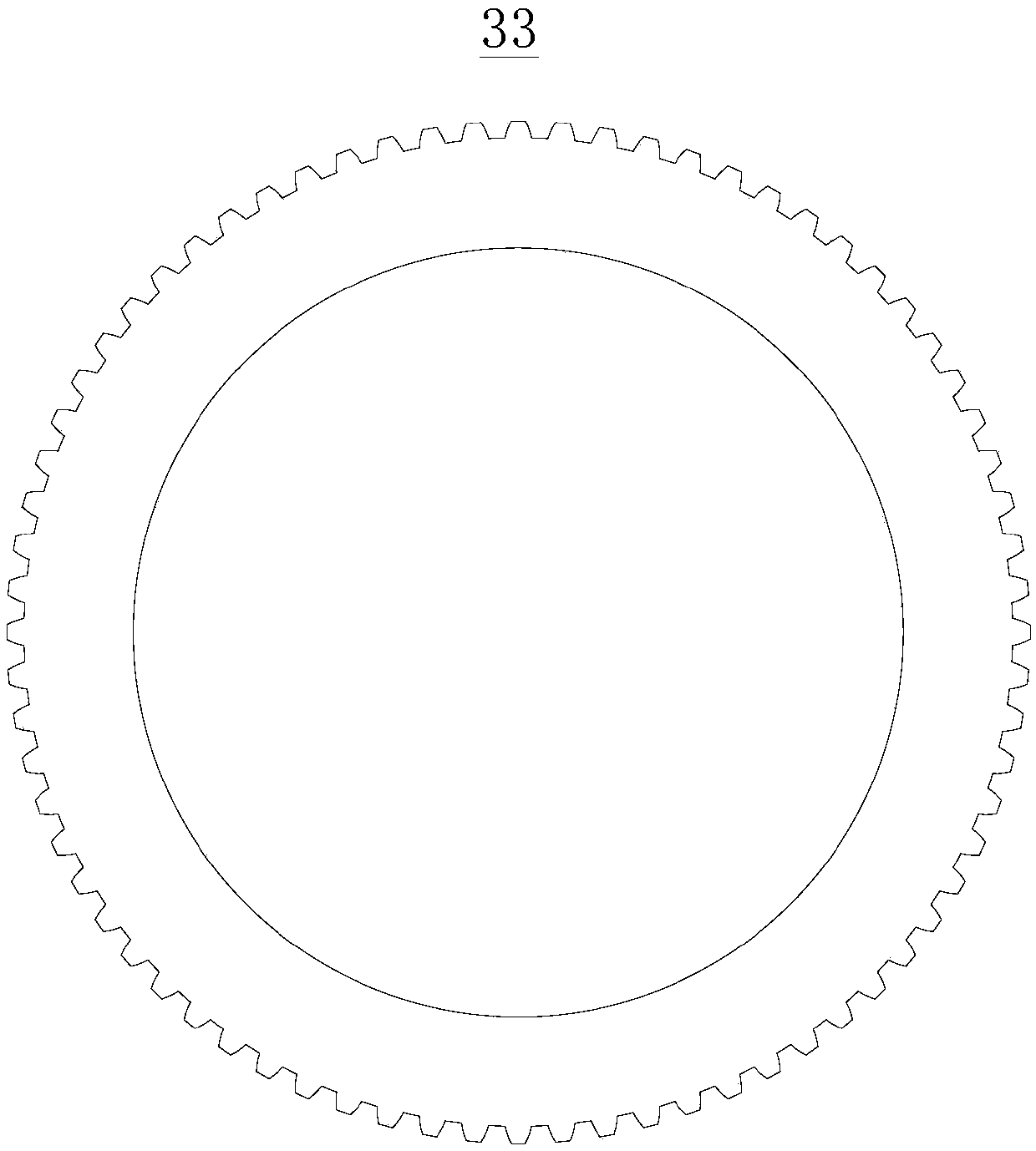

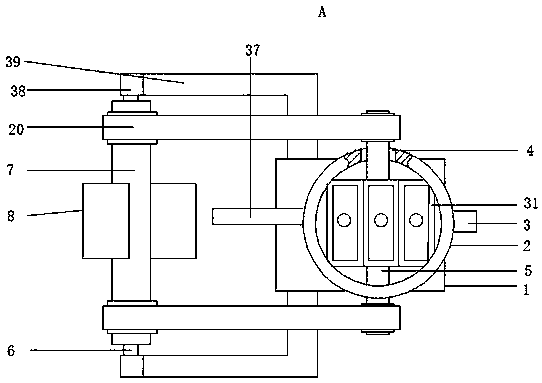

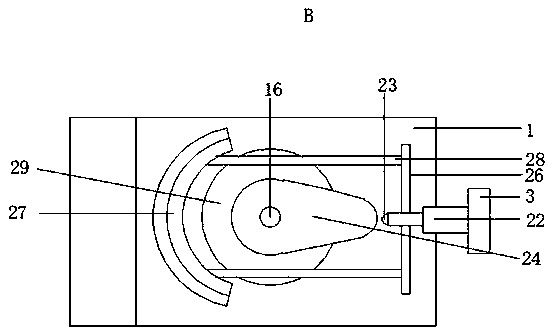

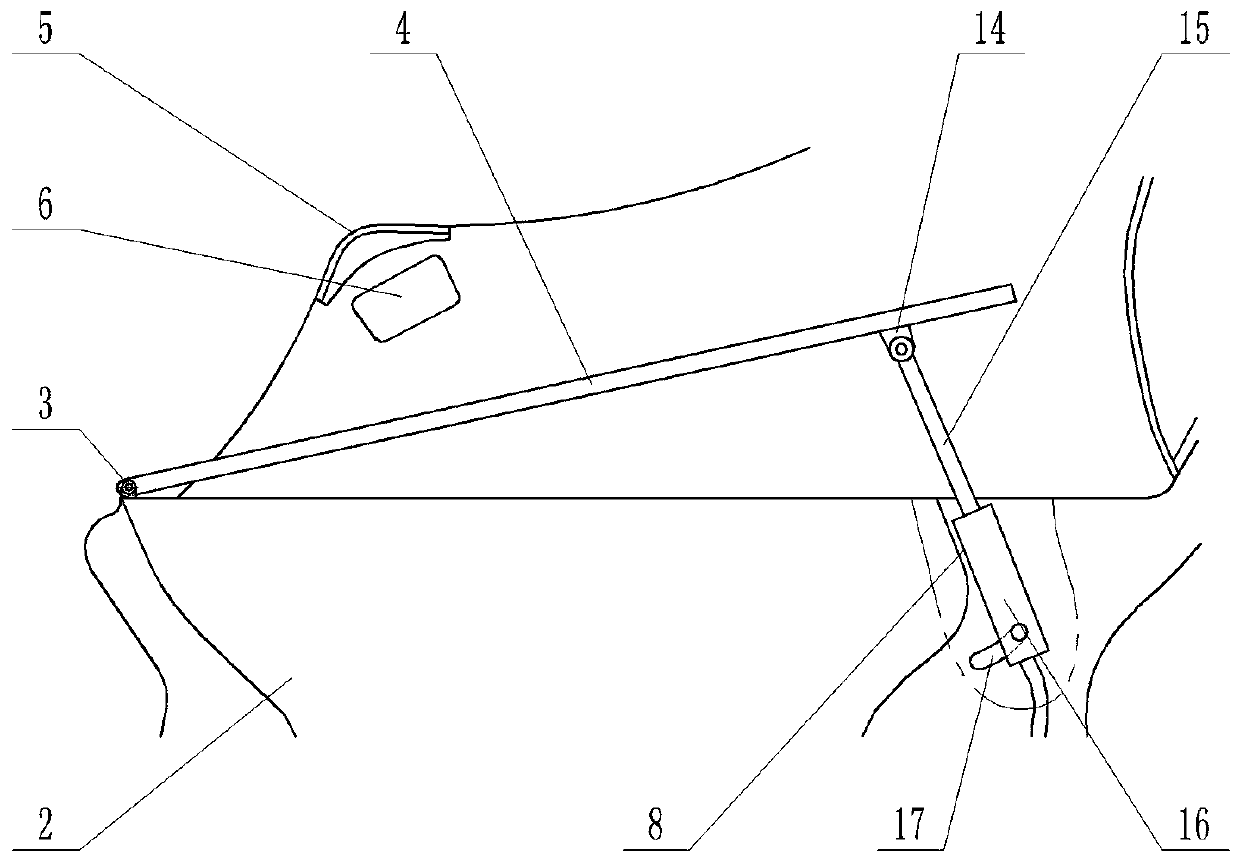

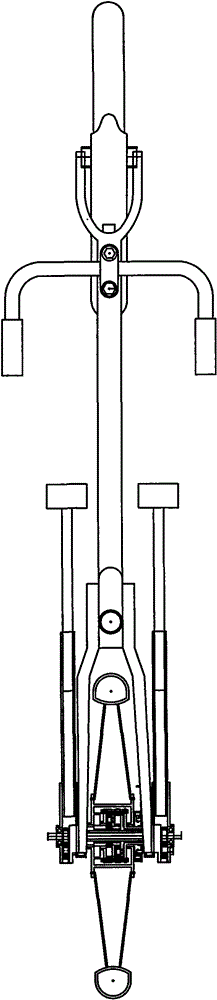

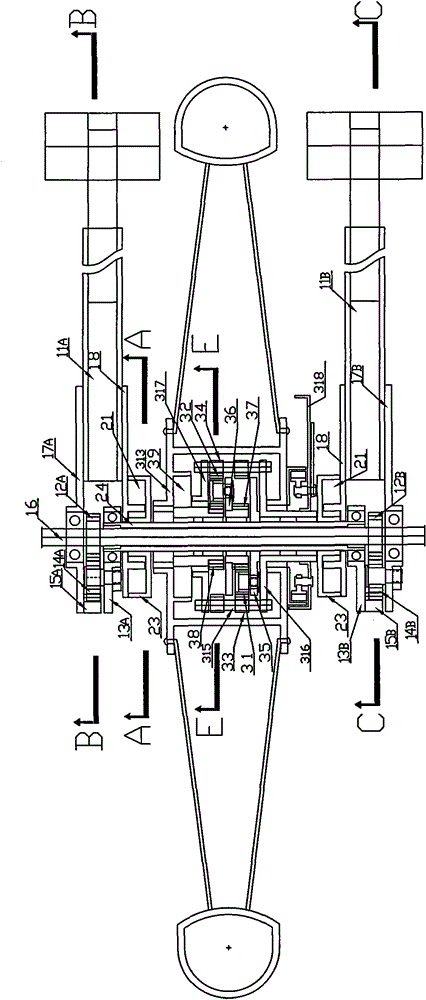

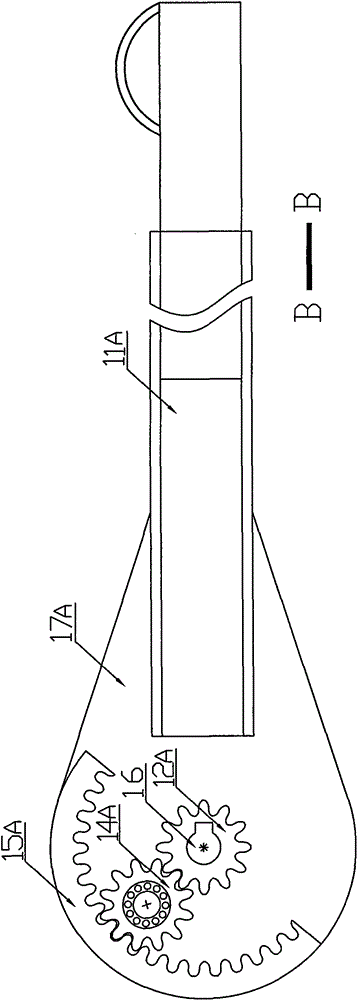

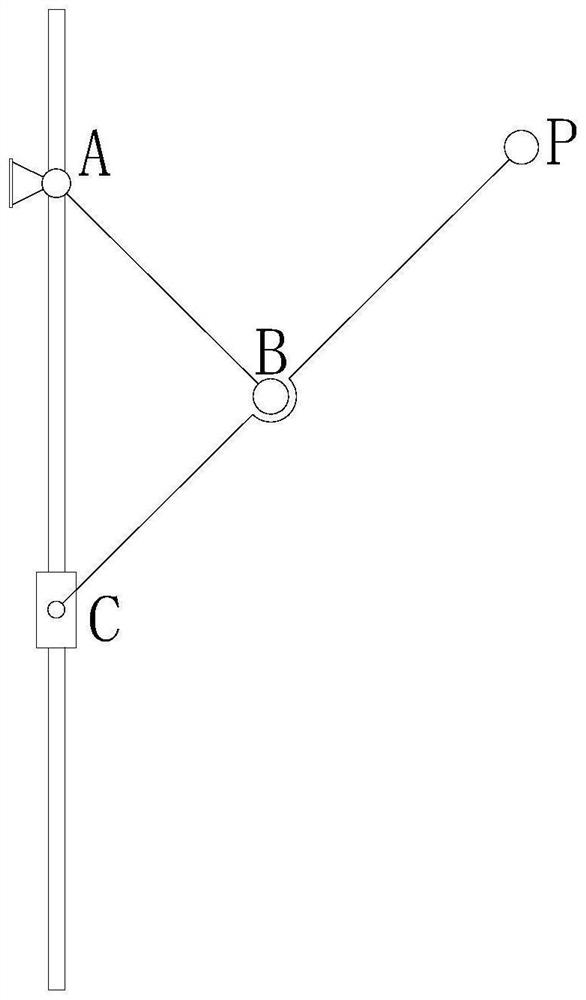

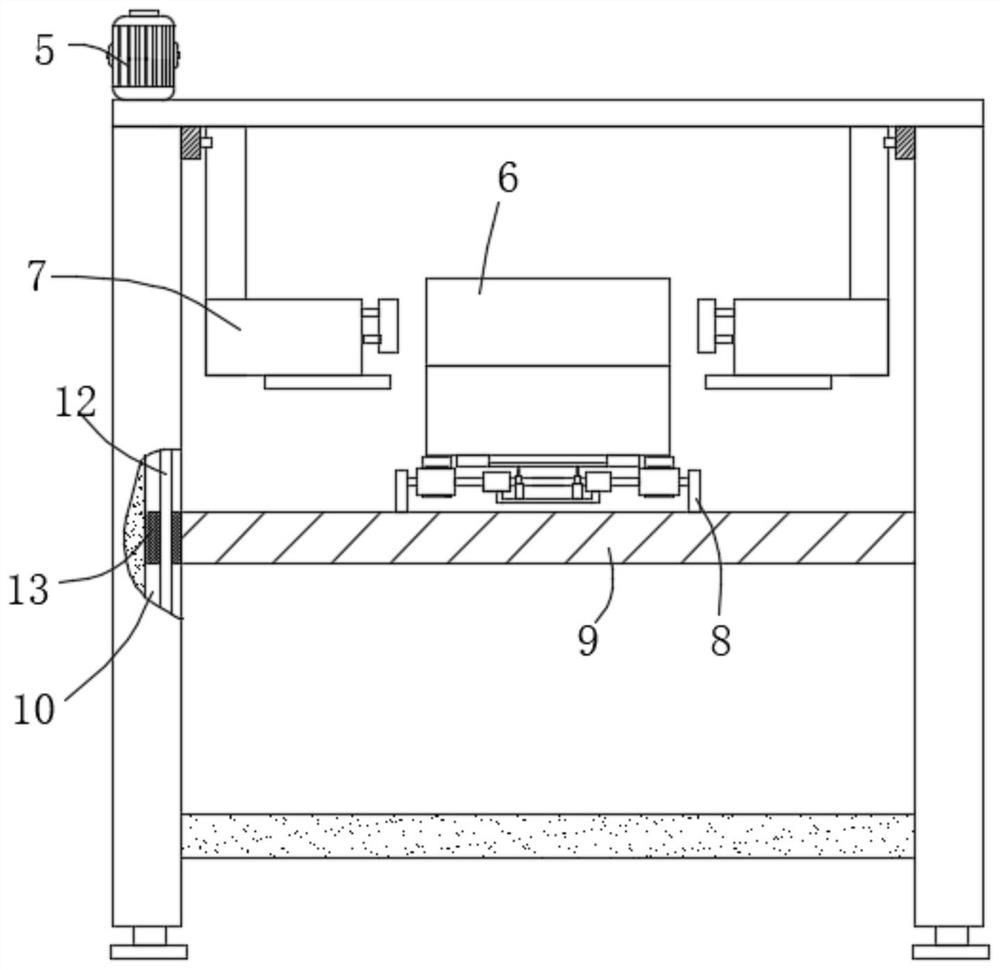

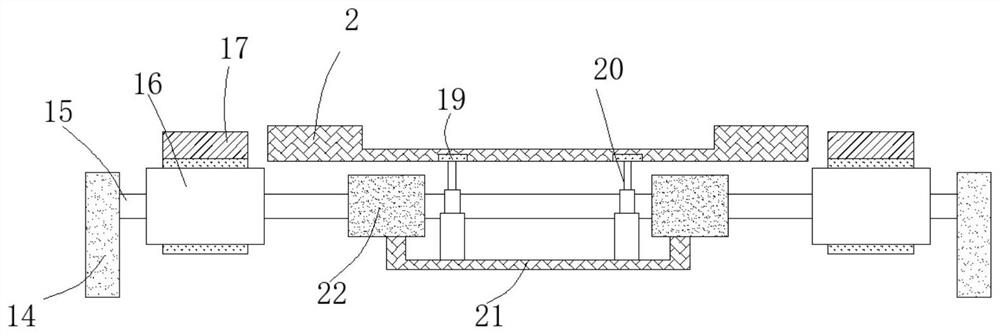

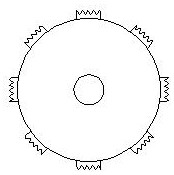

Lever ratchet wheel linkage bicycle

InactiveCN101973355ASolve the alternating movement of up and downResolve connectionWheel based transmissionRider propulsionTurning framesEngineering

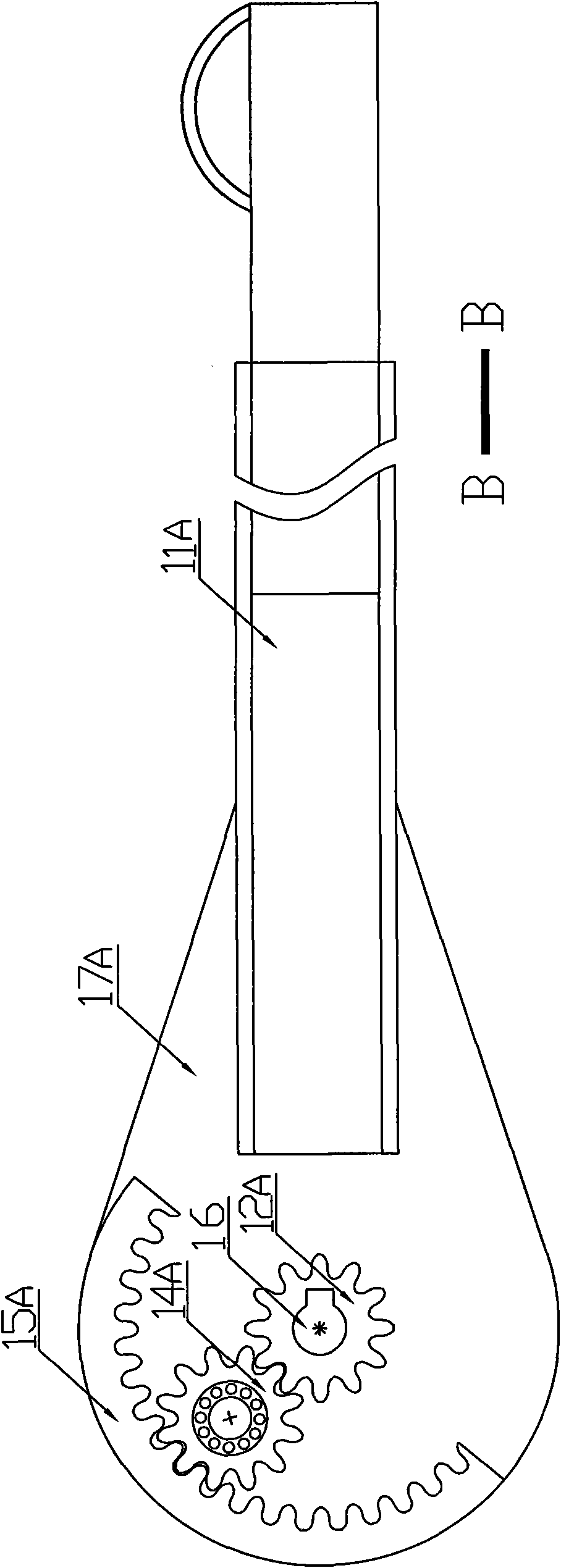

The invention discloses a lever ratchet wheel linkage bicycle, comprising a bicycle frame, a front bicycle wheel, a rear bicycle wheel, a rear wheel shaft and a bicycle wheel drive device, wherein, the bicycle wheel drive device comprises a left lever and right lever up-to-down conversion device and a left ratchet wheel and right ratchet wheel drive device, wherein, the left lever and right left up-to-down conversion device comprises a lever, a lever connector, a frame connector, a sun wheel, a planet wheel, a gear ring and a central shaft; and the left ratchet wheel and right ratchet wheel drive device is a friction-type ratchet wheel mechanism comprising a roller, a slope-type one-way clutch, a ratchet wheel hub and a ratchet wheel connector. In the invention, the drive, speed change and the acting force are wholly centralized on the rear wheel shaft to lead the length of the lever to be 3-5 times of a crank mechanism; the lever can be retracted; a seat cushion can be moved front and back; the pedal rotating angle of both feet is changed to form the action of stepless speed regulation; and the speed is changed by a star wheel structure, so as to lead the transmission to be compact and the operation to be reliable. The invention provides a bicycle which is brand new, has simple structure, high transmission rate, long service life, low failure rate, convenient maintenance and comfort and stable riding.

Owner:NANTONG BAOTIAN PACKING MACHINERY

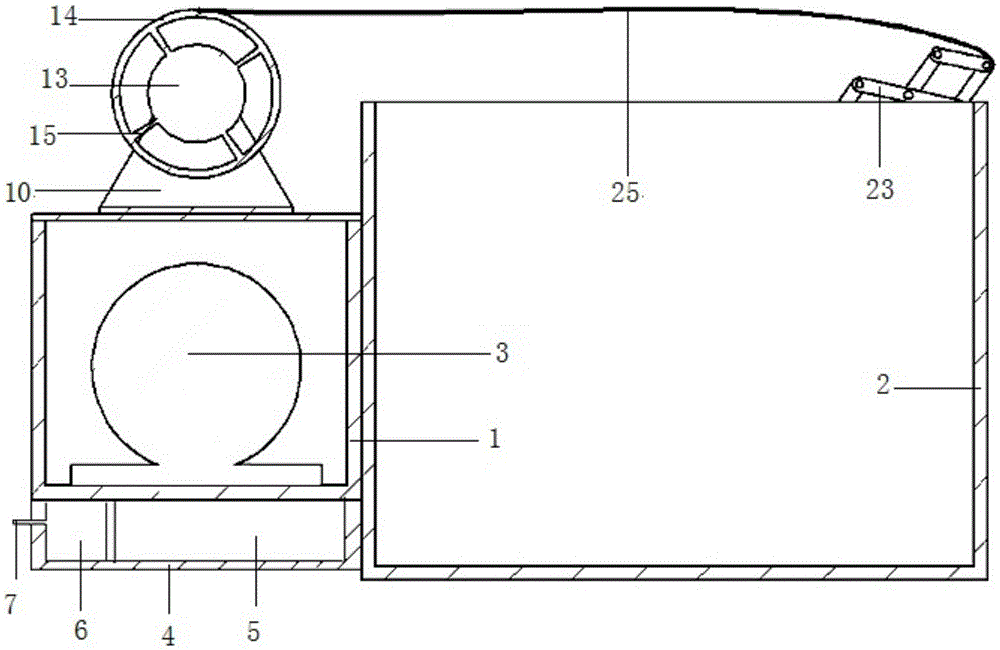

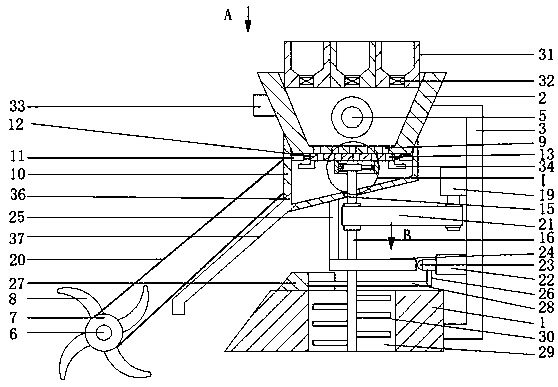

Drilling, expanding and cleaning integrated reverse-circulation rotating squeezed branch pile machine

ActiveCN102535448AImprove performanceExtended service lifeBulkheads/pilesArchitectural engineeringDrill bit

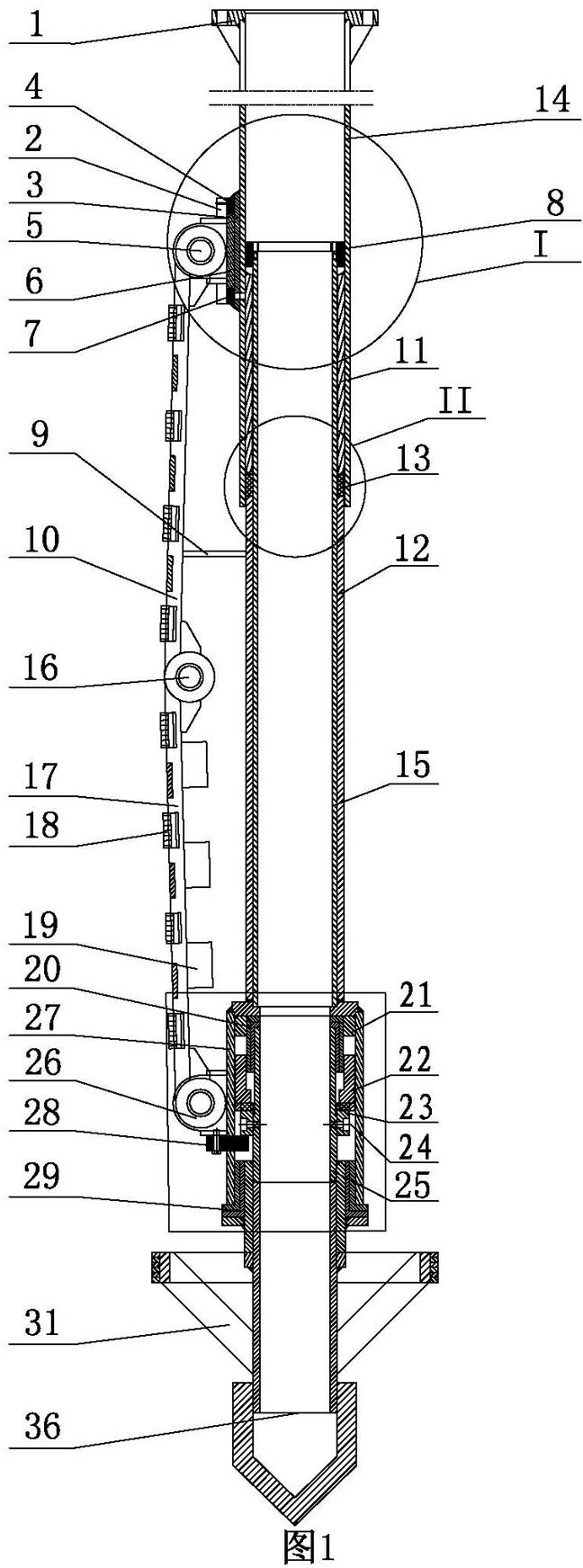

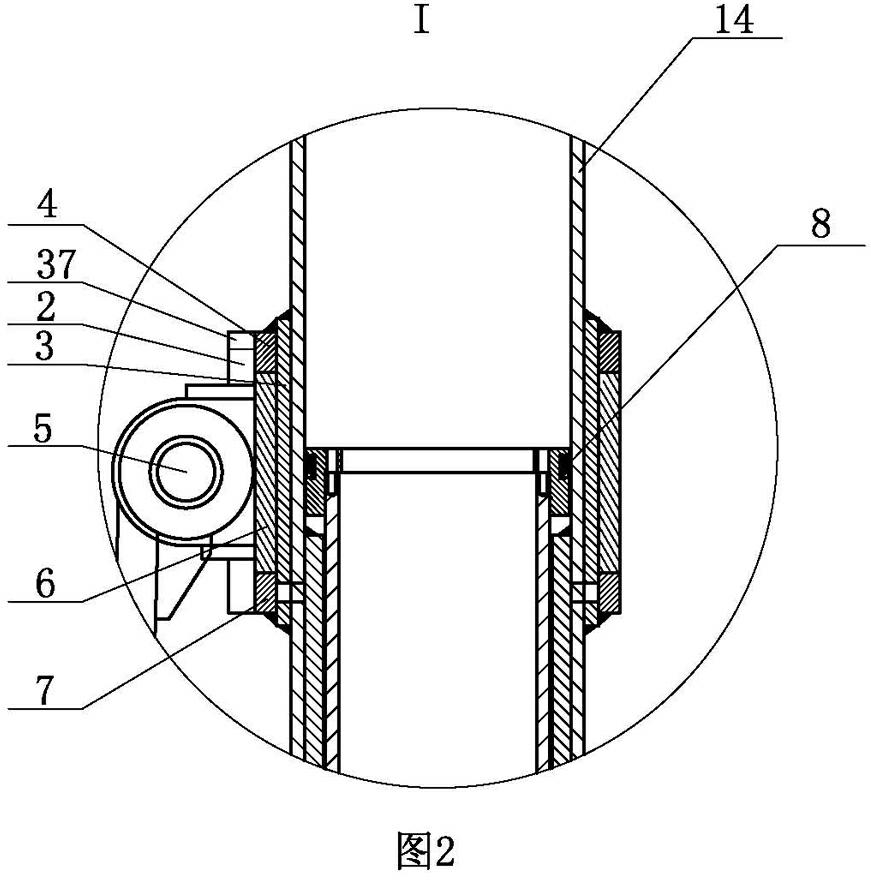

The invention discloses a drilling, expanding and cleaning integrated reverse-circulation rotating squeezed branch pile machine, comprising an outer pipe and an inner pipe, wherein the inner pipe is arranged in the outer pipe, and the inner pipe is connected with the outer pipe to form a telescopic pole; an outer pipe guide bar is arranged on the inner wall of the outer pipe, the outer wall of the inner pipe is provided with a vertical guide groove, a vertical guide block is arranged in the guide groove, the part between one end of the guide groove, close to the outer pipe, and the guide block is a rotating groove, the guide groove is arranged at one side of the guide block, and a part of the guide groove, capable of matching the guide bar of the outer pipe, is a vertical moving groove, the outer pipe guide bar is matched with the vertical moving groove and can vertically move in the vertical moving groove; the vertical moving groove is communicated with the rotating groove, the outer end of the inner pipe or the outer pipe is connected with a drill bit through a ratchet wheel mechanism, a mud-suction port is arranged on the drill bit; the outer pipe is articulated with one end of a first arm by a first connecting part, the other end of the first arm is articulated with one end of a second arm, and the other end of the second arm is articulated with the inner pipe by a second connecting part.

Owner:BEIJING RONGCHUANG GEOTECHNICAL ENG CO LTD

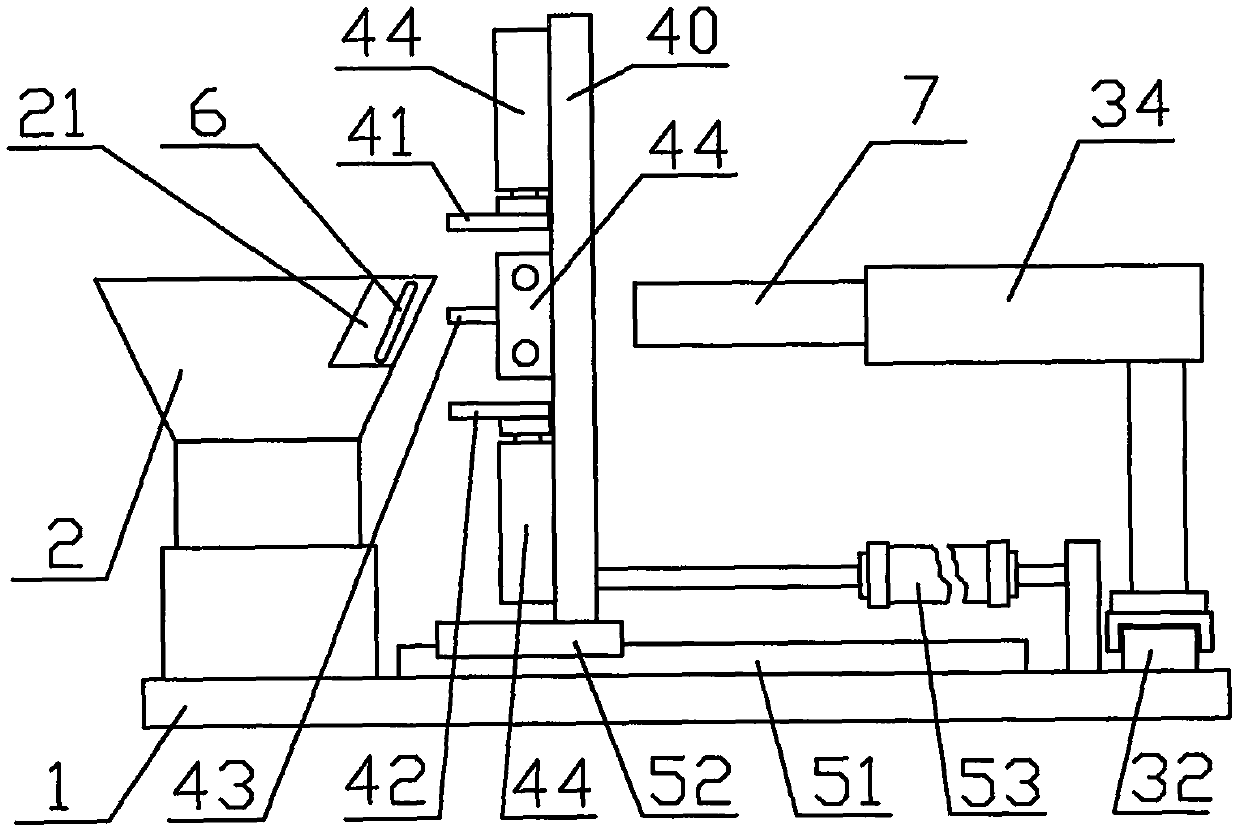

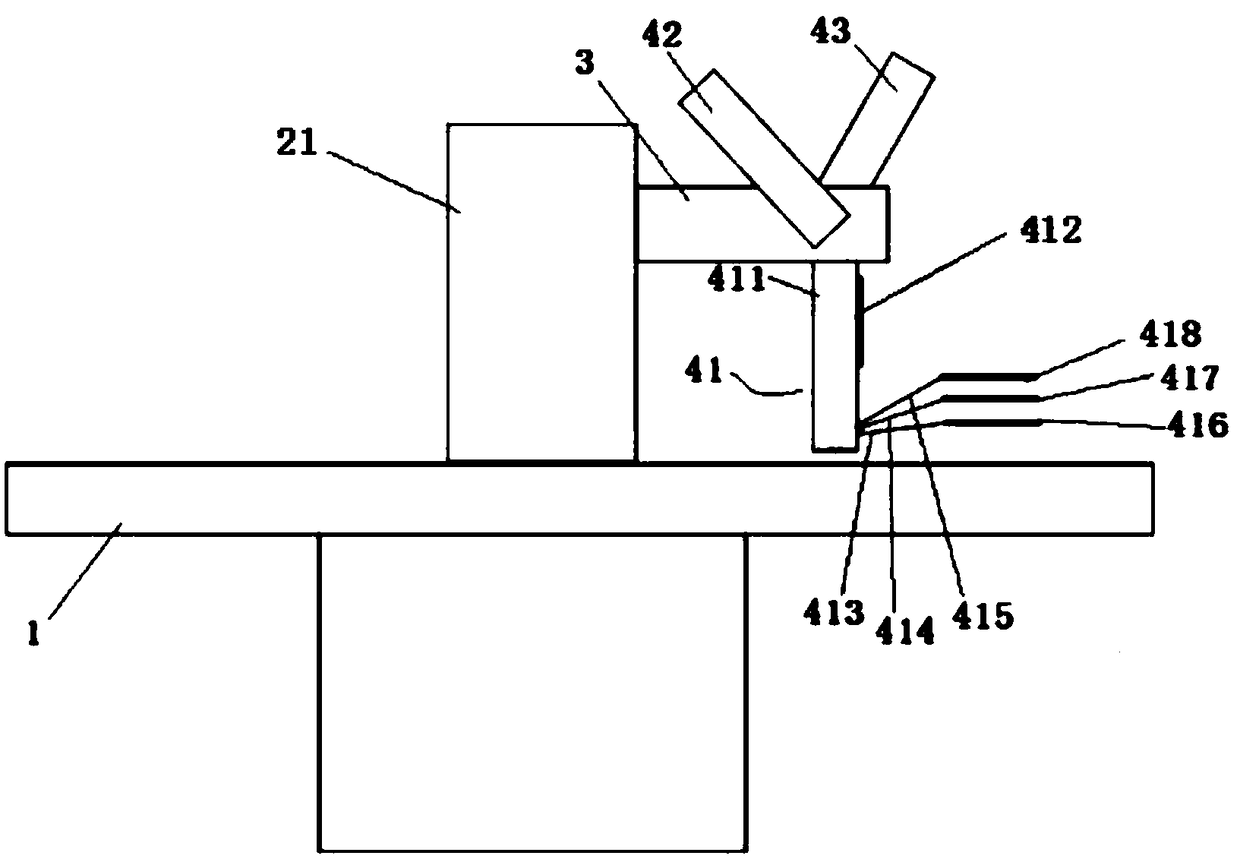

Automatic feeding device

ActiveCN105501941ASimple structureEasy to installConveyorsConveyor partsEngineeringMechanical engineering

The invention relates to an automatic feeding device which comprises a feeding assembly, a storage assembly and a transfer assembly. The storage assembly is arranged on one side of the feeding assembly. The feeding assembly can transfer materials to the storage assembly in the first direction. The storage assembly comprises a first baffle and a second baffle which are sequentially arranged in the first direction. The first baffle and the second baffle can move relative to the feeding assembly so as to block or allow passing of the materials. The transfer assembly comprises a pushing-blocking assembly and is arranged on the side, away from the feeding assembly, of the storage assembly. The pushing-blocking assembly can reciprocate in the second direction relative to the feeding assembly. The automatic feeding device can be used for storing and transferring stators and other materials, the materials are transferred from the feeding assembly to the storage assembly in order and then are allowed to pass and be transferred to the transfer assembly in order, so that the materials are automatically transferred in order to be machined or detected or operated in follow-up steps, the feeding efficiency is improved, and the labor intensity is lowered.

Owner:GREE ELECTRIC APPLIANCES INC

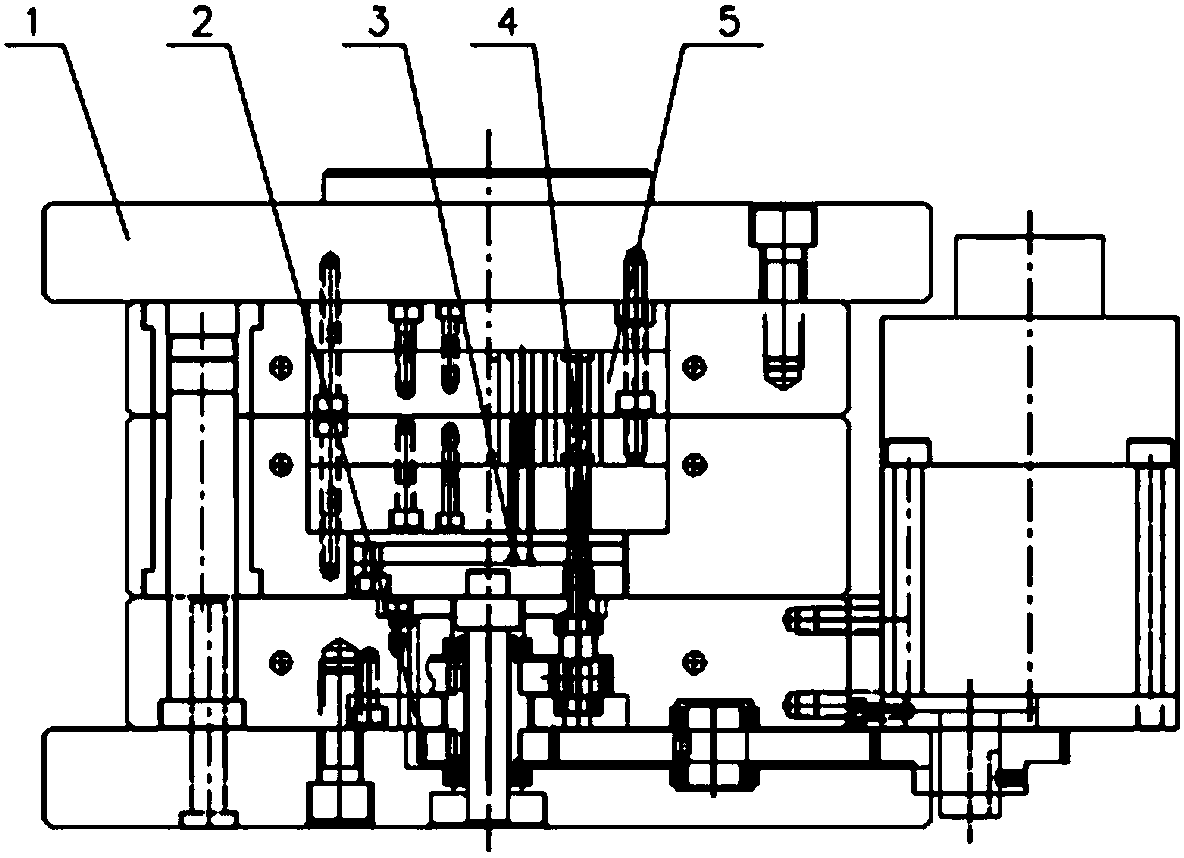

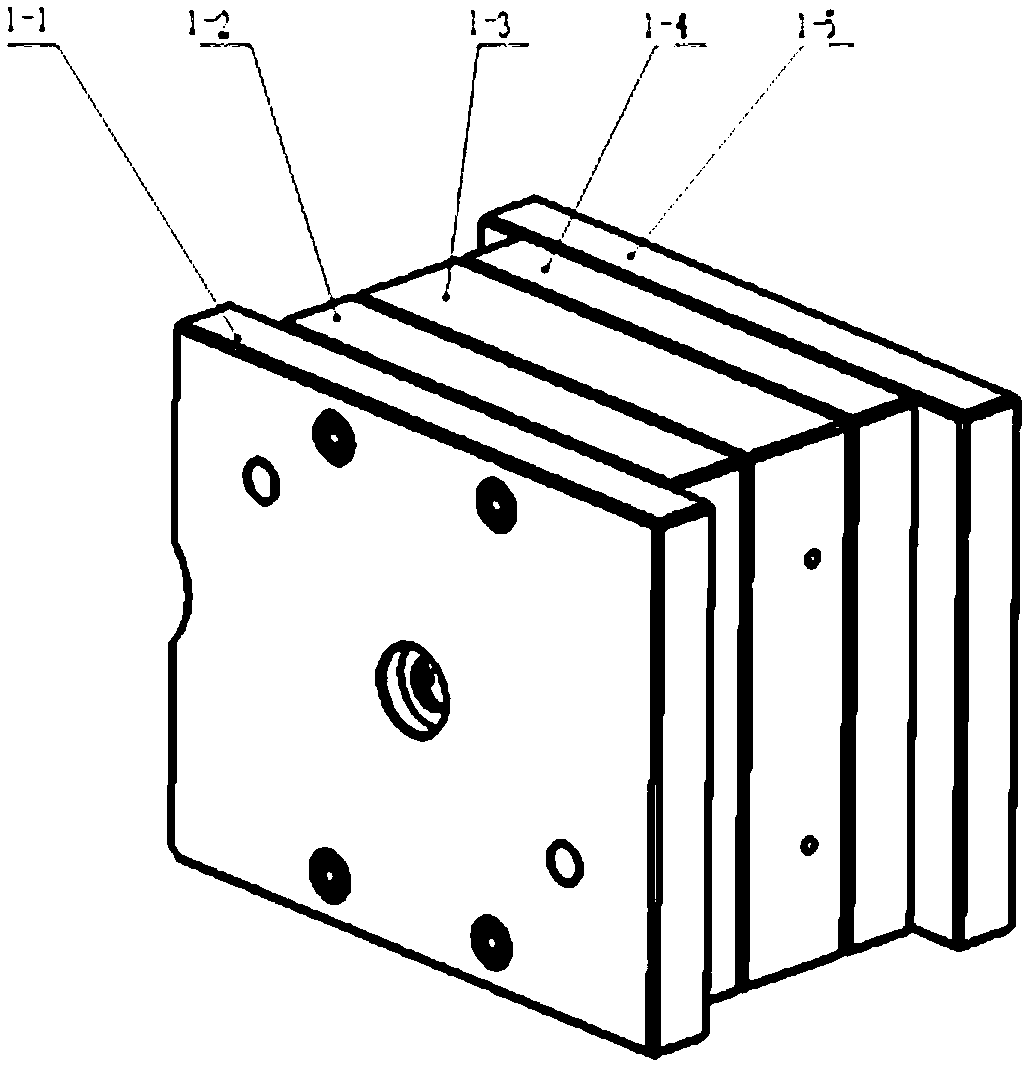

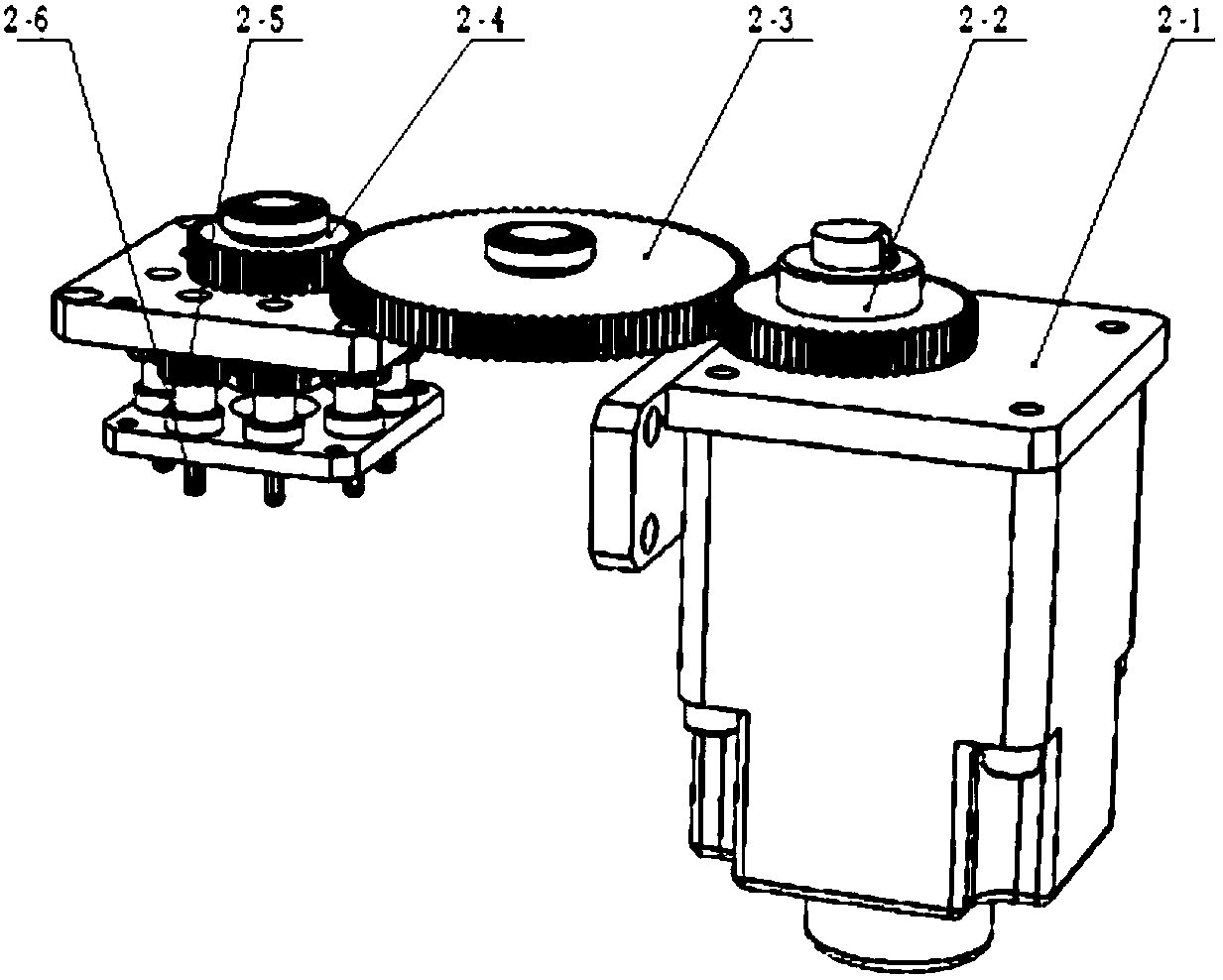

Mini-type thread mold with front mold hinged thread mechanism

The invention discloses a mini-type thread mold with a front mold hinged thread mechanism. The mini-type thread mold with the front mold hinged thread mechanism comprises a mold frame, a gear transmission mechanism, an ejection mechanism, a thread connection rod and a molding pouring system; the mold frame is composed of a fixed side mounting plate, a female mold plate, a male mold plate, a bearing plate and a movable mounting plate; the gear transmission mechanism is composed of a small servo motor speed reducer and a series gear mechanism; the ejection mechanism is composed of an ejector rob, an upper ejector plate, a lower ejector plate and centres; and the molding and pouring system is composed of a male mold insert, a female mold insert, a base plate, a male mold bush, a female mold bush and a machine nozzle. The overall mechanism is matched with an injection molding machine to finish molding of a base product, specifically, through high-pressure casting of the injection molding machine and mold opening, the servo motor speed reducer drives the gear mechanism, the connection rod transmits torque to a threaded rod to achieve hinged thread demolding action, the ejection mechanism ejects the product out, and the structure has the characteristics that the gear mechanism is concentrated on a front mold and embedded with the ejection mechanism in a concentrated mode, the size ofthe whole mold frame is reduced, and the machining precision of the mold and the product production efficiency are improved fundamentally.

Owner:辽宁中蓝光电科技有限公司

Plastic bag strapping machine

InactiveCN109733657AStable jobWork compactBinding material applicationBundling machine detailsEngineeringTransfer mechanism

The invention discloses a plastic bag strapping machine. The plastic bag strapping machine comprises a machine frame, a vibration disc device and a plastic bag conveying device. The plastic bag strapping machine is characterized in that a U-shaped notch is arranged on the vibration disc device; a rubber band expansion device is arranged at the position corresponding to the U-shaped notch; the rubber band expansion device comprises a bracket; the bracket is provided with an upper side supporting rod, a bottom side supporting rod, two side supporting rods and an expansion cylinder; an insertionmoving mechanism is connected between the bracket and the machine frame; and the plurality of supporting rods penetrate through the U-shaped notch to be inserted into an inner hole of a rubber band under driving of the insertion moving mechanism, so that the rubber band is expanded in one direction and taken out from the U-shaped notch after being narrowed, and then stretched again. Compared withthe prior art, the plastic bag strapping machine omits a rubber band transfer mechanism and a driving device thereof, so that the whole machine is compact in structure, the working procedure is simplified, and the grasping and expansion work of the rubber band is reliable and stable.

Owner:王秀来

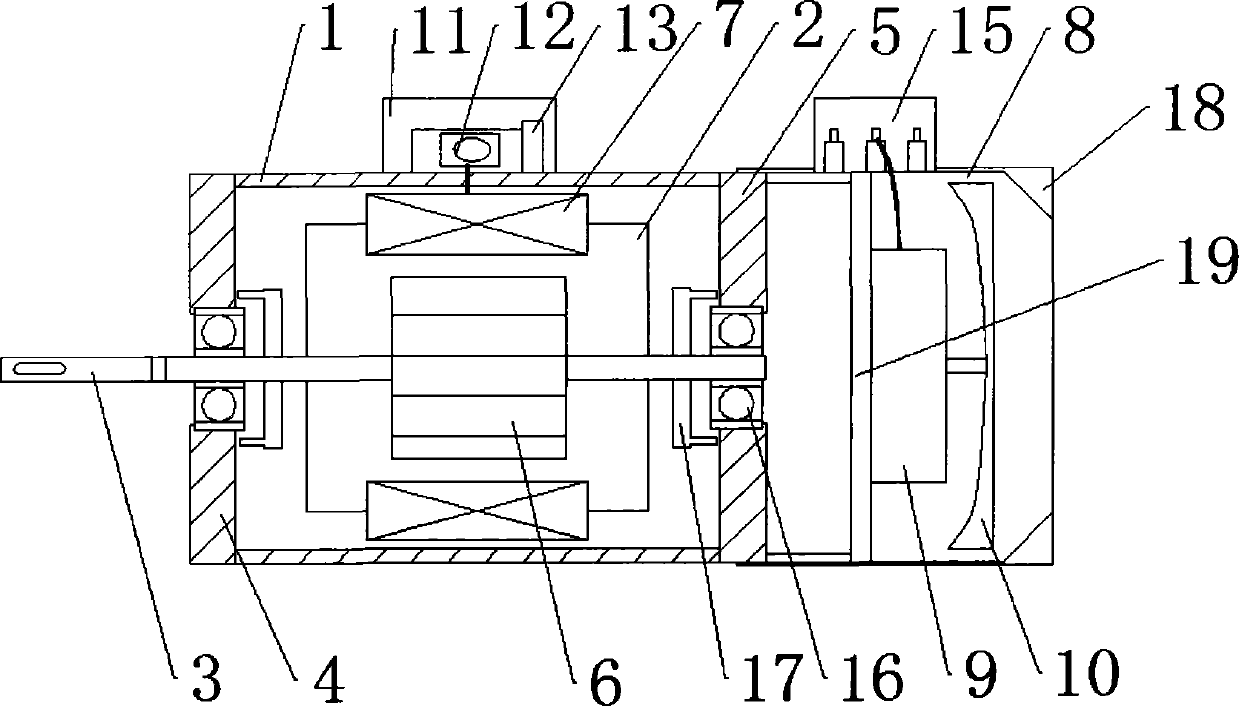

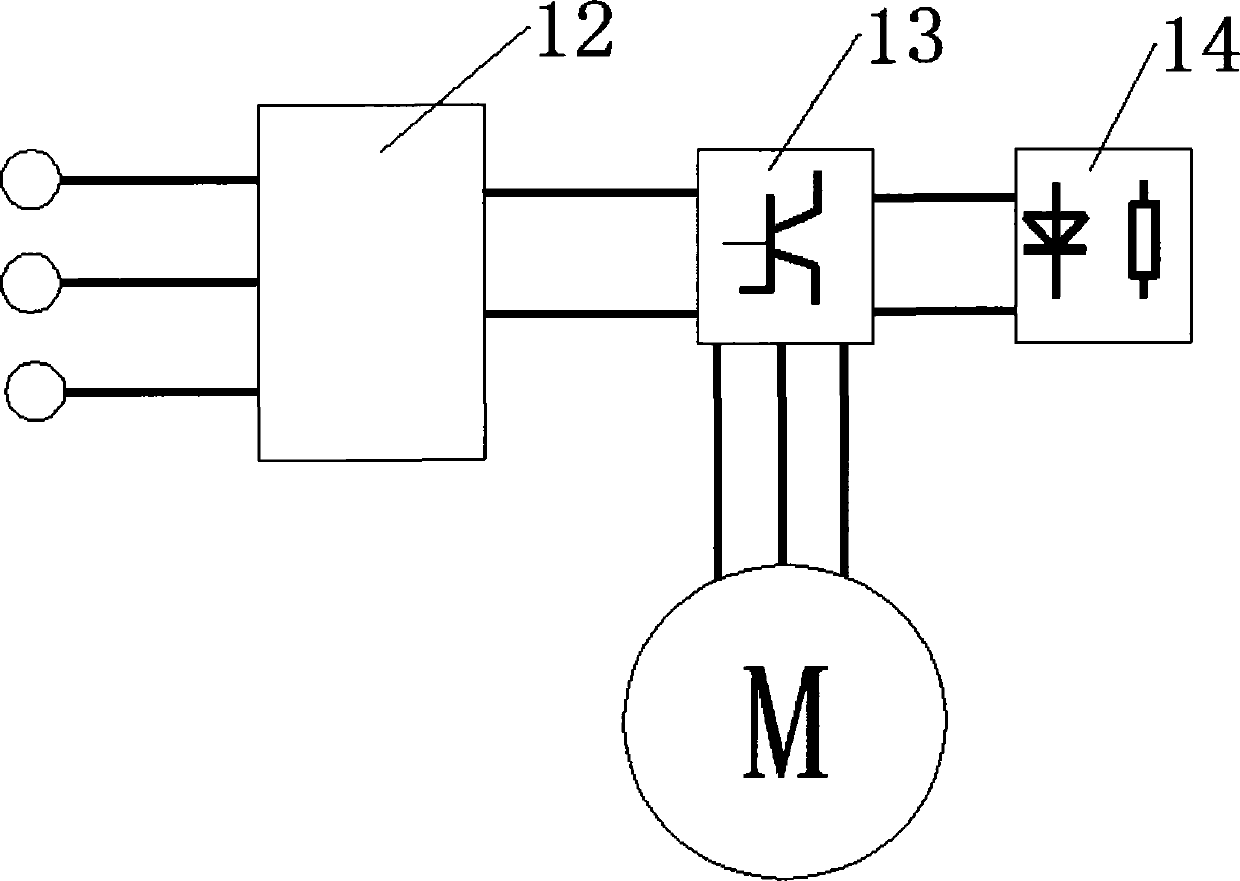

Variable frequency motor

InactiveCN103812249AReduce installation difficultyWork reliablyAssociation with control/drive circuitsMagnetic circuit rotating partsElectric machineIntegrated design

The invention discloses a variable frequency motor and relates to the field of motors. The variable frequency motor comprises a shell, a stator and a rotating shaft, the stator is mounted in the shell, an end cover is mounted at each of two ends of the shell, wherein the end cover comprises a front cover and a rear cover; the rotating shaft is provided with a rotor, and the rotor is a multi-polar magnetic ring which is made of permanent magnet oxysome; a coil winds the stator; the rear cover is provided with a radiating hood; an air blower and a fan are mounted in the radiating hood; the shell is provided with a control junction box which is connected with the coil; an IC control chip, an inverting tube and a buffer circuit are mounted in the control junction box; the inverting tube and the buffer circuit are connected with the IC control chip in series after being connected in parallel. The integrated design performance of the multi-polar magnetic ring of the rotor is reliable, and the mounting difficulty is low; the SPWM operation of the IC control chip and the inverting buffer of the inverting tube and the buffer circuit are capable of generating electric parameters with adjustable frequency, and the electric parameters are capable of realizing the regulation for the motor rotating speed after being input to the motor; the variable frequency motor saves energy, is effective, and is compact in structure.

Owner:NANTONG DAQING ENERGY SAVING TECH

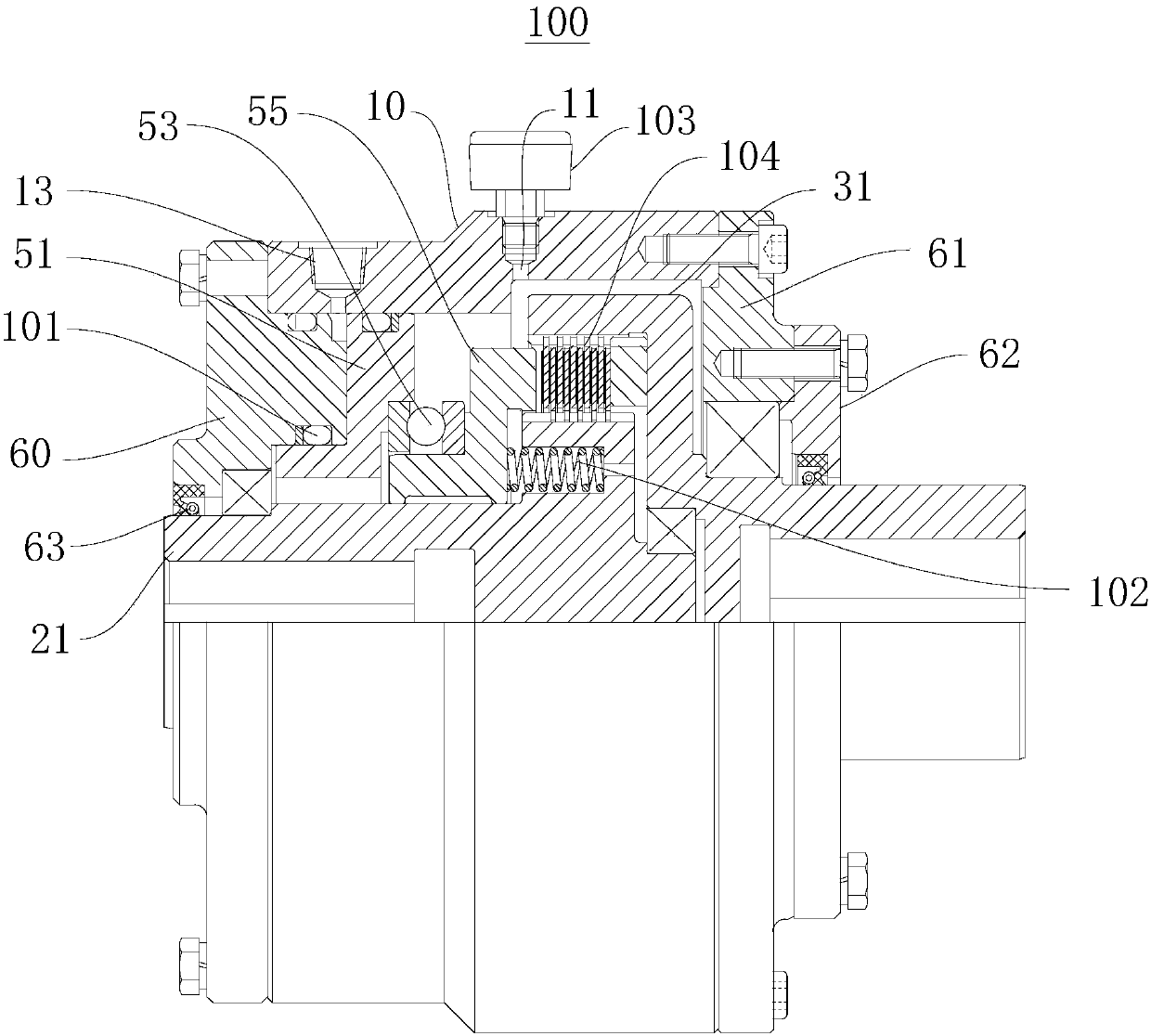

Inner-outer tooth friction plate type hydraulic clutch

PendingCN107588118AReliable transmissionGood cooling effectFluid actuated clutchesClutchWork performance

The invention provides an inner-outer tooth friction plate type hydraulic clutch relating to the technical field of clutches. The inner-outer tooth friction plate type hydraulic clutch comprises a shell, a power input component, a power output component, a pushing and pressing component and a resetting part, wherein the shell comprises a cylinder body which is provided with radiating holes, an oilfeeding hole for feeding hydraulic oil and a containing cavity for containing parts; the power input component comprises an input shaft and first friction plates which are meshed with the input shaft; the power output component comprises an output shaft and second friction plates which are meshed with the output shaft; the first friction plates and the second friction plates are arranged at intervals, have a gap, and are close to the radiating holes; the pushing and pressing component is positioned in the containing cavity and can push the first friction plates and the second friction platesto be attached; and the resetting part is arranged between the input shaft and the pushing and pressing component. The inner-outer tooth friction plate type hydraulic clutch provided by the inventionis reliable in working performance, is very practical and is suitable for promotion and application.

Owner:JIANGSU SHINRI GEAR SYST CO LTD

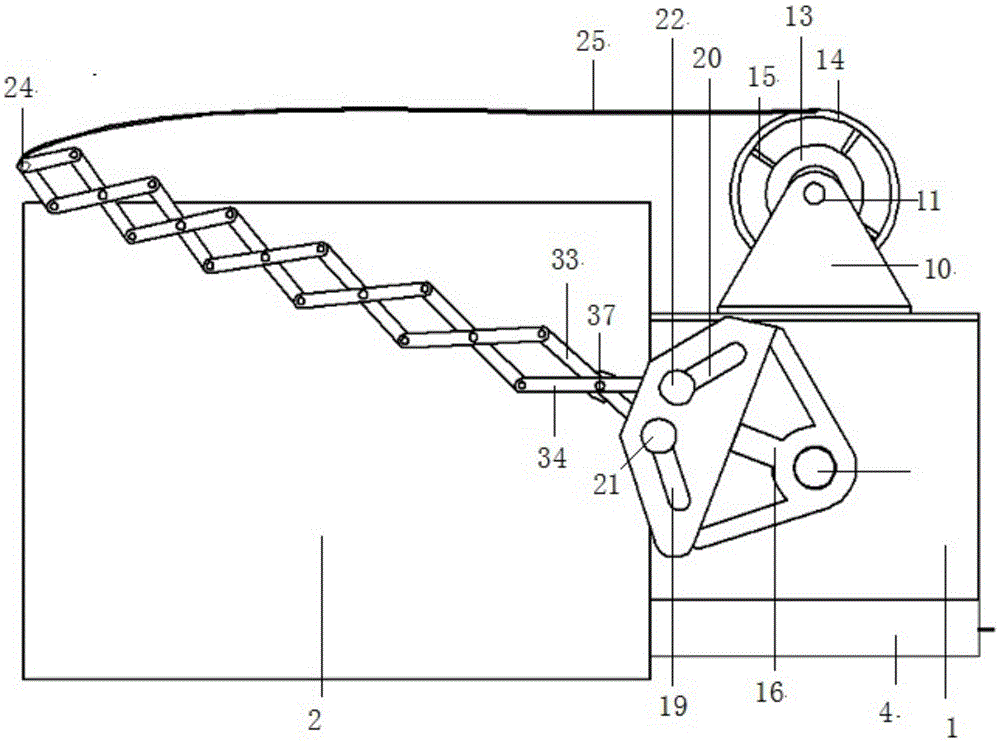

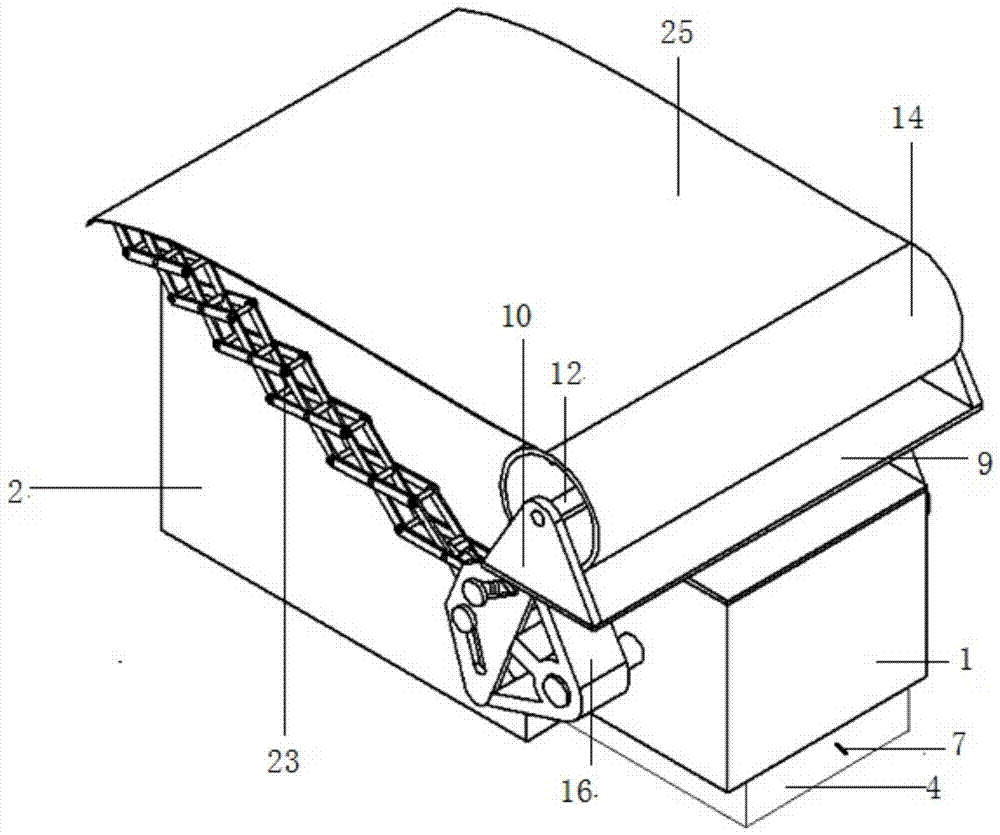

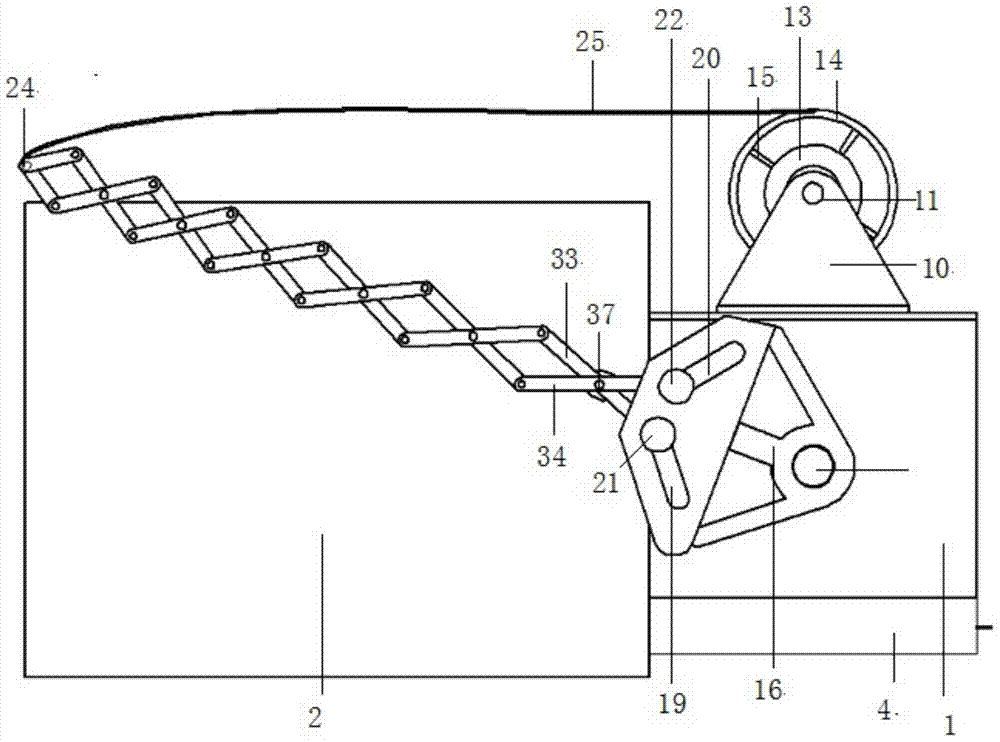

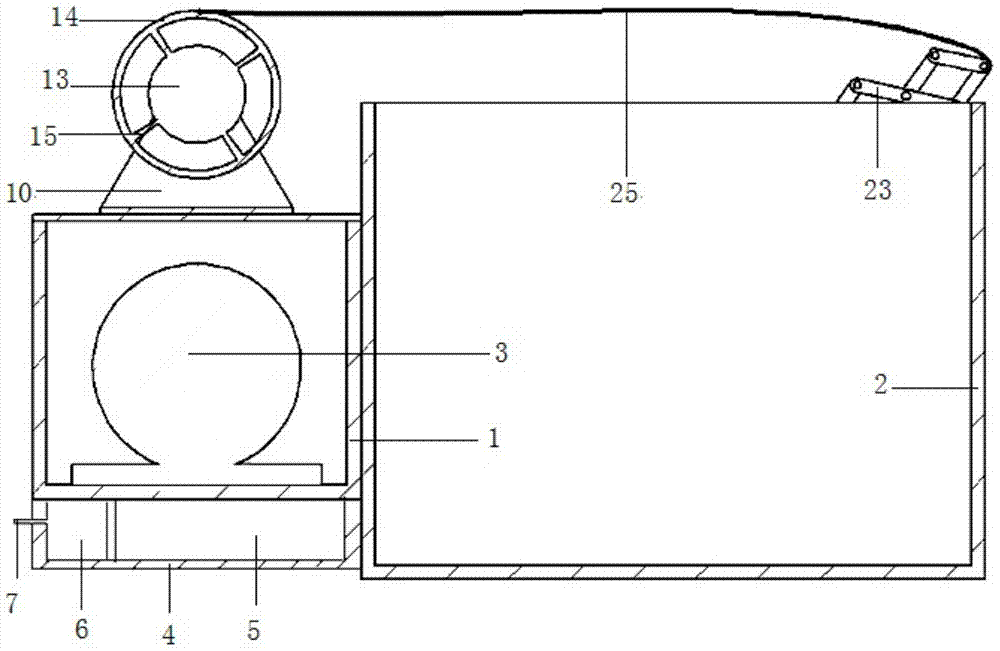

Device for automatically covering tarpaulin of truck

ActiveCN105539261AClosely connectedRapid expansion and contractionLoad coveringRemote controlMaterial resources

The invention relates to the technical field of carriage shield assembly parts, in particular relate to a device for automatically covering tarpaulin of a truck. According to the device disclosed by the invention, a stepping motor is adopted, so that the device can work more accurately and effectively; a control device and a remote control are adopted, so that people can remote control the work of the device, the work can be more efficient, and manpower and material resources can be saved; an external rotor motor is adopted, so that the structure of the device can be more simple, and assembly and maintenance are more convenient and efficient; a winding drum is adopted, so that device coverage and tarpaulin folding can be more efficient, and the manpower and the material resources can be saved; an expansion bracket is adopted, so that the mass of the device can be lighted, and the device structure can be more simple, lighter and convenient; a guide rail pulley is adopted, so that the expansion and the contraction of the expansion bracket can be more rapid, and the labor and the time can be saved; an inner shears-fork plate and an outer shears-fork plate are adopted, so that the structure of the expansion bracket can be more simple, lighter and convenient.

Owner:NANTONG ZHONGYI BOILER EQUIP

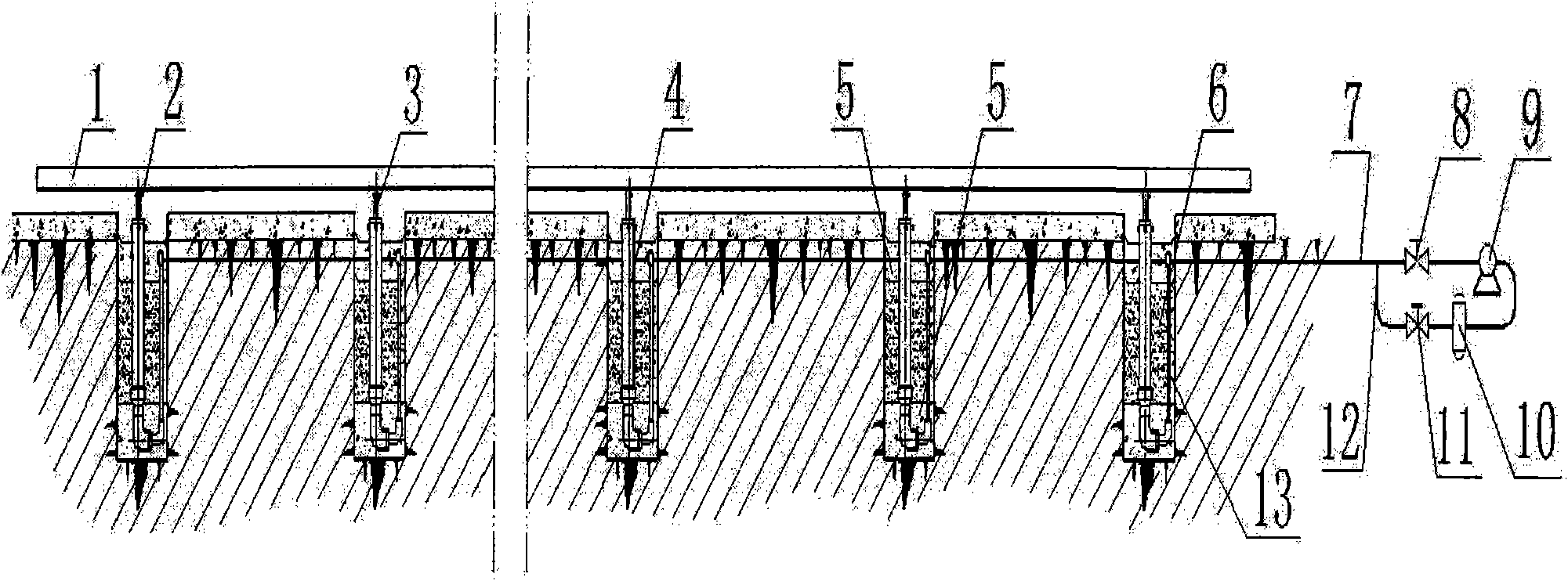

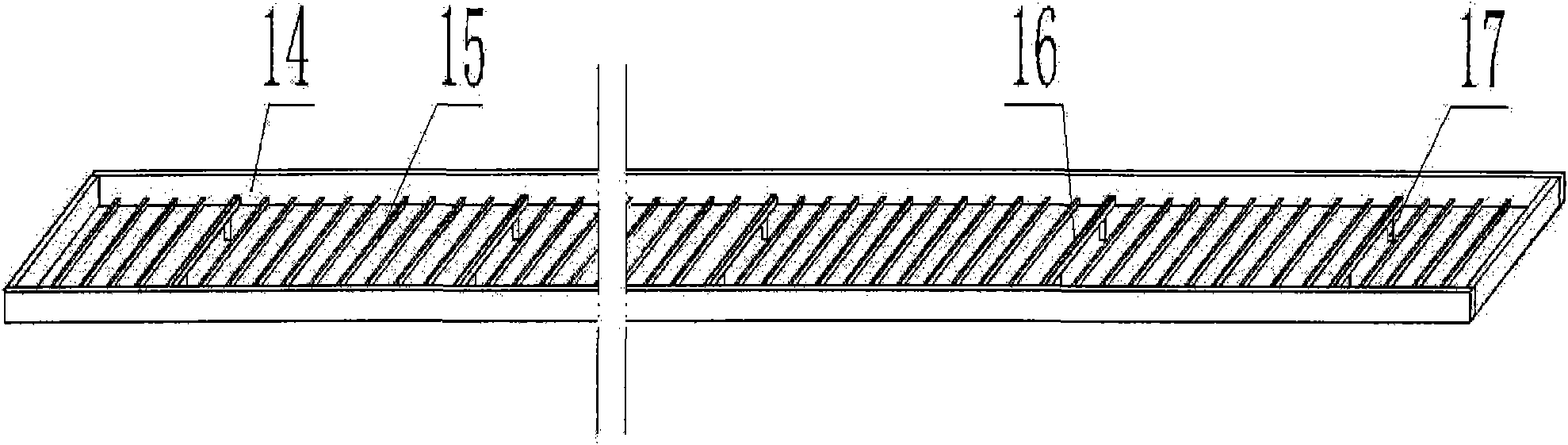

Pressure-driven lift seedling culture bed

InactiveCN102172206AReduce volumeReduce weightAgriculture gas emission reductionCultivating equipmentsPressure.driveSeedling

The invention relates to a seedling culture bed, in particular to a pressure-driven lift seedling culture bed, belonging to the technical field of seedling culture.Traditionally, an overhead seedling culture bed is employed for seedling culture, which is not conducive to root generation of the seedlings at the early stage but also consumes a lot of water; the seedlings can also be cultured on a ground seedling culture bed; although the practice is conducive to root generation of the seedlings and water conservation, the problems such as mutual interspersing of root systems, root segment mildew and the like are easily caused. Multiple lifters of the seedling culture bed are arranged at the same underground horizontal plane, piston connecting rods of the lifers serve as support columns of a seedling culture bed frame and are connected with connecting cylinders of the seedling culture bed frame to form the pressure-driven lift seedling culture bed. Water or gas is used as the transmission stress of the lifters; in particular, water from a nursery garden water supply system is used as the transmission stress to lift the seedling culture bed, thus simplifying the fabrication process of the pressure-driven lift seedling culture bed. by using the seedling culture bed in the invention, the problem that the existing seedling culture bed is confined in application in the process of culturing seedlings is solved, thus being applicable to different seedlings and enabling seedling culture at different seedling culture time periods.

Owner:GUANGXI FORESTRY RES INST

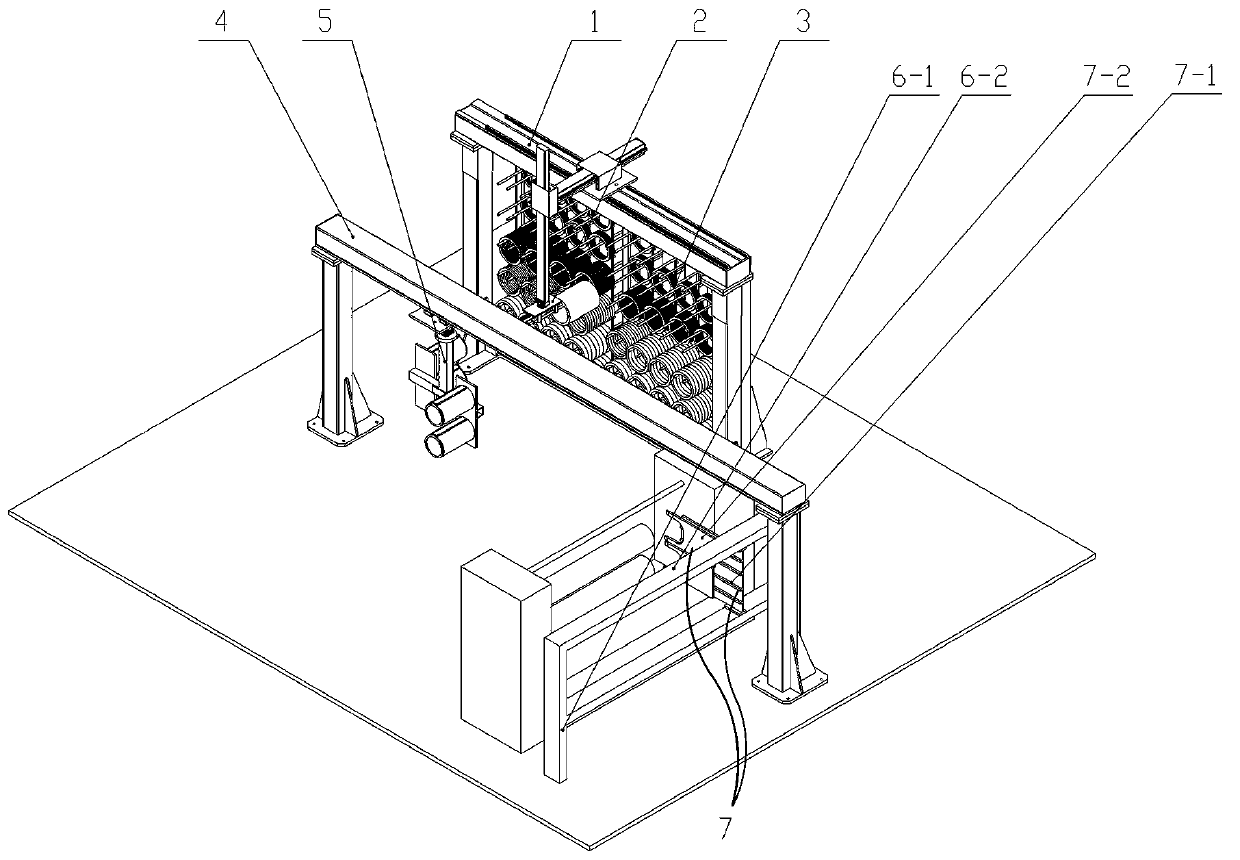

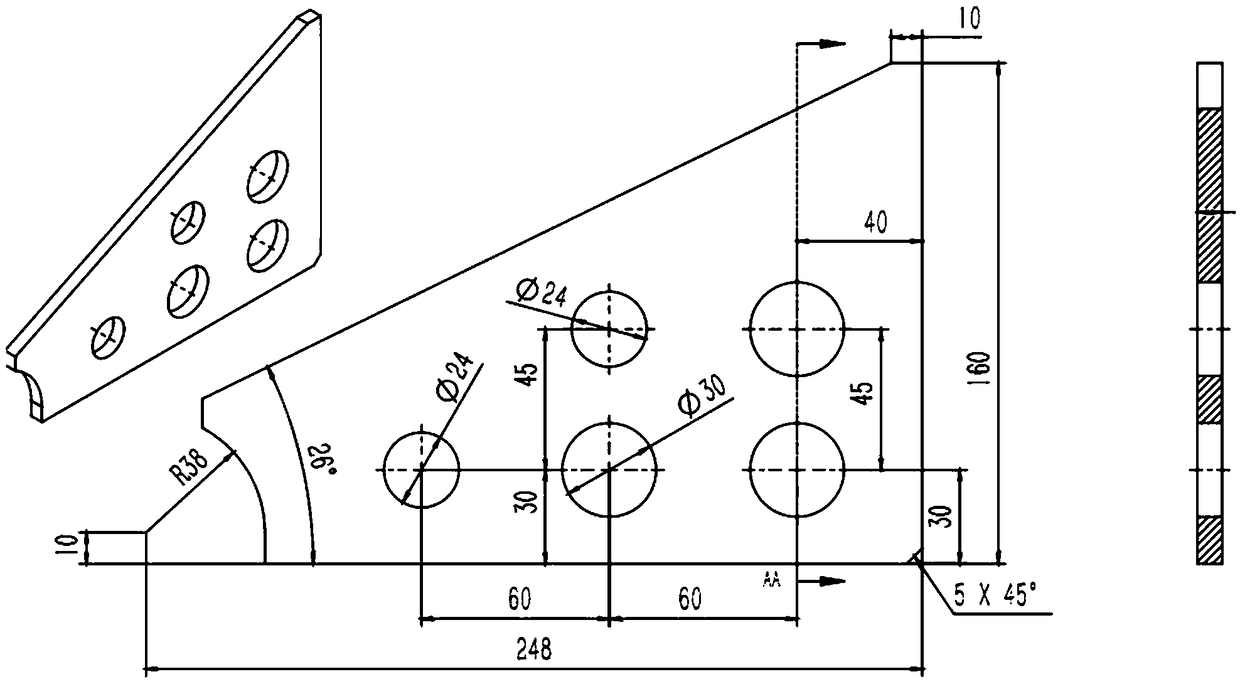

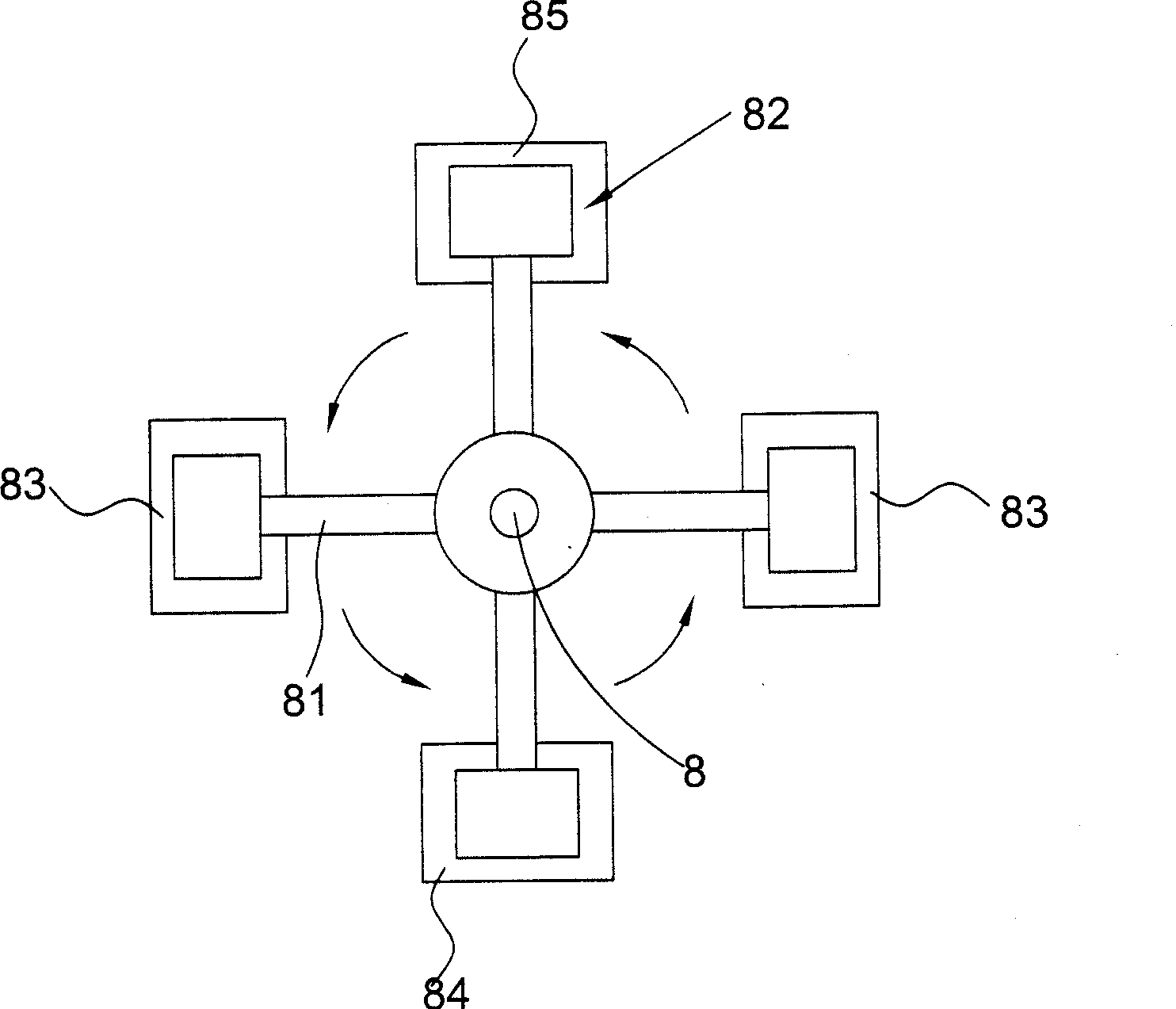

Automatic cutter changing device for spacer cutter

PendingCN110682143AHigh strengthHigh precisionPositioning apparatusMetal-working holdersEngineeringKnife blades

The invention discloses an automatic cutter changing device for a spacer cutter, and belongs to the technical field of transformer manufacturing. The device comprises a cutter magazine, a cutter moving portal frame mechanical arm and a cutter feeding device, wherein the cutter magazine is connected with the cutter feeding device through a cutter moving portal frame mechanical arm, a first materialreceiving device is connected with a second material receiving device in a insertable mode, the second material receiving device is connected with a third material receiving device in an insertable mode, a fourth material receiving device is located on the side surface of the third material receiving device, and the fourth material receiving device is connected with the third material receiving device in the radial direction in an insertable mode. In a moving process, the precision is high; and a multiple pieces of the cutters or spacers can be taken at a time through a cutter taking device,the next blade can be picked up when a transition cutter shaft rotates into a rotary device, the working beat is compact, and the efficiency is high. The automation degree of the equipment is improved, and the automatic upgrading cost input is reduced.

Owner:CECEP XIAN QIYUAN MECHANICAL & EIECTRICAL EQUIP CO LTD

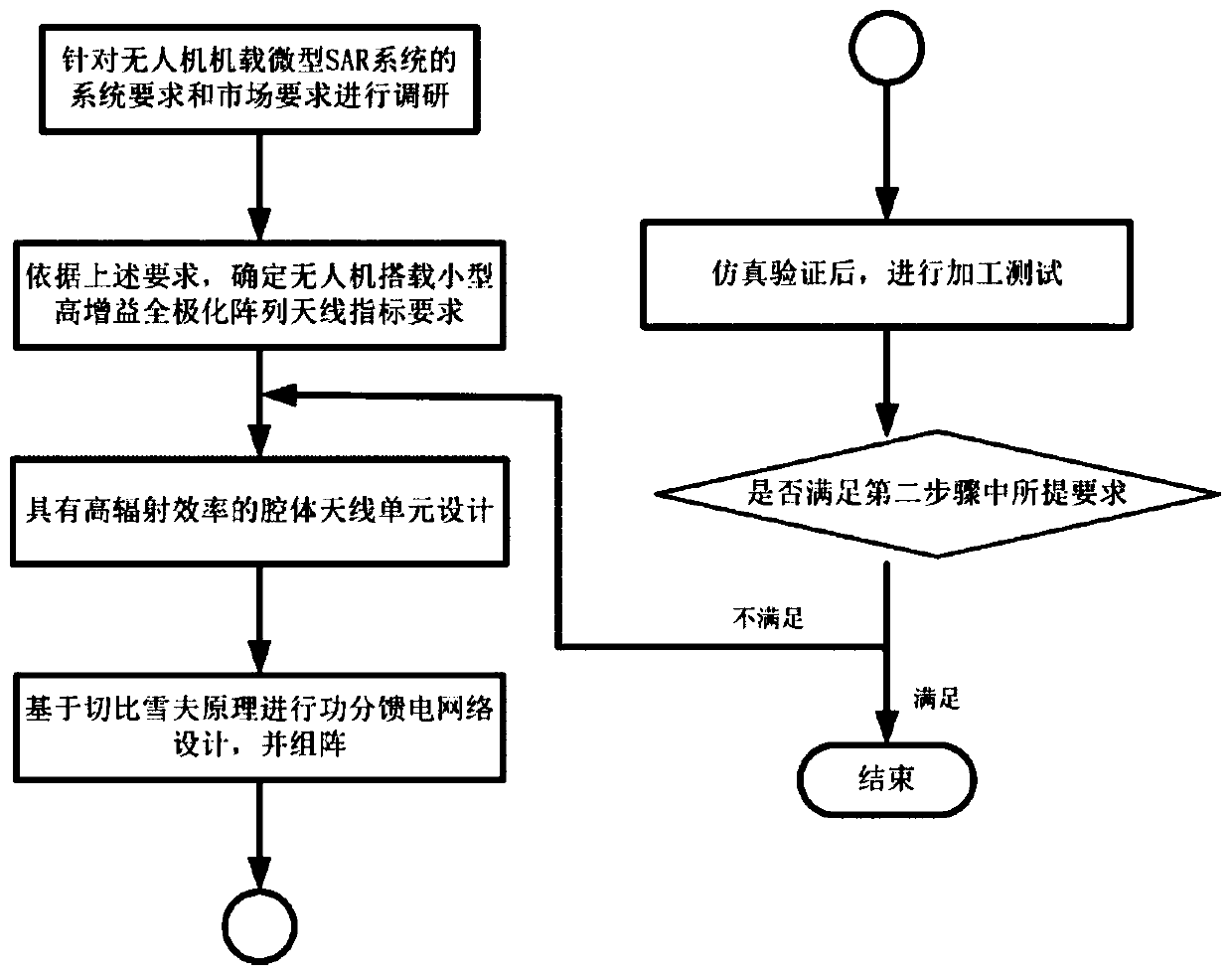

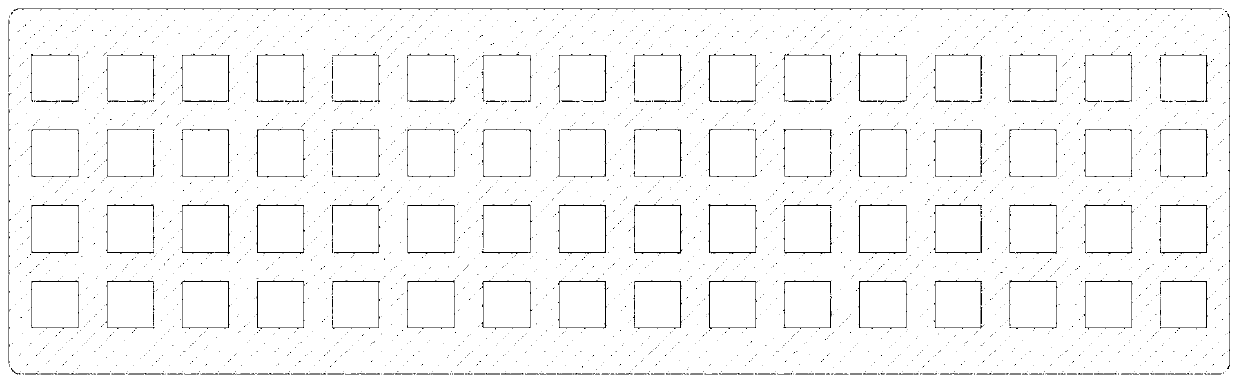

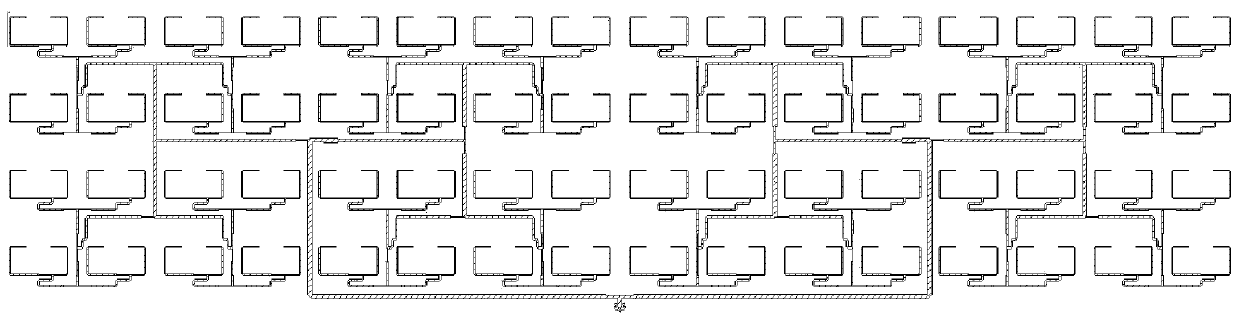

High efficiency broadband dual polarization cavity array antenna

InactiveCN110086001AMeeting the needs of polarized diversityGood electromagnetic performanceAntenna adaptation in movable bodiesRadiating elements structural formsElectricityMicrowave

The invention discloses a high efficiency broadband dual polarization cavity array antenna. A rectangular open waveguide antenna is used as an array unit form, feed is performed through a strip wire,dual polarization feed is realized by a laminated structure of a multilayer PCB substrate, moreover, the strip wire is utilized to form a power divider feed network to expand a cell structure to a 16*4 antenna array, weighted processing based on the Chebyshev principle is performed on the power divide feed network to suppress the antenna sidelobe level, the antenna array is fed by an SMA connectorto improve portability of the antenna, and conversion from the strip wire to a coaxial wire is designed at a tail end of the feed network. The antenna is advantaged in that needs of a microwave system for polarization diversity are met, and electromagnetic performance superior to conventional antennas can still be obtained under limited physical conditions.

Owner:UNIV OF SCI & TECH OF CHINA

Intelligent variable fertilizer application device based on internet of things

InactiveCN111066397AWell mixedMix evenlySpadesTransportation and packagingAgricultural scienceAgricultural engineering

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

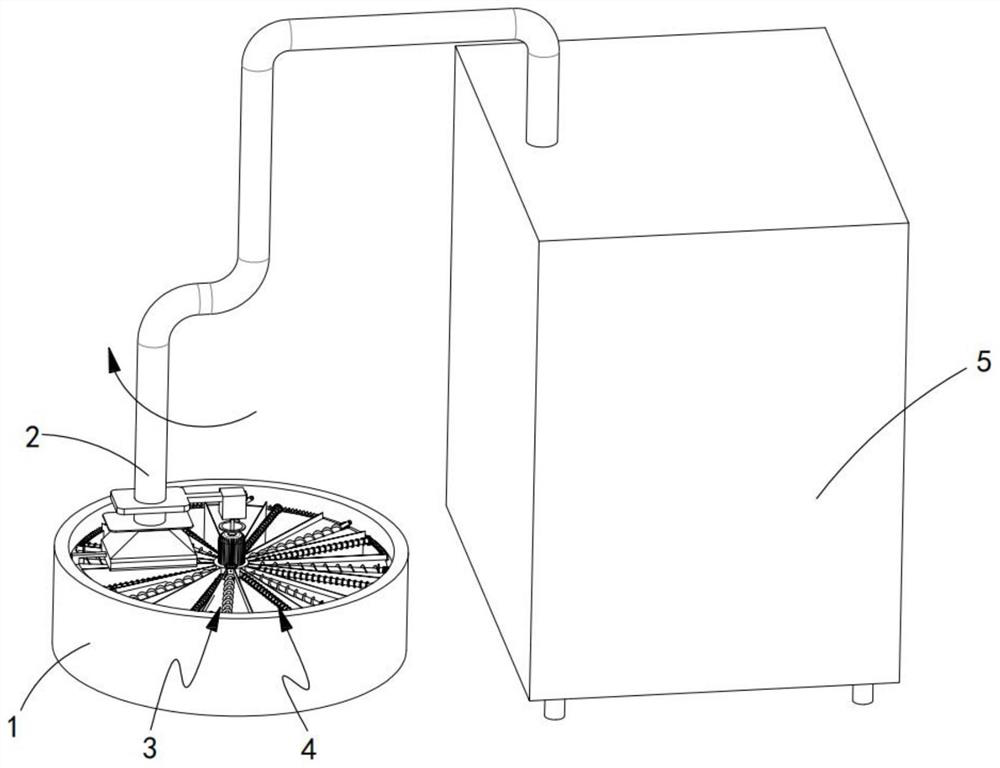

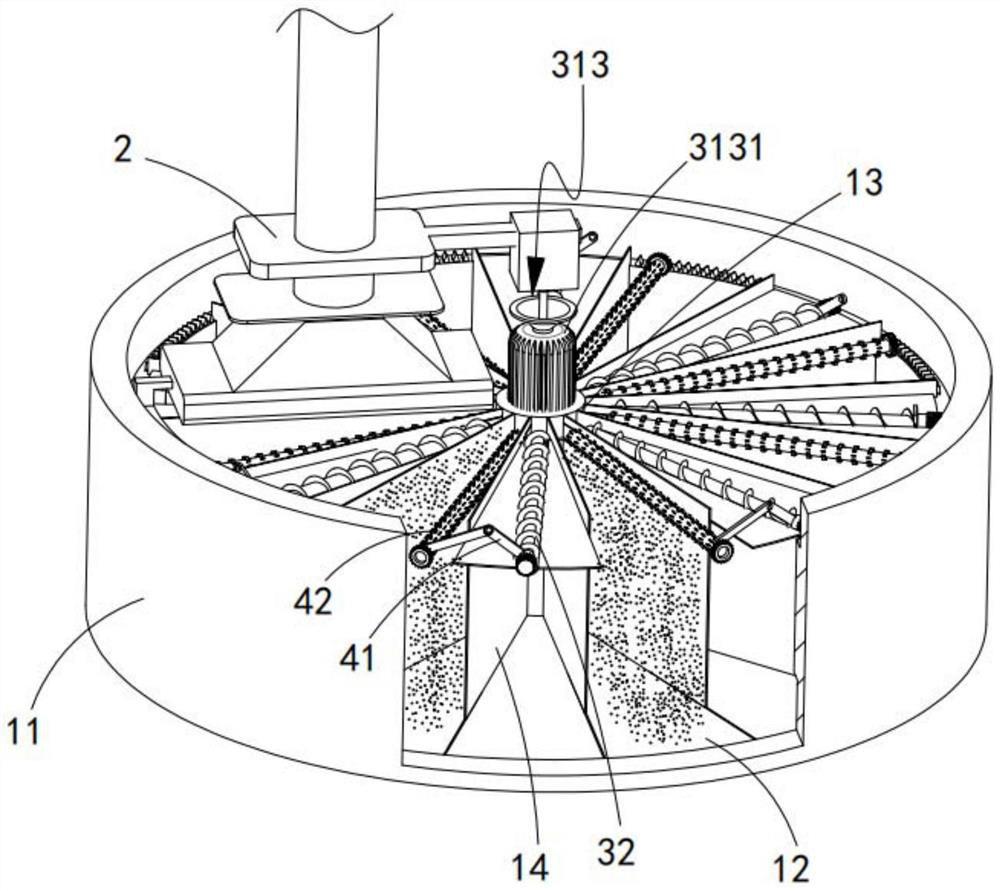

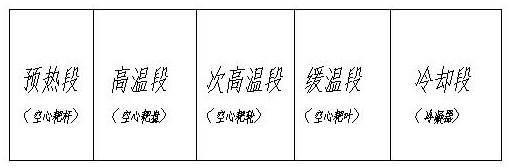

Processing equipment for color mixing of rotor spinning before color spinning and process thereof

ActiveCN111876855AImprove absorption efficiencyImprove mixing efficiencyContinuous processingSpinningProcess engineering

The invention relates to processing equipment for color mixing of rotor spinning before color spinning and a process thereof. The equipment comprises a bearing box, a cotton grabbing assembly arrangedabove the bearing box and rotating around the bearing box and a color mixing device arranged on one side of the bearing box, and the cotton grabbing assembly communicates with the color mixing device; and a compensation assembly and an evacuation assembly are further included. The process comprises a cotton feeding procedure, a cotton grabbing procedure, a cotton supplementing procedure, a scattering procedure, a lifting procedure and a color mixing procedure. By the arrangement of the compensation assembly, cotton raw materials thrown out when the cotton grabbing assembly sucks the raw materials are collected and compensated to an area, close to the side of the supporting column, of the raw material area in a centralized manner, and meanwhile automation of the cotton feeding procedure, the cotton grabbing procedure, the cotton supplementing procedure, the scattering procedure, the lifting procedure and the color mixing procedure of color mixing of rotor spinning before color spinningis effectively achieved; and the sucking and mixing efficiency of the color mixing raw materials is greatly improved, and mixing is more uniform.

Owner:ZHEJIANG HUZHOU WEIDA TEXTILE GRP

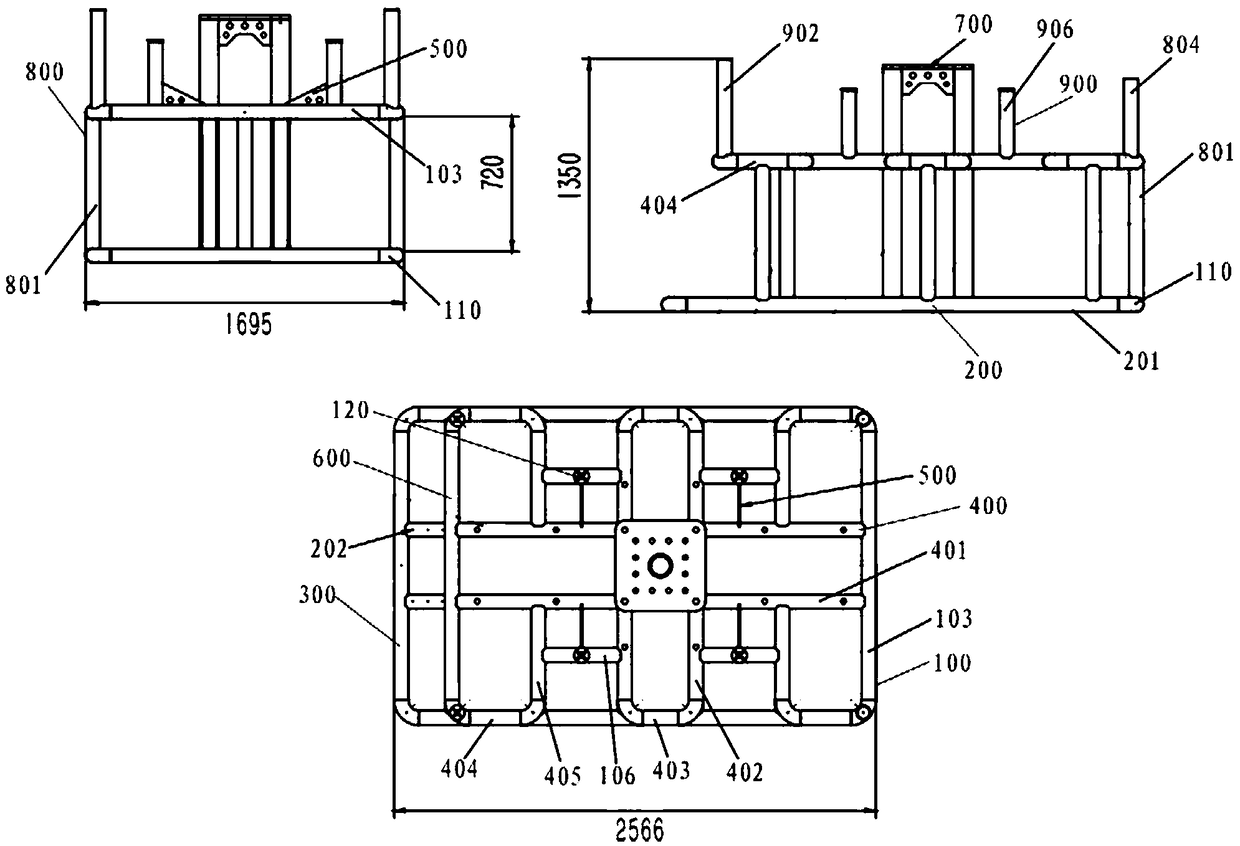

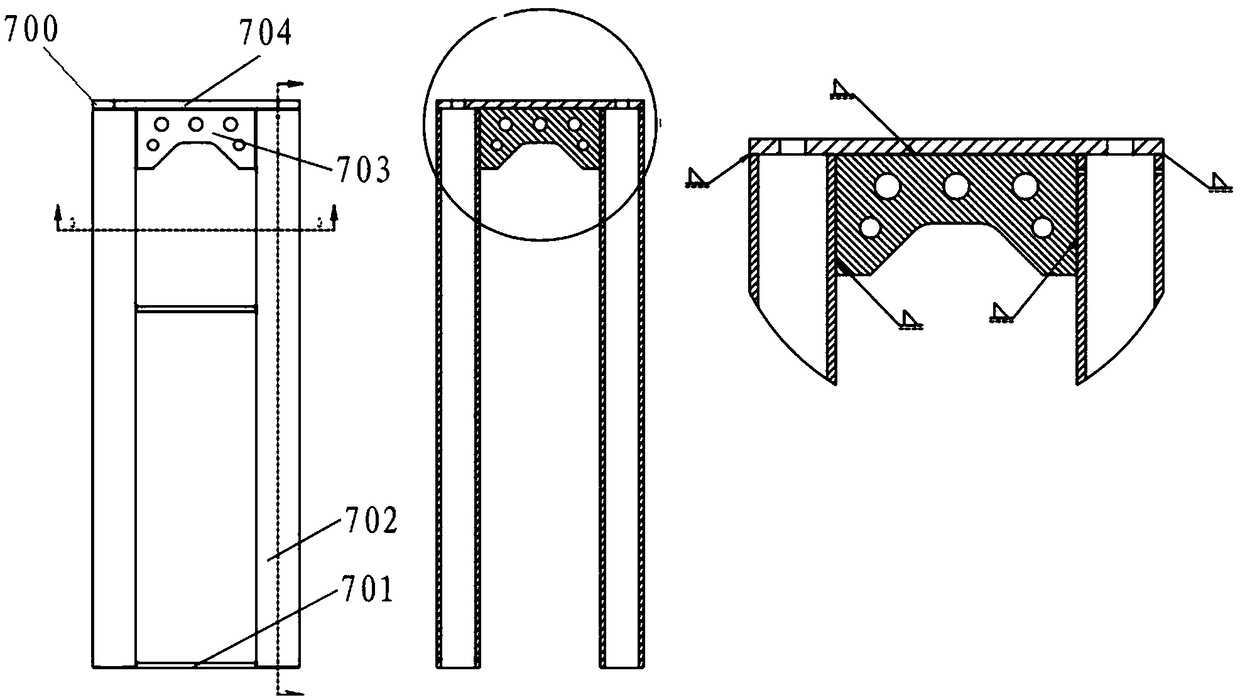

A large-depth ROV main frame device based on titanium alloy

PendingCN108995783AImprove stress resistanceEffective protectionUnderwater equipmentRobotic armPropeller

The invention discloses a large-depth ROV main frame device based on titanium alloy, comprises a bottom fixing bracket consisting of a lower horizontal tube and a bottom tube for mounting and fixing ahydraulic power unit and an actuating robot arm, an upper fixing bracket for fixing a horizontal propeller thruster consisting of an upper horizontal tube and a propulsion stiffening plate, a centerwelding bracket for mounting and fixing a driver, a controller, a riser, and riser welds; The bottom fixing bracket and the upper fixing bracket are welded and fixed through the riser and the riser welding piece; After the center welding bracket passes through the center of the upper fixing bracket, it is welded and fixed with the bottom fixing bracket. The invention solves the problem of strong pressure faced by the ROV when operating in the deep sea environment, and ensures that the core systems can be compactly fixed and smoothly operated.

Owner:CSSC SYST ENG RES INST

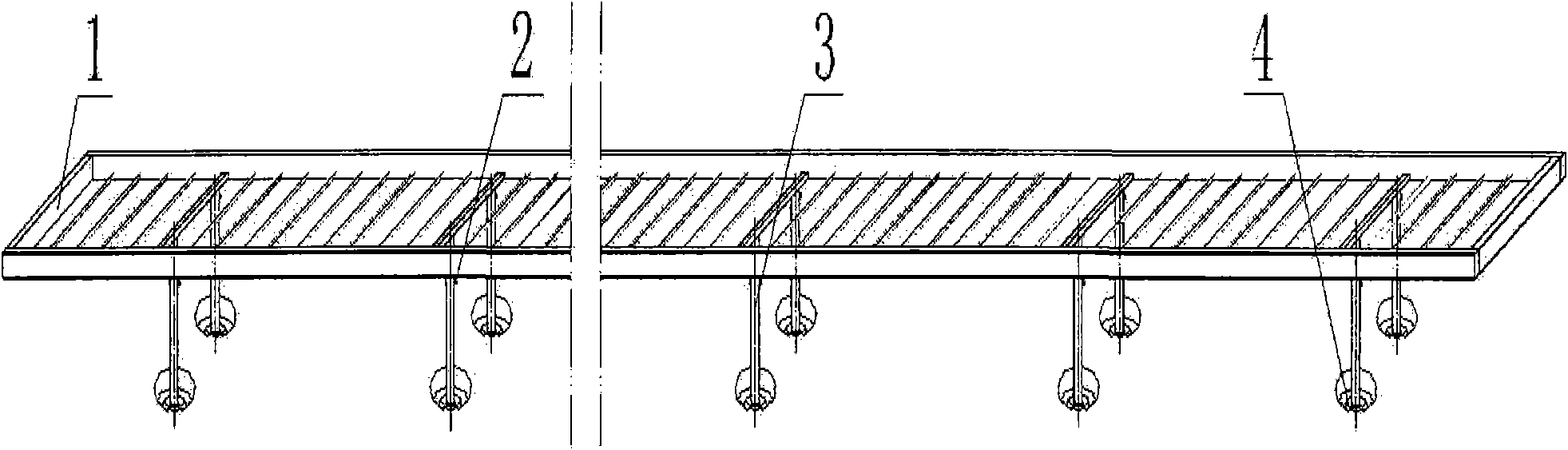

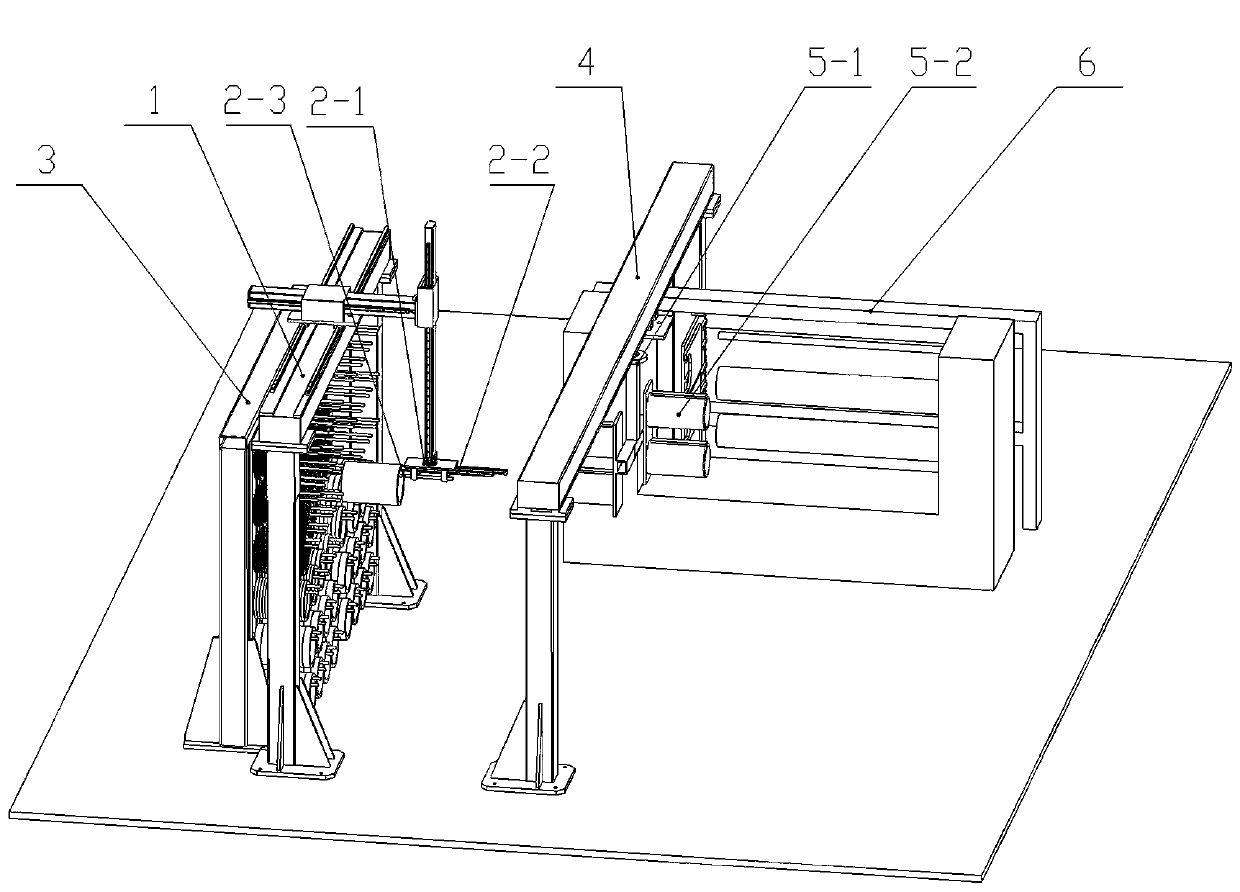

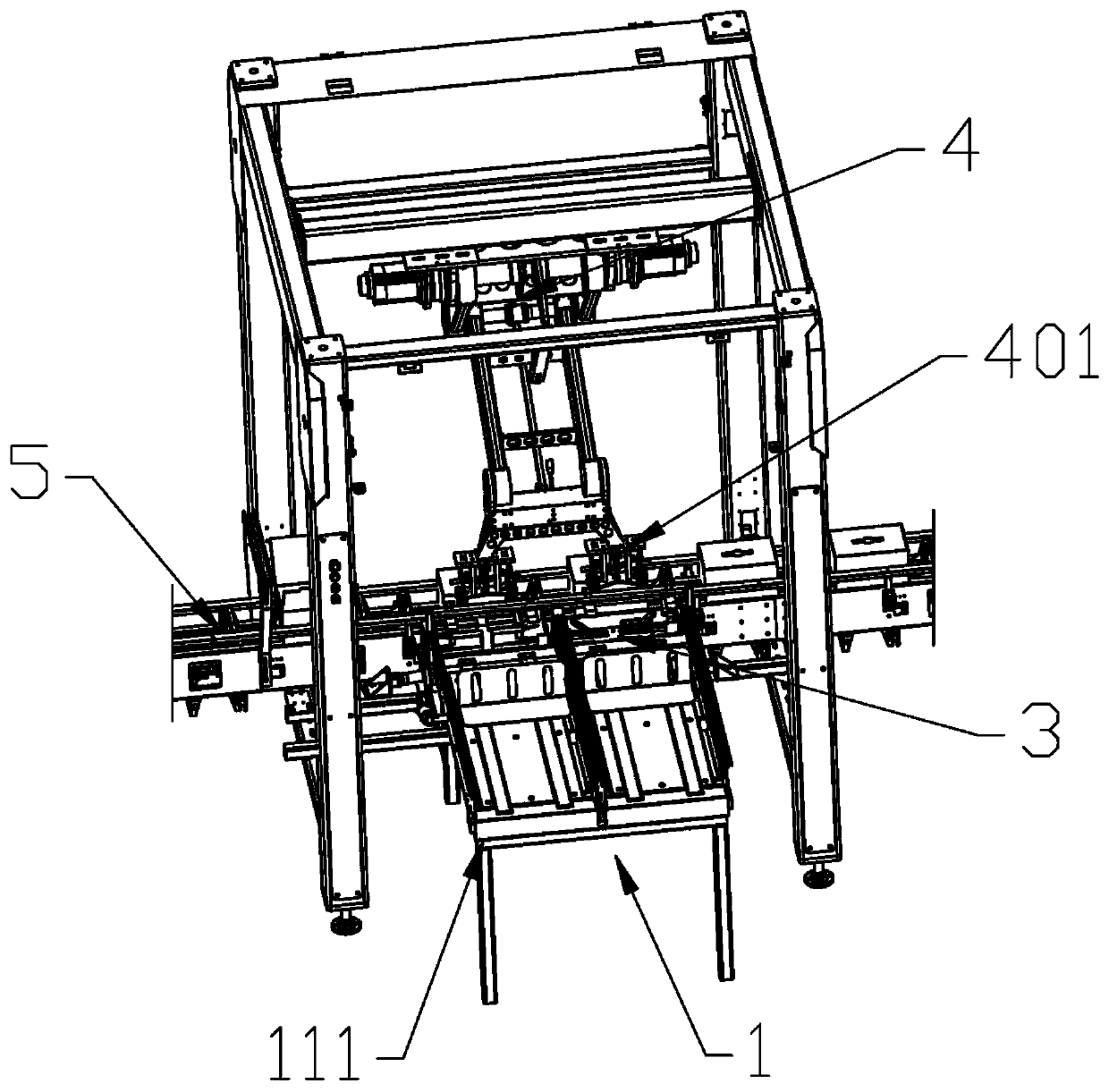

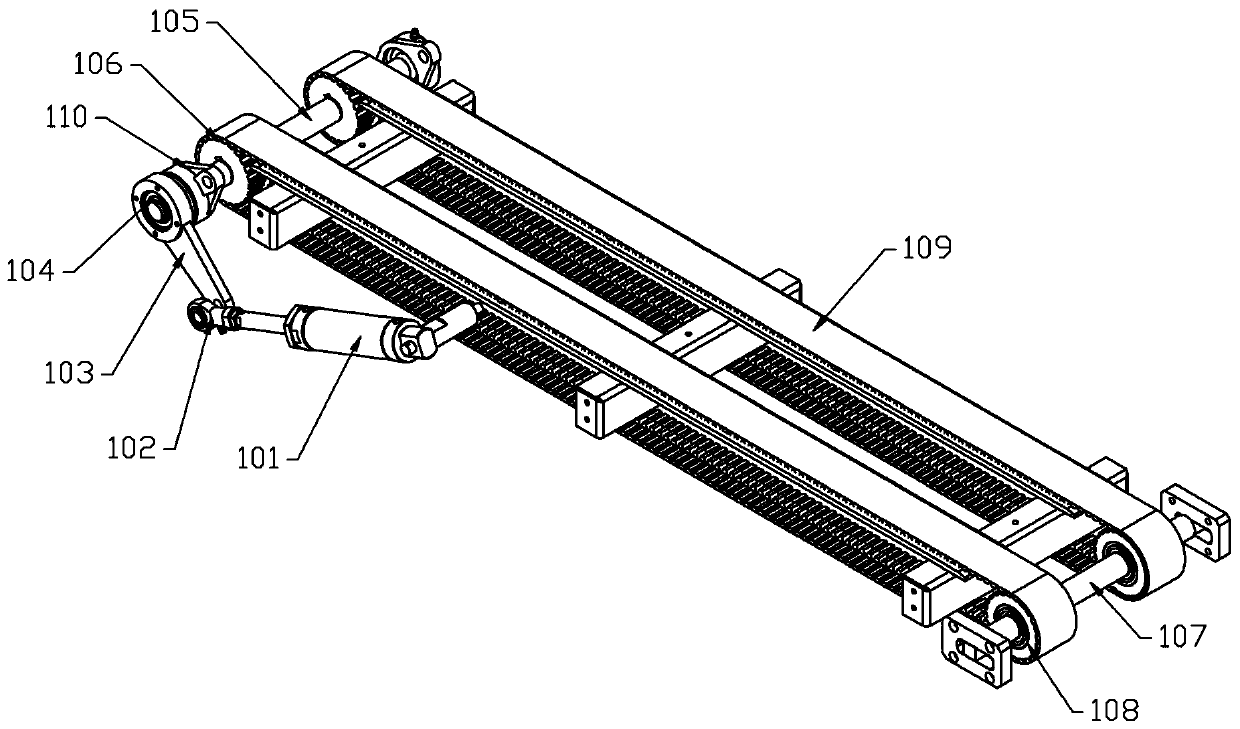

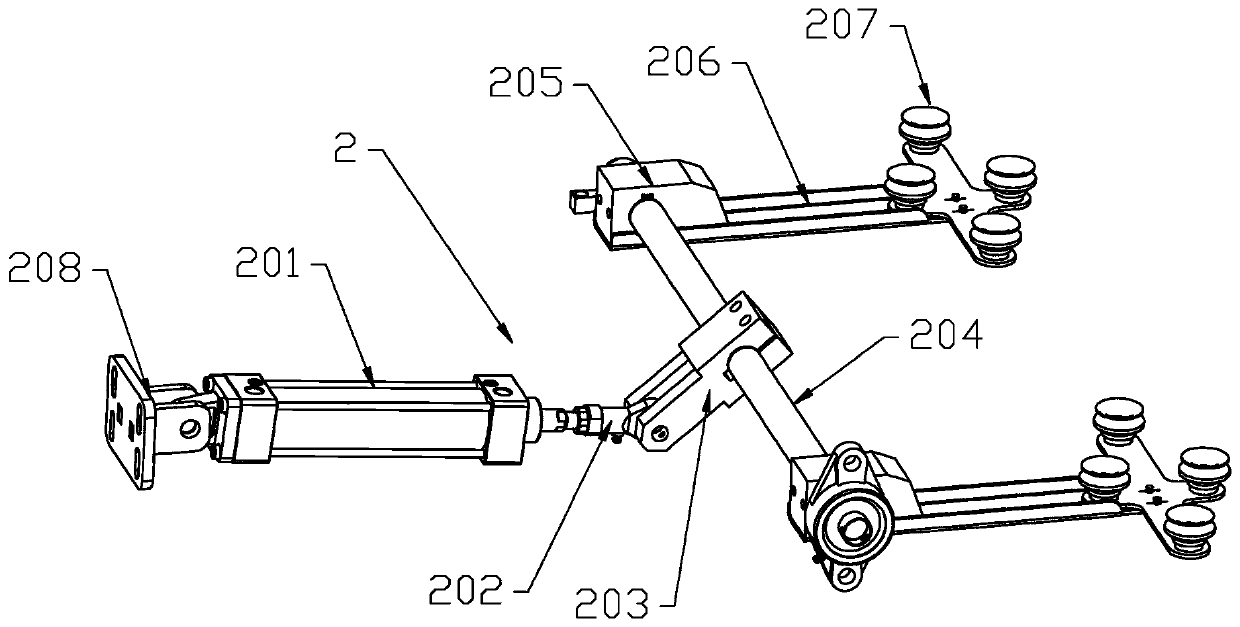

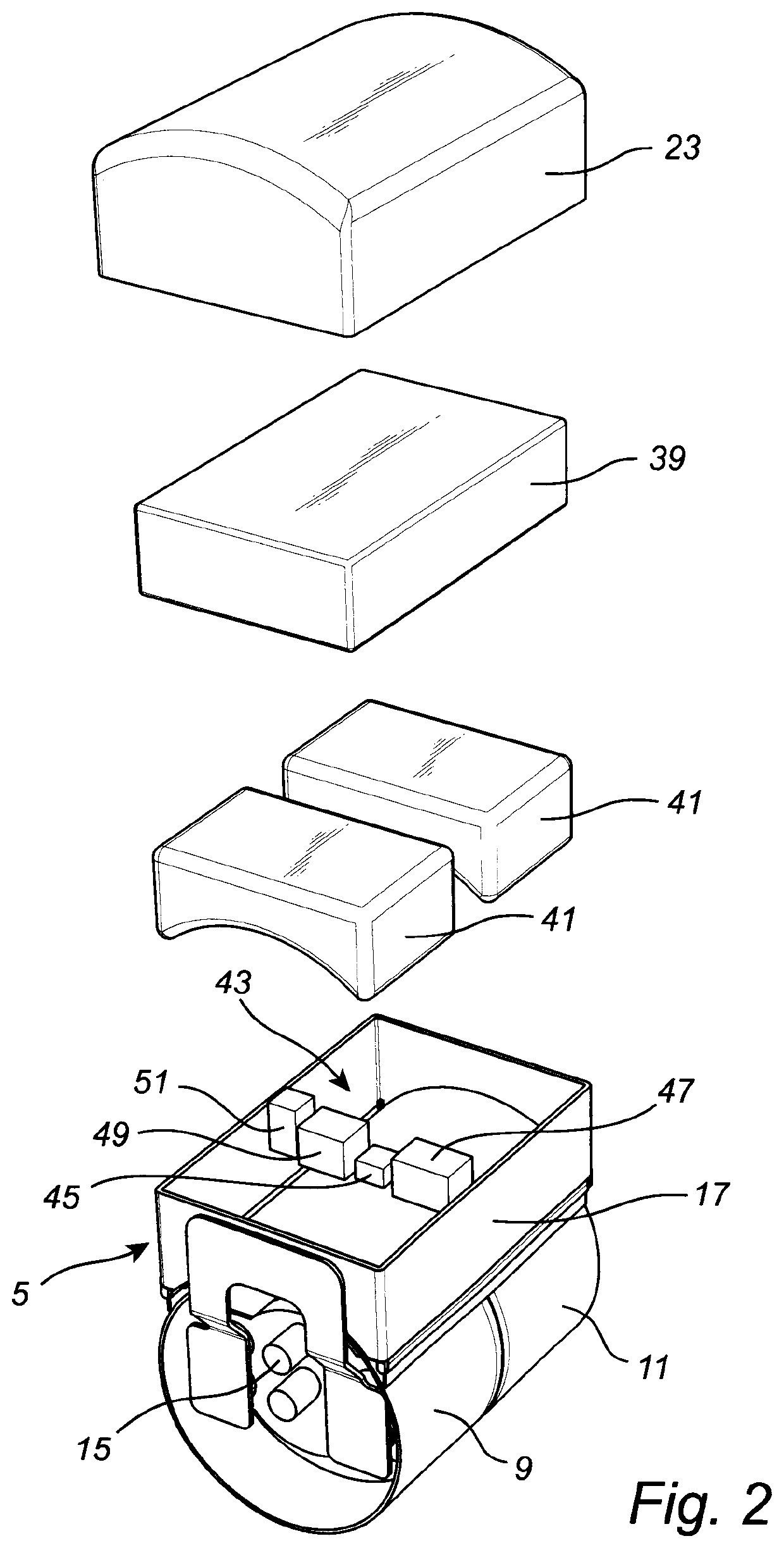

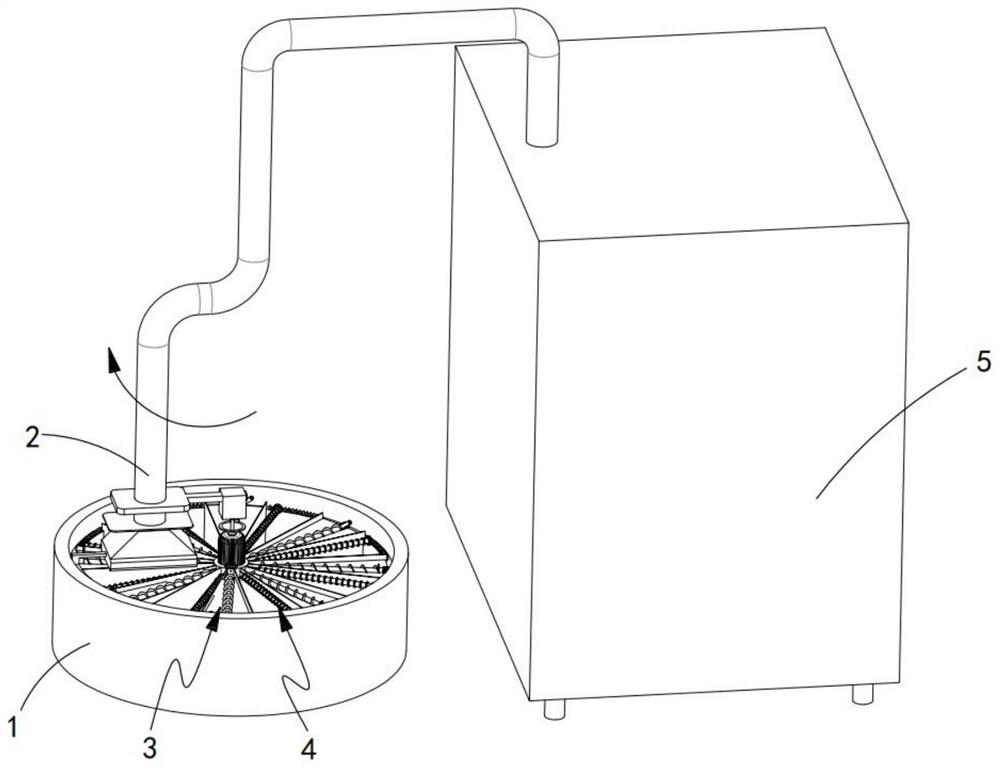

Partition module for flexible packaging system

ActiveCN107826325AImprove extraction efficiencyIncrease productivityPackagingMechanical engineeringPhysics

The invention discloses a partition module for a flexible packaging system. The partition module comprises a partition storage mechanism (1), a partition suction mechanism (2), a partition forming mechanism (3) and a partition grabbing robot (4), wherein the partition grabbing robot (4) is located above a packaging box conveying line (5), the partition storage mechanism (1) which corresponds to the partition grabbing robot (4) is arranged beside the packaging box conveying line (5), the partition forming mechanism (3) is located between the discharge side of the partition storage mechanism (1)and the packaging box conveying line (5), the driving side of the partition suction mechanism (2) is fixedly arranged at the bottom of the discharge side of the partition storage mechanism (1), and the suction side of the partition suction mechanism (2) can fall on a slotted bottom plate (301) of the partition forming mechanism (3). The partition module has the advantages of compact engagement, stability and rapidity of a working process and is suitable for popularization and use, and the automatic intelligent operation of supplying, sucking and forming partitions and putting into boxes can be quickly realized.

Owner:苏州澳昆智能机器人技术有限公司

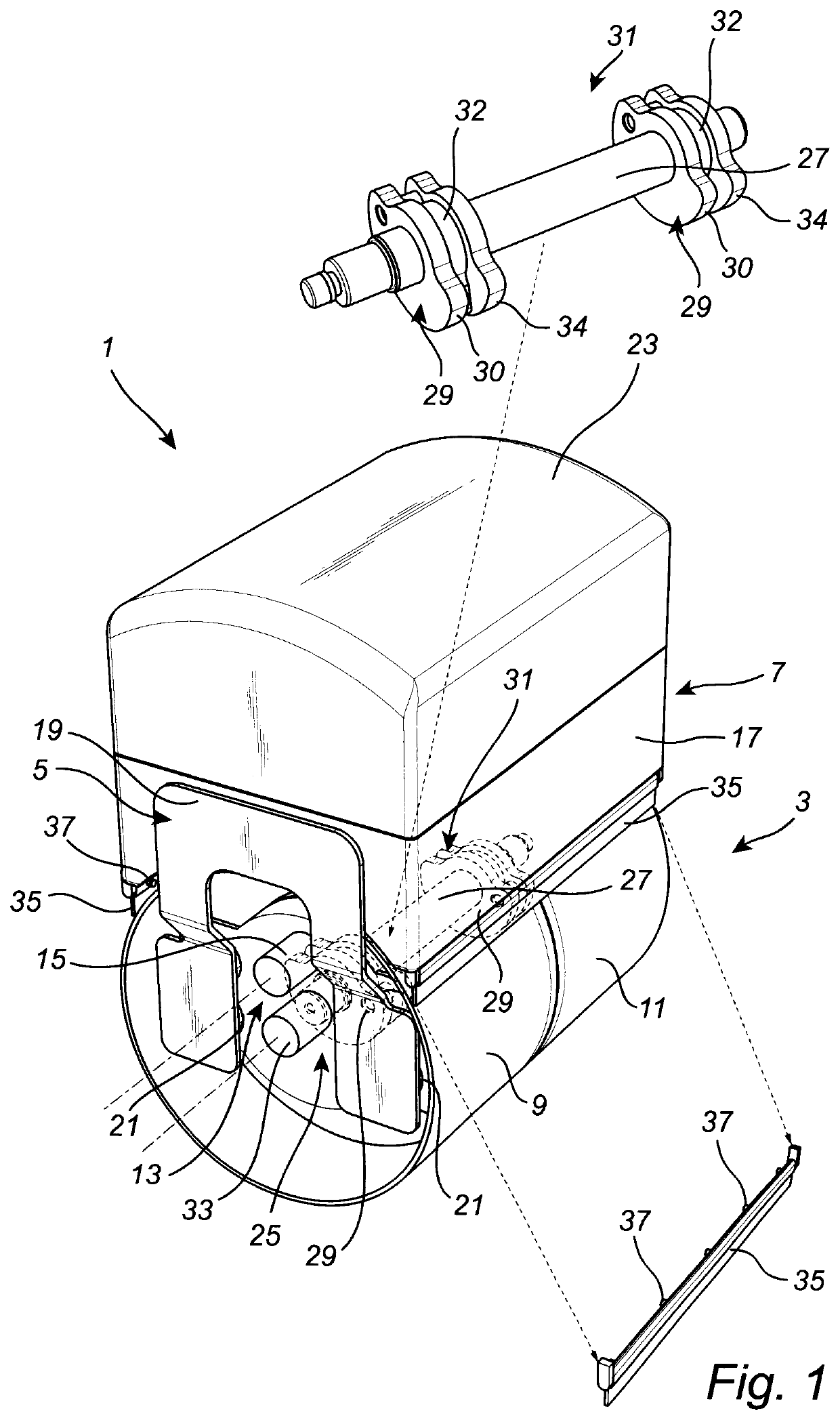

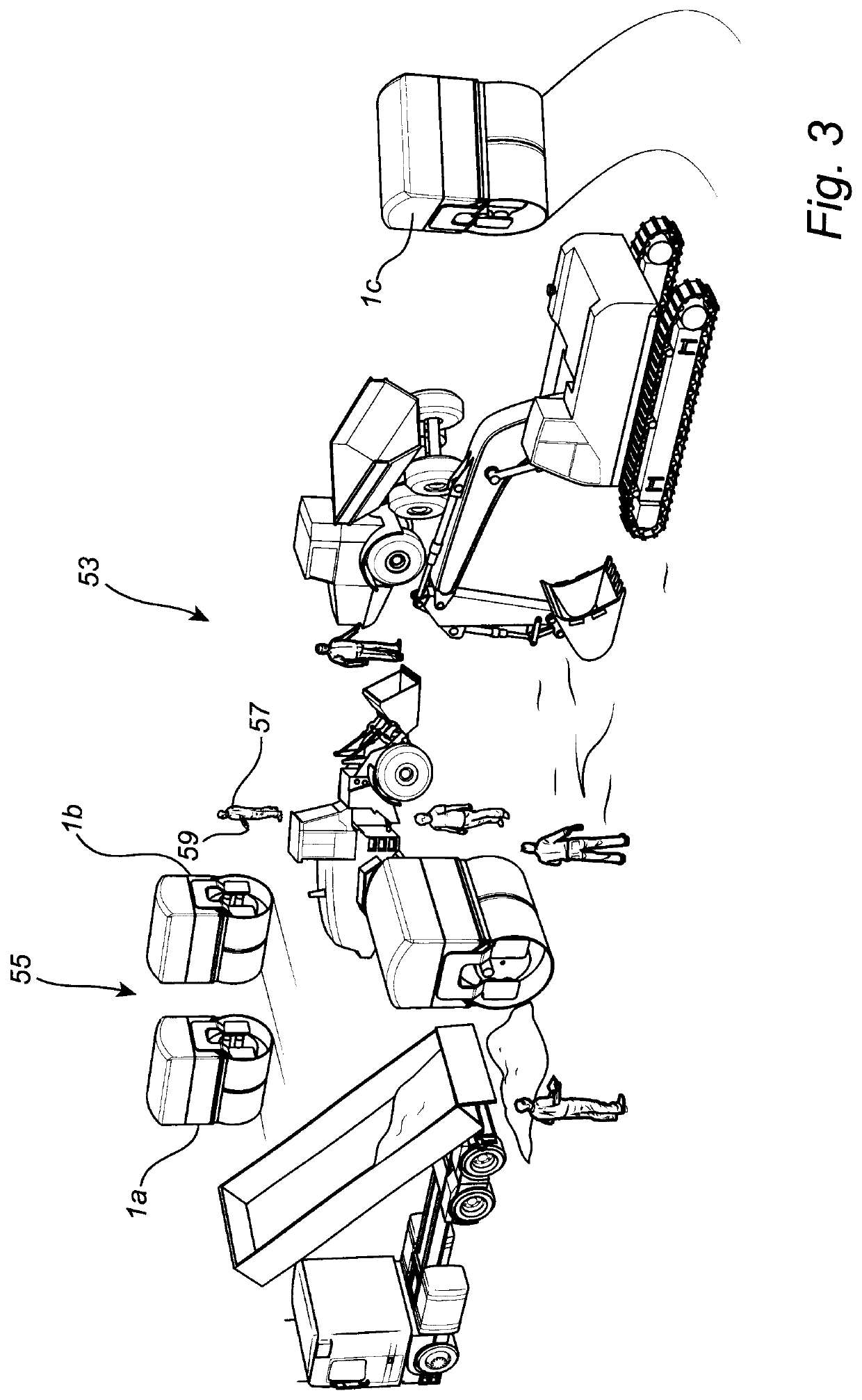

Compacting roller with an electronic balancing system for maintaining the roller in an upright position

PendingUS20220341103A1Reduce in quantityFacilitates charging and refueling and exchangeRoads maintainenceStructural engineeringMechanical engineering

The present invention relates to a compacting roller (1) comprising a roller drum arrangement (3) comprising a first roller drum (9) and a second roller drum (11) arranged next to each other, a drive arrangement (13) comprising a first drive unit (15) arranged to rotate said first roller drum (9) and a second drive unit arranged to rotate said second roller drum (11), and a power supply (39). The compacting roller by further comprises a frame (5) which is connected to said roller drum arrangement (3), wherein said power supply (39) is attached to said frame (5) outside each of the first roller drum (9) and the second roller drum (11), and an electronic balancing system (43) for maintaining the compacting roller (1) in an upright position during operation.

Owner:DYNAPAC COMPACTION EQUIP

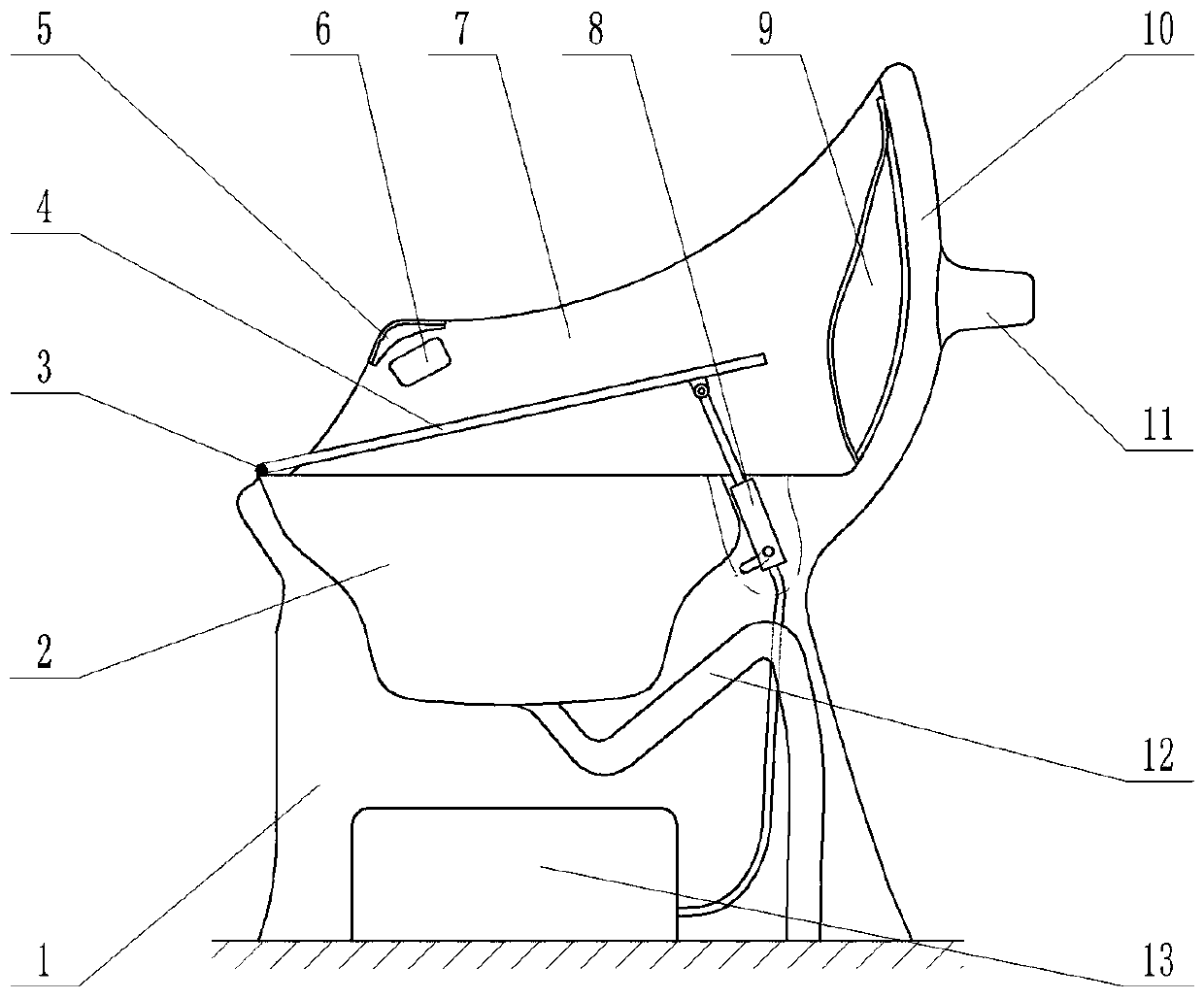

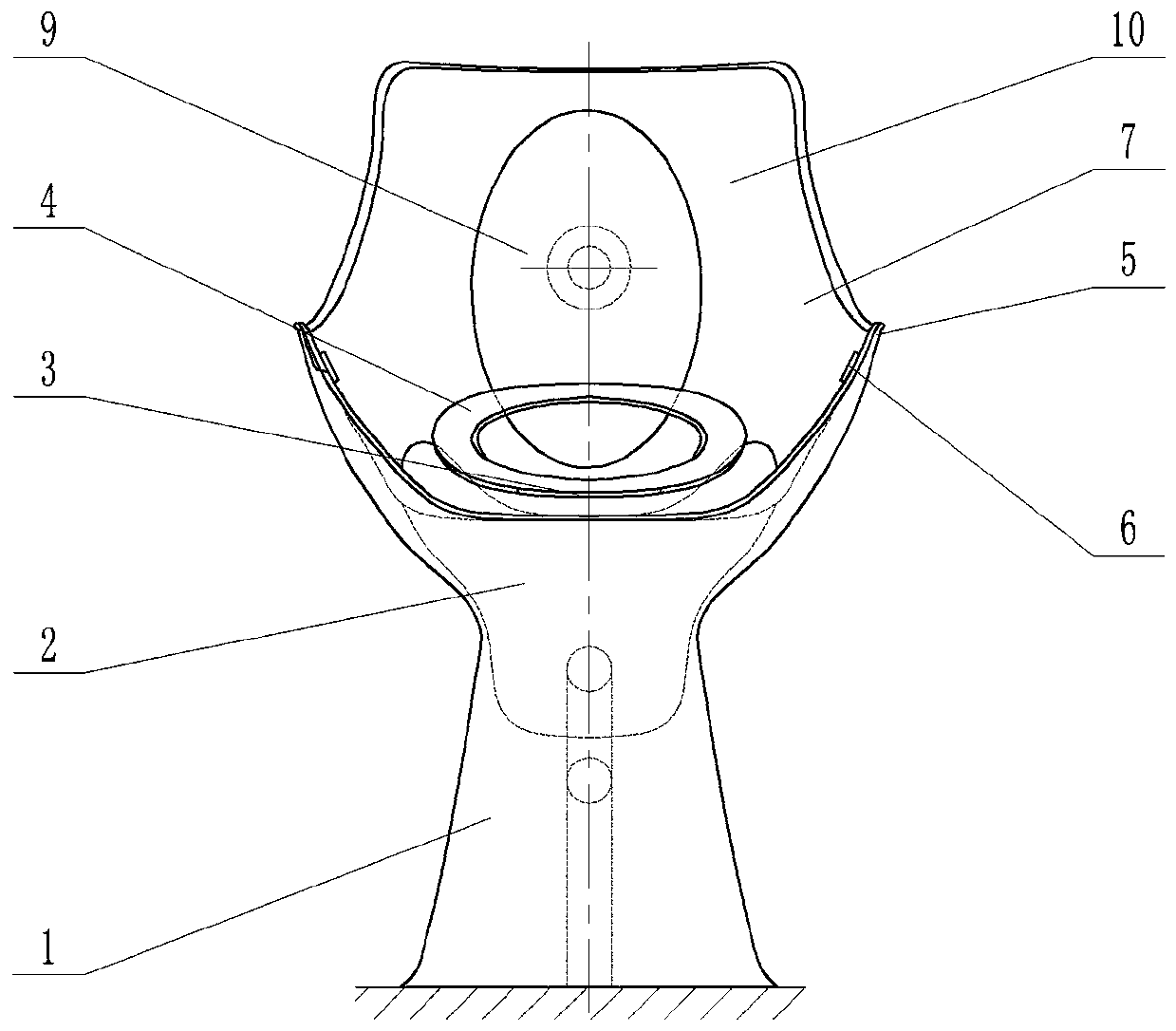

Intelligent heatable power-assisting toilet bowl

The invention relates to an intelligent heatable power-assisting toilet bowl. The problems that an existing toilet lacks an effective arising-assisting structure, is poor in fall-proof performance andlow in use comfort and cannot meet the needs of special users are solved. The toilet bowl comprises a toilet bowl base and a closestool; the toilet bowl is characterized in that a lifting seat cushion is arranged on the upper portion of the closestool, the front end of the lifting seat cushion is hinged to the front side of the closestool, and the two sides of the rear portion of the lifting seatcushion are hinged to a telescopic hydraulic cylinder and the toilet bowl base respectively; a backrest provided with a back cushion is arranged on the rear portion of the closestool, and a water inlet connector is arranged on the rear side of the backrest; side handrails are arranged on the front portions of side baffles arranged on the two sides of the closestool respectively, and a control panel is arranged on the inner sides of the side handrails; the main controller is electrically connected with a hydraulic pump and a flushing solenoid valve separately. Design is reasonable, the structure is compact, the arising-assisting function is achieved, and the phenomenon that a toilet user falls down can be effectively prevented; the seat cushion can be subjected to constant temperature heating quickly, the action is stable, and use is safe and reliable.

Owner:巩政辛

Lever ratchet wheel linkage bicycle

InactiveCN101973355BResolve connectionNovel shapeWheel based transmissionRider propulsionEngineeringHigh transmission

The invention discloses a lever ratchet wheel linkage bicycle, comprising a bicycle frame, a front bicycle wheel, a rear bicycle wheel, a rear wheel shaft and a bicycle wheel drive device, wherein, the bicycle wheel drive device comprises a left lever and right lever up-to-down conversion device and a left ratchet wheel and right ratchet wheel drive device, wherein, the left lever and right left up-to-down conversion device comprises a lever, a lever connector, a frame connector, a sun wheel, a planet wheel, a gear ring and a central shaft; and the left ratchet wheel and right ratchet wheel drive device is a friction-type ratchet wheel mechanism comprising a roller, a slope-type one-way clutch, a ratchet wheel hub and a ratchet wheel connector. In the invention, the drive, speed change and the acting force are wholly centralized on the rear wheel shaft to lead the length of the lever to be 3-5 times of a crank mechanism; the lever can be retracted; a seat cushion can be moved front and back; the pedal rotating angle of both feet is changed to form the action of stepless speed regulation; and the speed is changed by a star wheel structure, so as to lead the transmission to be compact and the operation to be reliable. The invention provides a bicycle which is brand new, has simple structure, high transmission rate, long service life, low failure rate, convenient maintenance and comfort and stable riding.

Owner:NANTONG BAOTIAN PACKING MACHINERY

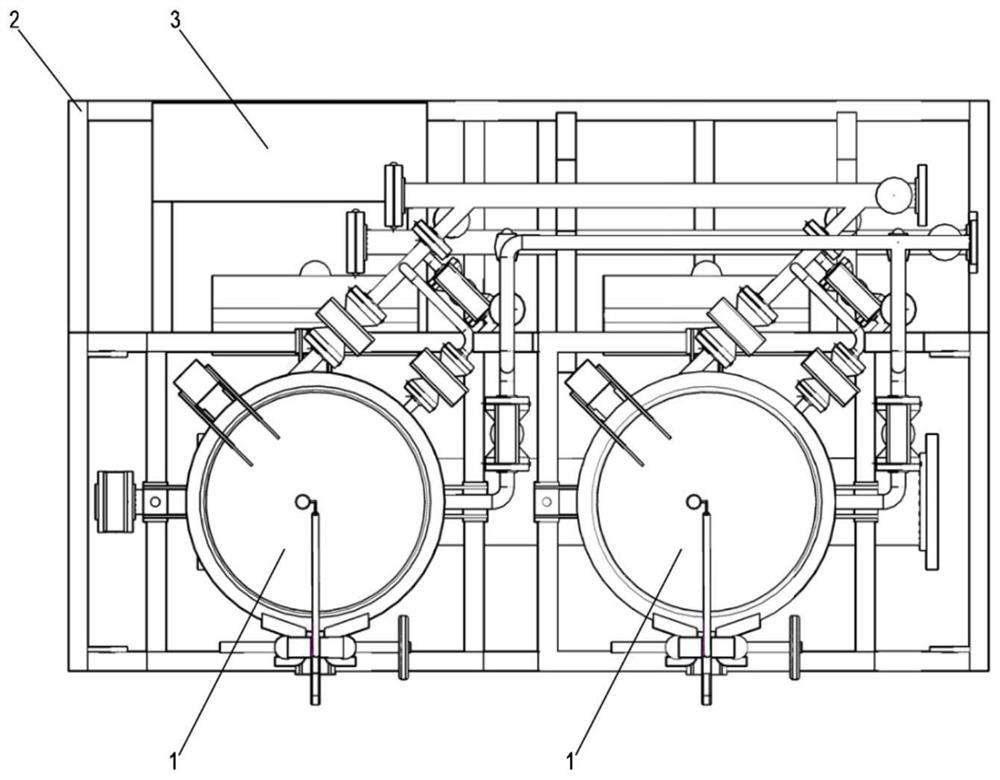

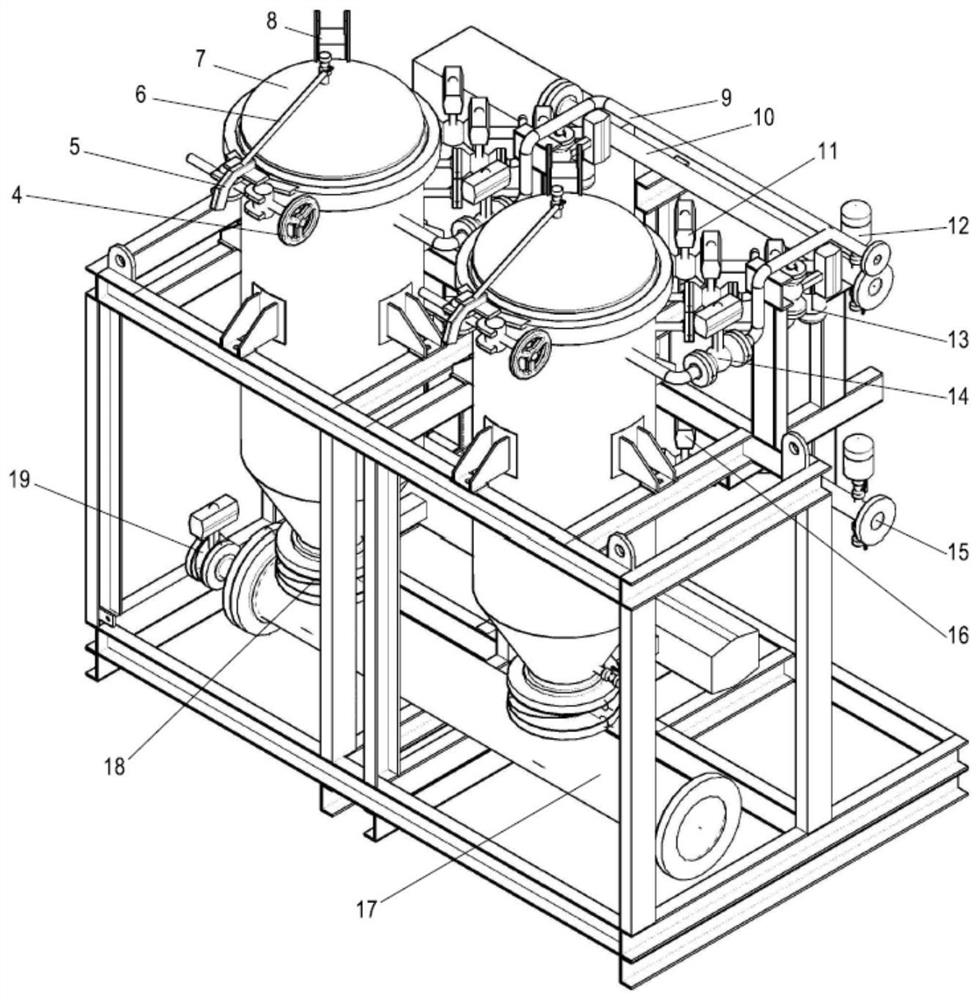

Full-automatic cleaning and filtering system

PendingCN112807827AImprove filtration efficiencyEasy to replaceFiltration separationInlet valveControl engineering

The invention provides a full-automatic cleaning and filtering system. The full-automatic cleaning and filtering system comprises a plurality of filters connected in parallel, an inlet pipeline, an outlet pipeline and a back flushing pipeline, a deslagging pipeline, wherein the inlet pipeline, the outlet pipeline and the back flushing pipelineare connected with the filters, and the deslagging pipeline is arranged below the filters; the filters are communicated with the deslagging pipeline through deslagging valves at the bottoms of the filters; a flushing valve is arranged at one end of the deslagging pipeline; an inlet valve is arranged on the inlet pipeline; an outlet valve is arranged on the outlet pipeline; and a back flushing valve is arranged on the back flushing pipeline. The filtering system is provided with a unique quick uncovering structure, so that filtering elements are convenient to replace; the filtering system integrates the valves, instruments and electric control units, is compact in overall structure, small in occupied area and suitable for being used on a ship; the filtering system can realize full-automatic operation and continuous operation without manual operation and maintenance; and stable work of the system can be ensured just with the filtering elements regularly replaced, so that the maintenance cost of the system is greatly reduced.

Owner:FEATURE-TEC (WUXI) FILTRATION TECH CO LTD

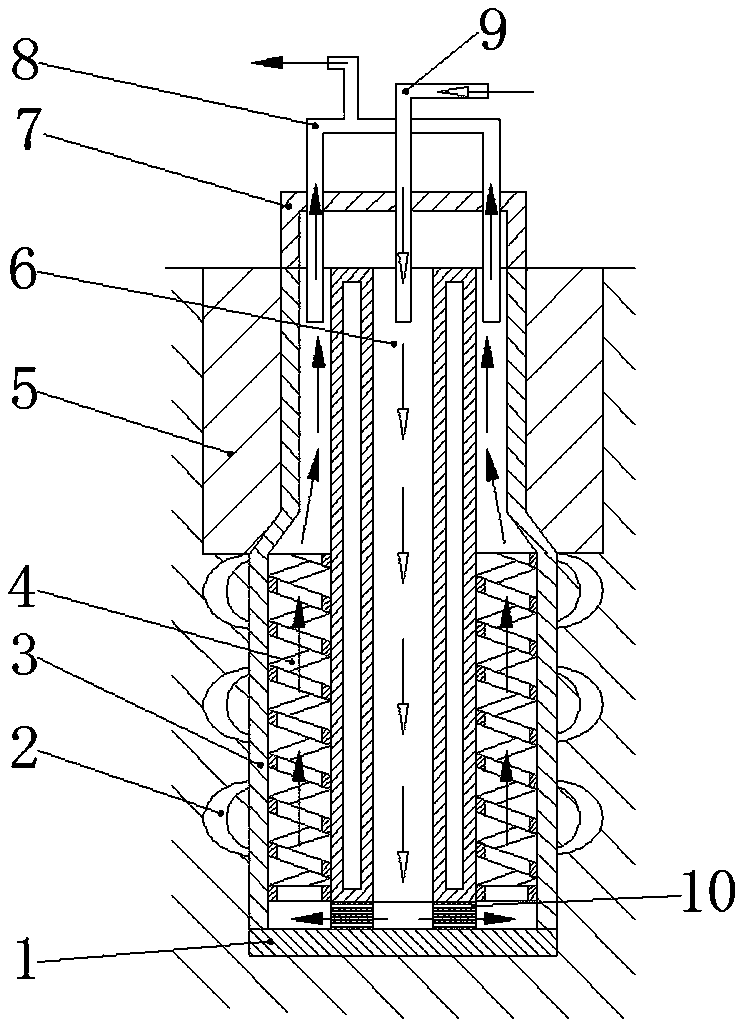

Heat tube type hot dry rock efficient heat exchange device

PendingCN108050717AIncrease the heat exchange areaExtend heat exchange timeGeothermal energy generationCollectors with underground reservoirsPipingEngineering

The invention discloses a heat tube type hot dry rock efficient heat exchange device, belongs to the technical field of hot dry rock heat exchange, and solves the technical problem that a hot dry rockheat exchange system is low in heat exchange efficiency. The scheme is as follows: a transfusion heat conducting tube comprises a widemouthed section and a narrowmouthed section, the top and bottom of the transfusion heat conducting tube are arranged as open ends, an end enclosure is arranged on the lower end surface of the widemouthed section, a water collecting and dividing end enclosure is arranged on the top end of the narrowmouthed section, a water supply pipe and a water return pipe are arranged on the water collecting and dividing end enclosure, the water supply pipe communicates to acavity of the transfusion heat conducting tube, a heat-isolating tube is arranged at the heart of the transfusion heat conducting tube, the lower portion of the widemouthed section communicates to thelower portion of the heat-isolating tube, a spiral runner is arranged between the inner wall of the widemouthed section and the outer wall of the heat-isolating tube, and the volume of the cavity ofthe transfusion heat conducting tube is 2-4 times of that of the heat-isolating tube. Spiral fins and the spiral runner increase the heat exchange area, an insulating layer and the heat-isolating tubereduce heat diffusion, and the heat exchange efficiency of the hot dry rock heat exchange system is improved.

Owner:王盛昌

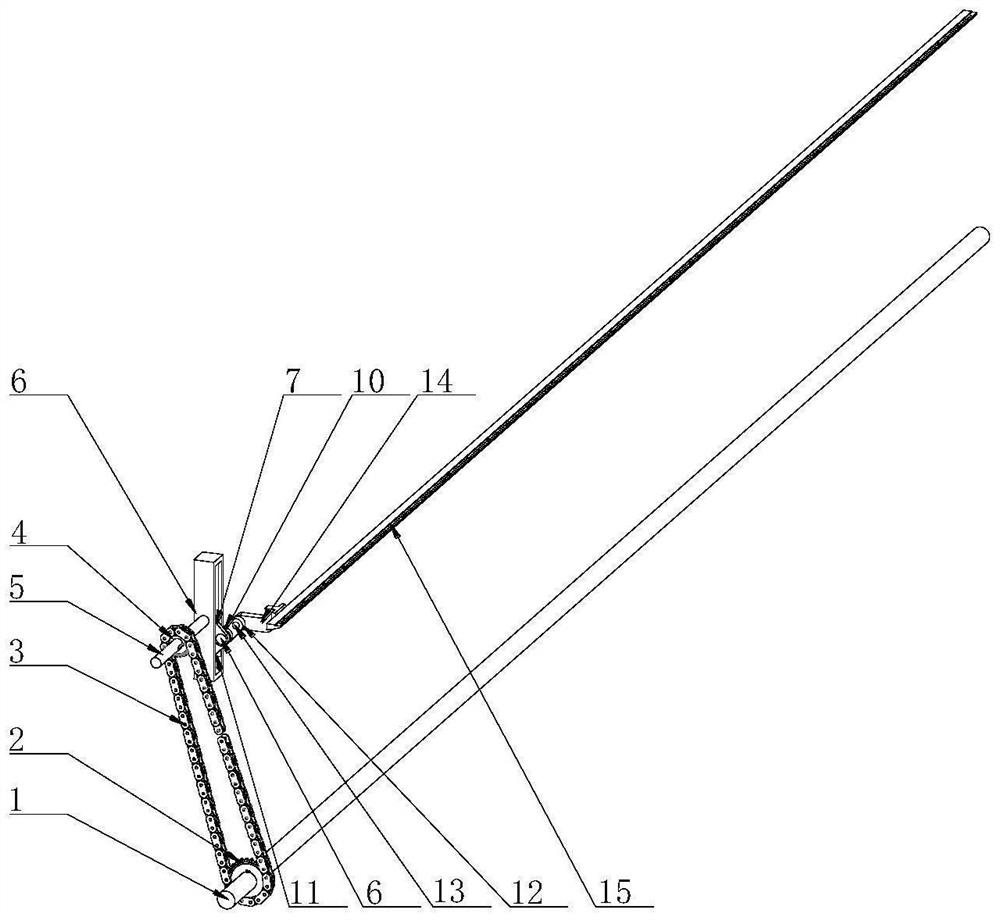

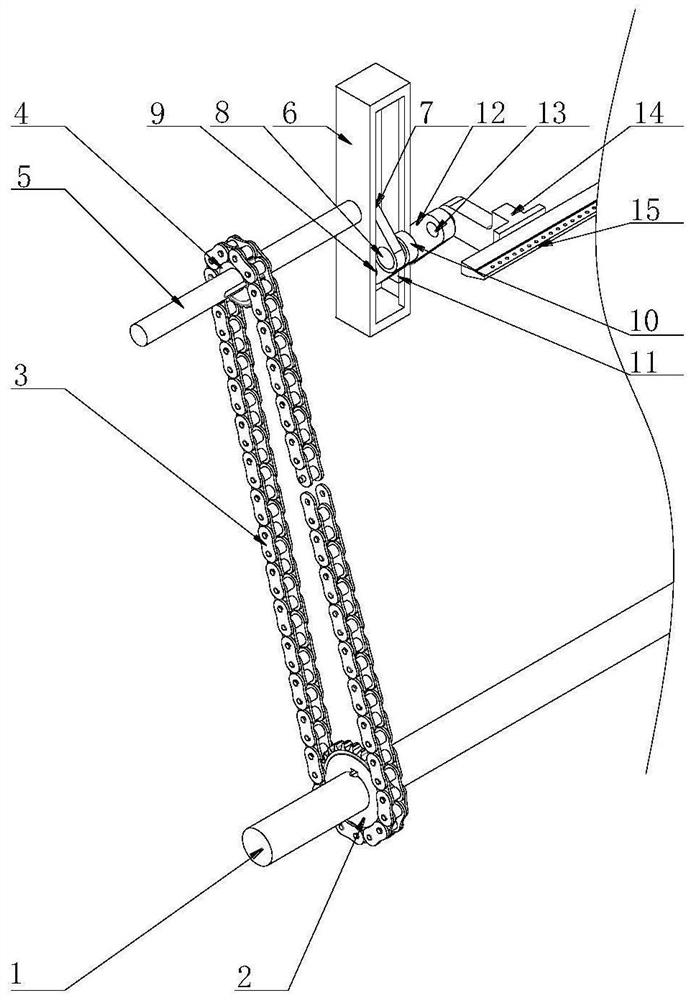

Moving device of yarn pushing mechanism and adjusting method

ActiveCN114855350AImprove reliabilityStable structureWarp knittingTextile disintegration and recoveryControl engineeringSprocket

The invention discloses a motion device of a yarn pushing mechanism, which comprises a driving input shaft, the driving input shaft is in key connection with a driving chain wheel, the driving chain wheel is in meshed connection with a driven chain wheel through a chain, the driven chain wheel is in key connection with a driven input shaft, the driven input shaft is provided with a guide rail frame, and the driven input shaft penetrates through the guide rail frame and is rotationally connected with a driving shaft; one end of the driving shaft is rotationally connected with a first yarn pushing rod through a first pin shaft, the bottom end of the first yarn pushing rod is rotationally connected with a second pin shaft, the second pin shaft is rotationally connected with a sliding block, the sliding block is fixedly connected with a second yarn pushing rod through a pin shaft, the driving chain wheel is installed on a main shaft of the warp knitting machine, and the driven chain wheel is directly connected with the yarn pushing part. Power is directly transmitted to the input shaft of the yarn pushing part from the main shaft of the warp knitting machine through the driving chain wheel and the driven chain wheel, and compared with an existing plane multi-connecting-rod mechanism, the structure for transmitting the power is simple in structural composition, small in number of needed parts, reliable in work, small in loss, high in efficiency, large in transmission power and high in overload capacity.

Owner:丹阳市益讯机械有限公司

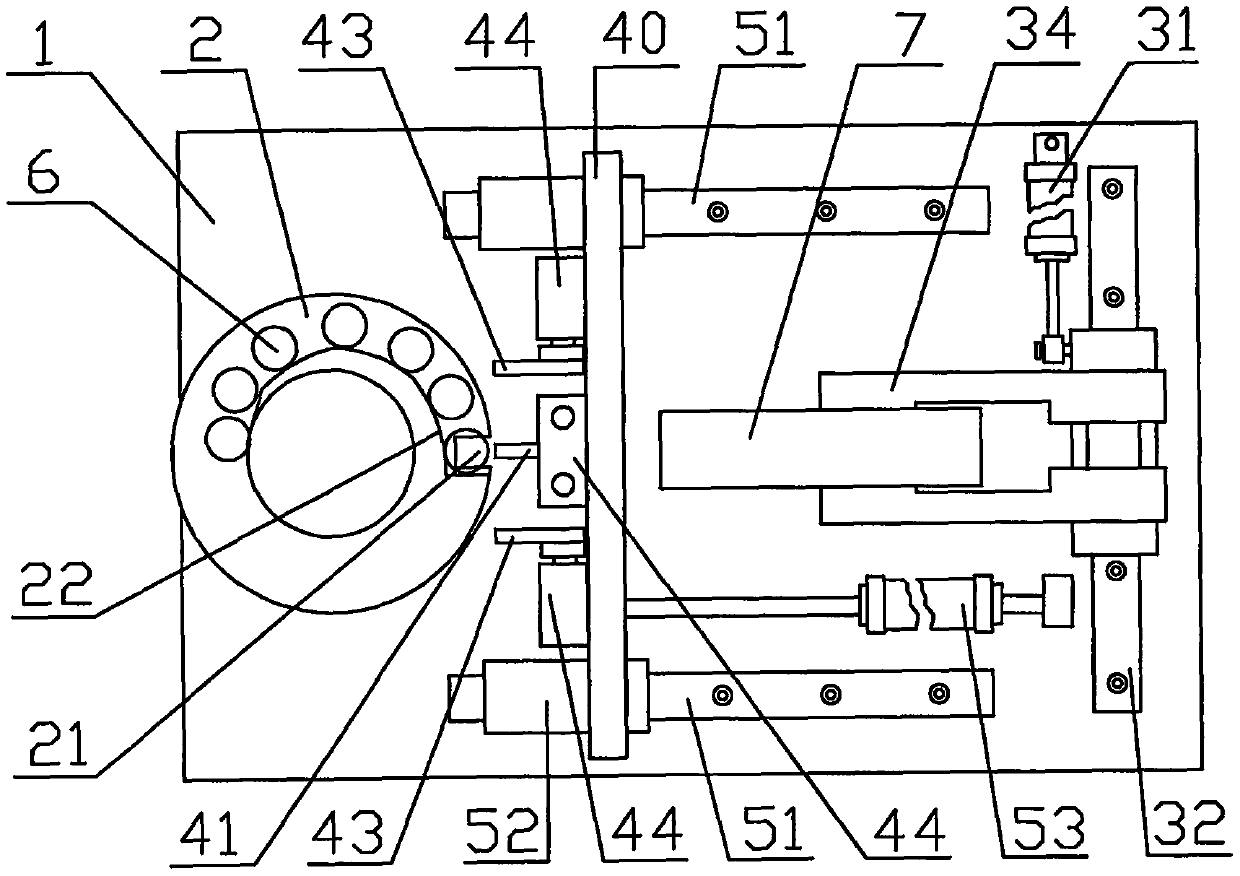

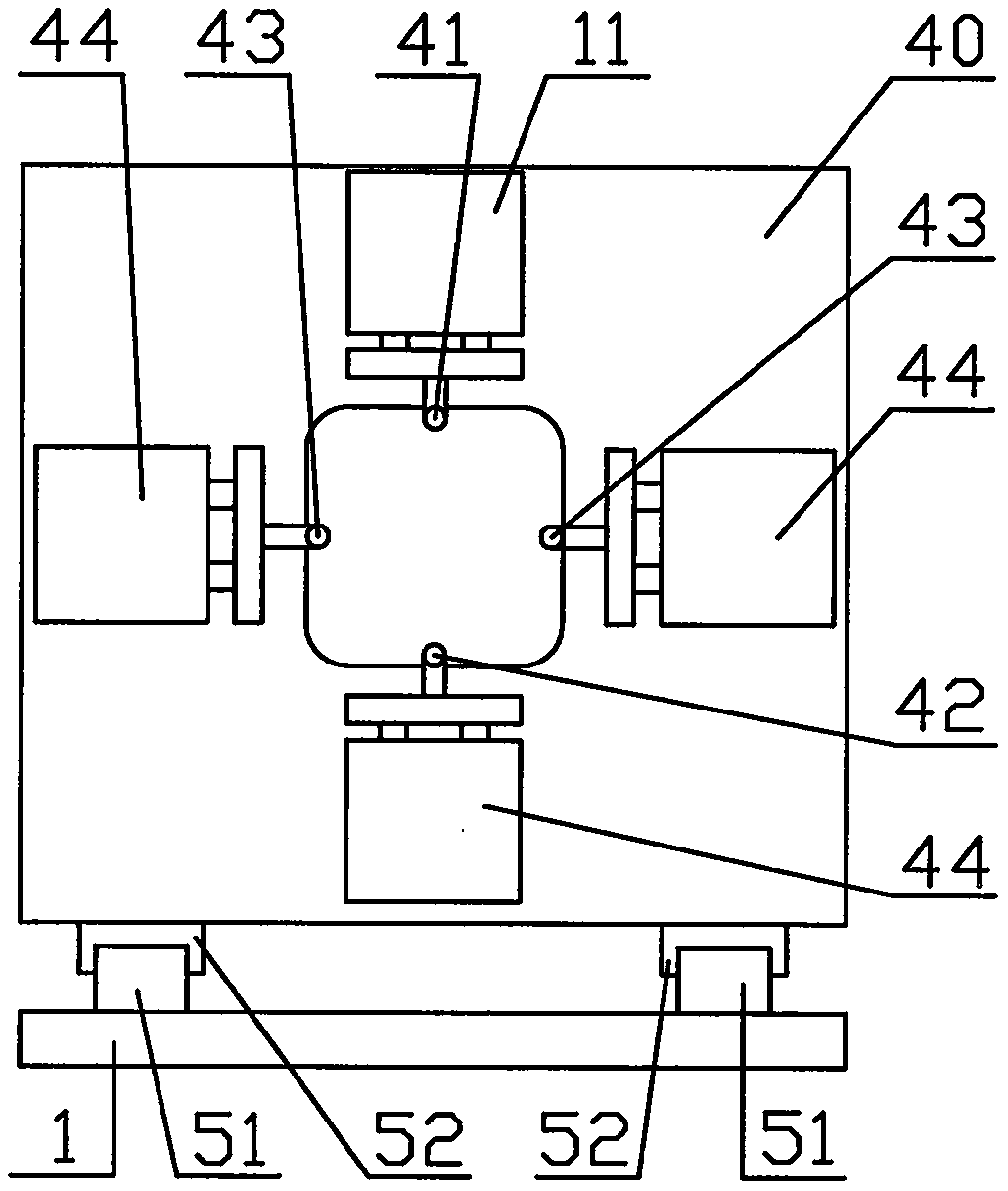

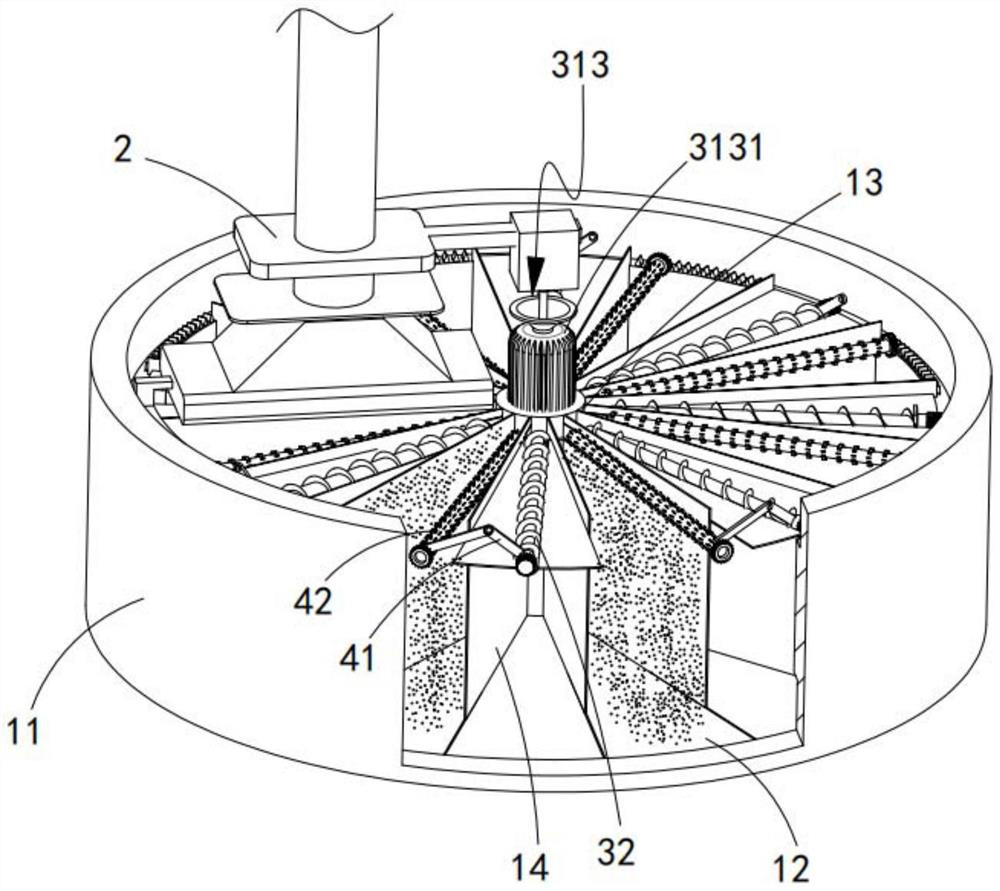

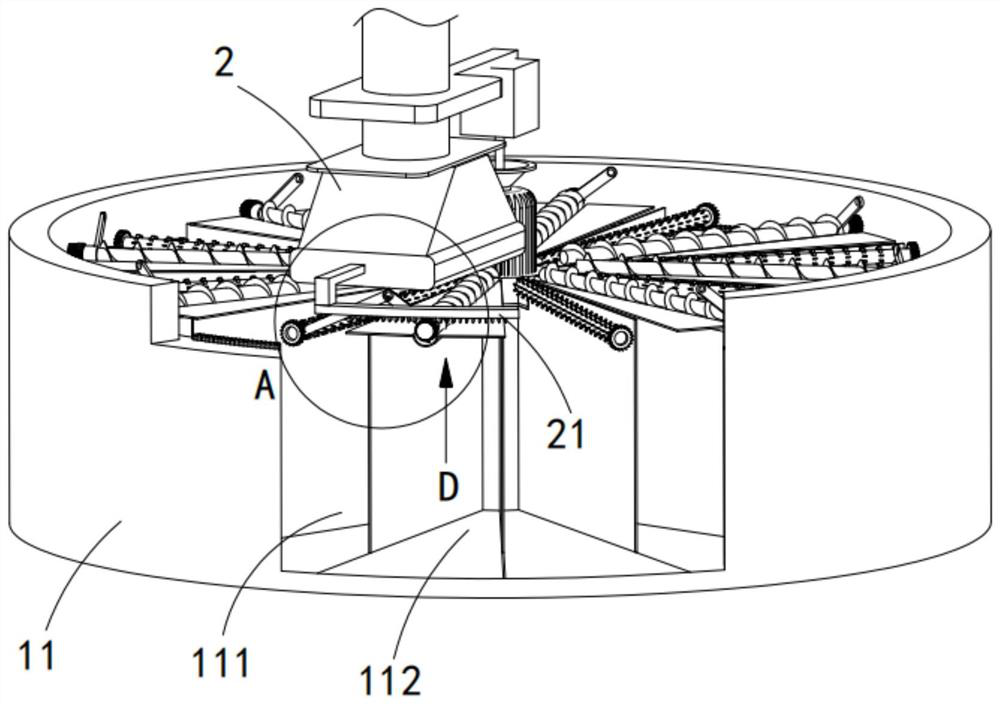

A garment multifunctional sewing machine

ActiveCN105887369BMeet different process requirementsImprove efficiencyWorkpiece carriersWork-feeding meansControl systemEngineering

The invention discloses a multifunctional garment sewing machine which comprises a rack and a control system, wherein a worktable and a rotating mechanism are arranged on the rack; a plurality of working areas are formed in the worktable; the rotating mechanism comprises a rotating disc; the rotating disc is arranged in the middle of the worktable; a first rotating shaft which rotates along the rotating disc is longitudinally arranged on the rotating disc; the first rotating shaft is composed of a plurality of equally divided intervals; the number of the intervals is equal to that of the working areas; the bottom of each interval is connected with the rotating disc by virtue of a Y-axis transmission mechanism so as to realize Y-direction movement of the intervals on the rotating disc; a second rotating shaft is transversely arranged on each interval; a plurality of working groups with different using functions are arranged on the second rotating shaft; the plurality of working groups are respectively uniformly and fixedly distributed on the second rotating shaft by taking the second rotating shaft as an axis and are positioned just above the worktable; and function switching of the working groups is realized by virtue of rotation of the second rotating shaft. According to the invention, the rotating mechanism is combined with the plurality of working groups, so that function selection diversity and automatic operation are realized.

Owner:南京润泽华针纺织科技发展有限公司

Intelligent stacking machine

PendingCN111924548AStacking GuaranteeReduce manpowerStacking articlesDe-stacking articlesRobot handStack machine

The invention discloses an intelligent stacking machine, relates to the technical field of mechanical manufacturing, and aims to solve the problem that in the prior art, the stacking efficiency is low. In order to solve the above problem, the following scheme is provided: the intelligent stacking machine comprises a supporting frame, wherein motors are fixedly connected with the top of the supporting frame; lead screws are fixedly connected with the output ends of the motors through couplings; sliding blocks are in transmission fit with the outer sides of the lead screws spirally; a moving plate which is slidably connected with the supporting frame is fixedly connected with the corresponding sides of the sliding blocks; a conveying device is fixedly connected with the upper side of the moving plate; a collecting box is placed on the upper side of the conveying device; manipulators which are fixedly connected with the supporting frame are arranged on the corresponding sides of the collecting box; and a PLC controller is fixedly connected with one side of the supporting frame. The intelligent stacking machine is simple in structure, convenient to use, and capable of being matched with the transport operation of a transport vehicle for automated stacking; and through the automated stacking process, the input of manpower and material resources can be reduced, the efficiency can beimproved, and the cost can be reduced.

Owner:QIJING MACHINERY

A kind of color mixing processing equipment and technology before air spinning color spinning

ActiveCN111876855BImprove absorption efficiencyImprove mixing efficiencyContinuous processingSpinningProcess engineering

Owner:ZHEJIANG HUZHOU WEIDA TEXTILE GRP

Vacuum rake dryer

InactiveCN111649546ASolve production discontinuityWork compactDrying solid materials without heatHeating arrangementProcess engineeringEngineering

The invention relates to a vacuum rake dryer. By means of the structure of the dryer, drying process treatment is achieved, the problem that production is discontinuous is solved, work is compact, andefficiency is high; the problems that caking happen, the outer portions are burnt, and the inner portions are wet are solved, and the quality of dried products is good and stable; the vacuum degree is constant, and moisture absorption and damping are not prone to happening; and few materials are accumulated, and the cleaning workload is small; and heat efficiency is high.

Owner:JIANGSU BOSIWEI ENG TECH CO LTD

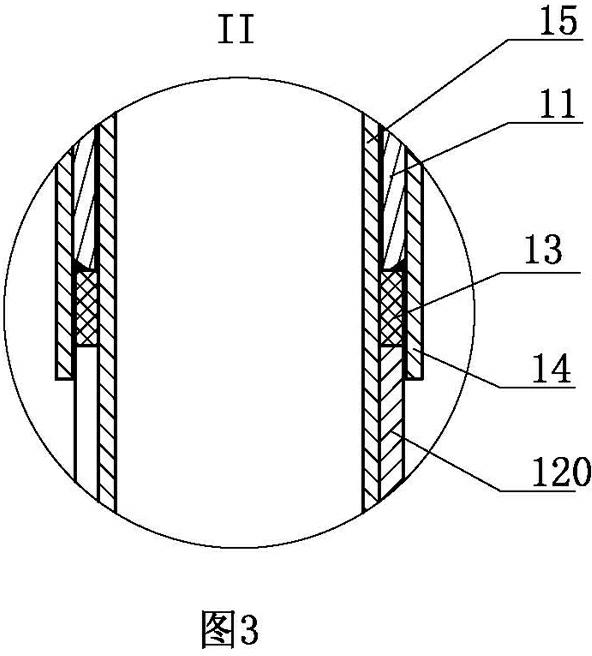

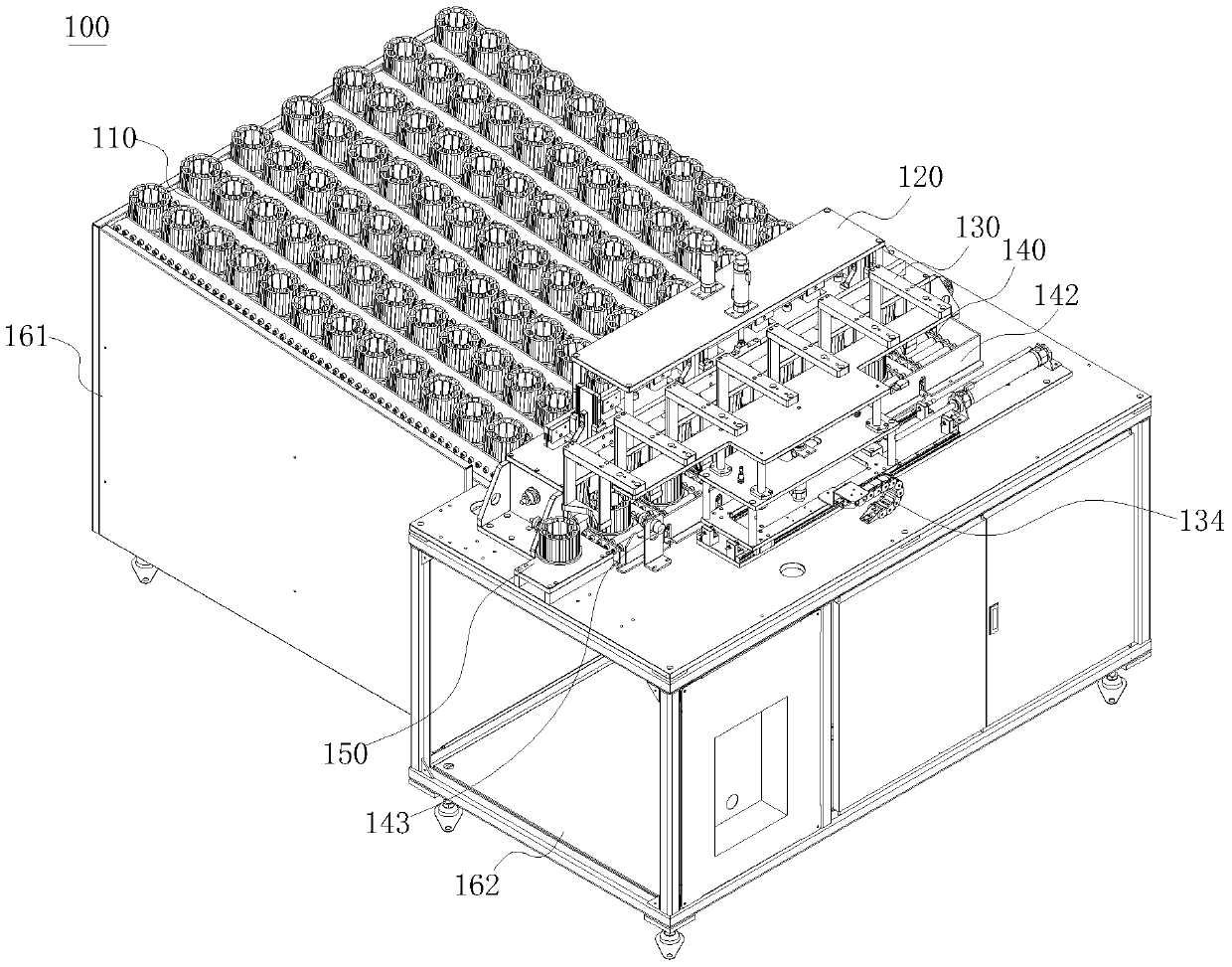

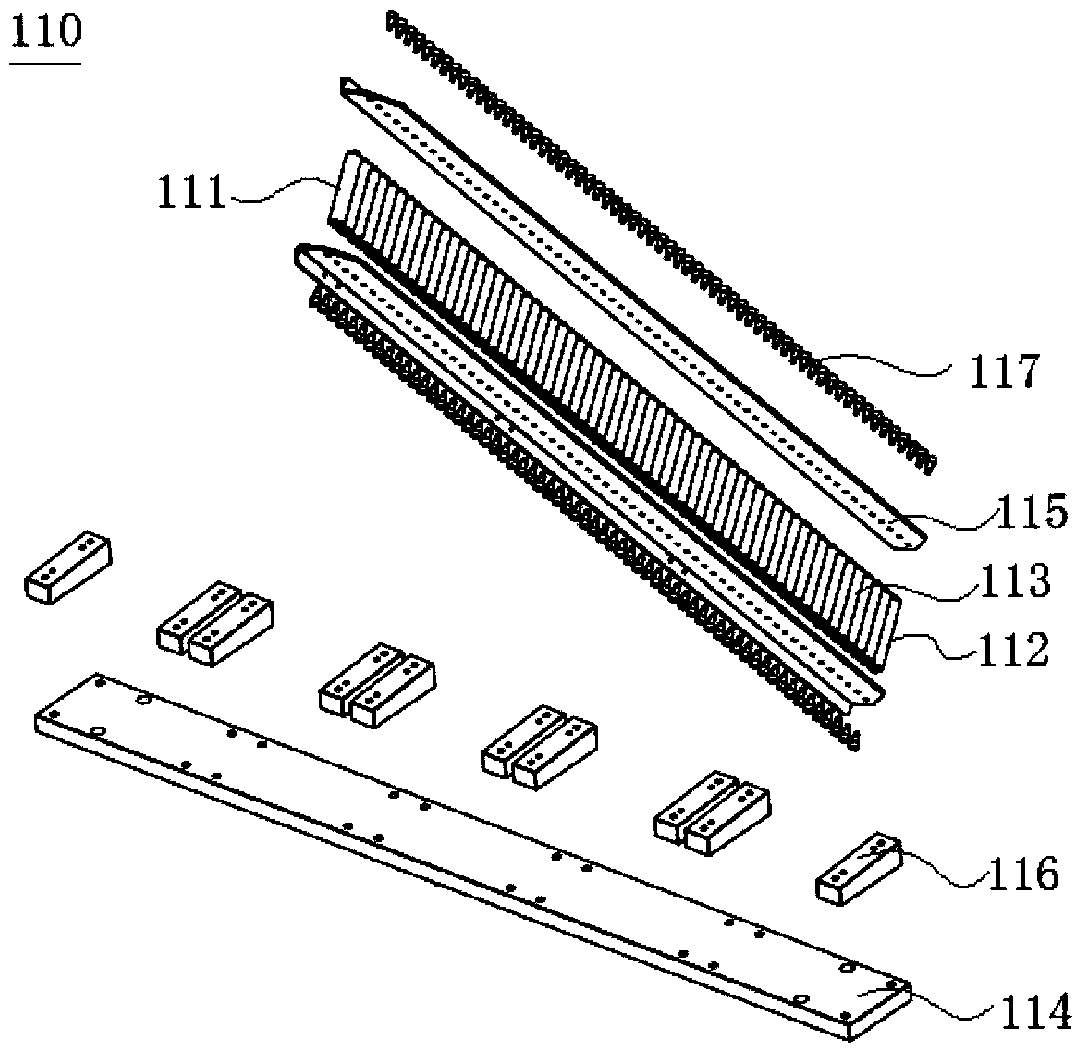

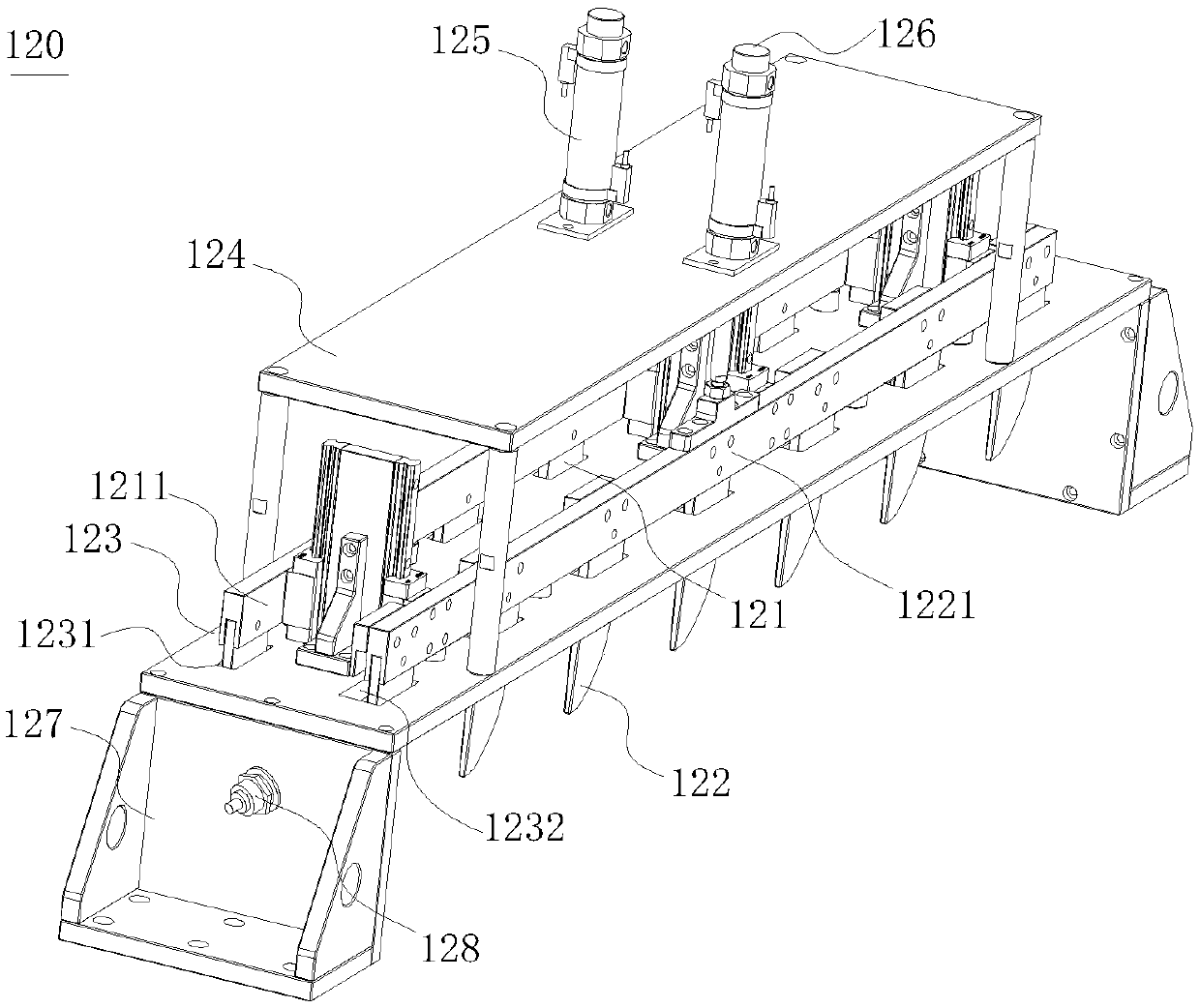

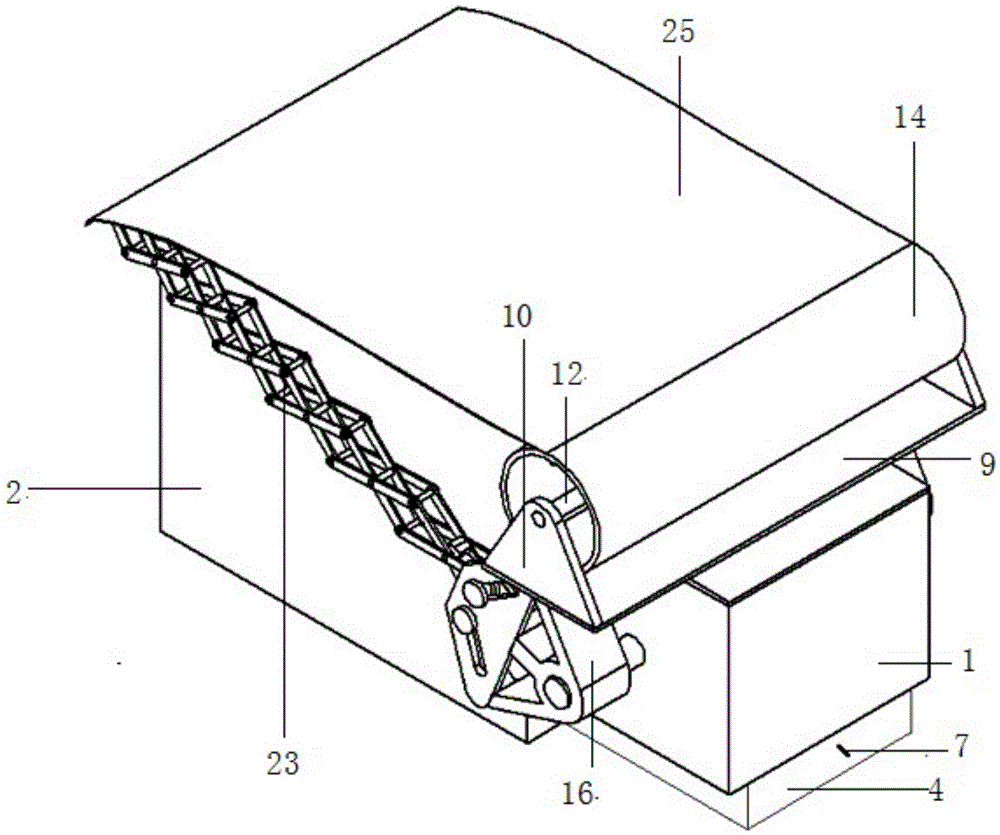

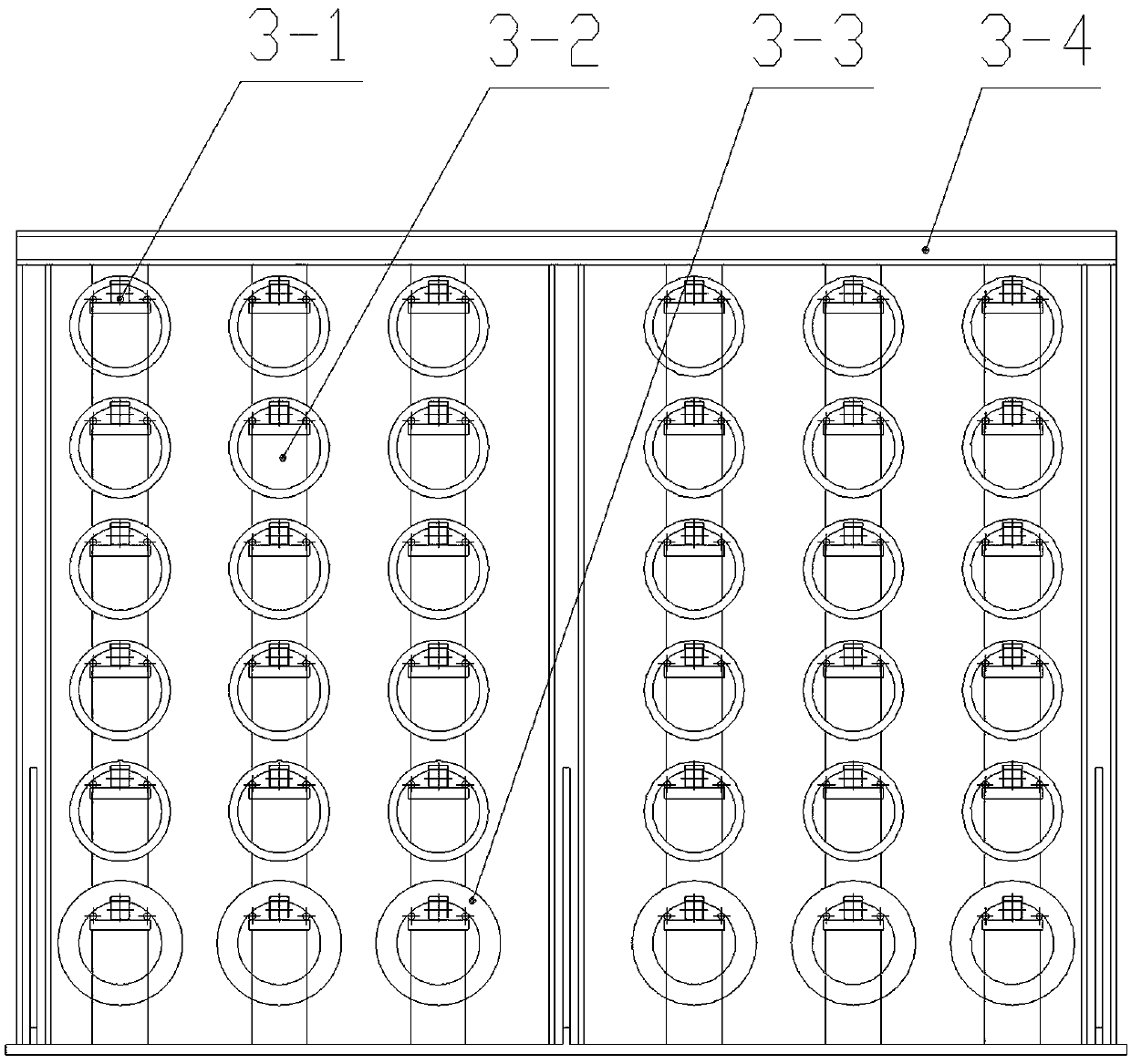

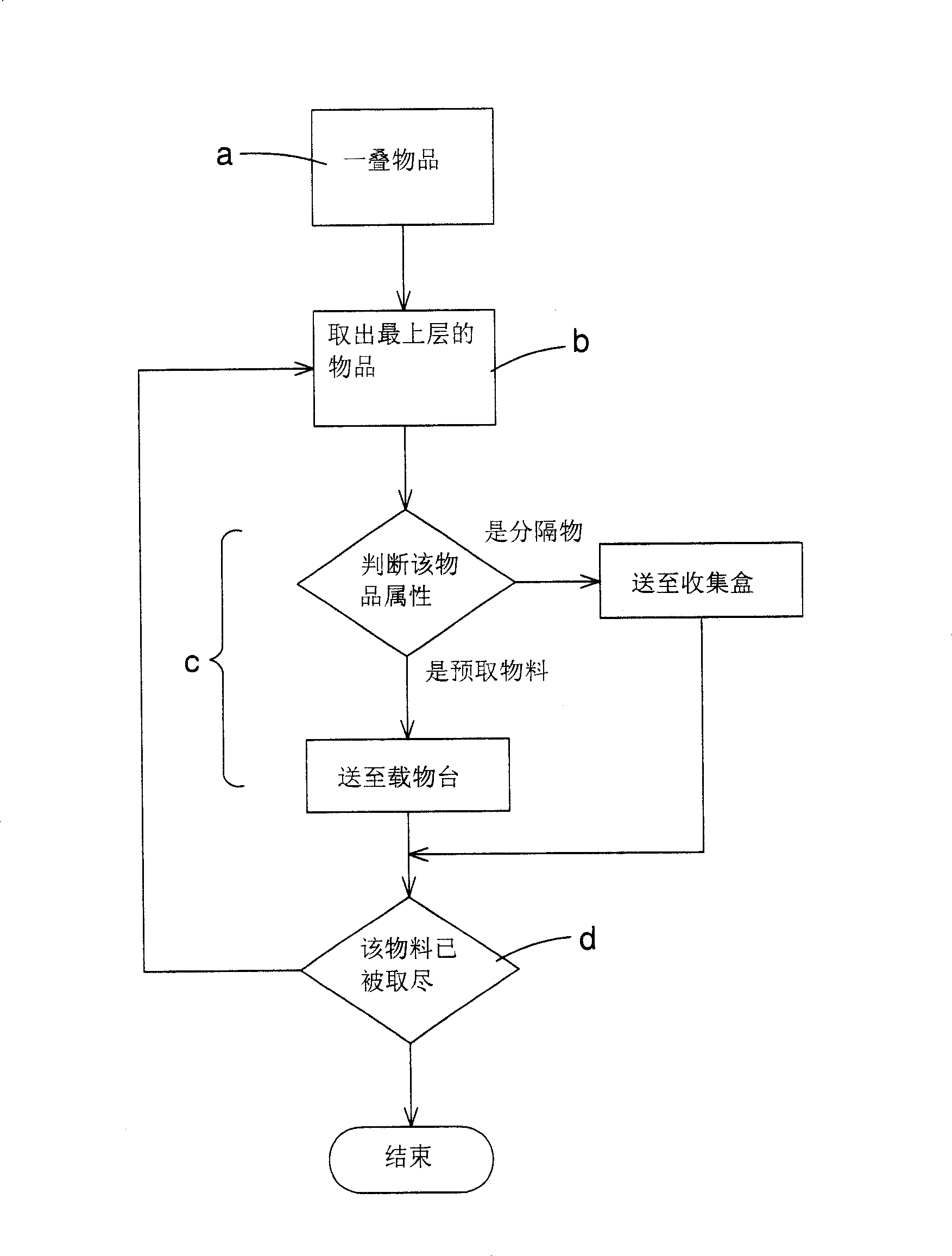

Material-fetching method and automatic material-fetching machine for implementing the method

InactiveCN100468148CSolve the problem of long travelSimple structureLoading/unloadingNon-linear opticsEngineeringFace sheet

The invention relates to the liquid crystal board auto-assemble equipment field, especially relates to an auto-stock-fetching process of fetching the liquid crystal board from the a container, which includes the following steps: a) a stack goods are moved to a stock-fetching location; b) the goods on the top of the layer is fetched out; c) the attribute of the goods is judged and the goods is arranged at the corresponding location according to the attribute; d) the b step to c step are repeated until all the goods are fetched out. In the step c, if the goods is a spacer, the amass caddy loading the spacer is transferred to the underside of the spacer, and the spacer is set down and arranged in the amass caddy; if the goods is the predetermined material, the material will be horizontally moved a distance in the Y direction, and then, is set down and arranged in the amass caddy.

Owner:庄添财

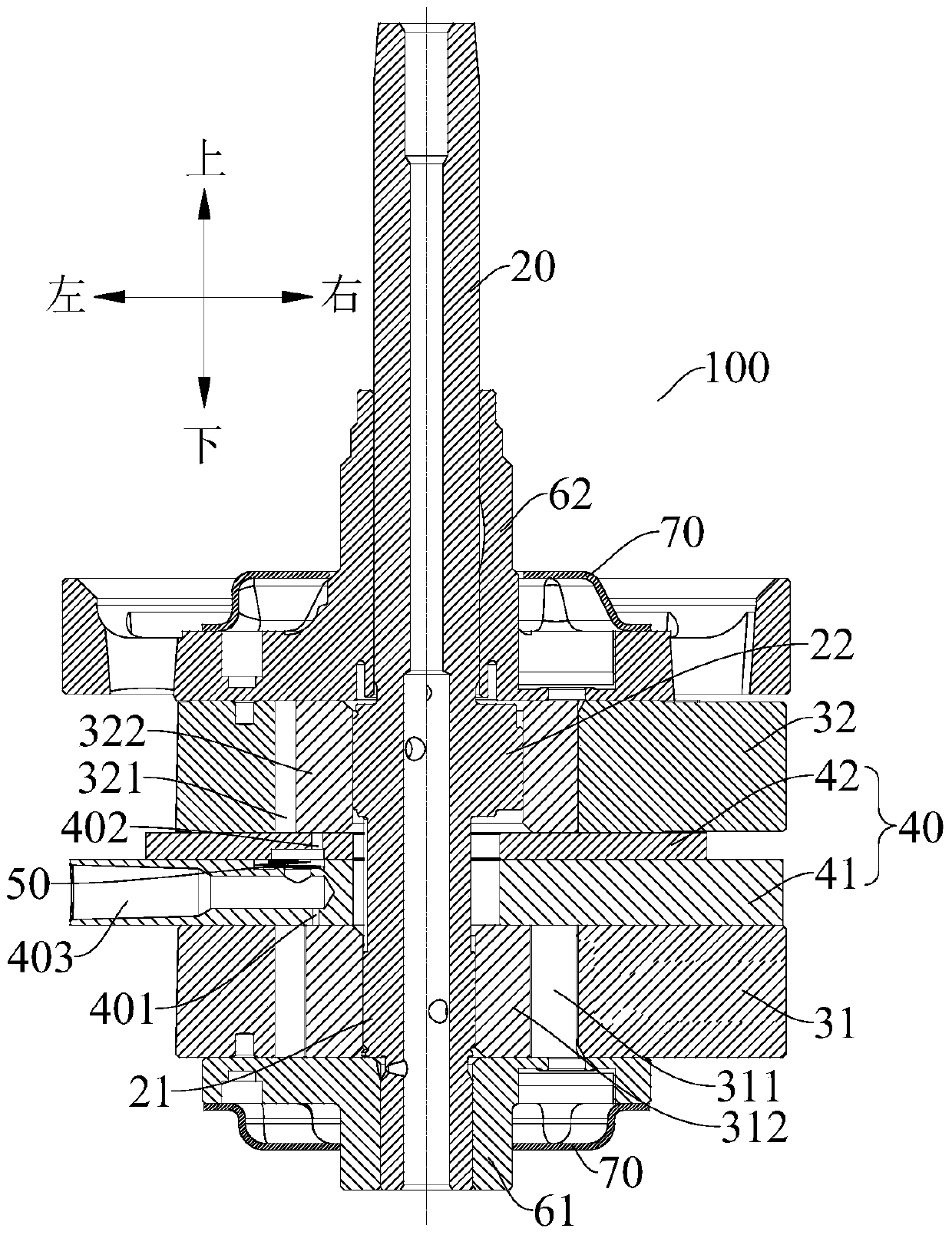

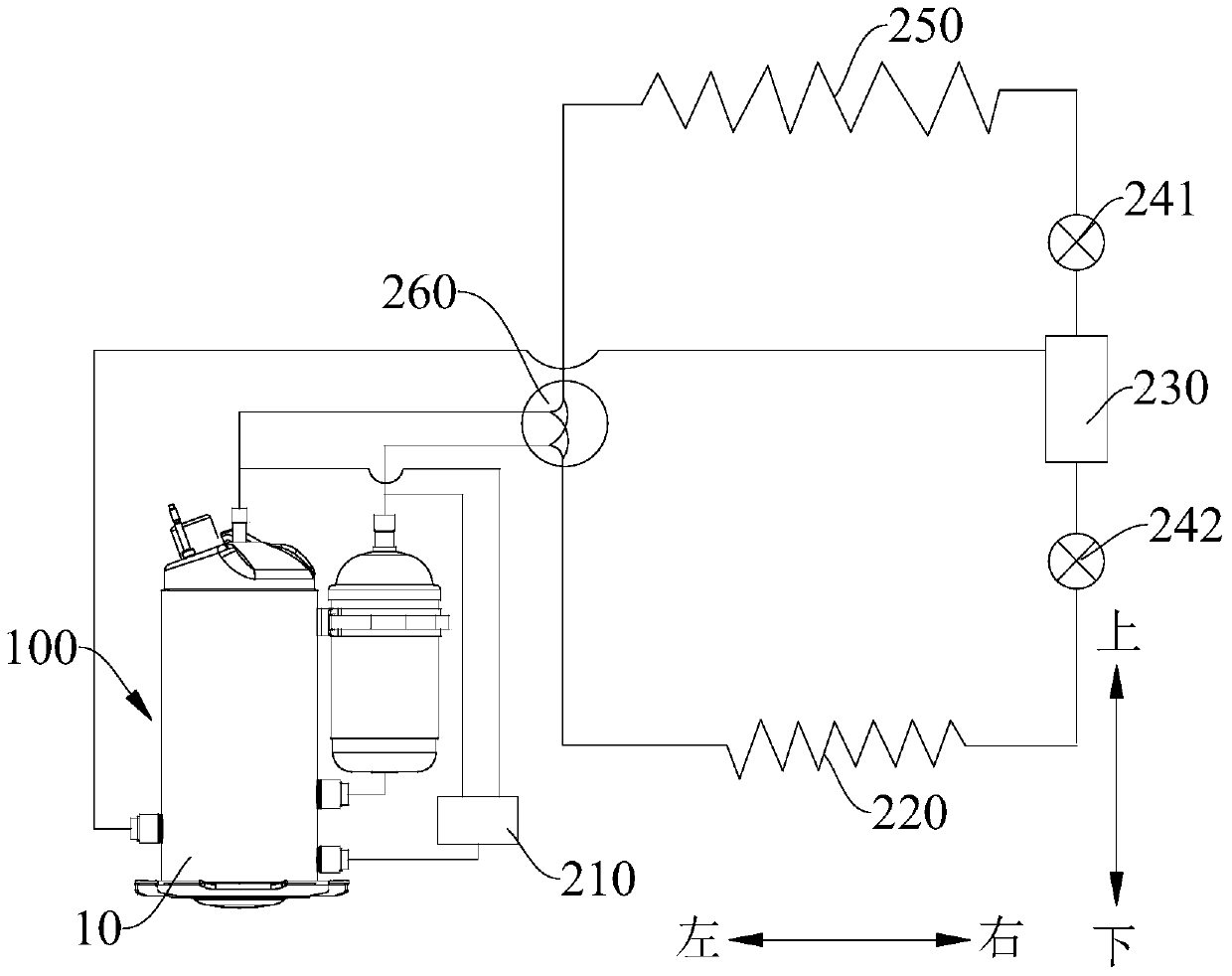

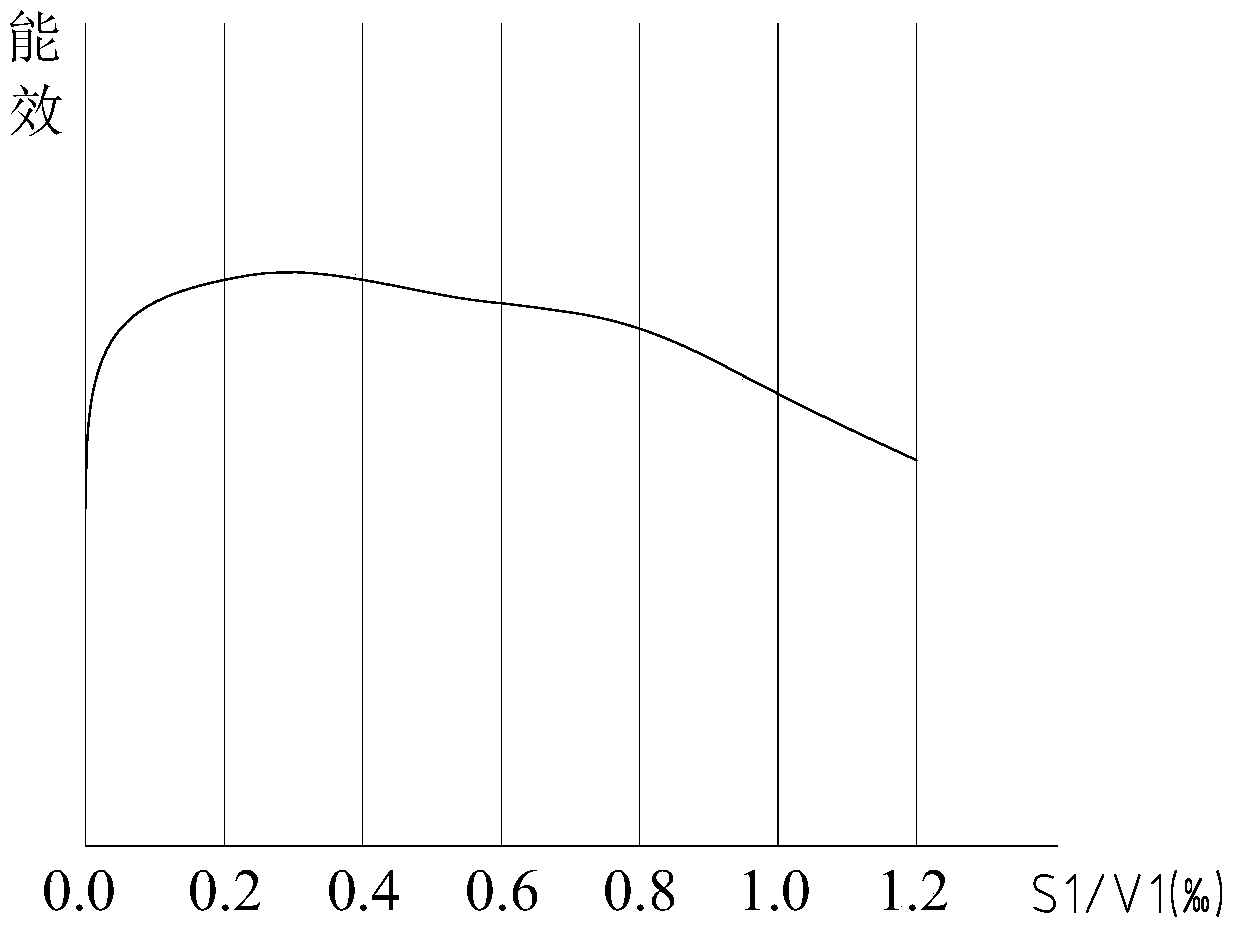

Rotary Variable Capacity Compressor

ActiveCN105422462BWork compactImprove abilitiesRotary/oscillating piston pump componentsLiquid fuel engine componentsBusiness efficiencyMechanical engineering

Owner:ANHUI MEIZHI PRECISION MFG

Truck automatic cover sheet device

ActiveCN105539261BClosely connectedRapid expansion and contractionLoad coveringRemote controlEngineering

The invention relates to the technical field of carriage shield assembly parts, in particular relate to a device for automatically covering tarpaulin of a truck. According to the device disclosed by the invention, a stepping motor is adopted, so that the device can work more accurately and effectively; a control device and a remote control are adopted, so that people can remote control the work of the device, the work can be more efficient, and manpower and material resources can be saved; an external rotor motor is adopted, so that the structure of the device can be more simple, and assembly and maintenance are more convenient and efficient; a winding drum is adopted, so that device coverage and tarpaulin folding can be more efficient, and the manpower and the material resources can be saved; an expansion bracket is adopted, so that the mass of the device can be lighted, and the device structure can be more simple, lighter and convenient; a guide rail pulley is adopted, so that the expansion and the contraction of the expansion bracket can be more rapid, and the labor and the time can be saved; an inner shears-fork plate and an outer shears-fork plate are adopted, so that the structure of the expansion bracket can be more simple, lighter and convenient.

Owner:NANTONG ZHONGYI BOILER EQUIP

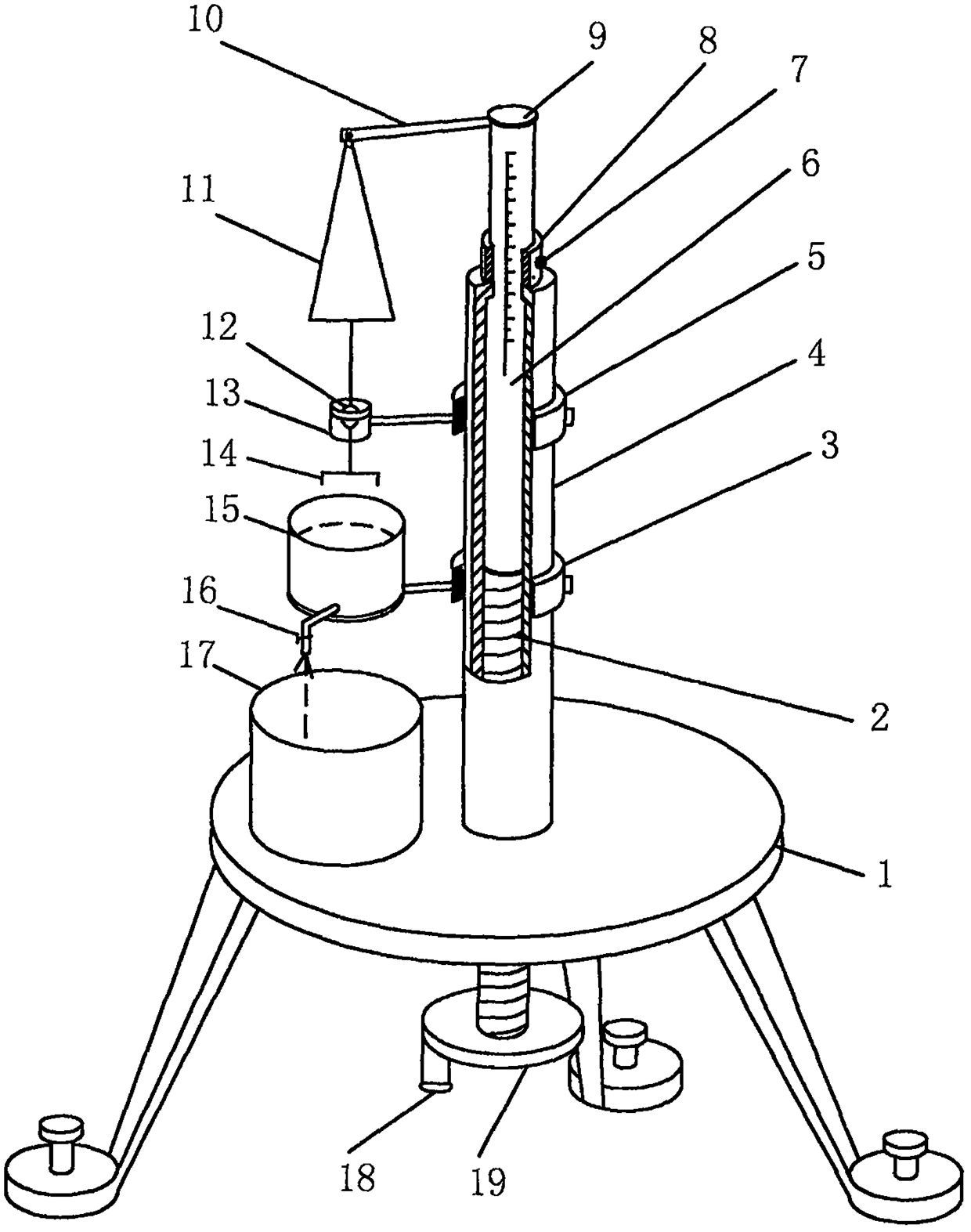

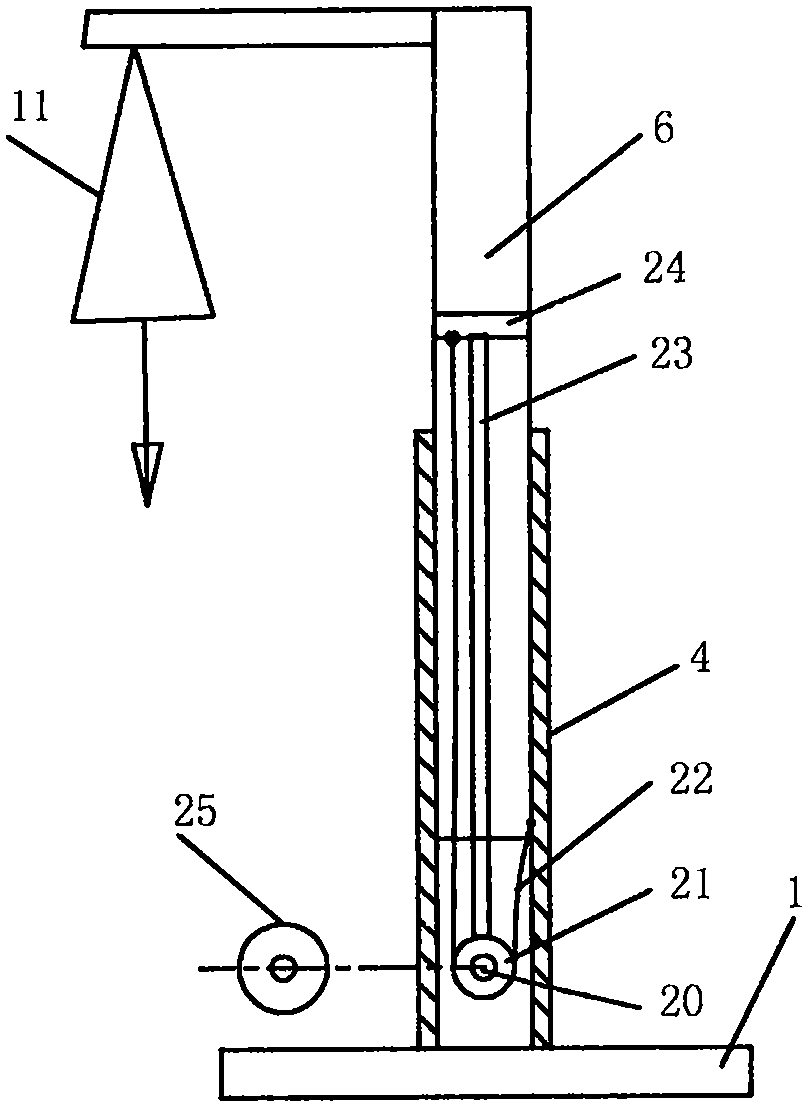

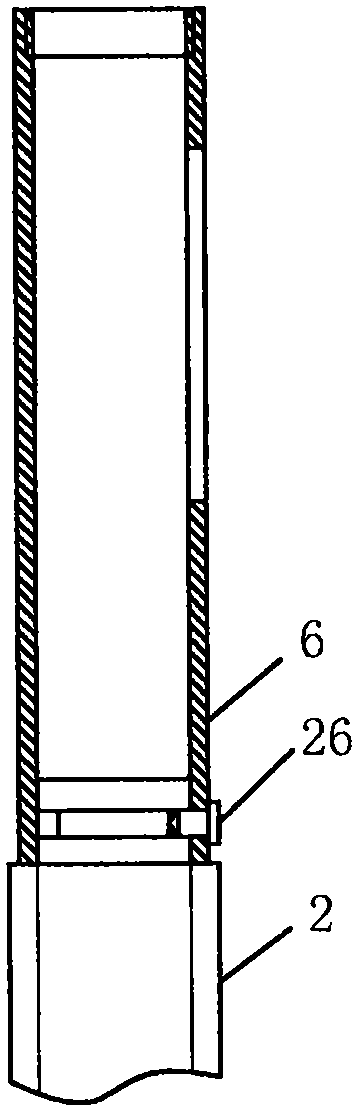

Novel Joly balance

PendingCN109187282ANo more slippageNo longer will it be pulled offEducational modelsSurface tension analysisEngineeringMechanical engineering

The invention discloses a novel Joly balance, which comprises a stand (1), a screw rod (2), an outer barrel (4), a lifting barrel (6), a rotation stopping screw (7), a vernier (8), a screw (9), a handle (18), a turntable (19), a connecting screw (26) and a measuring part, wherein the inner bottom end of the outer barrel (4) is provided with an internal thread; the outer barrel (4) is perpendicularly fixed at the center position of the stand (1); the screw rod (2) passes through the bottom of the stand (1) and is screwed into the outer barrel (4); the upper end of the screw rod (2) is providedwith a ring slot; after the lifting barrel (6) is inserted into the outer barrel (4) from the upper part, the ring slot in the upper end of the screw rod (2) is inserted into the bottom of the liftingbarrel (6); the connecting screw (26) passes through the lifting barrel (6) and is inserted into the ring slot in the upper end of the screw rod (2); and the screw rod (2) can drive the lifting barrel (6) to move axially, but cannot drive the lifting barrel (6) to rotate. The measuring precision of the novel Joly balance is greatly improved, and the novel Joly balance works reliably and is convenient to operate.

Owner:HUZHOU TEACHERS COLLEGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com