Processing equipment for color mixing of rotor spinning before color spinning and process thereof

A technology of processing equipment and processing technology, which is applied in the field of air spinning, can solve problems such as different cloth surface areas, uneven cotton picking work, and differences in raw material ratios, and achieve uniform mixing, improved absorption and mixing efficiency, and high synchronization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

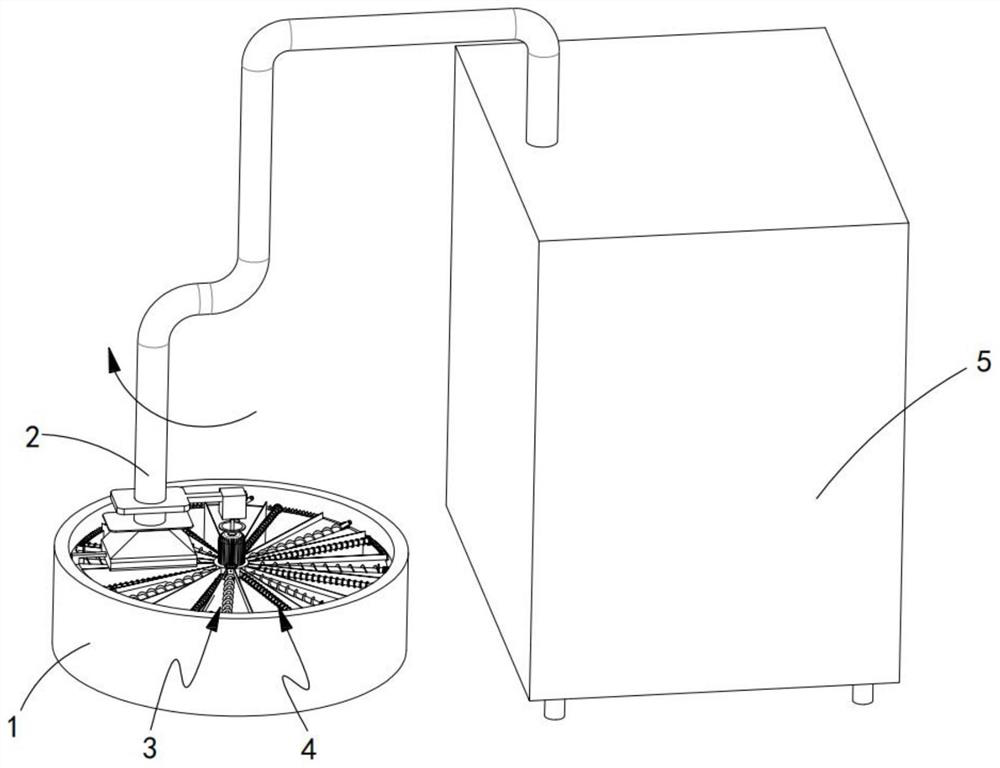

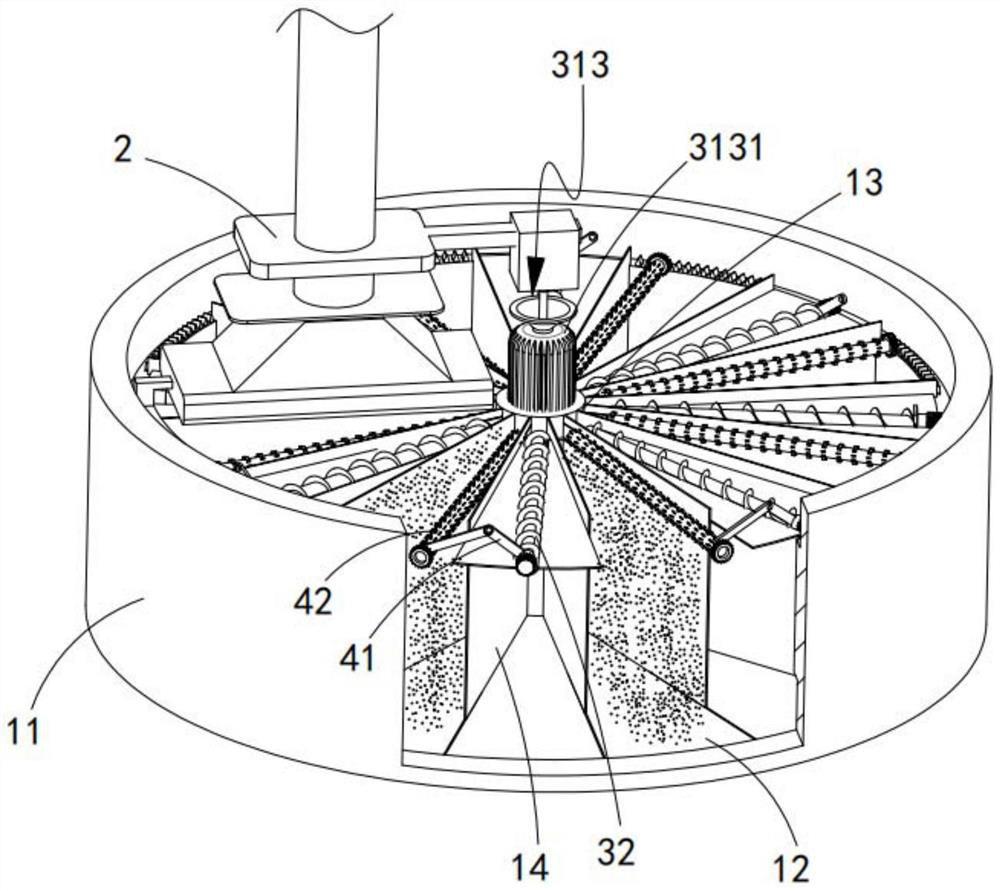

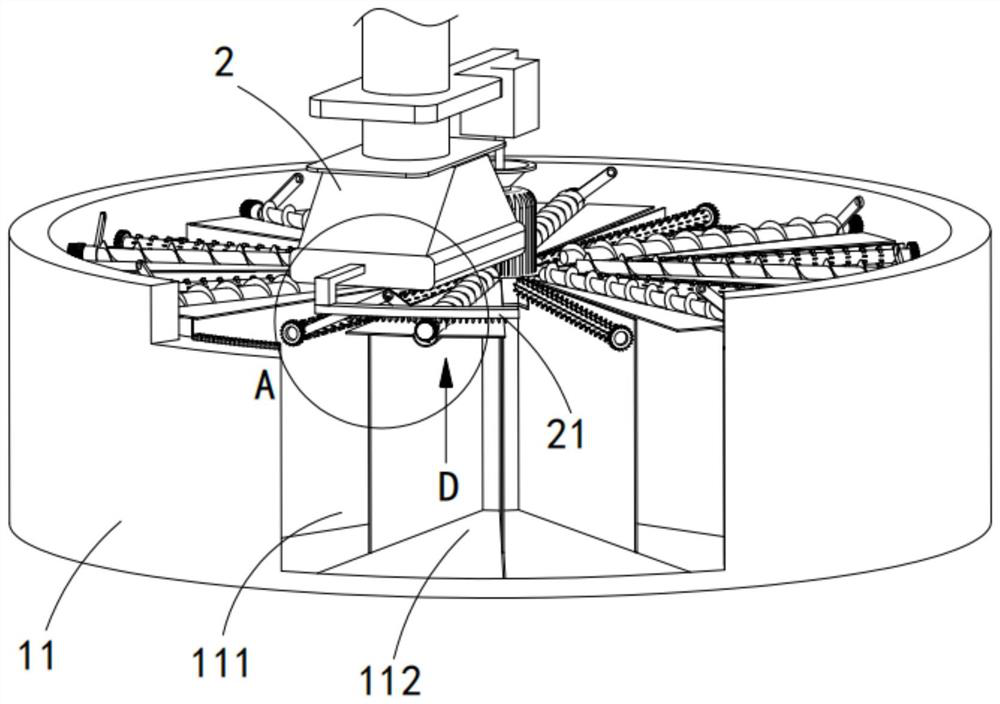

[0051] Such as Figure 1 to Figure 4 Shown, a kind of air-spinning color mixing processing equipment before color spinning, comprises:

[0052] A kind of color mixing processing equipment before air-end spinning color spinning, comprising: a carrying box 1, a cotton grabbing assembly 2 arranged above the carrying box 1 and rotating around the carrying box 1, and a color mixing assembly arranged on one side of the carrying box 1 The device 5, the cotton-catching component 2 communicates with the color mixing device 5, also includes:

[0053] The compensation assembly 3, the compensation assembly 3 includes a compensation unit 31 arranged inside the carrying case 1 and rotating around the carrying case 1 and a cotton collection unit 32 that cooperates with the compensation unit 31 to collect cotton for it;

[0054] The evacuation assembly 4, the evacuation assembly 4 includes a rotating member 41 that is transmission-connected to the cotton collection unit 32 and located on the...

Embodiment 2

[0076] Such as figure 1 , 2 Shown in and 13, a kind of color-mixing processing technology before air spinning colored spinning, comprises the following steps:

[0077] Step 1, the cotton loading process, manually filling raw cotton materials of different colors into each raw material area 111 in the carrying box 1;

[0078] Step 2, the cotton picking process, the cotton picking assembly 2 is set above the carrying box 1, and it rotates around the carrying box 1 in the same direction of rotation, and the cotton picking assembly 2 is sequentially removed from each of the raw material areas 111 absorb raw materials;

[0079] Step 3, the cotton filling process, after the cotton grabbing component 2 passes through the raw material area 111 to absorb raw materials, a part of the raw material is thrown out from the cotton grabbing component 2 and falls to the compensation area 112, and the cotton collecting unit 32 in the compensation component 3 collects the raw materials to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com