Automatic cutter changing device for spacer cutter

A technology of automatic tool changer and knife device, which is applied in the field of transformer manufacturing, can solve the problems of high price and achieve the effects of saving floor space, high precision and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

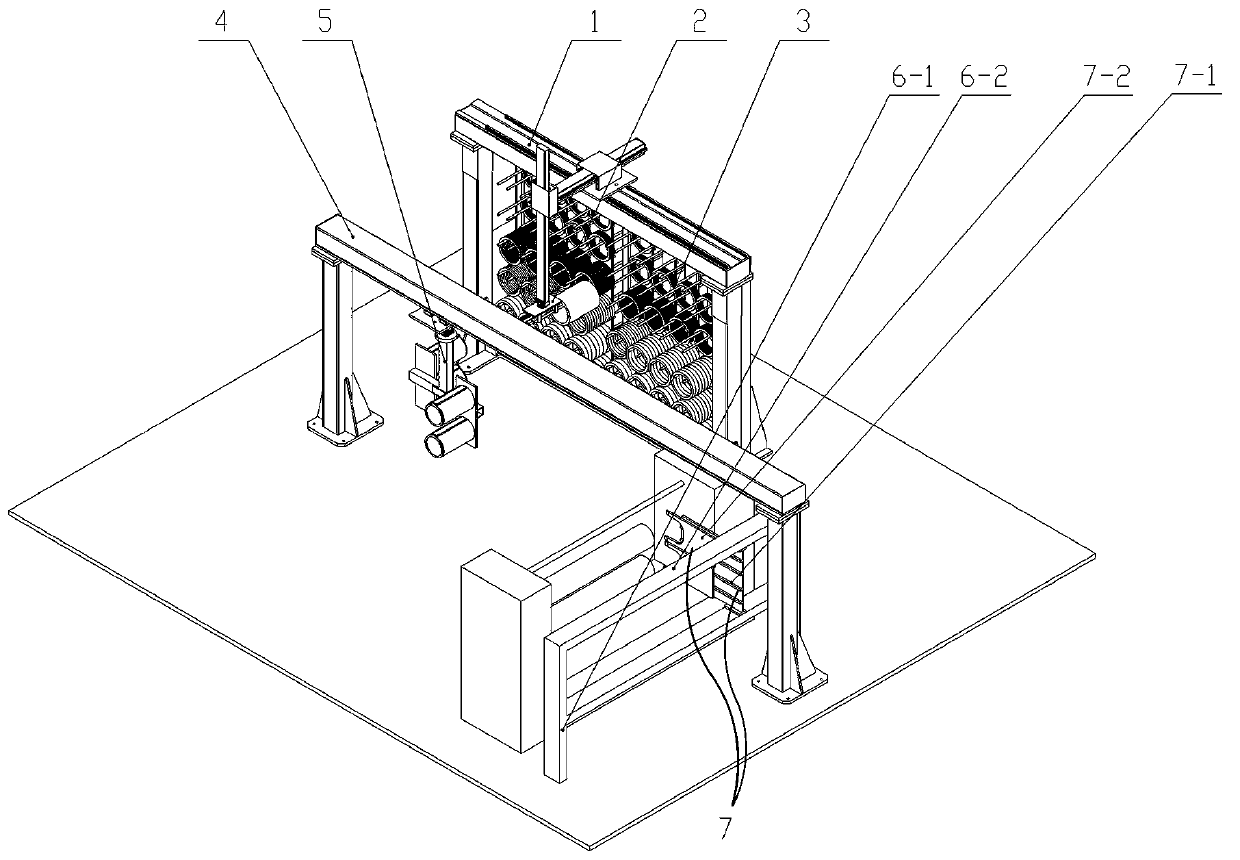

[0043] Please refer to Figure 1 to Figure 3 , which shows a schematic diagram of the overall structure of an automatic tool changer for a spacer knife provided in an embodiment of the present invention. The automatic tool changer for a spacer knife includes:

[0044] Tool magazine, said tool magazine includes:

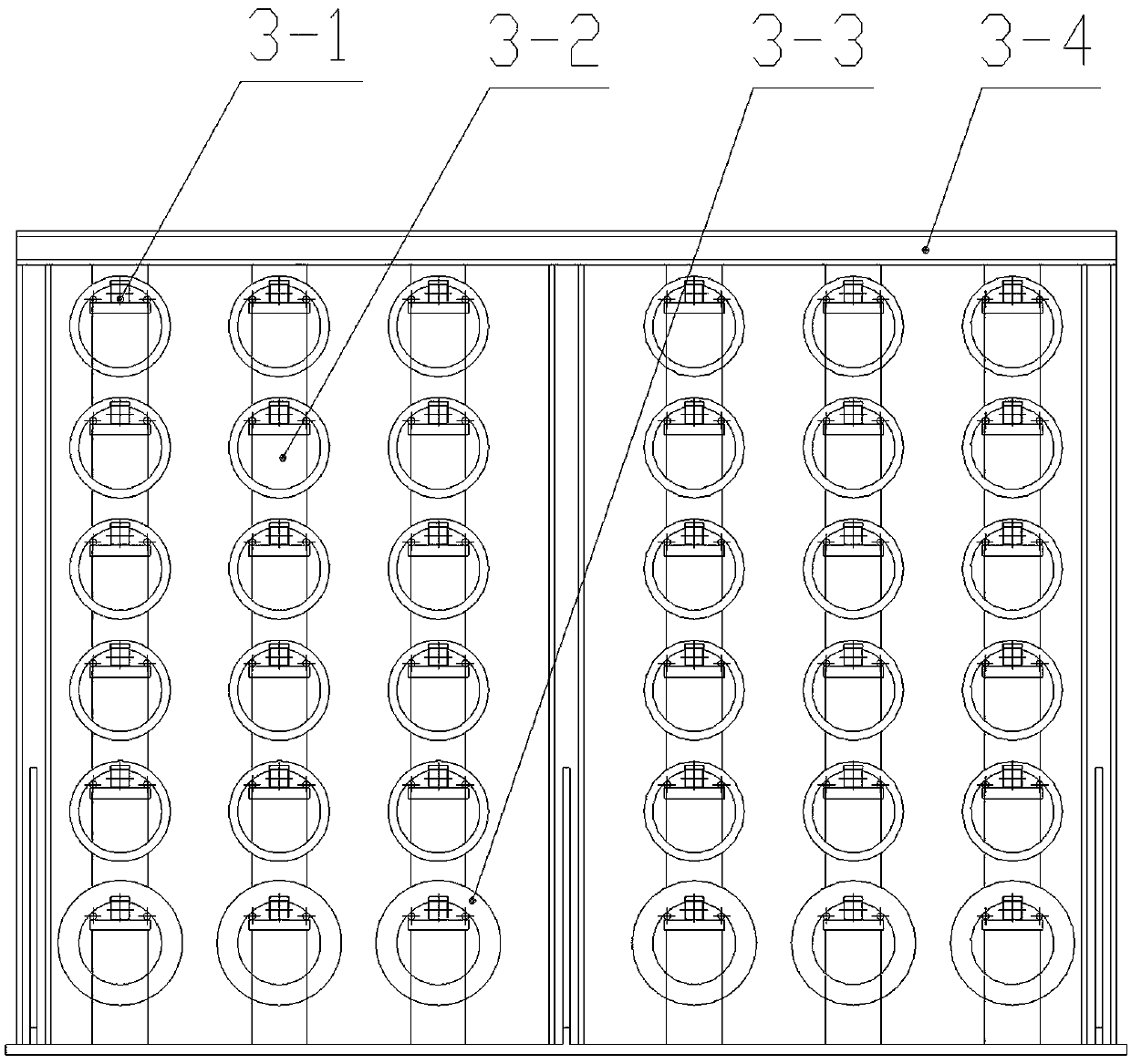

[0045] The three-dimensional warehouse 3-4 has multiple storage positions on the three-dimensional warehouse 3-4;

[0046] The three-axis gantry mechanical arm 1, the three-axis gantry mechanical arm 1 is set on the three-dimensional warehouse 3-4;

[0047] Knife fetching device 2, the knife fetching device 2 is arranged on the manipulator end of three-axis gantry mechanical arm 1;

[0048] The multiple storage positions of the three-dimensional warehouse 3-4 are all within the range of the manipulator of the three-axis gantry mechanical arm 1;

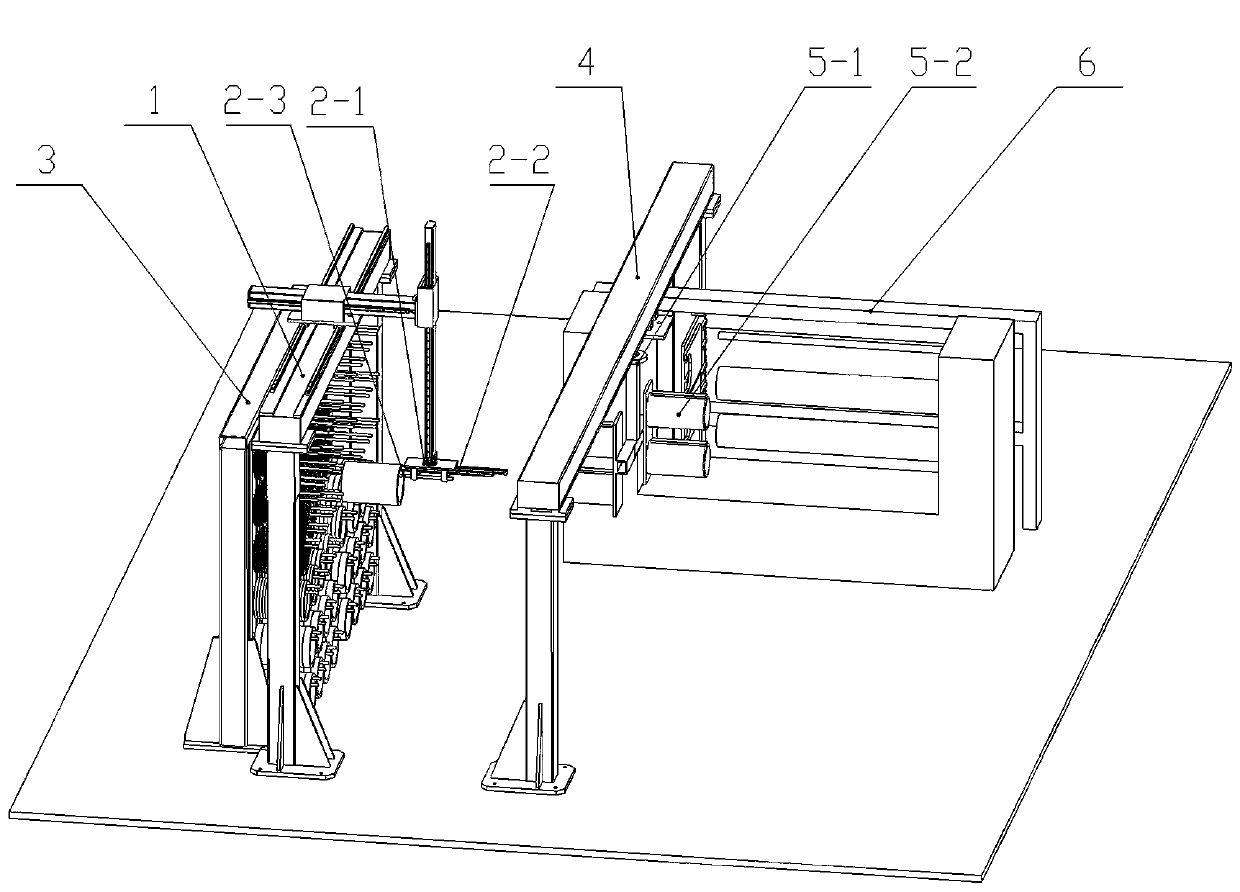

[0049] Moving the knife gantry mechanical arm 4, the end of the mechanical arm of the moving knife gantry mechanical arm 4...

Embodiment 2

[0062] Further, please refer to Figures 1 to 3 , another embodiment of the automatic tool changing device for spacer knives of the present invention, each storage position has a first material receiving device for storing knives, and the end of the knife taking device 2 has a device for removing the knives from the first receiving device The second material receiving device that the material device is removed, the end of the transition cutter shaft 5-2 has a third material receiving device for removing the cutter from the second material receiving device, and the end of the moving blade 7-2 has a The fourth material receiving device that removes the tool from the third device, the first material receiving device is pluggably connected to the second material receiving device, the second material receiving device and the third material receiving device can be Plug-in connection, the fourth material receiving device is located on the side of the third material receiving device, ...

Embodiment 3

[0066] Further, please refer to figure 2 , another embodiment of an automatic tool changer for a spacer knife in the present invention, the knife-moving gantry mechanical arm 4 is a linear conveying device, and the conveying end of the linear conveying device passes through the knife-moving rotary mechanism 5-1 It is connected with the transitional knife shaft 5-2, and the position of the transitional knife shaft 5-2 has a first position and a second position, and the transitional knife shaft 5-2 is in the first position and the second position through the moving knife turning mechanism 5-1. switch between the second positions, when the transitional knife shaft 5-2 is in the first position, the transitional knife shaft 5-2 faces the tool magazine, and the third receiving device on the transitional knife shaft 5-2 is connected to the The second material receiving device is coaxial, when the transitional knife shaft 5-2 is in the second position, the transitional knife shaft 5-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com