Inner-outer tooth friction plate type hydraulic clutch

A technology of hydraulic clutches and friction plates, applied in the field of clutches, can solve problems such as poor lubrication and heat dissipation, insufficient hydraulic power, unfavorable design and installation, etc., and achieve the effects of favorable production cost control, beneficial installation and disassembly, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

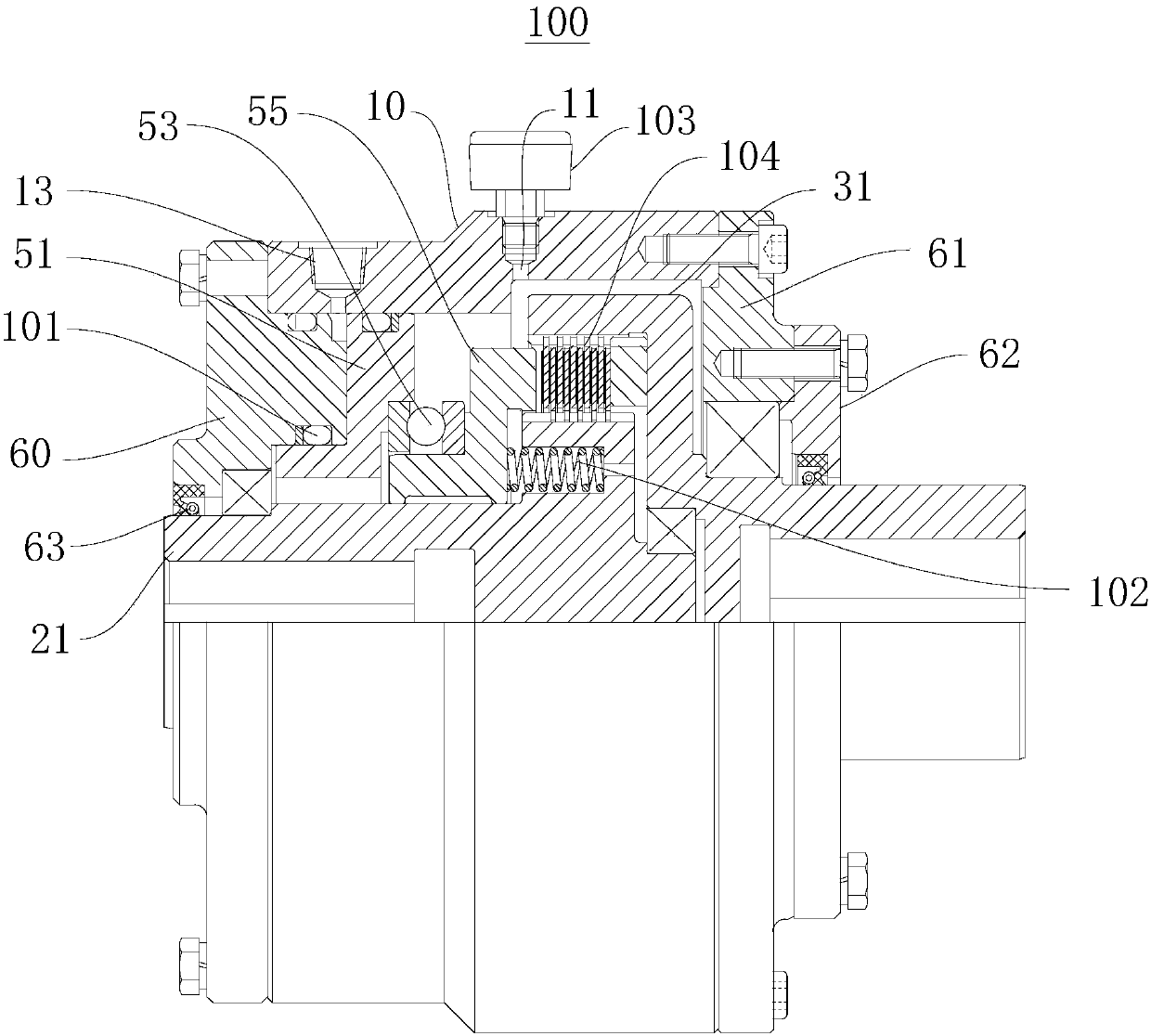

[0043] Please refer to Figure 1 to Figure 5 , this embodiment provides an internal and external gear friction plate hydraulic clutch 100, including:

[0044] The casing, the casing includes a cylinder block 10, the cylinder block 10 has a heat dissipation hole 11, an oil inlet hole 13 for hydraulic oil to enter, and an accommodating cavity for accommodating components;

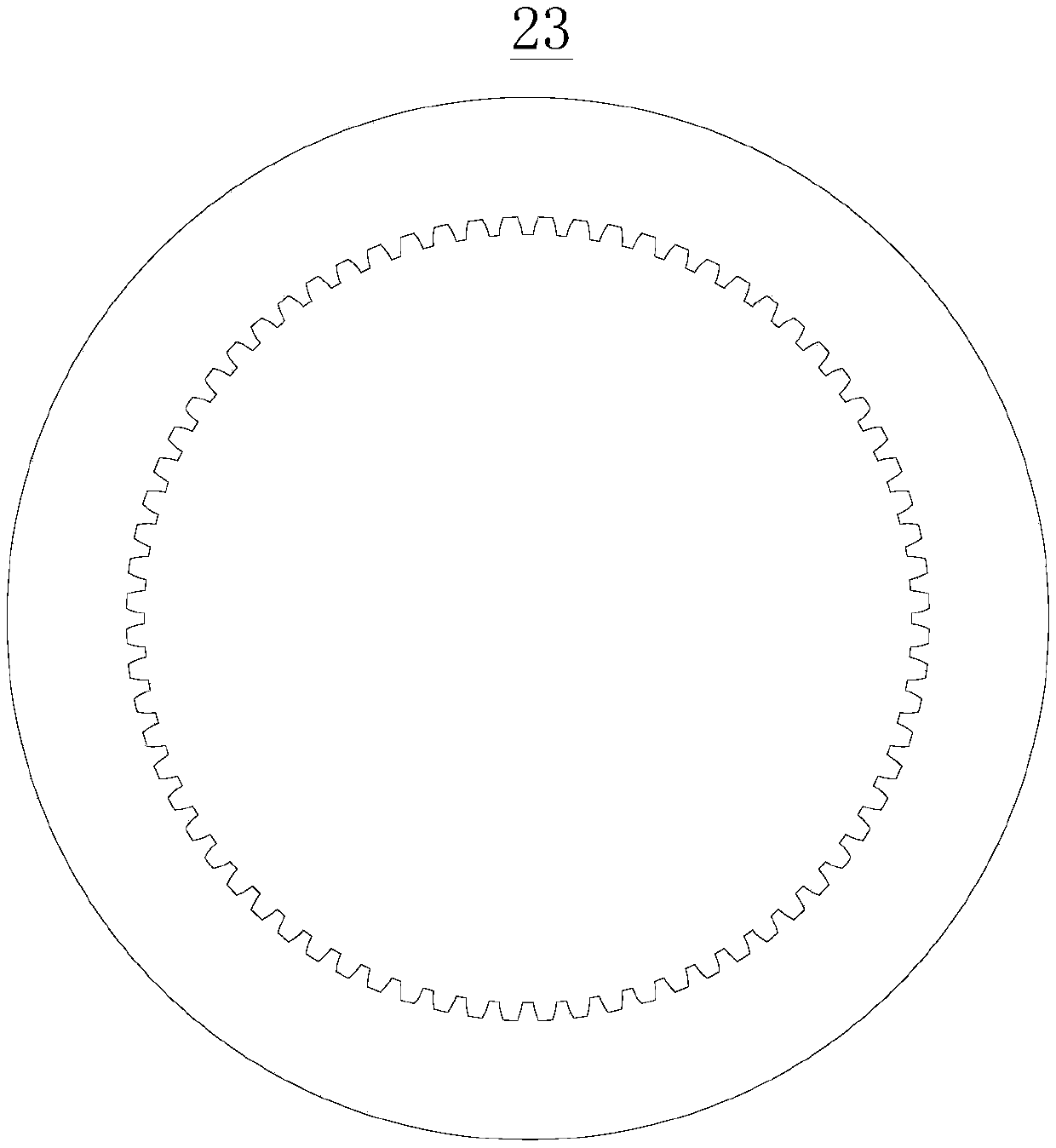

[0045] The power input assembly, the power input assembly is located in the accommodation cavity, the power input assembly includes an input shaft 21 and a first friction plate 23, and the first friction plate 23 is engaged with the input shaft 21;

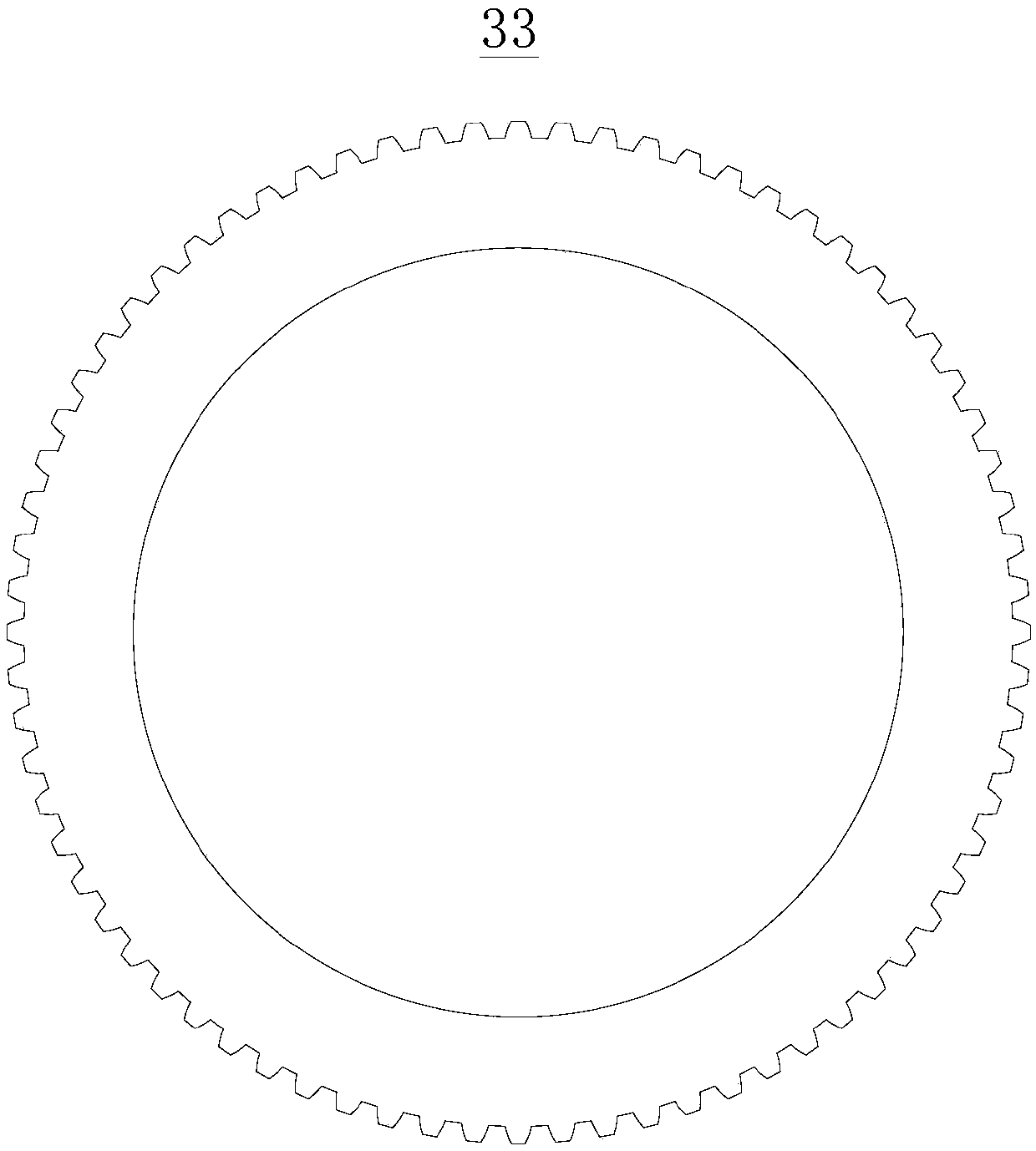

[0046] The power output assembly, the power output assembly is located in the housing cavity, the power output assembly includes an output shaft 31 and a second friction plate 33, the second friction plate 33 is engaged with the output shaft 31, and the first friction plate 23 and the second friction plate 33 are arranged at intervals And there is a gap, the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com