Patents

Literature

51results about How to "Realize automatic cropping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

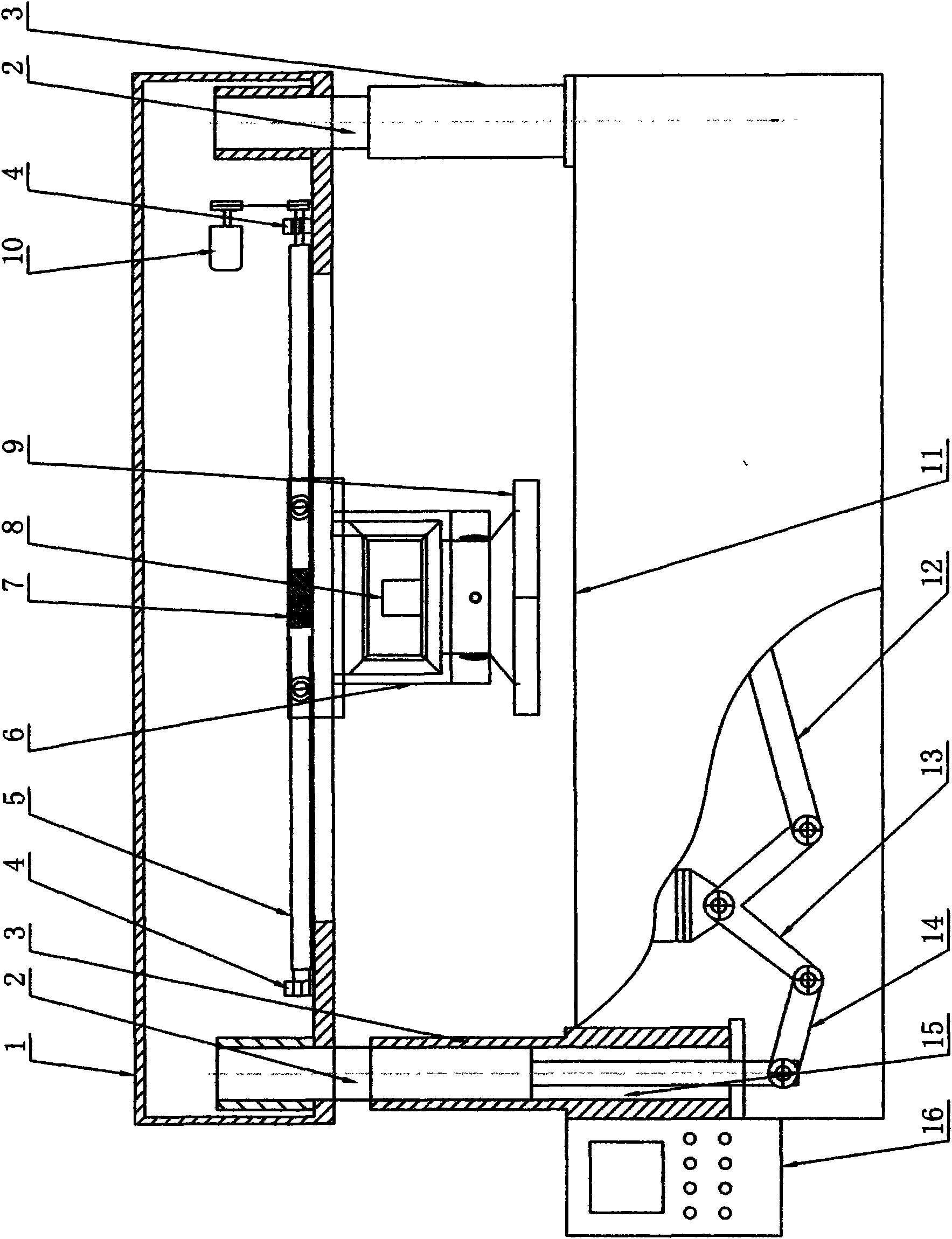

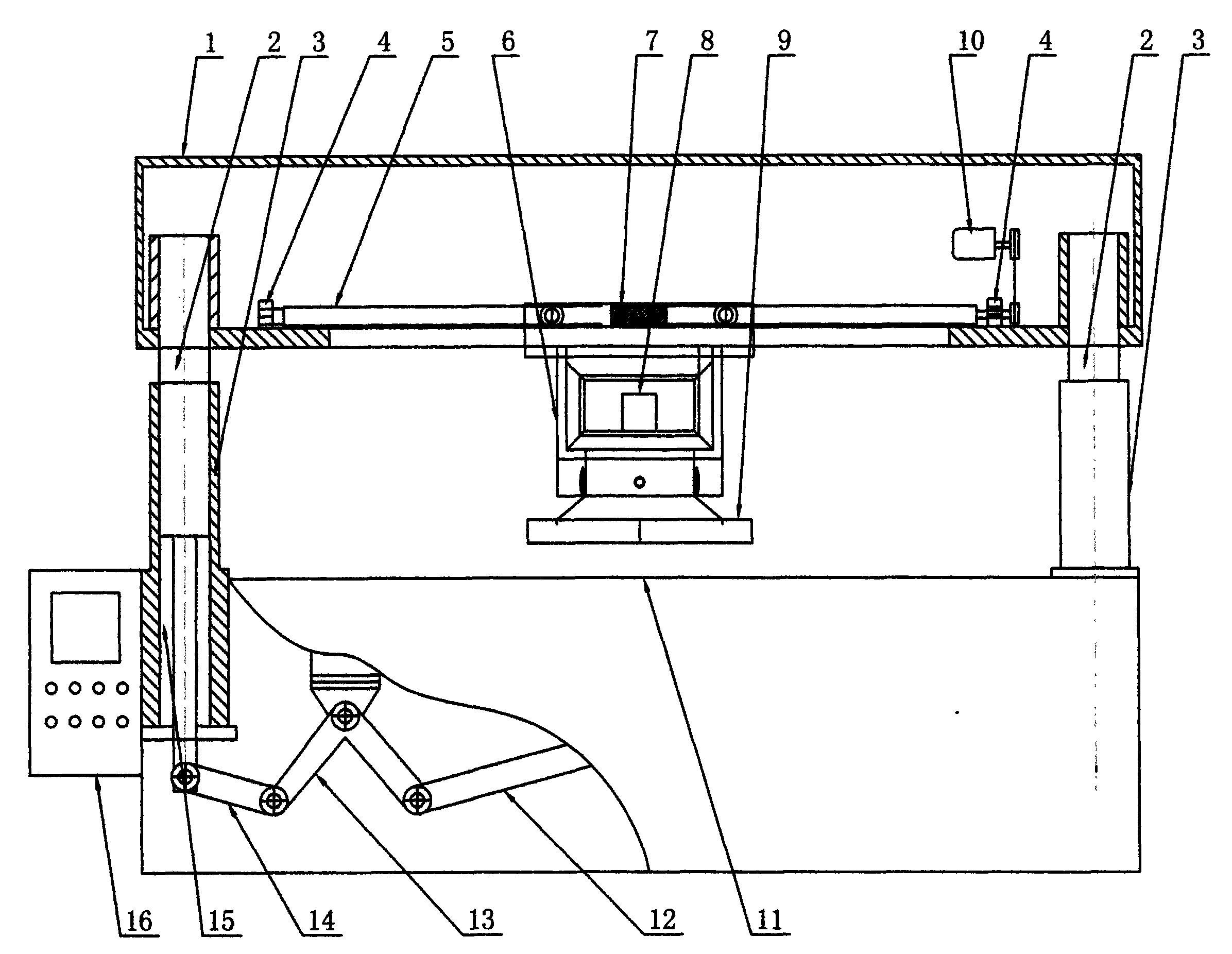

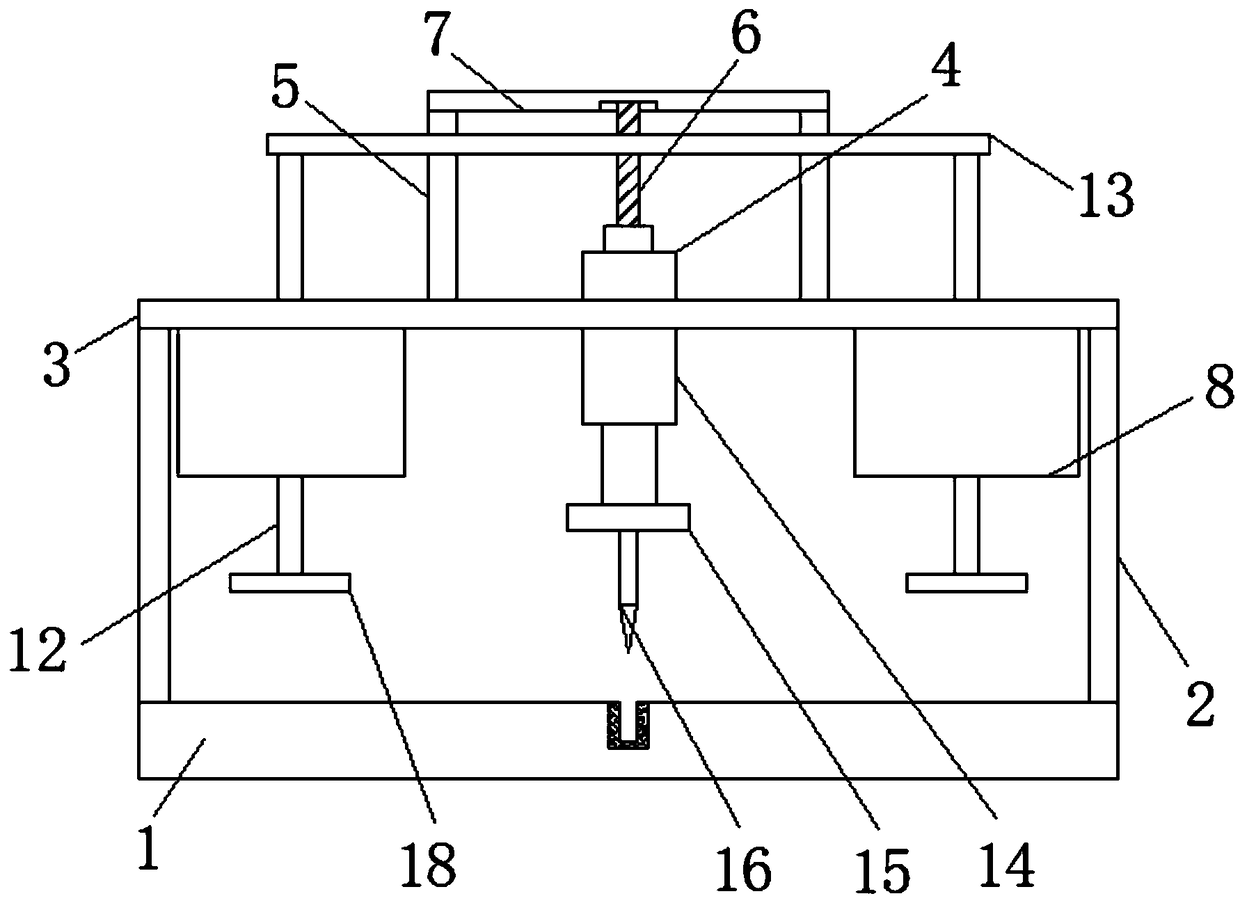

Numerical control cutting machine

InactiveCN101987464ARealize mobile cuttingRealize automatic croppingMetal working apparatusFailure rateNumerical control

The invention discloses a numerical control cutting machine, which comprises an upper workbench, a guide post, a guide sleeve, a screw support, a ball screw, a numerical control moving head, a connecting seat, a step motor, a rotary die holder, a servomotor, a workbench, a balancing connecting rod, a swing plate, a connecting plate, an oil cylinder, and a numerical control box. The computer programming control technology and a human-computer interface are adopted by the machine, a chain wheel on the servomotor drives a chain wheel on the ball screw through a chain, so that the connecting seat on the ball screw drives the numerical control moving head to advance and retreat in the longitudinal direction to realize mobile cutting; the rotary die holder on the numerical control moving head driven by the step motor can rotate 360 DEG; layout and blanking are carried out digitally; and the computer controls a hydraulic system to push the guide post on the oil cylinder to drive a balance mechanism, so that the upper workbench drives the numerical control moving head ascend and descend to realize automatic cutting. The machine has quick response, high precision, stable mechanical properties, low failure rate, high automation degree, and high production efficiency without waste and ungraded product, is convenient and safe to operate, and obviously saves energy.

Owner:陆存林

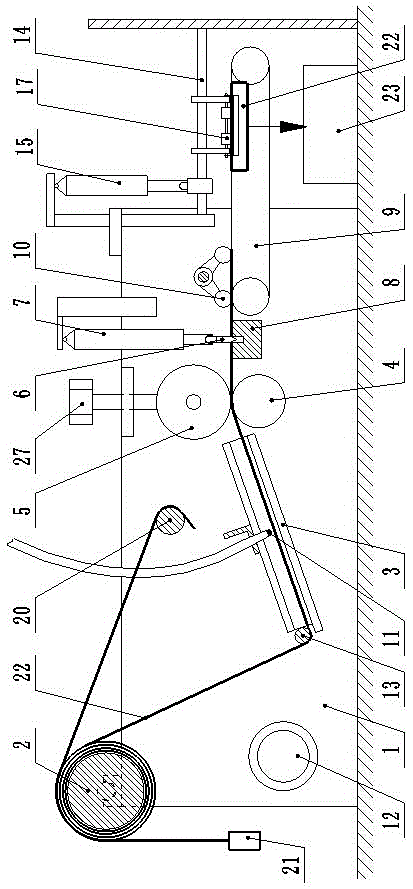

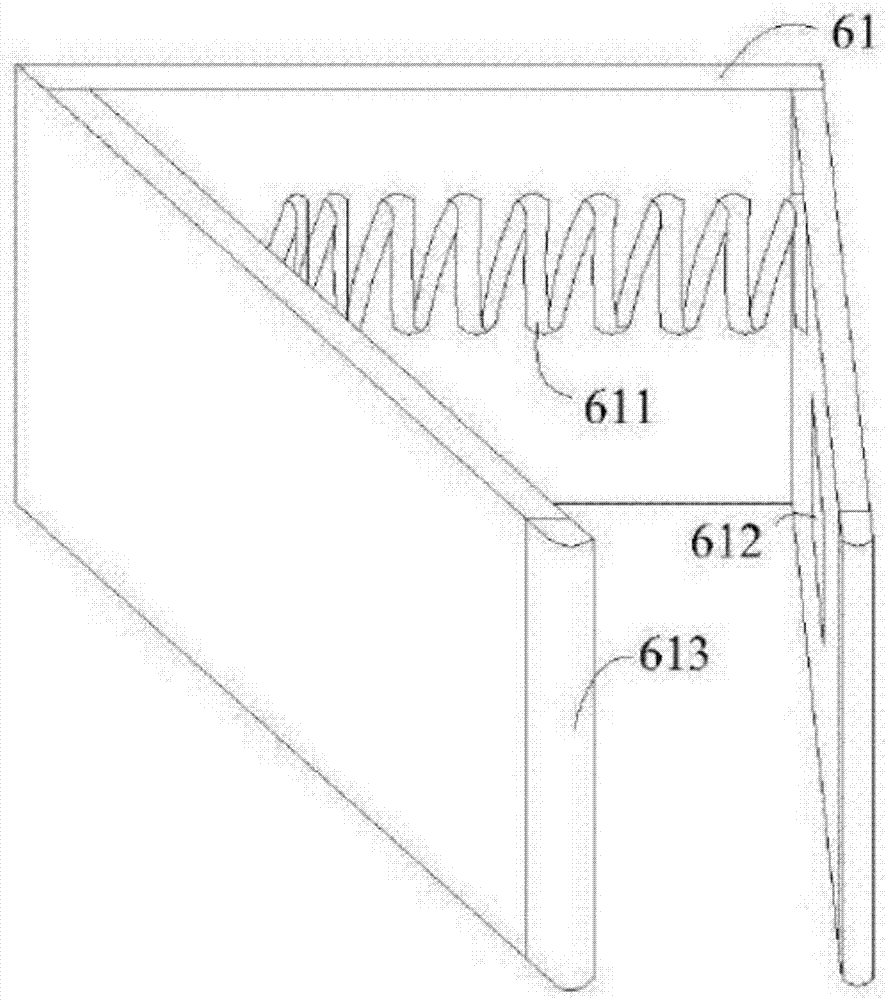

Automatic cutting and conveying device of trademark paper of woven bags or mesh bags

InactiveCN105538380ARealize automatic croppingRealize automatic one-shot moldingSevering textilesMetal working apparatusFixed frameTrademark

The invention discloses an automatic cutting and conveying device of trademark paper of woven bags or mesh bags and belongs to the technical field of automatic manufacture of the woven bags or the mesh bags. The technical problem to be solved is to provide an automatic cutting and conveying device of trademark paper of woven bags or mesh bags, achieve full automation of sewing of the trademark paper and save labor cost and time cost. The technical scheme adopted by the invention is as follows: a paper winding shaft is mounted at one end of a box body; a fixing frame is mounted inside the box body; a circular reversing rod is arranged on one side near the paper winding shaft; a driving conveying wheel, a cutting device, a conveying belt and an unloading device; the unloading device is mounted at the top of an outlet section of the conveying belt; a conveying device of a host for sewing the woven bags or the mesh bags is arranged at the lower part of the outlet section of the conveying belt; a plurality of mark points are uniformly arranged on trademark paper of the paper winding shaft; a trademark paper movable end passes through the fixing frame, the driving conveying wheel and the cutting device and is clamped between a second pressing wheel and the conveying belt; a probe is mounted on the fixing frame and corresponds to a mark point path of the trademark paper.

Owner:XINJIANG TIANLI PLASTIC CHEM CO LTD

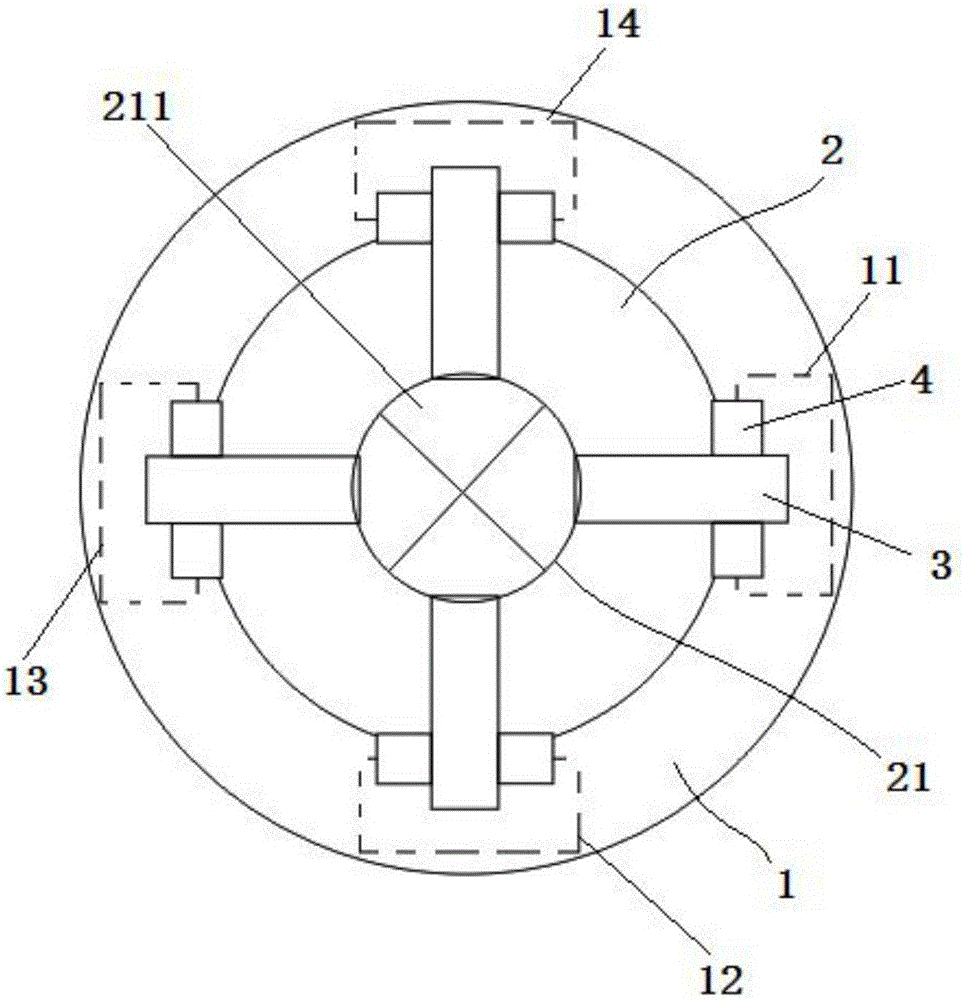

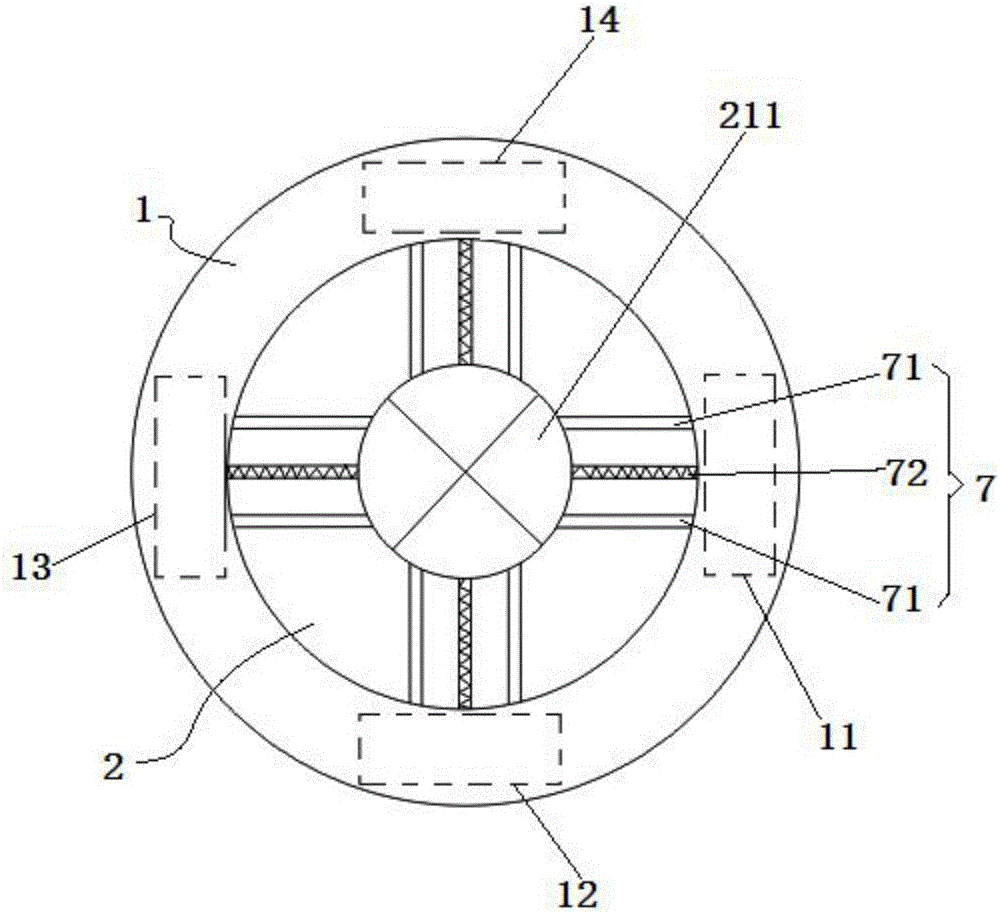

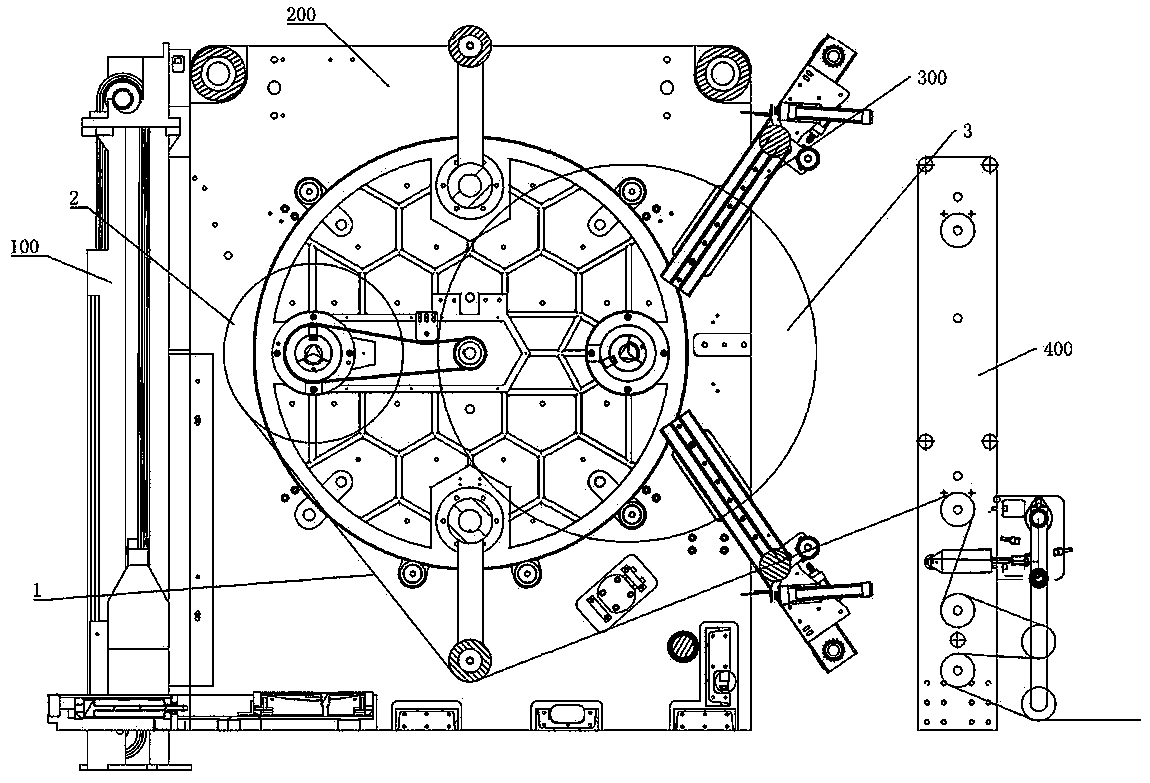

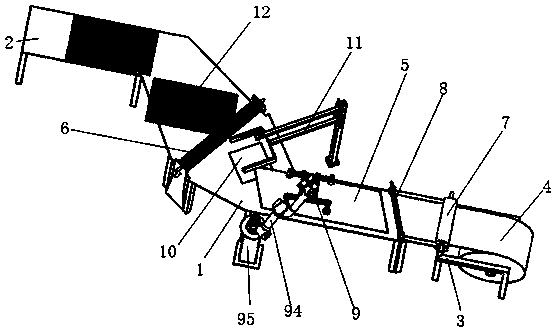

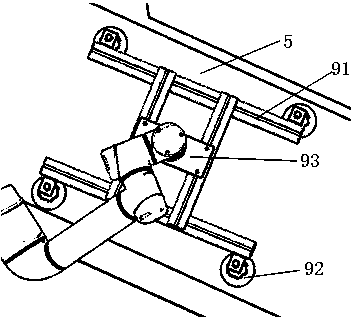

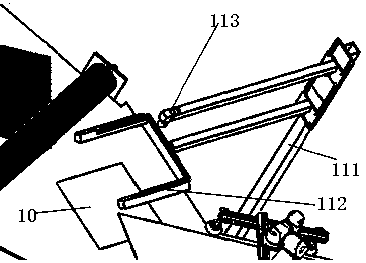

Multifunctional garment sewing machine

ActiveCN105887369AMeet different process requirementsImprove efficiencyWorkpiece carriersWork-feeding meansControl systemEngineering

The invention discloses a multifunctional garment sewing machine which comprises a rack and a control system, wherein a worktable and a rotating mechanism are arranged on the rack; a plurality of working areas are formed in the worktable; the rotating mechanism comprises a rotating disc; the rotating disc is arranged in the middle of the worktable; a first rotating shaft which rotates along the rotating disc is longitudinally arranged on the rotating disc; the first rotating shaft is composed of a plurality of equally divided intervals; the number of the intervals is equal to that of the working areas; the bottom of each interval is connected with the rotating disc by virtue of a Y-axis transmission mechanism so as to realize Y-direction movement of the intervals on the rotating disc; a second rotating shaft is transversely arranged on each interval; a plurality of working groups with different using functions are arranged on the second rotating shaft; the plurality of working groups are respectively uniformly and fixedly distributed on the second rotating shaft by taking the second rotating shaft as an axis and are positioned just above the worktable; and function switching of the working groups is realized by virtue of rotation of the second rotating shaft. According to the invention, the rotating mechanism is combined with the plurality of working groups, so that function selection diversity and automatic operation are realized.

Owner:南京润泽华针纺织科技发展有限公司

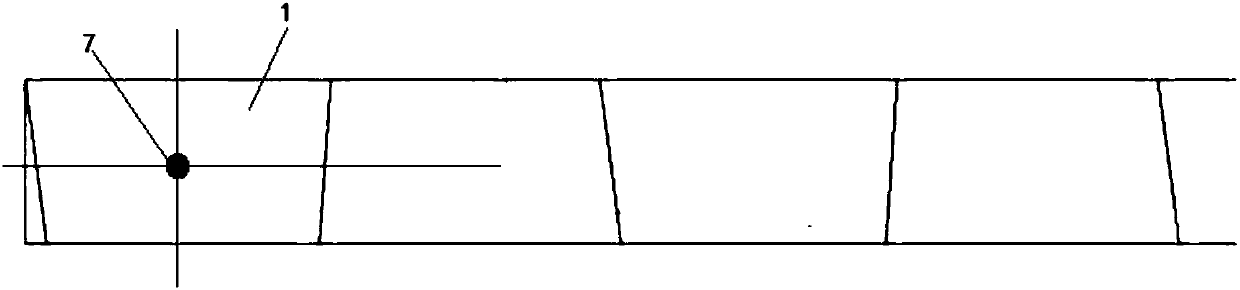

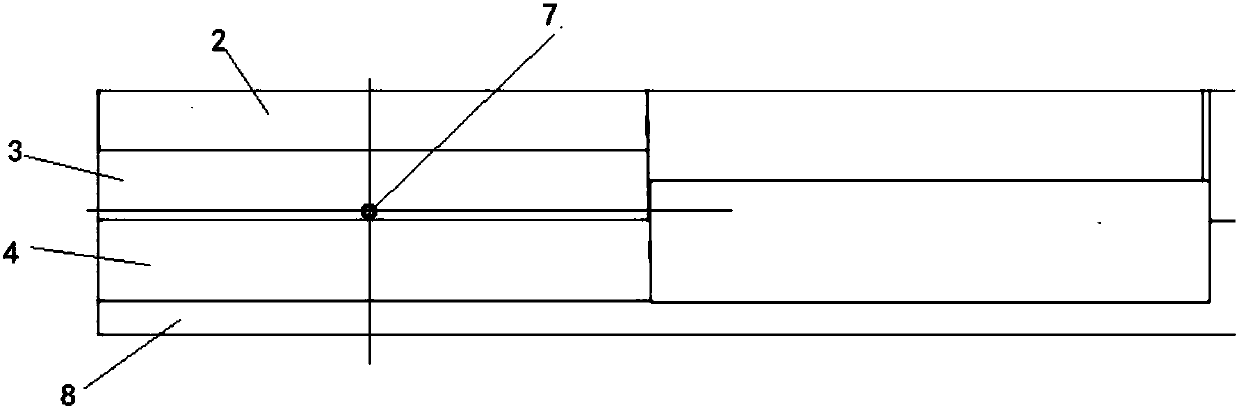

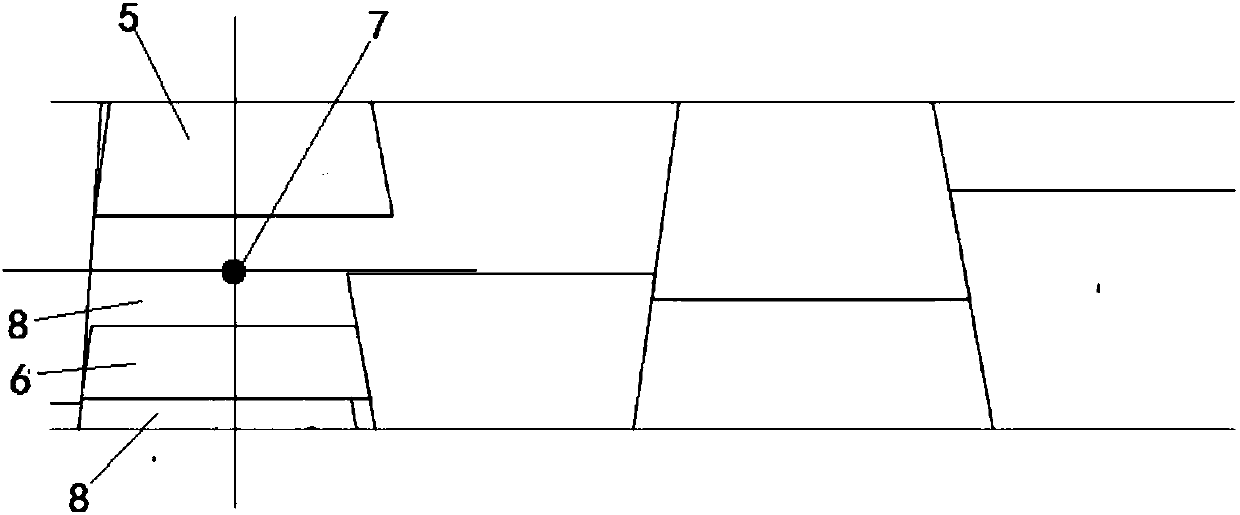

Fabric cutting and fetching method

ActiveCN107724052ARealize automatic croppingRealize automatic pickingSevering textilesMetal working apparatusFiberControl system

The invention belongs to the field of complex fiber fabric processing and particularly relates to a cloth cutting method for complex fiber fabrics. The method specifically comprises the steps that distribution design is conducted on multiple shapes of pieces to be cut in a complementary way, distribution design results are imported into a cutting machine control system; the control system segmentsthe distribution design, wherein each segment can be completely covered by the cutting range of a cutting machine in the cutting process, and it is ensured that only one row of pieces exists in eachsegment in the fabric conveying direction; positioning points of the segments are determined and need to coincide with the central line of the cutting range of the cutting machine; the control systemcontrols a device to operate and achieves fabric positioning in the conveying process in the mode that the positioning points coincide with the central line, and cutting is performed by using the distribution design of each segment as a motion trail after positioning is completed. By adopting the fabric cutting and fetching method, automatic fabric cutting and taking can be achieved, the working efficiency is effectively improved, and the labor cost is reduced.

Owner:NEWTRY COMPOSITE

Cable cutting system

ActiveCN109351889AImprove cutting efficiencyReduce labor costsWorkloadElectrical and Electronics engineering

The invention discloses a cable cutting system. The system comprises a traction mechanism, a shearing mechanism, a length measuring mechanism and a processor, wherein the traction mechanism is used for driving a cable to move, the shearing mechanism and the length measuring mechanism are sequentially arranged along the moving direction of the cable, the length measuring mechanism and the shearingmechanism are both electrically connected with the processor, the length measuring mechanism is used for measuring moving distance of the cable, and when the moving distance of the cable reaches a preset value, the processor is used for controlling the shearing mechanism to cut off the cable. According to the cable cutting system, the cable is driven to move through the traction mechanism, meanwhile, the length measuring mechanism can measure the moving distance of the cable, when the moving distance of the cable reaches the preset value, the length measuring mechanism outputs a signal to theprocessor, the processor controls the shearing mechanism to cut off the cable, so that automatic cutting of the cable with specific length can be achieved, the cutting efficiency is high, the labor workload can be reduced, the labor cost can be reduced, and errors caused by manual measurement of the length of the cable can be reduced.

Owner:GUANGZHOU POWER SUPPLY CO LTD +1

Film cutting device

ActiveCN109514624ARealize automatic deliveryRealize automatic croppingMetal working apparatusReciprocating motionSheet film

The invention provides a film cutting device, and belongs to the technical field of rubber plug production equipment. The film cutting device comprises a frame, a conveying mechanism, a first die mechanism, a second die mechanism, a first cutting mechanism and a second cutting mechanism; the conveying mechanism is used for conveying films from the feeding position to the target position, the firstdie mechanism and the second die mechanism are driven synchronously, and the first cutting mechanism and the second cutting mechanism are both used for cutting the films into the target size; and thefirst die mechanism and the second die mechanism are both used for moving in a reciprocating mode under driving of the conveying mechanism, and the first die mechanism and the second die mechanism are opposite in moving direction. According to the film cutting device provided by the invention, the films are automatically cut, through arrangement of the first die mechanism and the second die mechanism which are driven synchronously and are opposite in moving direction, the films are conveyed and cut continuously, and thus the production efficiency of the films is improved greatly.

Owner:青岛时间河智能科技有限公司

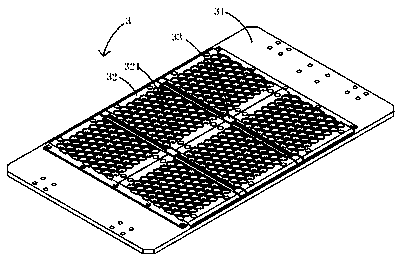

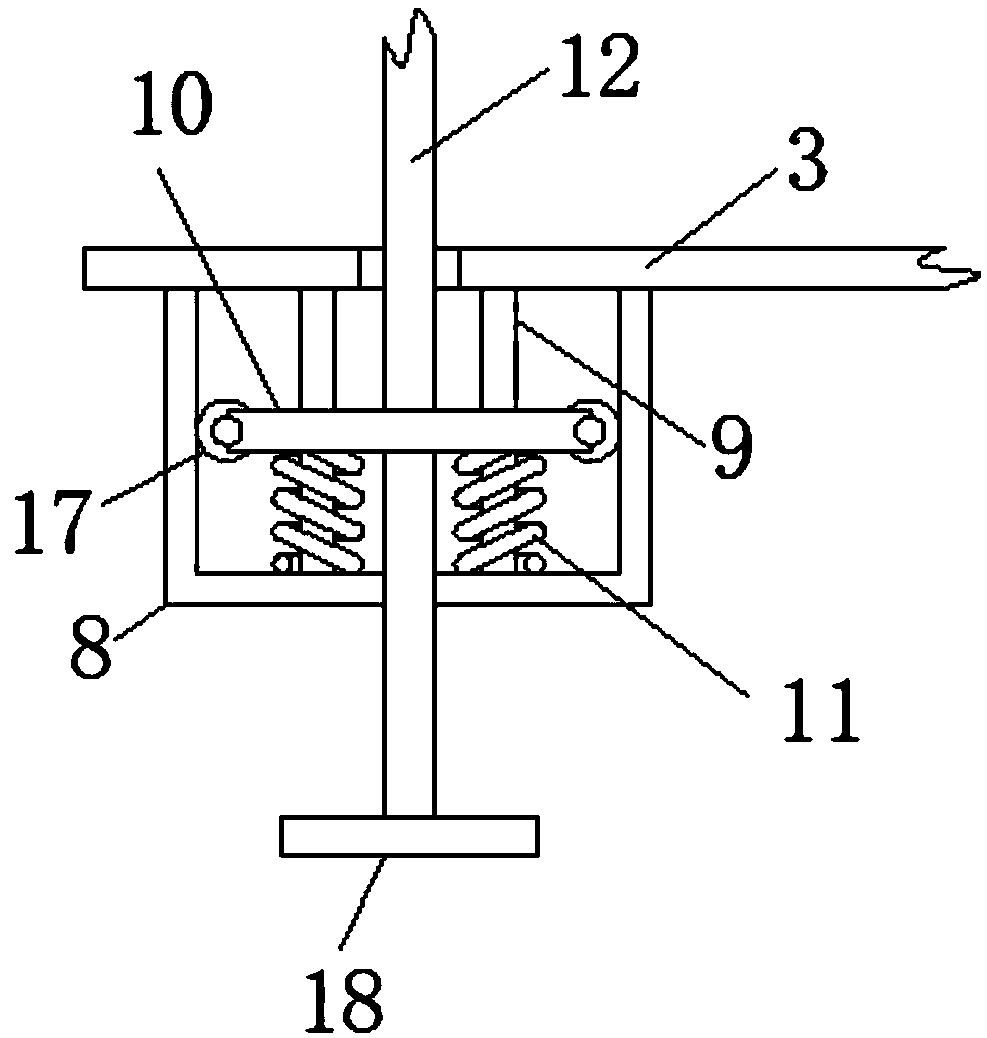

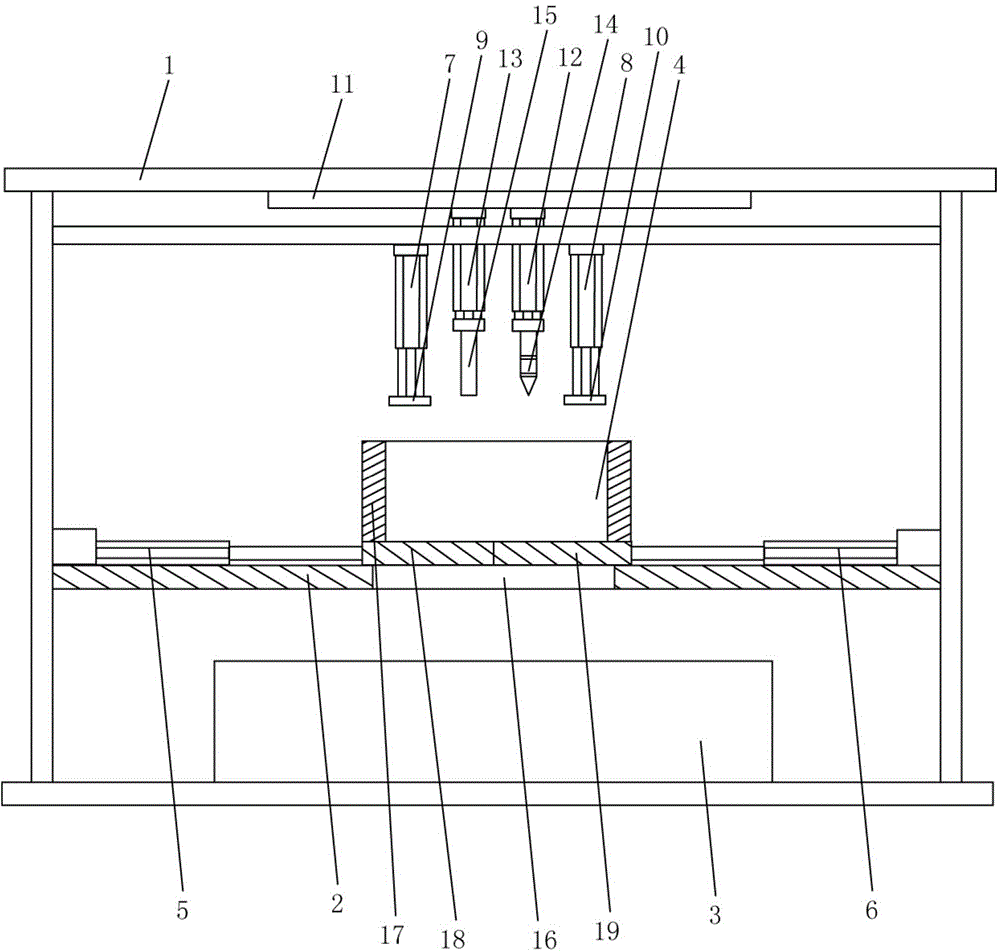

Small-sized garment accessory pressing and cutting device

PendingCN108842423ARealize automatic croppingImprove work efficiencySevering textilesEngineeringMechanical engineering

The invention discloses a small-sized garment accessory pressing and cutting device, and relates to the technical field of garment accessory pressing and cutting devices. The device comprises a workbench, support pillars are arranged at both sides of the upper surface of the workbench, a support top plate is arranged at the tops of the support pillars, a forward and reverse motor is arranged in the middle of the upper surface of the support top plate, and fixed rods are arranged at both sides of the forward and reverse motor; a first fixed plate is arranged at the tops of the fixed rods, the middle of the lower surface of the support top plate is fixedly connected with one end of an air cylinder, the other end of the air cylinder is provided with a second connecting plate, and a cutter isarranged on the lower surface of the connecting plate. According to the small-sized garment accessory pressing and cutting device, the second connecting plate can be driven by the air cylinder to moveup and down, and the cutter can be driven to move up and down through the up-and-down movement of the second connecting plate; through the up-and-down movement of the cutter, cloth can be automatically cut, the time and labor are saved, and the working efficiency of cutting the cloth is improved.

Owner:湖州韩源进出口有限公司

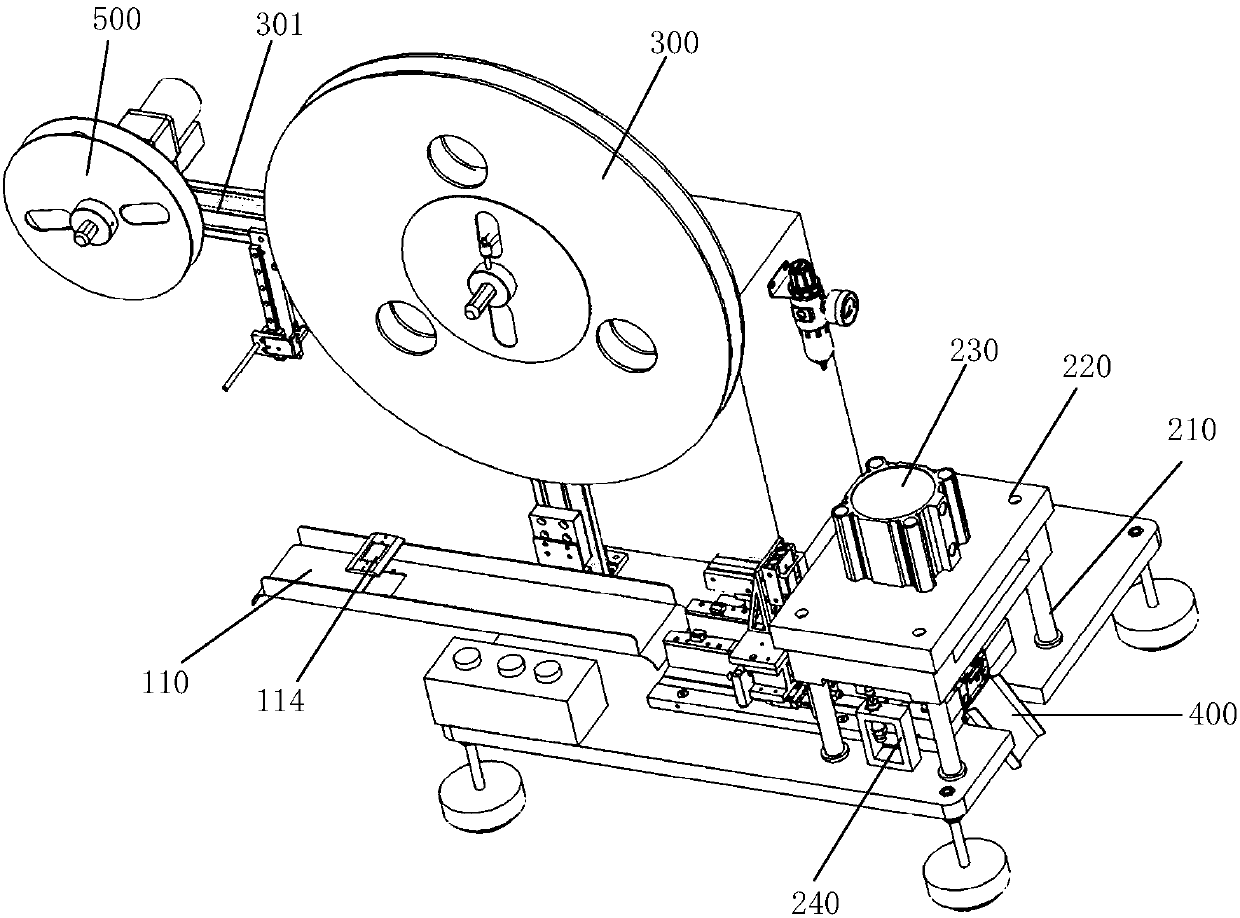

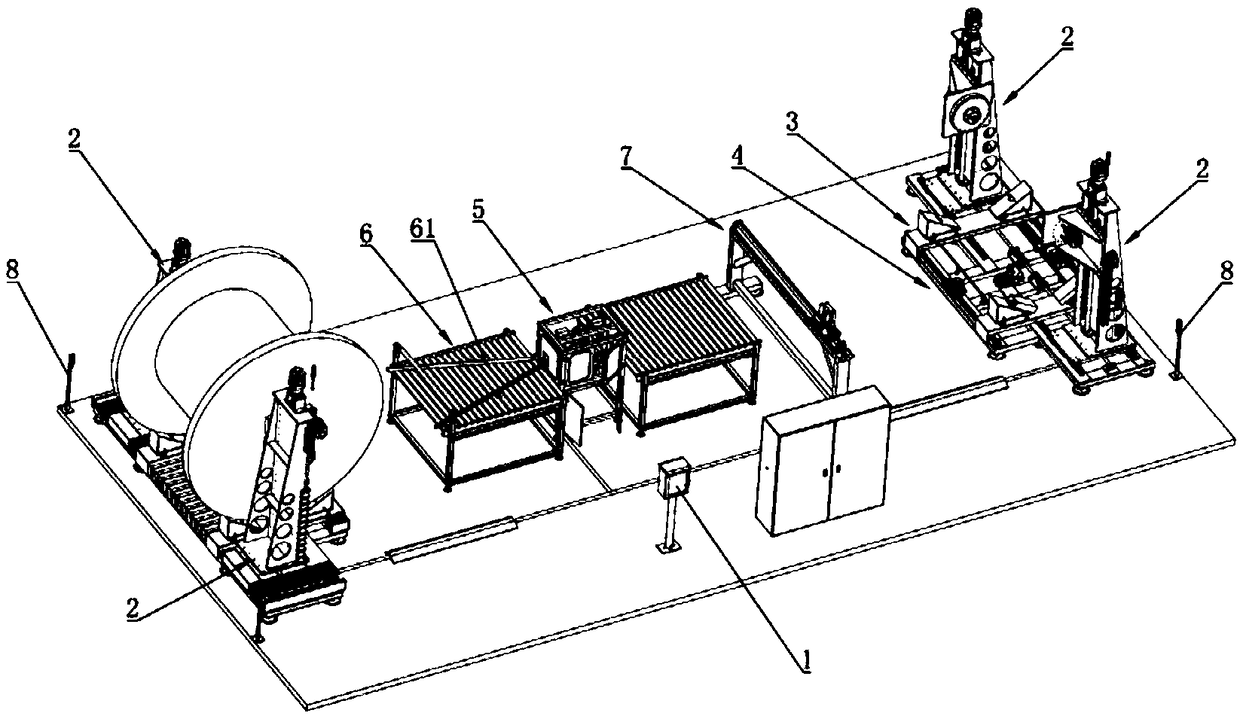

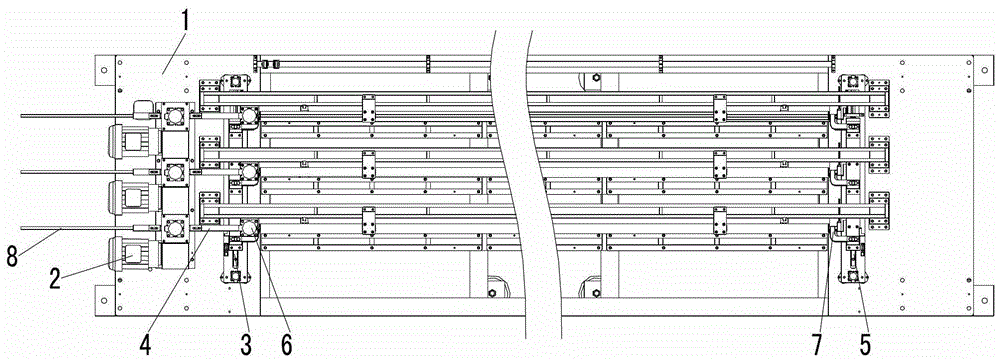

Rotary tower type non-stop unwinding equipment

ActiveCN111532846AImprove efficiencyEasy to put in and take outWebs handlingWall plateIndustrial engineering

The invention provides rotary tower type non-stop unwinding equipment. The rotary tower type non-stop unwinding equipment comprises a scroll lifting part, a scroll rotating part, a cutting part and apaper path buffer part, wherein the scroll lifting part comprises a supporting frame and a tray frame; a V-shaped disc driven by a regulating mechanism is arranged on the tray frame; one end of the tray frame is provided with a protective mechanism; the scroll rotating part comprises two unwinding wall boards and a rotary disc; a supporting positioning mechanism is arranged between each rotary disc and each unwinding wall board; two scroll clamping mechanisms are arranged on the two rotary discs; a transmission mechanism is arranged between each unwinding wall board and each scroll clamping mechanism; the cutting part comprises two groups of cutting devices; and ach cutting device comprises a pressing mechanism and a cutter. A non-shaft type two-side synchronous drive way is adopted, so that the problems such as poor unwinding stability and poor accuracy are solved; and moreover, the rotary tower type non-stop unwinding equipment is stable for positive and negative unwinding ways, andhas characteristics of transmission stability, high safety and applicability to smaller-roll-diameter scroll cutting.

Owner:青州蒙特机械有限公司

Trimming device for terminals

PendingCN109514796AGuaranteed to work properlyRealize automatic croppingCoatingsMechanical engineeringMultiple Models

The invention relates to the technical field of terminal trimming and discloses a trimming device for terminals. The trimming device for the terminals comprises a feeding mechanism, a trimming mechanism and a terminal feeding disk. The feeding mechanism comprises a feeding groove with width adjustable and a locating assembly matched with the width of the feeding groove. The feeding groove and thelocating assembly are used for limiting movement locus of a terminal material belt. According to the trimming device for the terminals, automatic and continuous trimming can be conducted on the terminal material belt, and in addition, the trimming device for the terminals is applicable to terminal products of multiple models.

Owner:上海天檀电子科技有限公司

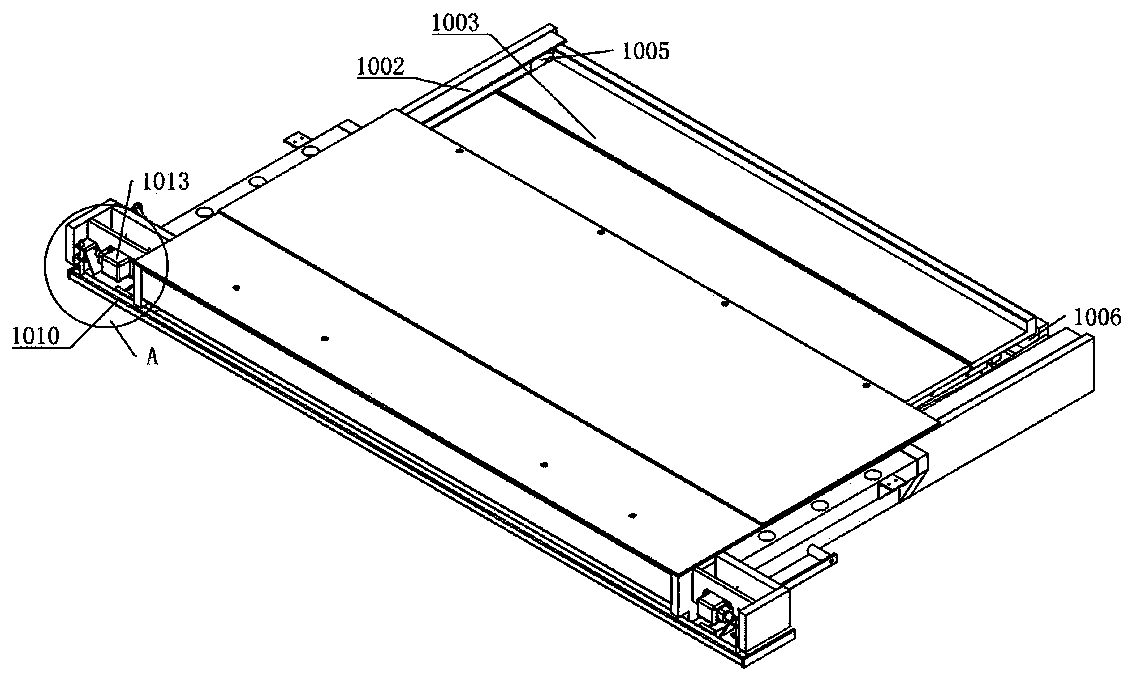

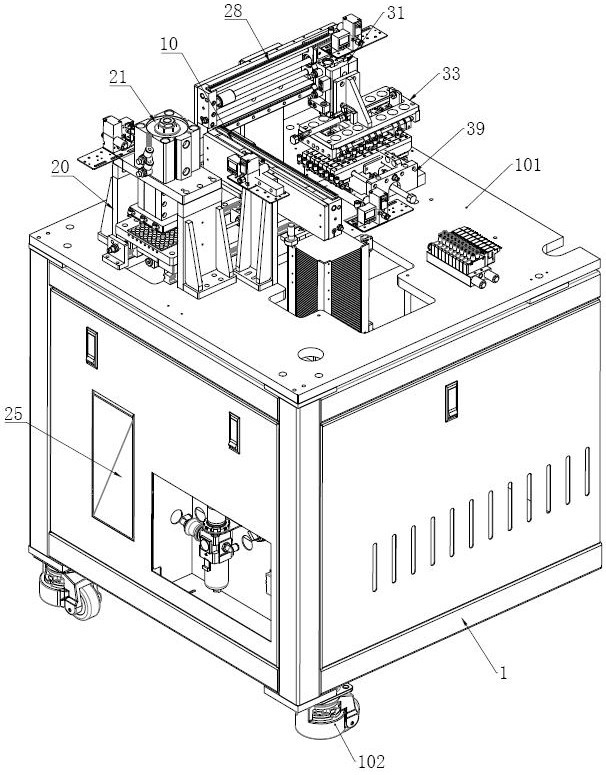

Noninvasive soluble microneedle patch feeding device

ActiveCN112623810APrecise feedingTimely dischargeMetal working apparatusArticle feedersBiotechnologyMicro nano

The invention belongs to the technical field of micro-nano patches, and provides a noninvasive soluble microneedle patch feeding device. The noninvasive soluble microneedle patch feeding device comprises a rack, wherein a workbench of the rack is provided with an original sheet feeding mechanism, an original sheet taking mechanism, an original sheet cutting mechanism, a material sheet taking and torque changing mechanism and a material sheet torque changing containing table; the original sheet taking mechanism is located between the original sheet feeding mechanism and the original sheet cutting mechanism; the two ends of the original sheet taking mechanism correspond to the original sheet feeding mechanism and the original sheet cutting mechanism respectively; the material sheet taking and torque changing mechanism is located between the original sheet cutting mechanism and the material sheet torque changing containing table; and the two ends of the material sheet taking and torque changing mechanism correspond to the original sheet cutting mechanism and the material sheet torque changing containing table respectively. By means of the noninvasive soluble microneedle patch feeding device, automatic feeding, transferring and cutting of soluble microneedle original sheets and automatic torque changing between the cut material sheets can be achieved, the sanitation of the material sheets cannot be influenced in the machining process, the cutting efficiency and the cutting quality are greatly improved, and the rear material sheets can be more efficiently and accurately attached to hydrogel slide glass.

Owner:SHANDONG NOVOSHINE OPTOELECTRONICS CO LTD

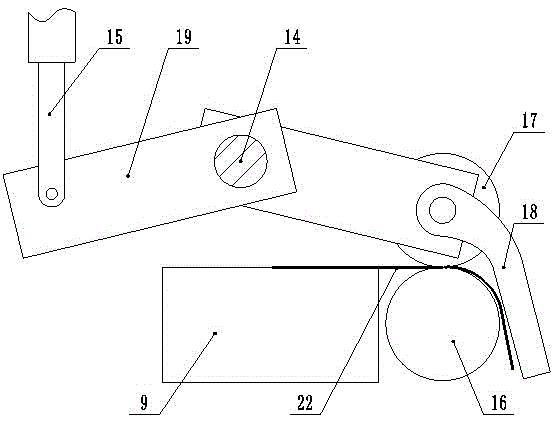

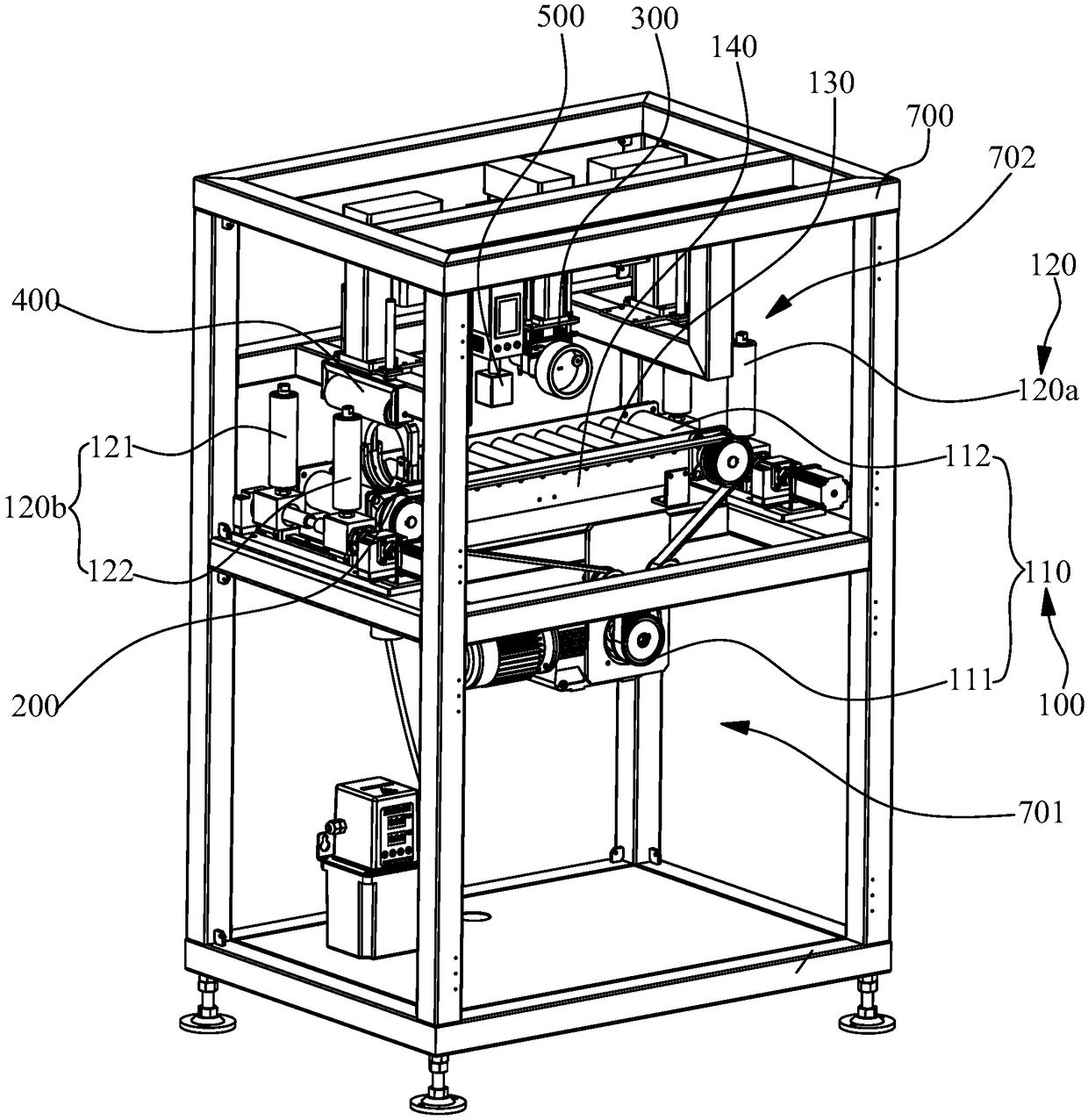

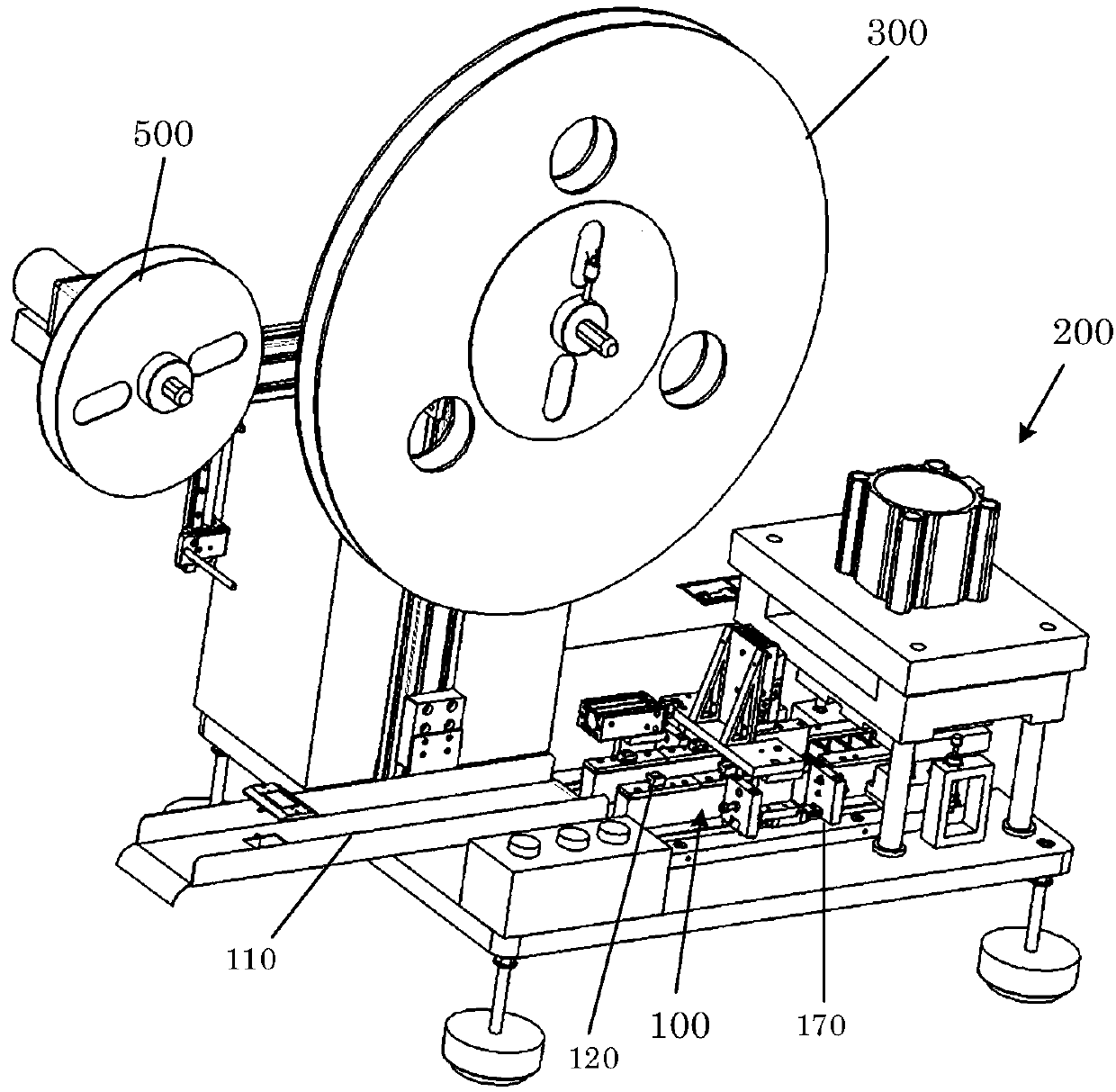

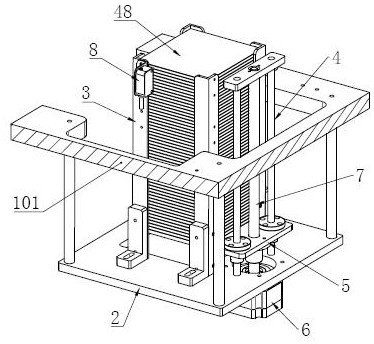

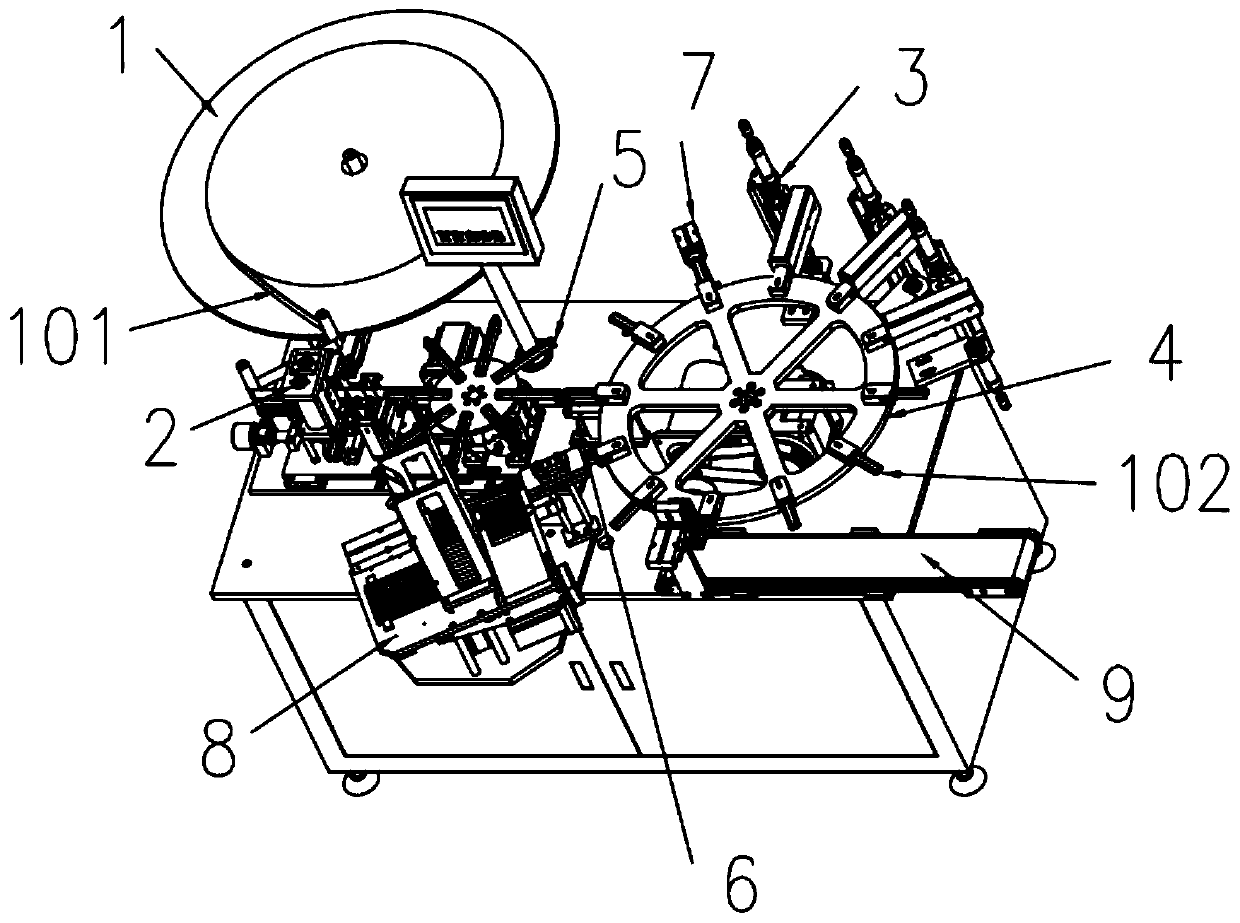

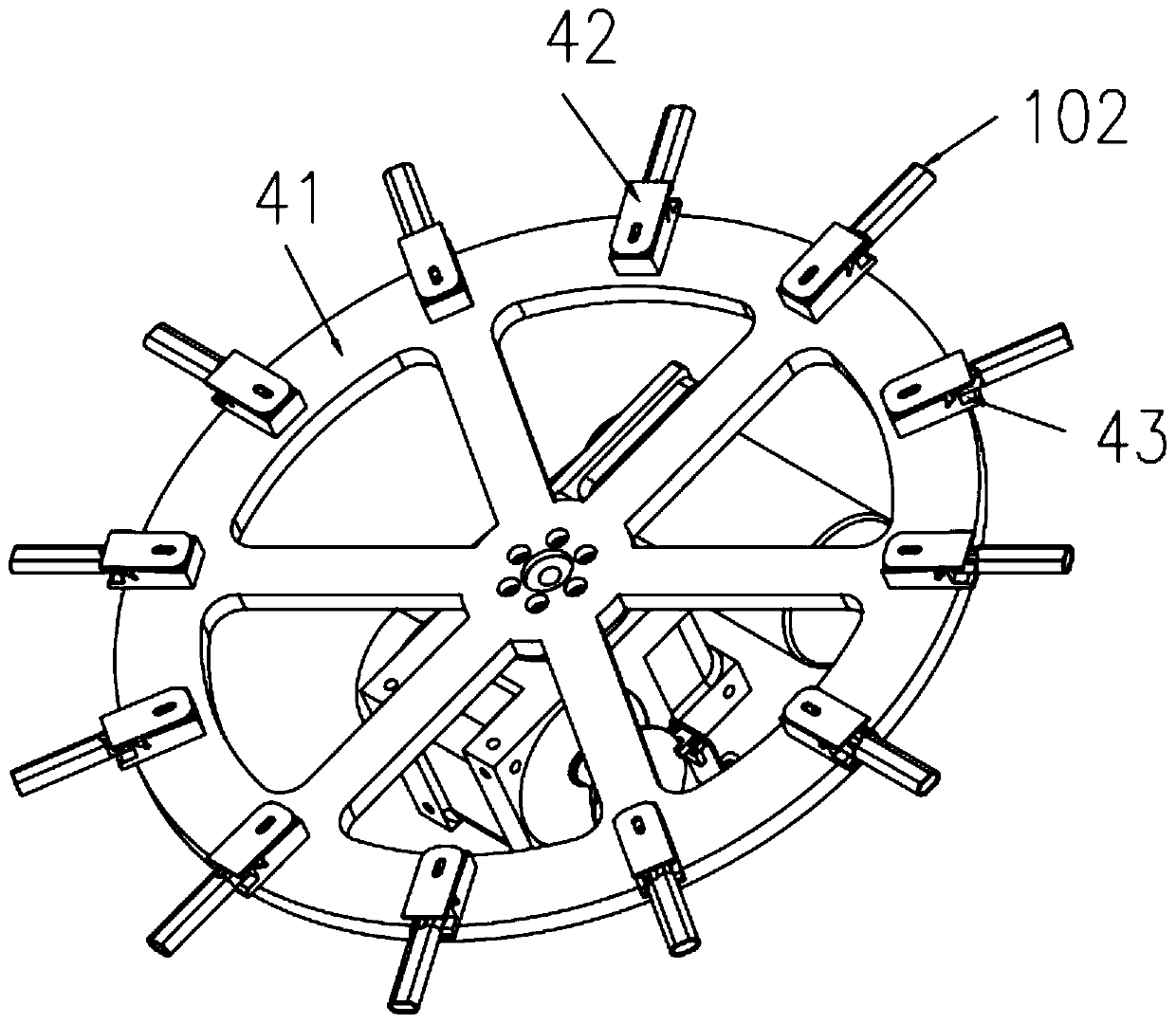

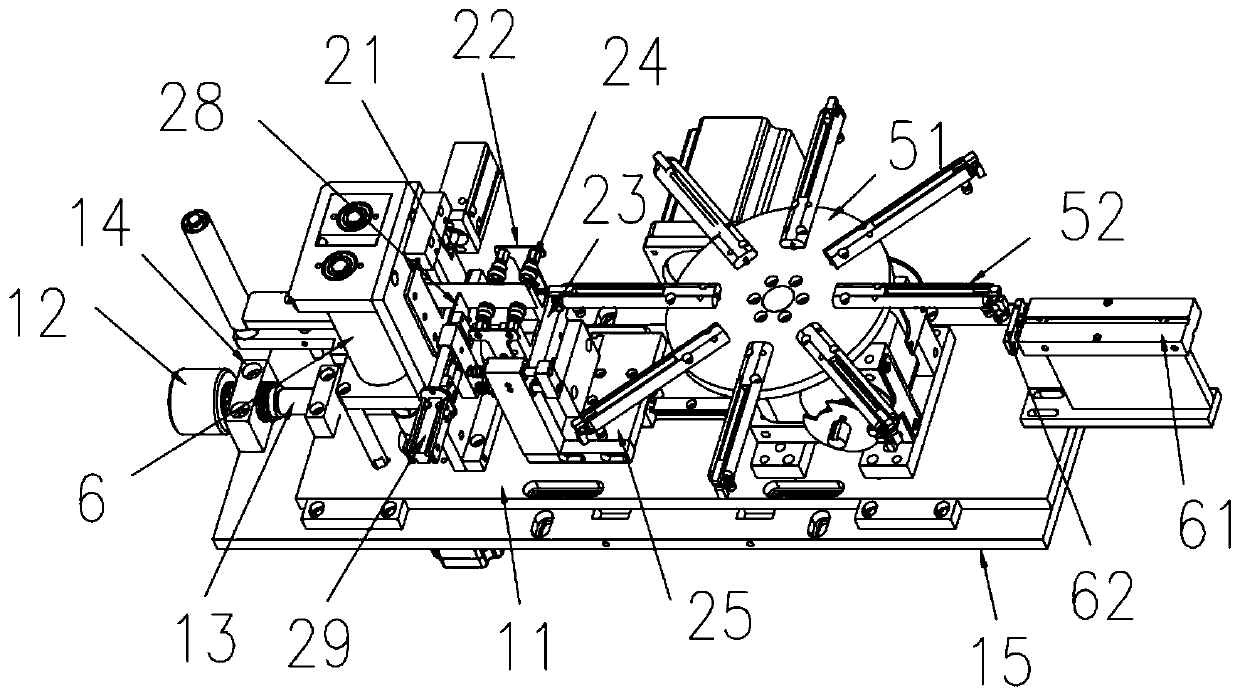

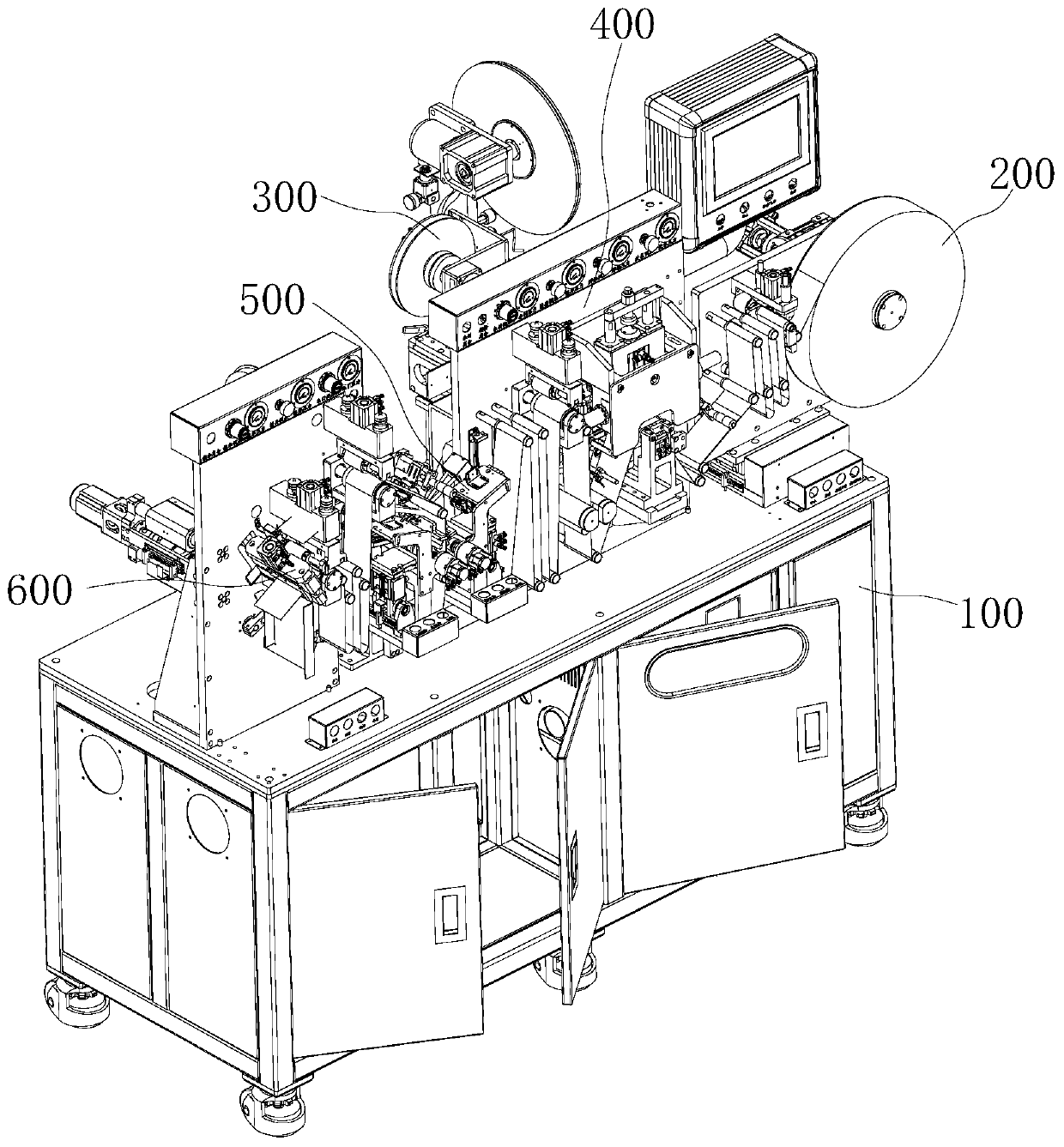

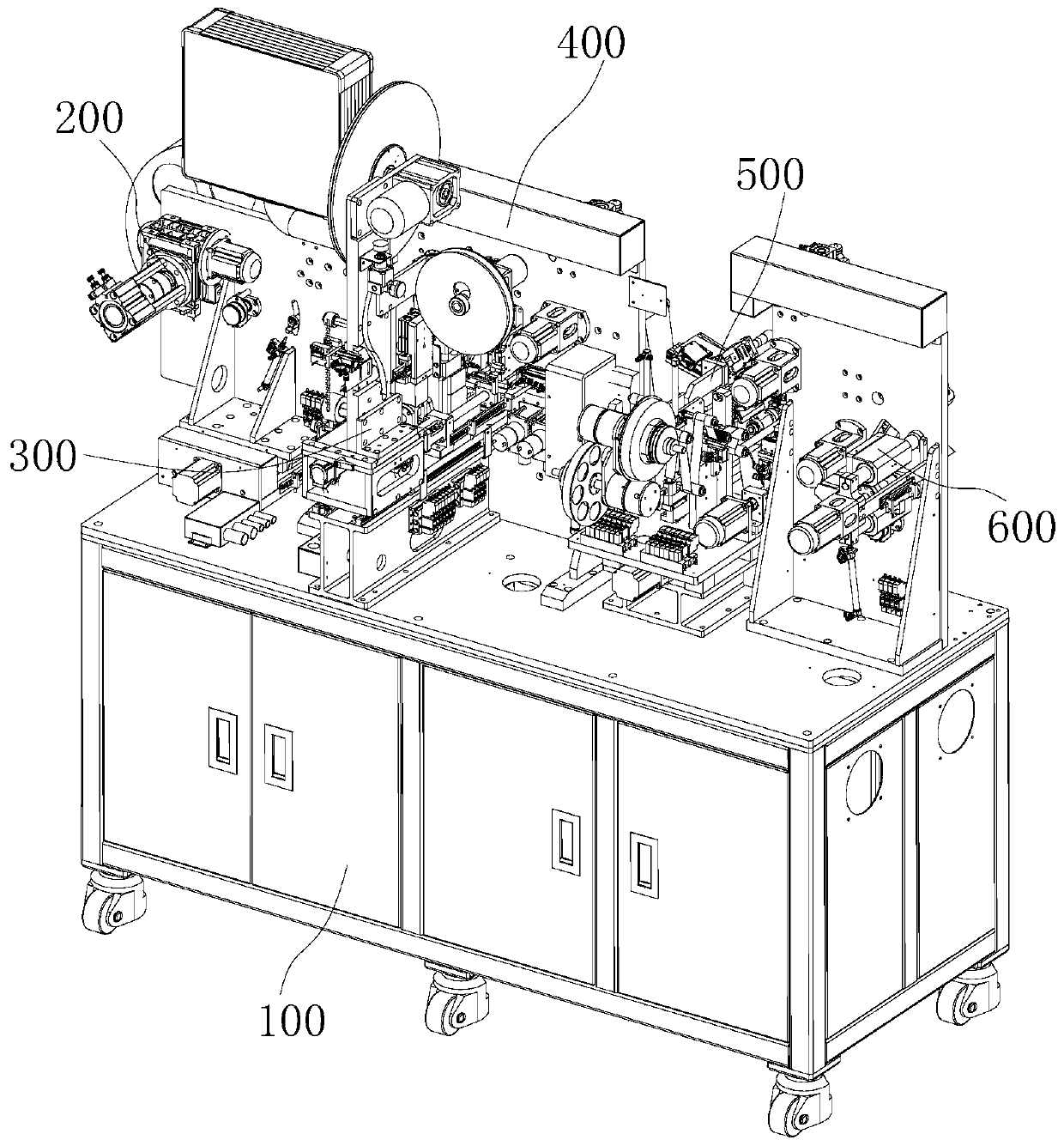

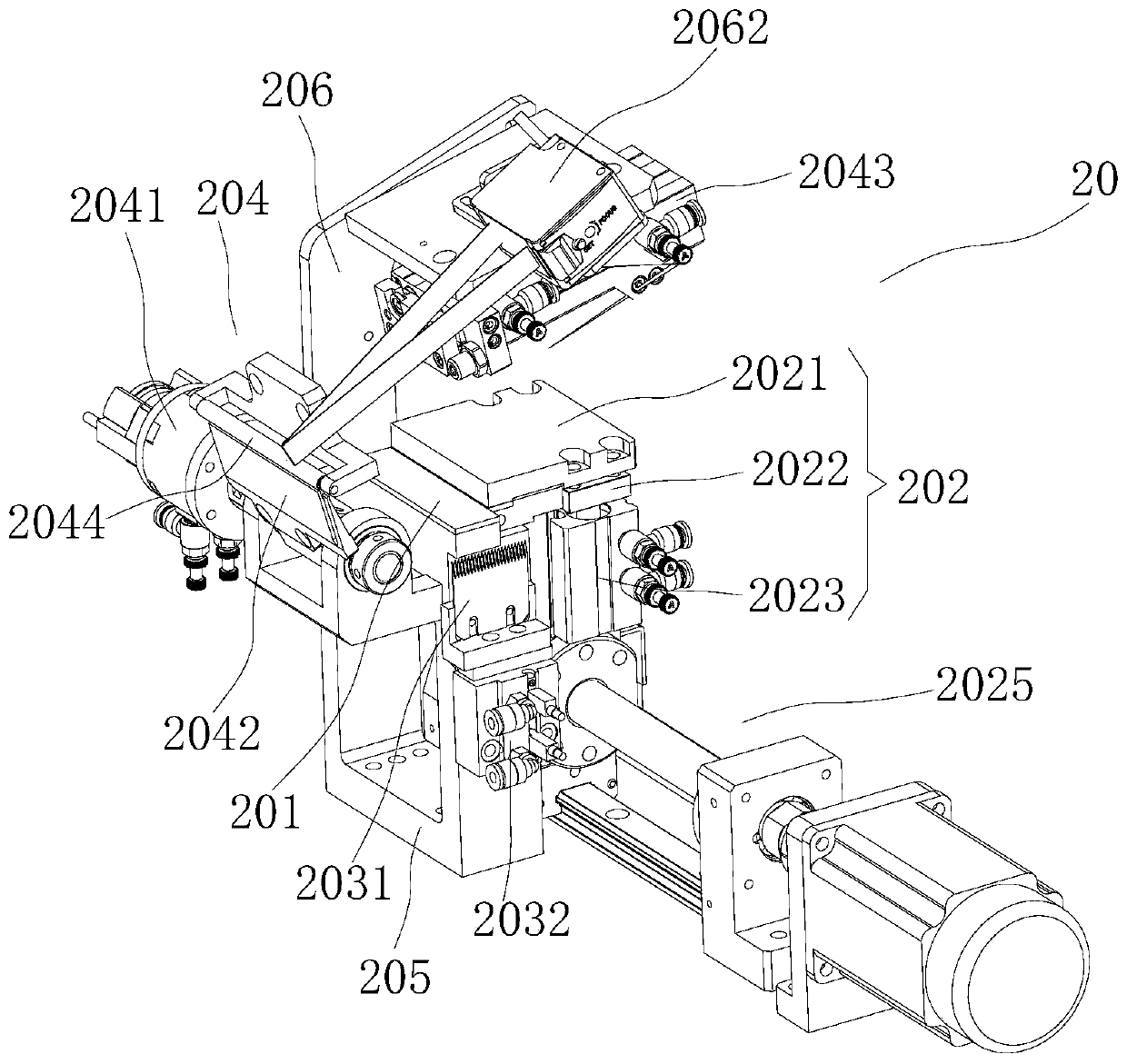

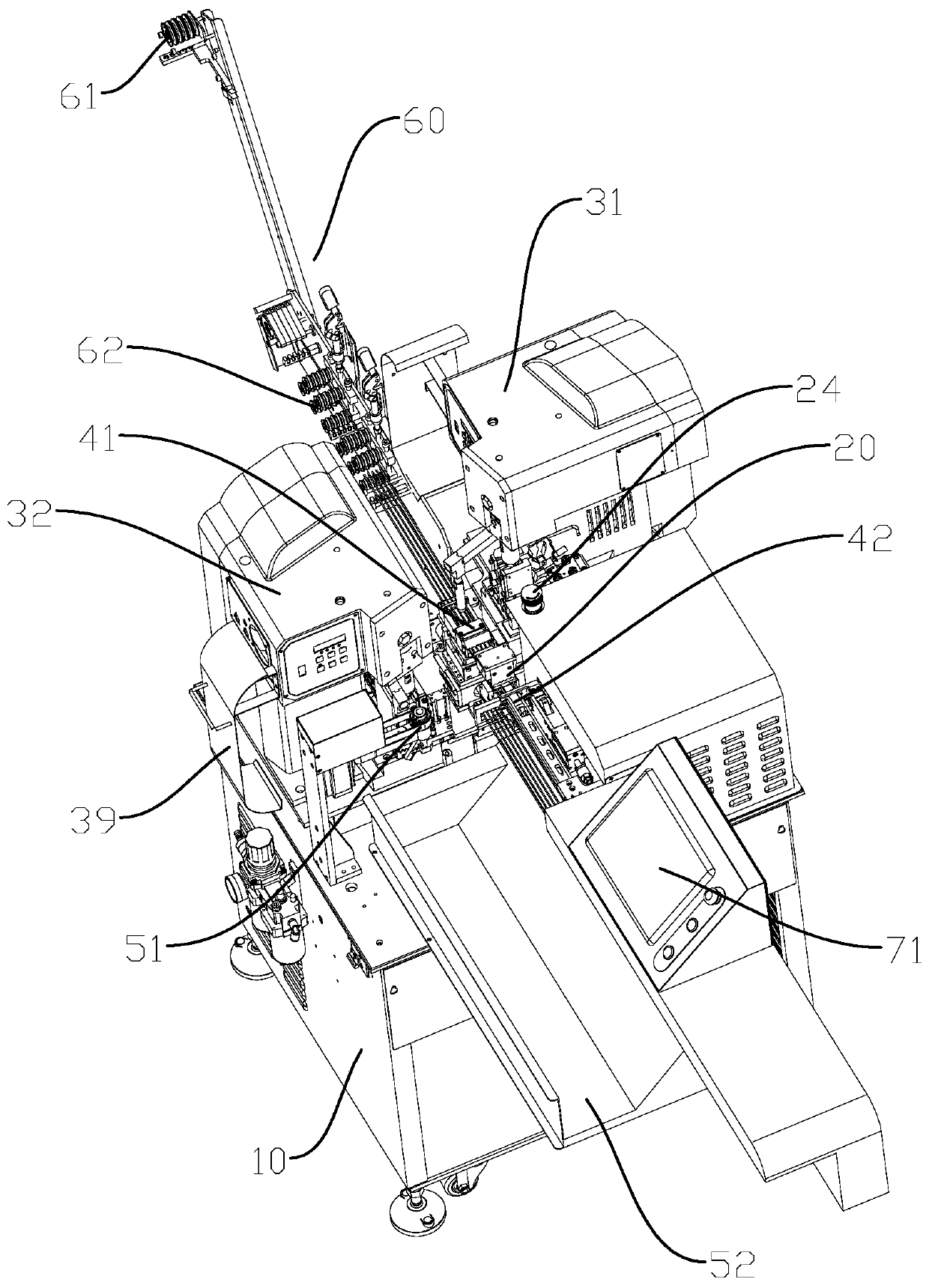

Fully-automatic assembling machine of lighter heat shrinking tube sleeve

ActiveCN109986346ARealize automatic croppingImplement automatic assemblyMetal working apparatusEngineeringFully automatic

The invention discloses a fully-automatic assembling machine of a lighter heat shrinking tube sleeve. The fully-automatic assembling machine of the lighter heat shrinking tube sleeve includes a feeding tray mechanism, a material belt automatic feeding mechanism, a steam baking mechanism, a lighter feeding rotating tray mechanism, a tube sleeve feeding rotating tray mechanism, a material sleeving assembly, a lighter fully-automatic distributing mechanism, a finished product discharging mechanism, so that fully-automatic assembling of the lighter heat shrinking tube sleeve is realized, the workefficiency and quality are improved, and the manual cost is also lowered.

Owner:龚培生

Cable cutting equipment

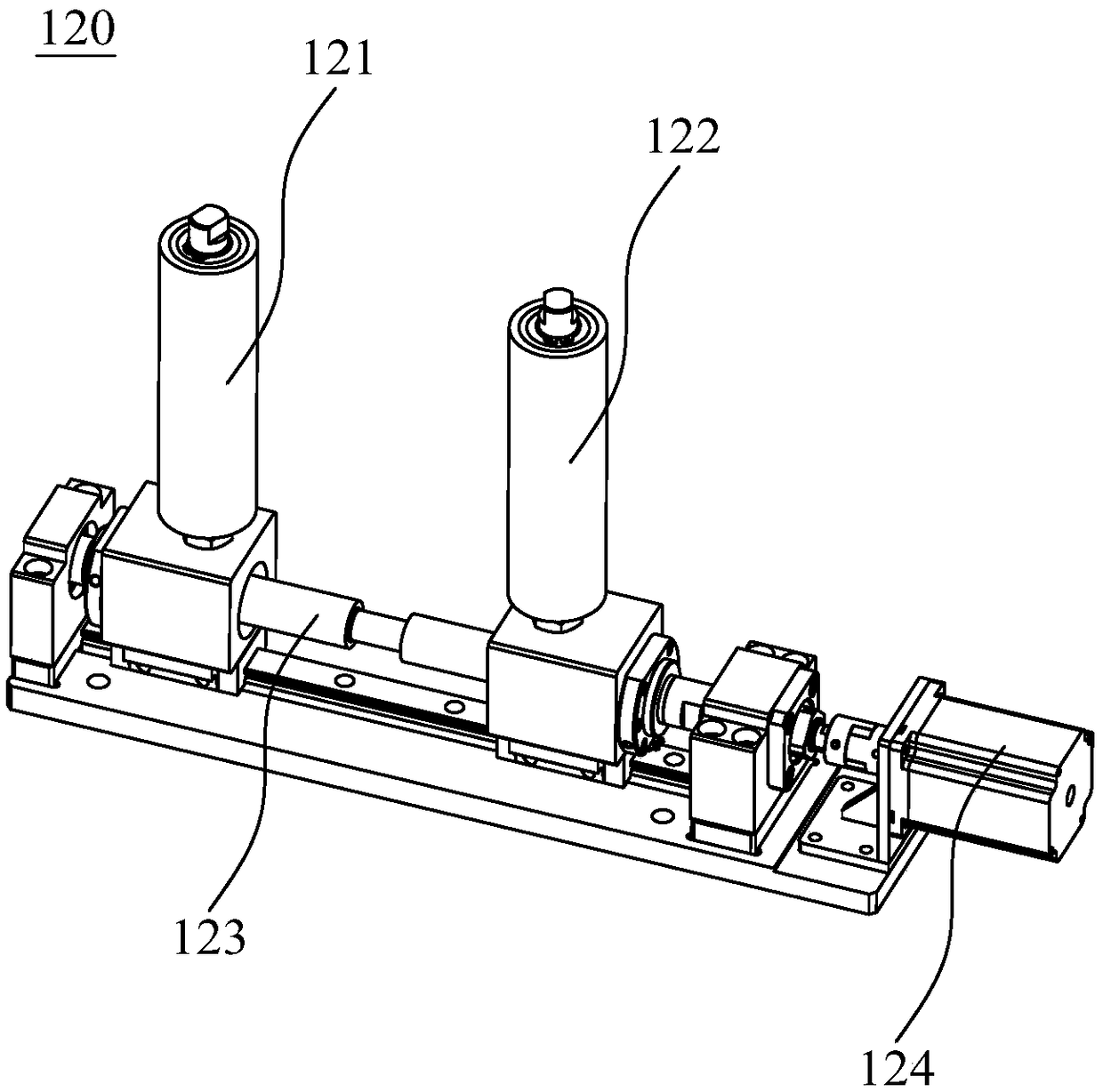

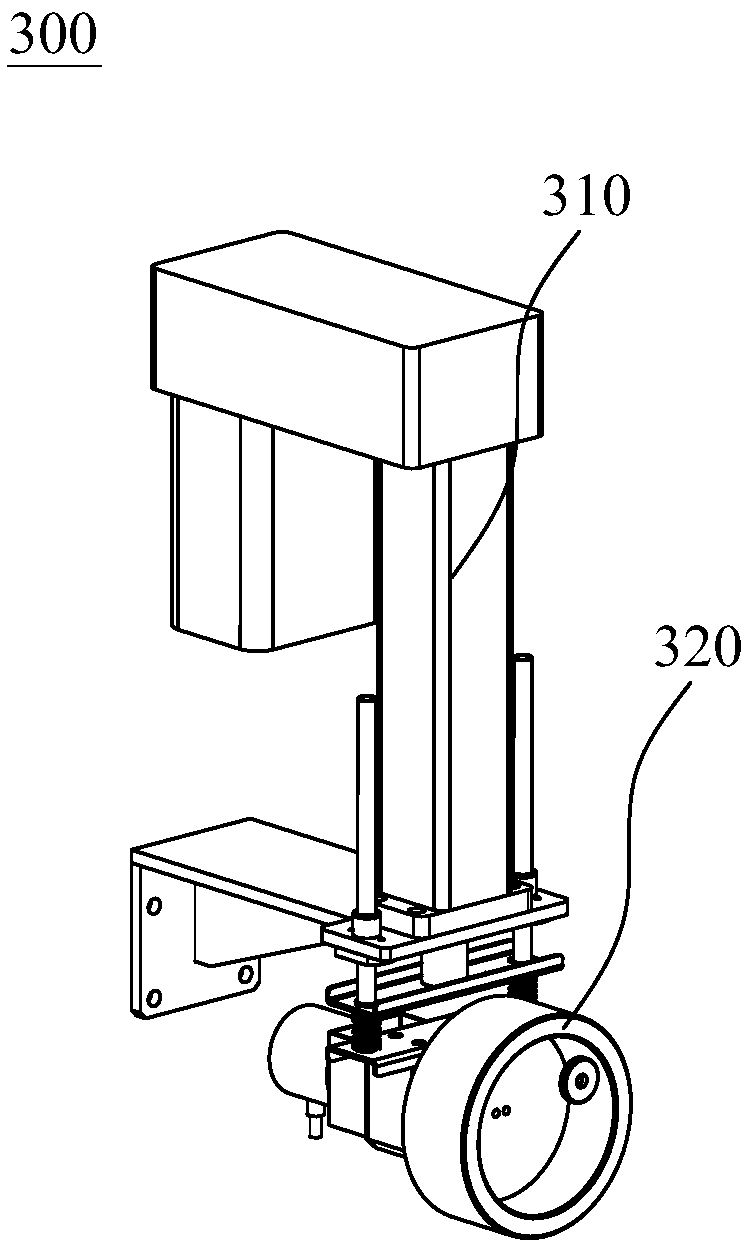

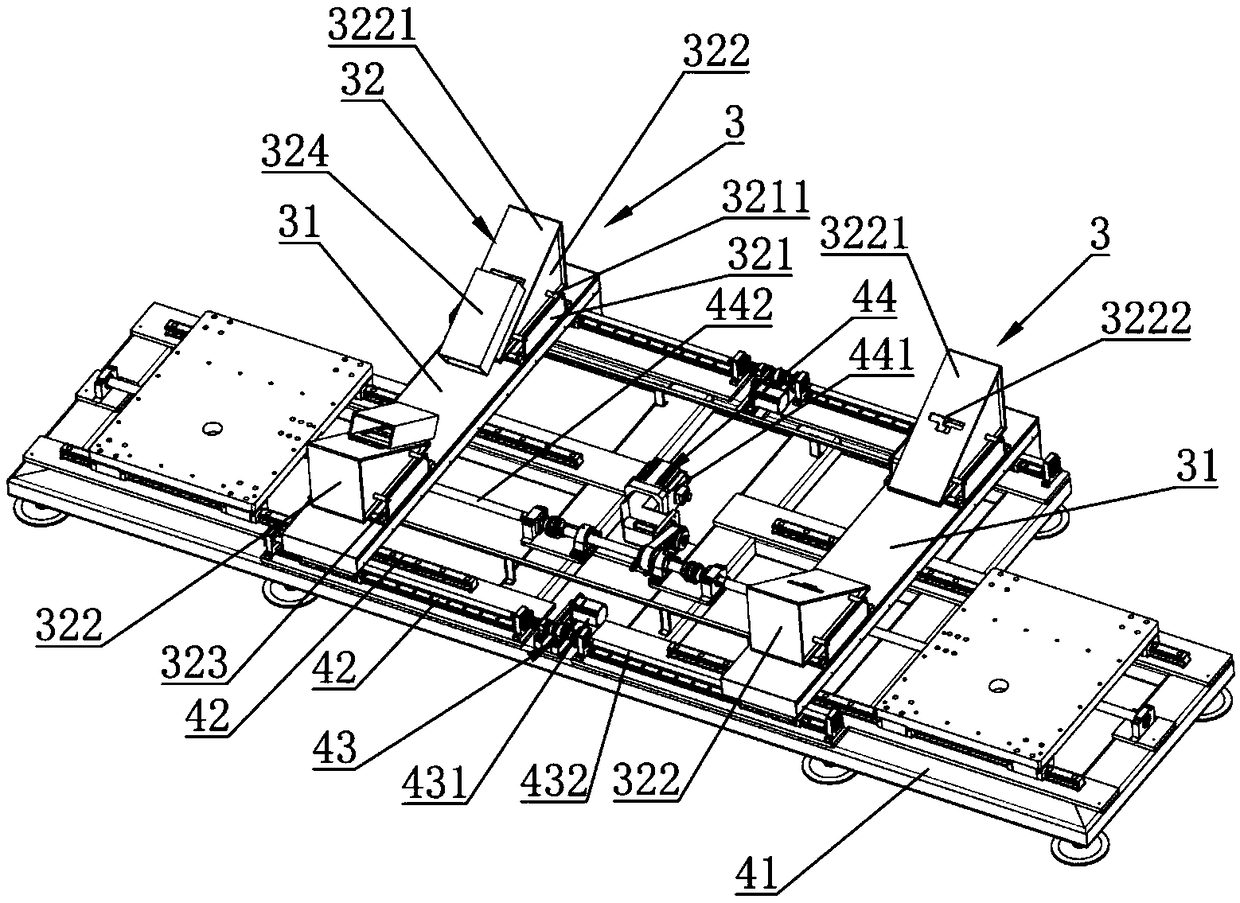

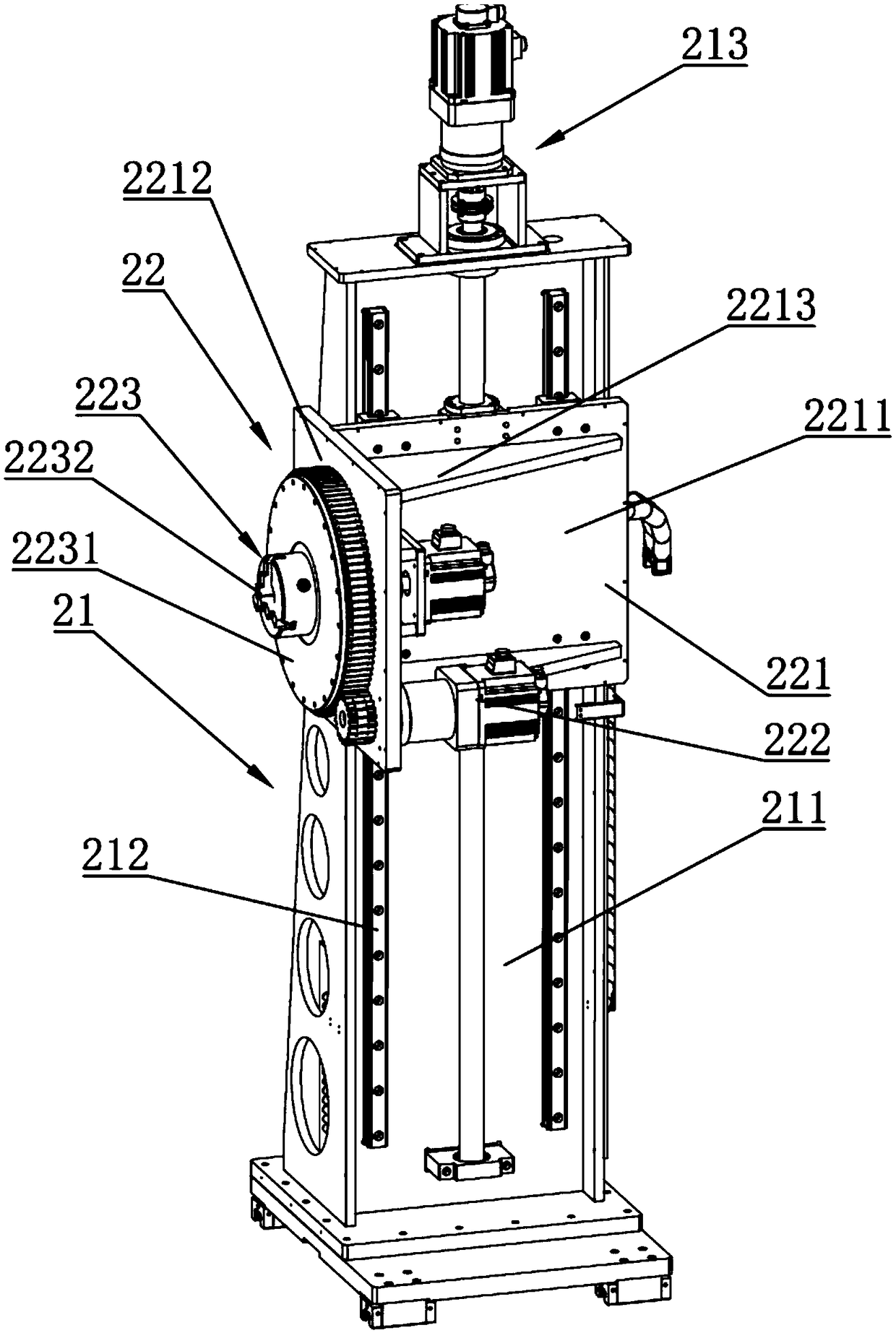

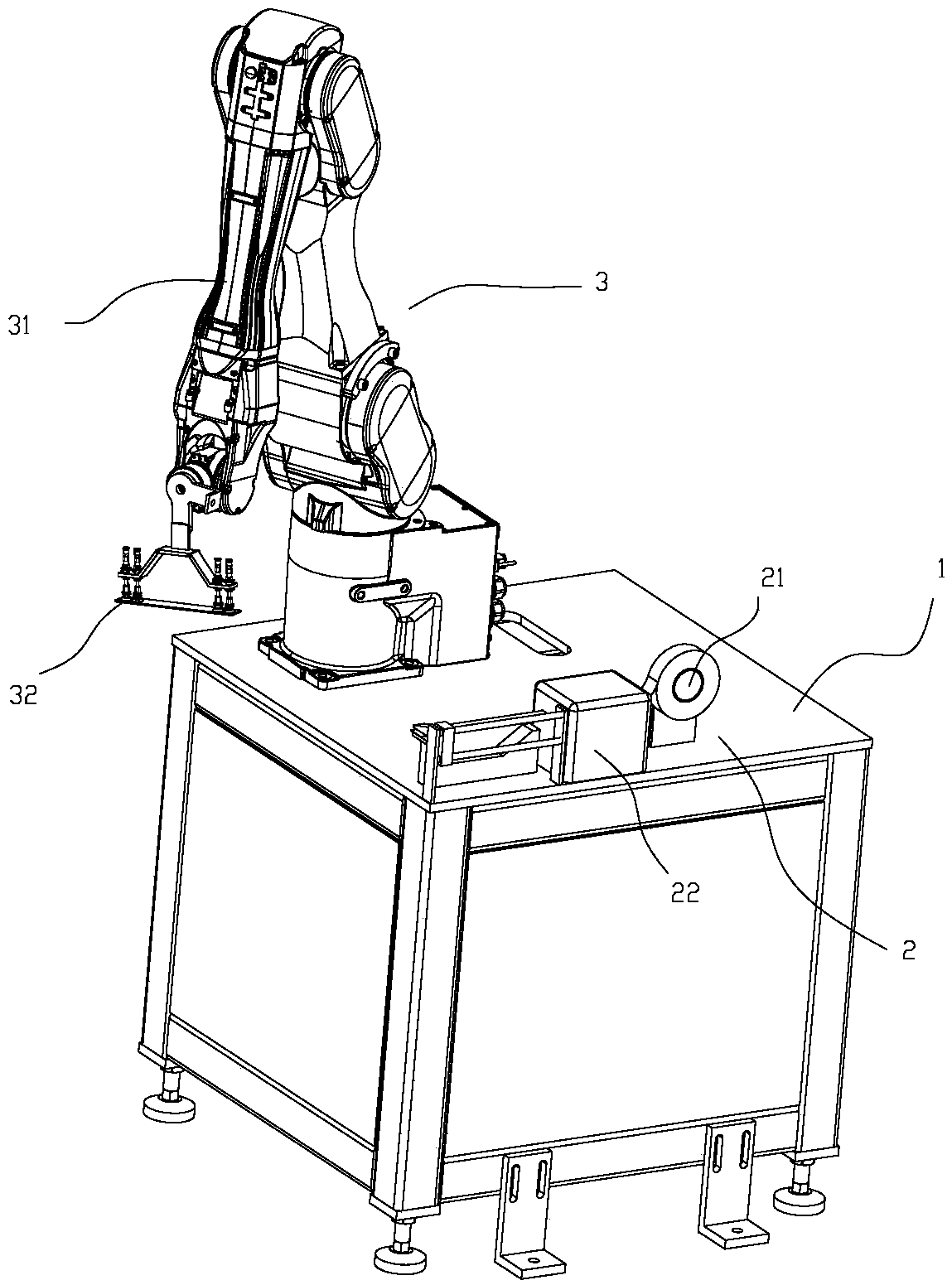

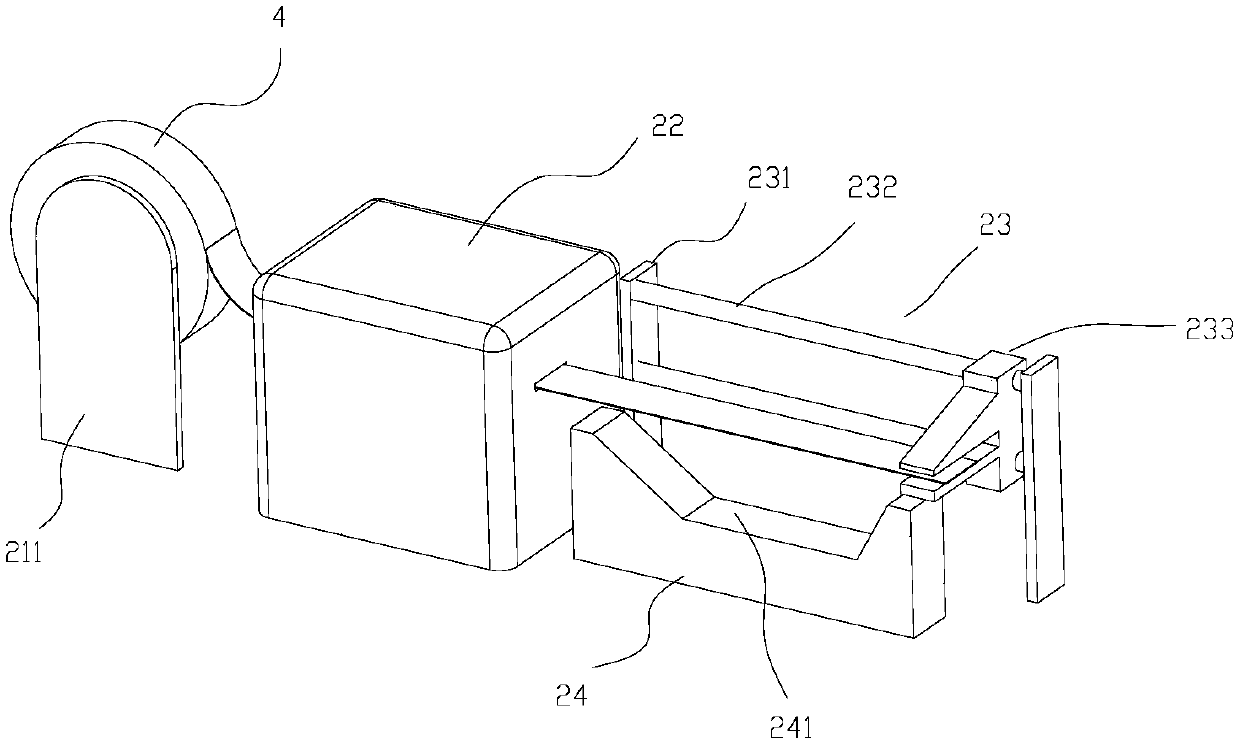

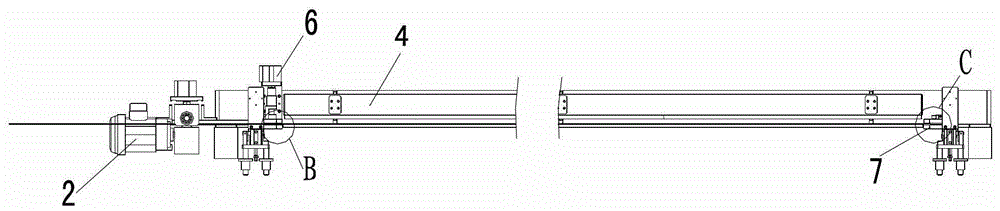

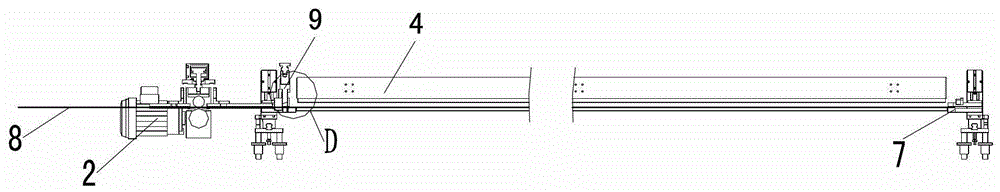

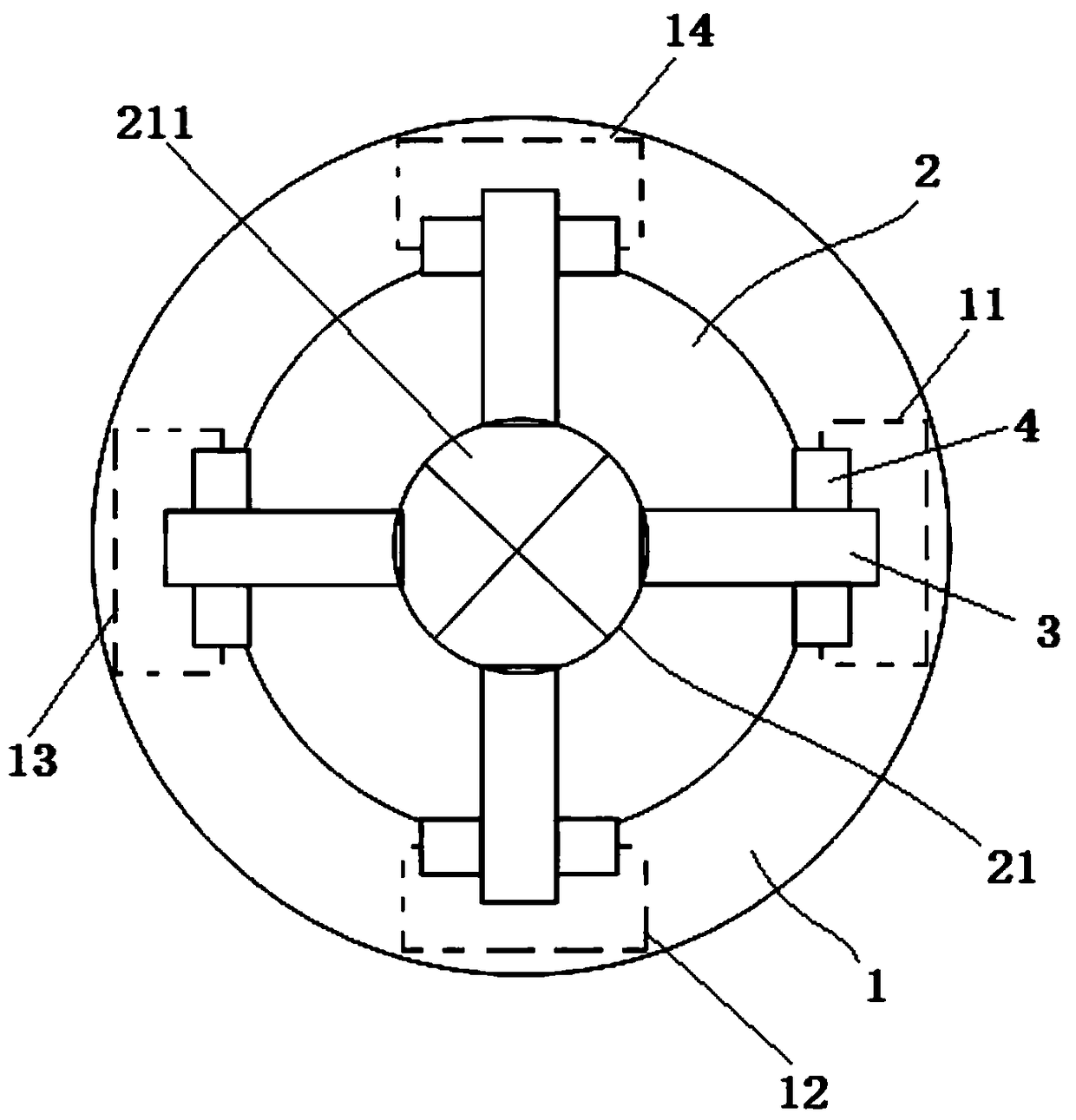

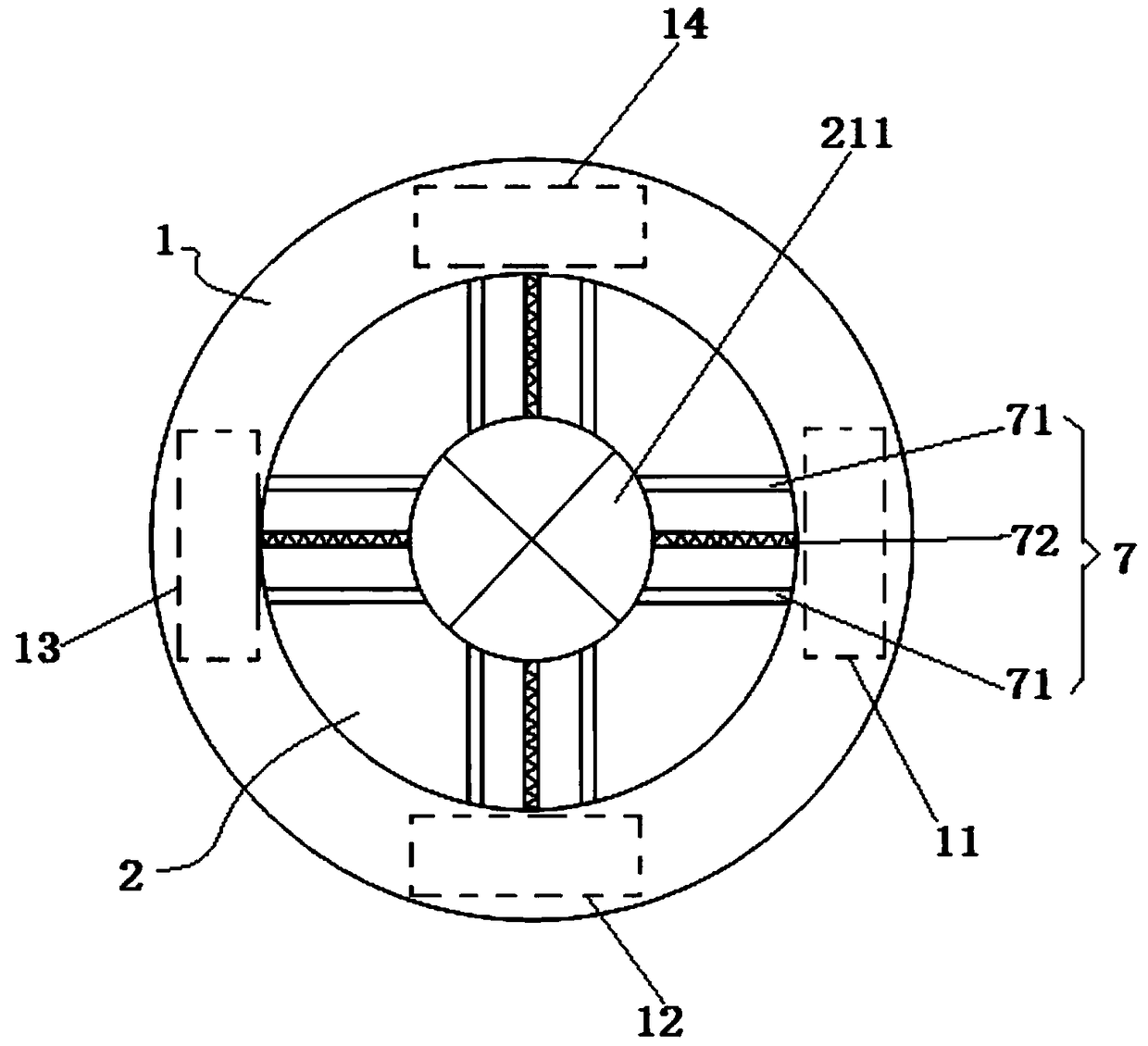

The invention relates to the technical field of cable cutting, in particular to cable cutting equipment. The equipment comprises a control device, two sets of material reeling devices and a cutting device arranged between the two sets of material reeling devices; the control device is electrically connected with the material reeling devices and the cutting device; each material reeling device comprises a reel receiving and discharging mechanism for rotary discharging or receiving of reeled materials, a reeled material positioning mechanism for placing the reeled materials and facilitating thereel receiving and discharging mechanism, and a Y-axis moving component for driving the reel receiving and discharging mechanism and the reeled material positioning mechanism to move in the Y-axis direction; each reel receiving and discharging mechanism comprises a Z-axis moving component and a reeled material rotating component which can move in the Z-axis direction through the Z-axis moving component; the Z-axis moving components are mounted on the Y-axis moving components and can move in the Y-axis direction; each reeled material positioning mechanism comprises two sets of reel positioningcomponents; and the two sets of reel positioning components are connected with the Y-axis moving components correspondingly. Cables can be cut conveniently through the equipment, and the cutting precision and efficiency are improved.

Owner:广州国机智能电力科技有限公司 +1

Adhesive tape pasting machine

The invention discloses an adhesive tape pasting machine. The adhesive tape pasting machine comprises a cutting mechanism and an absorbing mechanism; the cutting mechanism comprises a sleeve for winding adhesive tapes, a support part for supporting the adhesive tapes, and a clamping part arranged at the downstream of the support part; the clamping part comprises a mounting frame, and a clamping jaw slidingly connected to the mounting frame; the clamping jaw is used for clamping and stretching free ends of the adhesive tapes; a cutter is arranged at the tail end of the support part, and is driven through a driver to cut the adhesive tapes; the absorbing mechanism comprises a manipulator, and a sucker connected to the manipulator; and the manipulator can drive the sucker to absorb and bond the cut adhesive tapes. The adhesive tape pasting machine can realize automatic cutting of the adhesive tapes with a certain lengths and bonding of the adhesive tapes on products, improves the workingefficiency, and can prevent such phenomenon as drapes and hemming of the adhesive tapes.

Owner:苏州弘瀚自动化科技有限公司

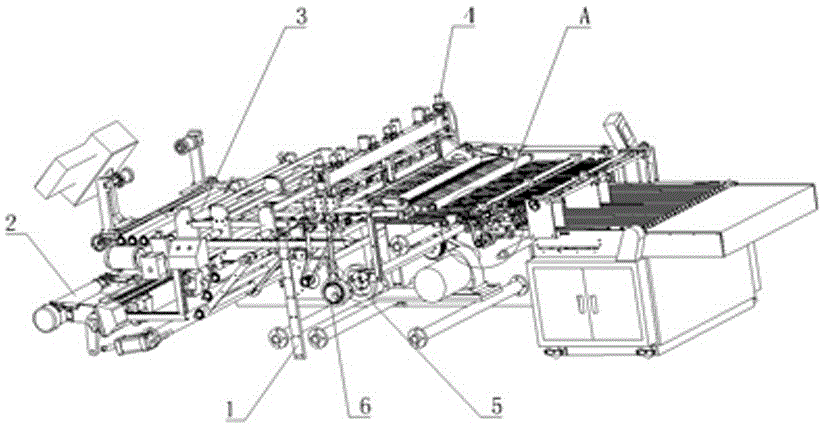

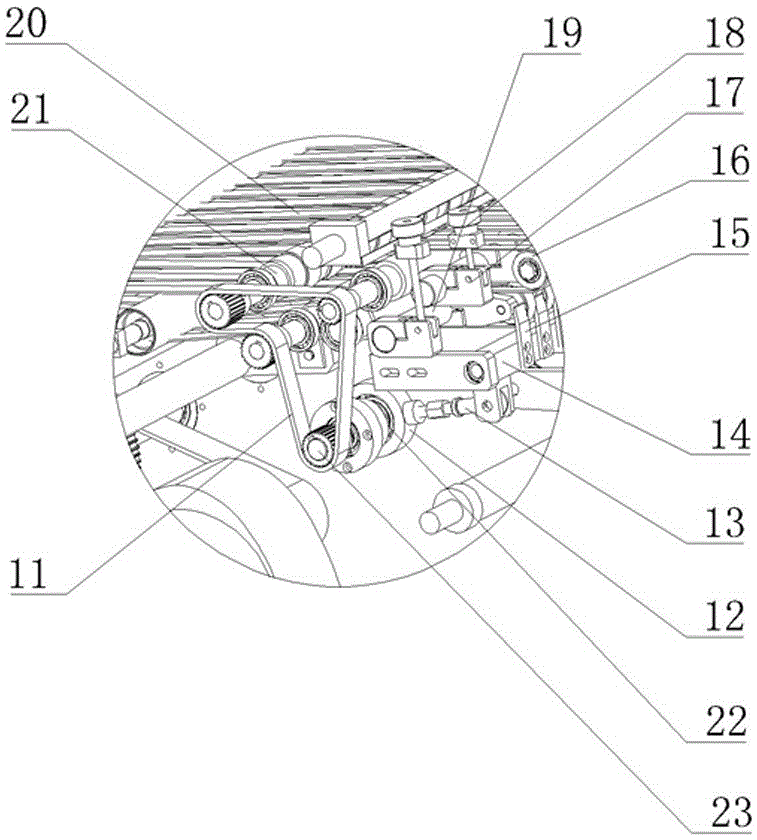

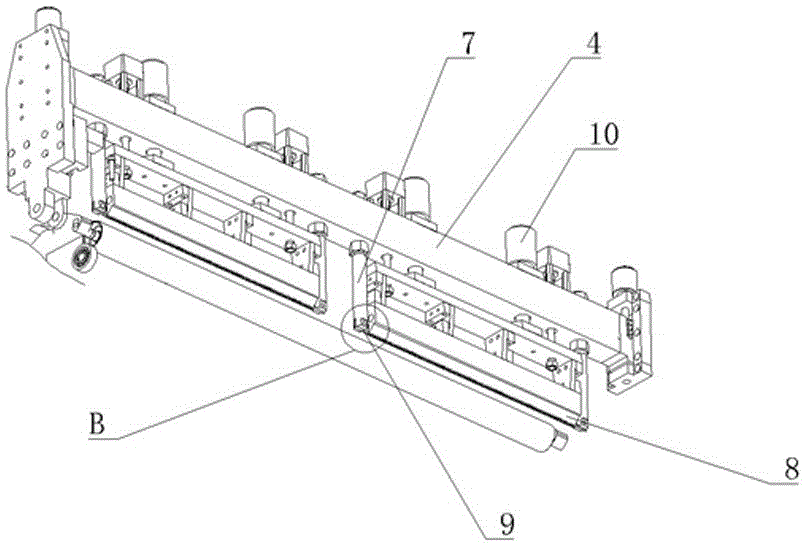

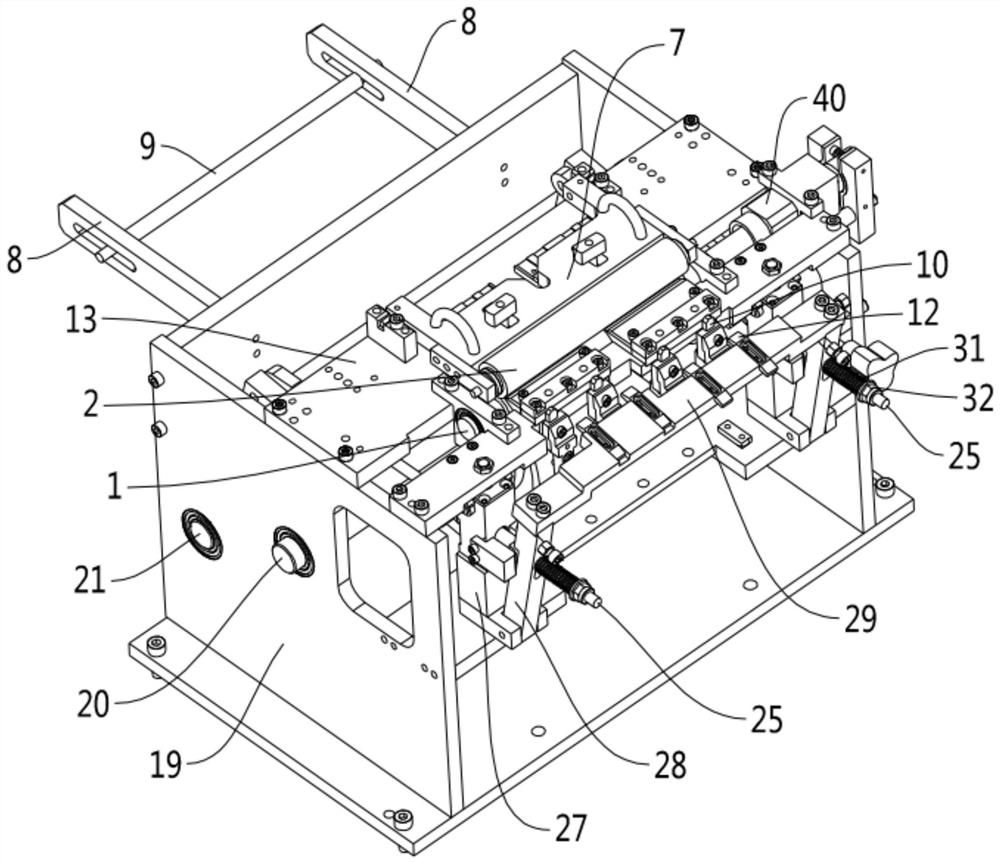

Automatic paper feeder of corrugating machine

PendingCN110077891ASimple structurePaper feeding speedArticle deliveryWebs handlingPaper sheetFixed length

The invention discloses an automatic paper feeder of a corrugating machine. The automatic paper feeder comprises a corrugating medium paper conveying platform and a corrugating paper conveying platform; the free end of the corrugating medium paper conveying platform is provided with a paper roll support; the paper roll support is provided with a corrugating medium paper roll; corrugating medium paper passes through a corrugating medium paper feeding roller, a corrugating medium paper cutter, a corrugating medium paper dragging device and a photographing region in sequence in a process that thecorrugating medium paper is conveyed to the corrugating machine; the side edge of the photographing region is provided with a visual system; and the corrugating medium paper feeding roller is provided with a sensor. The automatic paper feeder is simple in structure, high in paper feeding speed and high in precision; traditional manual operation can be replaced; and automatic fixed-length cuttingof the corrugating medium paper can be realized, and the corrugating medium paper can be automatically fed into the corrugating machine, so that the work efficiency is significantly increased.

Owner:CHANGZHOU TEXTILE GARMENT INST

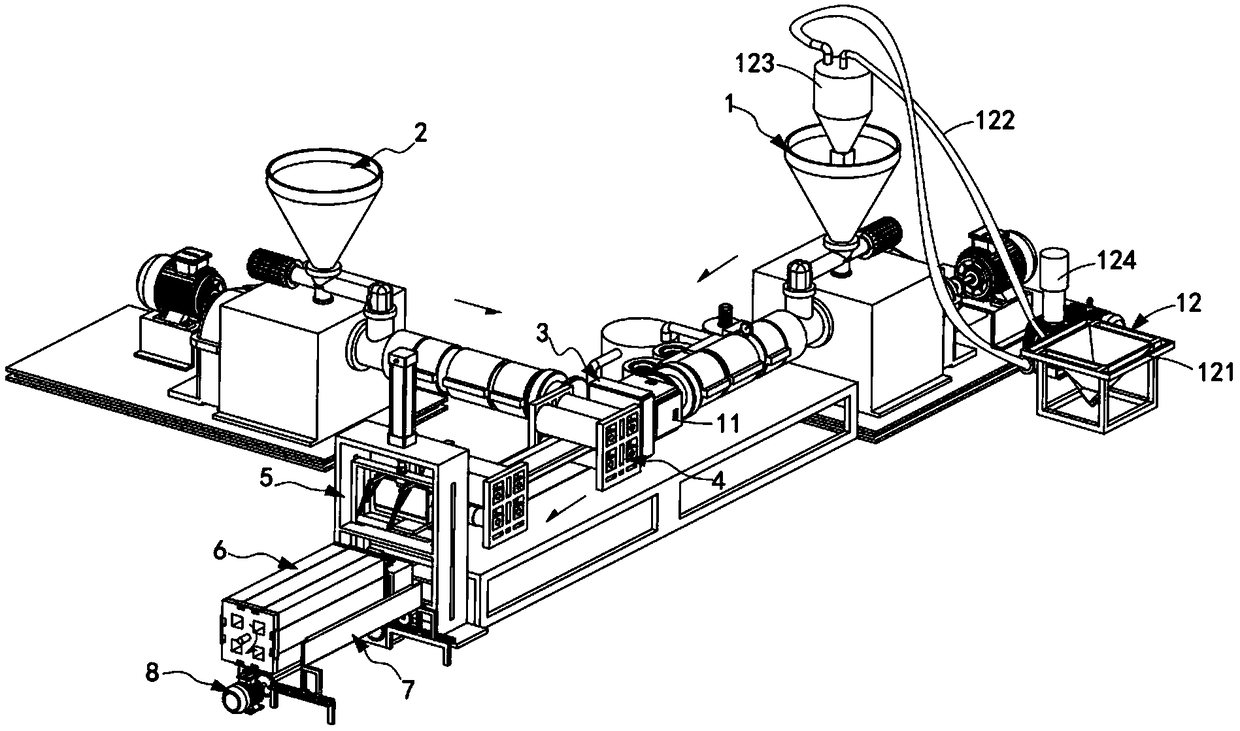

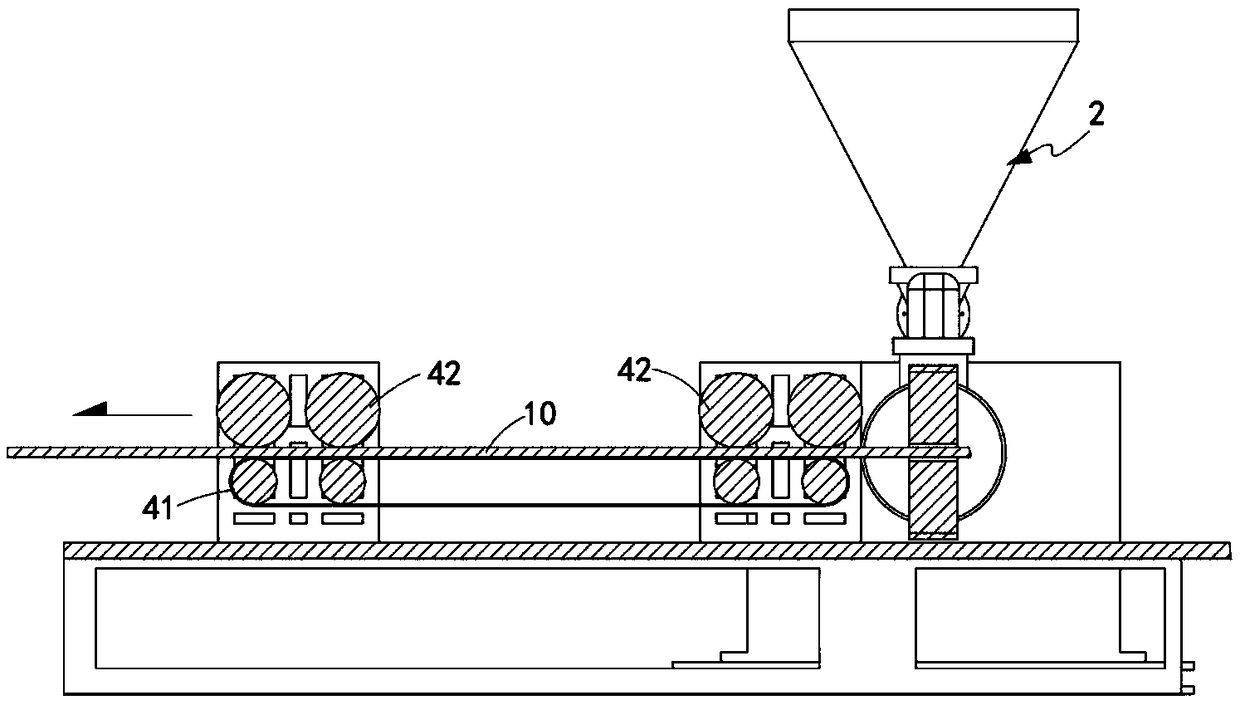

High viscosity and scratch resisting PE wood-plastic plate composite production line and production technology

InactiveCN109176764ASolve the deformationRealize automatic croppingPlywood pressesProfiling/shaping machinesProduction lineEngineering

The invention provides a high viscosity and scratch resisting PE wood-plastic plate composite production line. A working table is rotated synchronously by a push cylinder which drives a cutting tool to cut a wood-plastic plate, and therefore switching among four working stations on the working table of wood-plastic plate products after cutting is automatically achieved. A shaping mechanism is synchronously driven to conduct extrusion shaping on the wood-plastic plate products at the shaping station. The technical problem of deformation of the wood-plastic plate in the production process is solved. The invention provides a high viscosity and scratch resisting PE wood-plastic plate composite production technology. Compared with a traditional wood-plastic plate production technology, three steps of shaping, cutting discharging and waste collecting are added, the driving force in the cutting process is adopted to drive the shaping mechanism synchronously to conduct shaping processing of the wood-plastic plate products. The technical aim of forming the wood-plastic plate products after cutting is achieved. Synchronous conducting of four production steps of cutting, shaping, cutting discharging and waste collecting is achieved.

Owner:ZHEJIANG YUANSENTAI FURNITURE

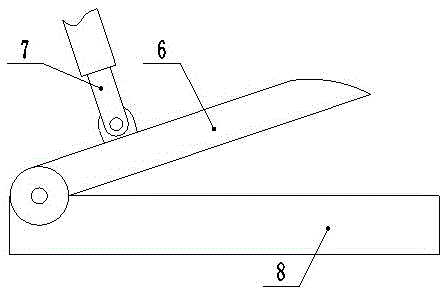

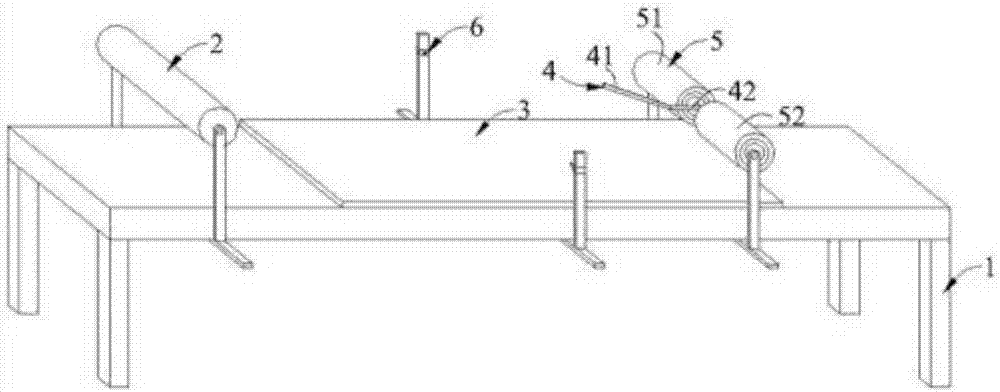

Tailoring equipment

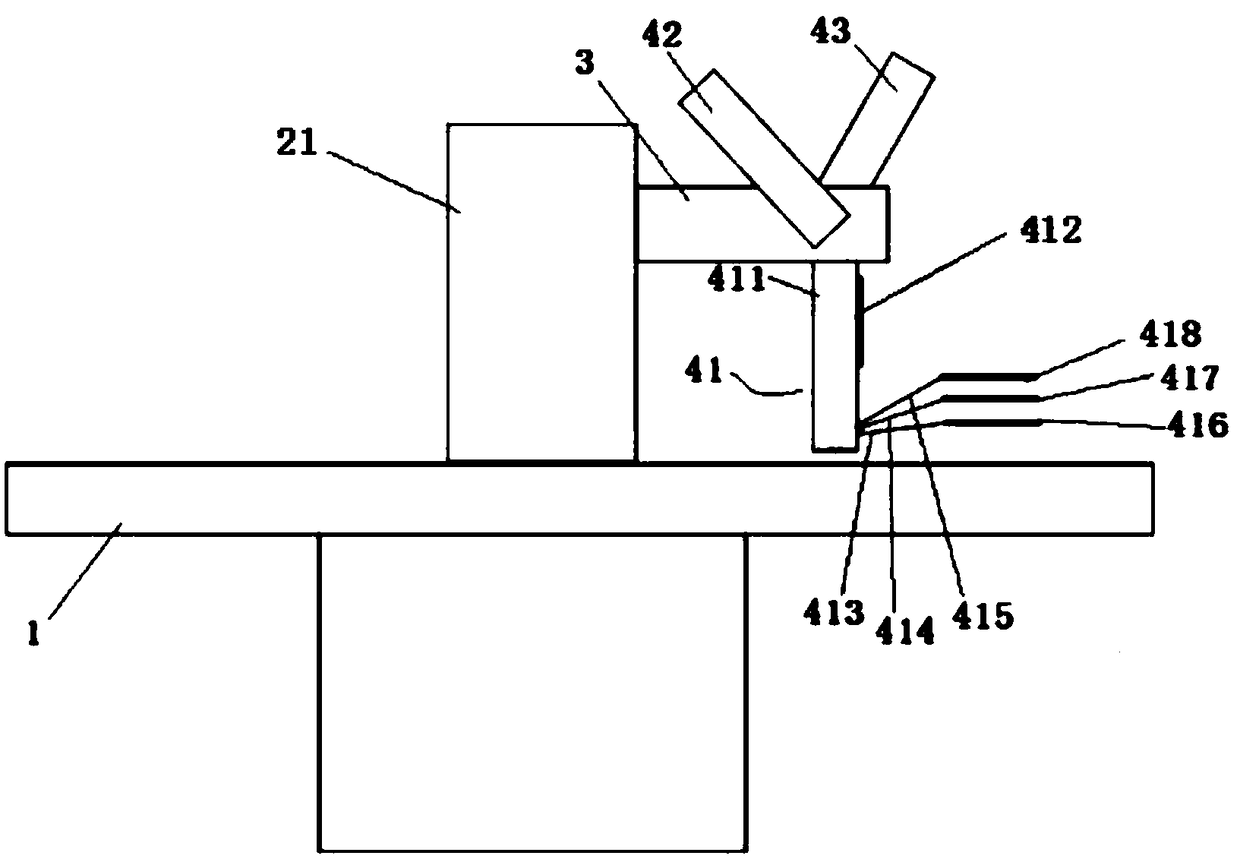

InactiveCN107956100AAchieving cut size requirementsRealize automatic croppingSevering textilesMechanical engineeringEngineering

A garment cutting device of the present invention includes a platform, a rotating device, a table, a cutting part, and a storage part; the storage part is fixed on the platform through a fixing mechanism, and the storage part includes a first storage part, a second Two storage parts; the storage part is a storage part covered with a protective cover, and the protective cover is provided with an anti-skid surface and a limit block; the first storage part and the second storage part are provided with the The cutting part; the cutting part includes a rod part and a cutter, the rod part is arranged horizontally, and the cutter is arranged obliquely; fastening parts are arranged on both sides of the table; the fastening part includes a fastening block, the The cross section of the fastening block is concave. The invention can realize the automatic cutting of clothes, and has the advantages of convenient operation, accurate cutting and high cutting efficiency.

Owner:NANJING YUANJIAHONG INTIOINAL TRADE CO LTD

Automatic pearl cotton cutting device

PendingCN110735314ARealize automatic croppingHigh degree of automationSevering textilesAgricultural scienceAgricultural engineering

The invention discloses an automatic pearl cotton cutting device, which comprises a machine frame, a discharging mechanism, a gathering mechanism and a cutting mechanism, wherein the discharging mechanism is arranged on the machine frame, and is configured to continuously output pearl cotton outwards; the gathering mechanism is arranged on the machine frame, and is configured to receive pearl cotton output by the discharging mechanism and gather the pearl cotton in the width direction; and the cutting mechanism is arranged on the machine frame and is configured to cut the pearl cotton gatheredby the gathering mechanism. According to the technical scheme, the pearl cotton is automatically conveyed outwards through the setting of the discharging mechanism, the pearl cotton is gathered in the width direction through the gathering mechanism, the pearl cotton is finally cut through the cutting mechanism, and the gathering mechanism gathers the pearl cotton to be beneficial to cutting a relatively flat incision. The technical scheme can realize automatic cutting of the pearl cotton, has high automation degree and high production efficiency.

Owner:GUANGDONG HOSHION IND ALUMINUM CO LTD

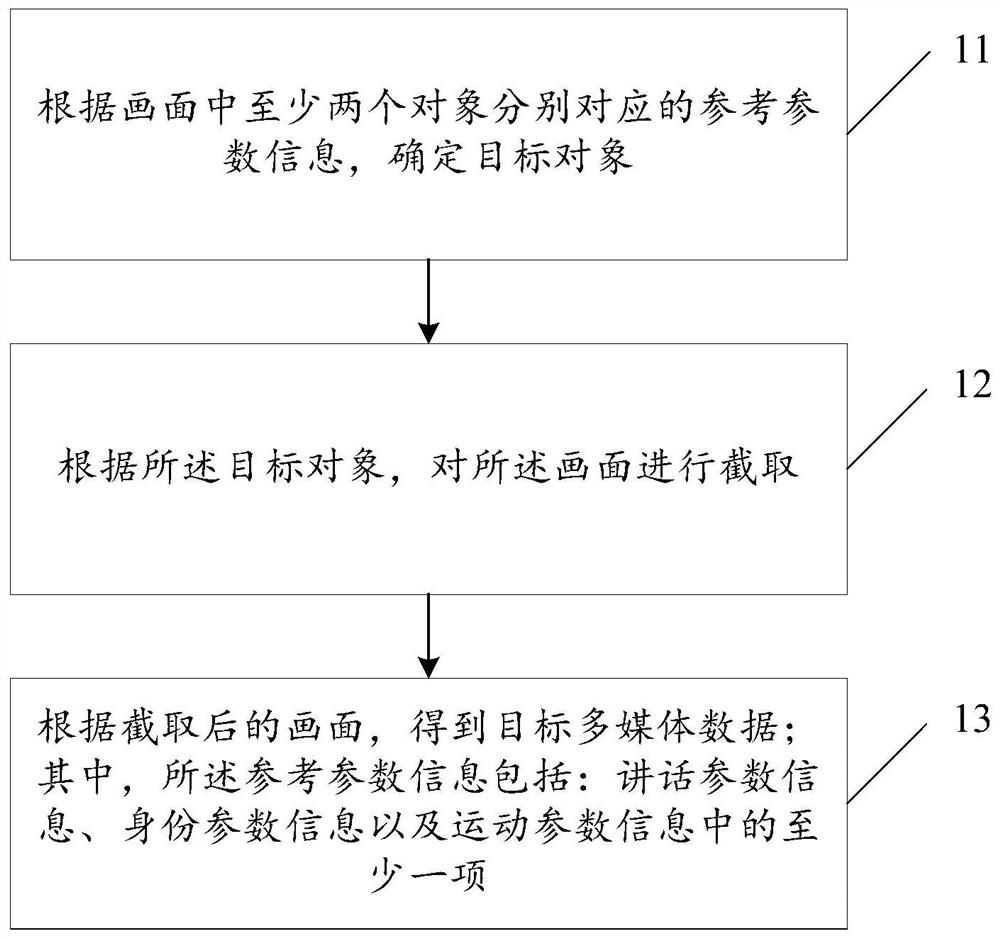

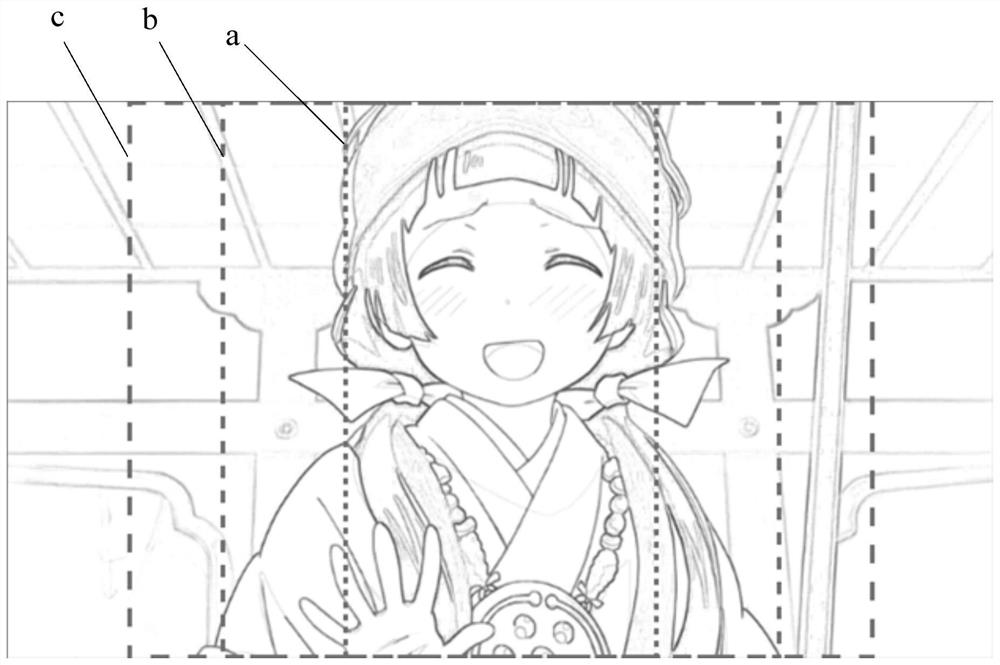

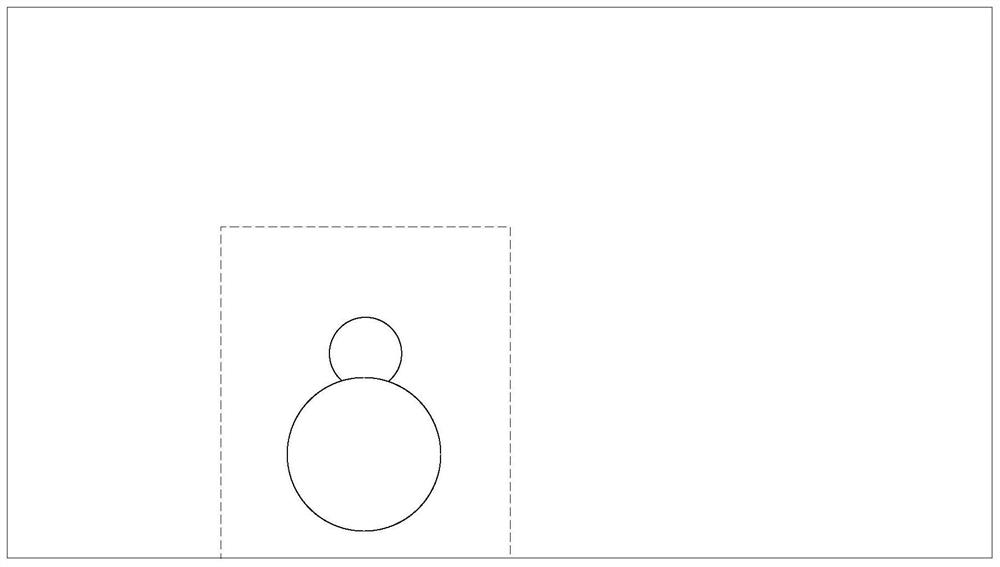

Multimedia data processing method, communication equipment and readable storage medium

PendingCN112967288ARealize automatic croppingShort timeImage analysisMetadata multimedia retrievalTelecommunicationsVideo processing

The invention provides a multimedia data processing method, communication equipment and a readable storage medium, and the method comprises the steps of determining a target object according to reference parameter information corresponding to at least two objects in a picture; according to the target object, intercepting the picture; obtaining target multimedia data according to the intercepted picture, wherein the reference parameter information comprises at least one of speech parameter information, identity parameter information and motion parameter information. According to the scheme, automatic cutting can be realized to the greatest extent, the time consumption is greatly reduced, and the problem of long time consumption of a multimedia data processing scheme for video processing in the prior art is well solved.

Owner:MIGU CO LTD +1

Polymer cutoff pelleter

PendingCN110834356ARealize automatic feedingRealize automatic croppingElectrode manufacturing processesMetal working apparatusPole pieceMechanical engineering

The invention discloses a polymer cutoff pelleter and relates to the technical field of pelleters. The polymer cutoff pelleter comprises a pole piece unreeling mechanism, a tab dividing mechanism, a tab welding mechanism and a contraposition rubberizing mechanism, wherein the pole piece unreeling mechanism is positioned on one side of the tab welding mechanism and is used for providing pole piecesof to-be-welded tabs for the tab welding mechanism; the tab dividing mechanism is positioned below the tab welding mechanism and is used for providing to-be-welded tabs for the tab welding mechanism;and the contraposition rubberizing mechanism is positioned on the other side of the tab welding mechanism and is used for rubberizing the pole piece. The polymer cutoff pelleter has the benefits of realizing automatic tab supply and automatic rubberizing of gummed paper, increasing the degree of automation and improving the production efficiency.

Owner:深圳市兴盛林科技有限公司

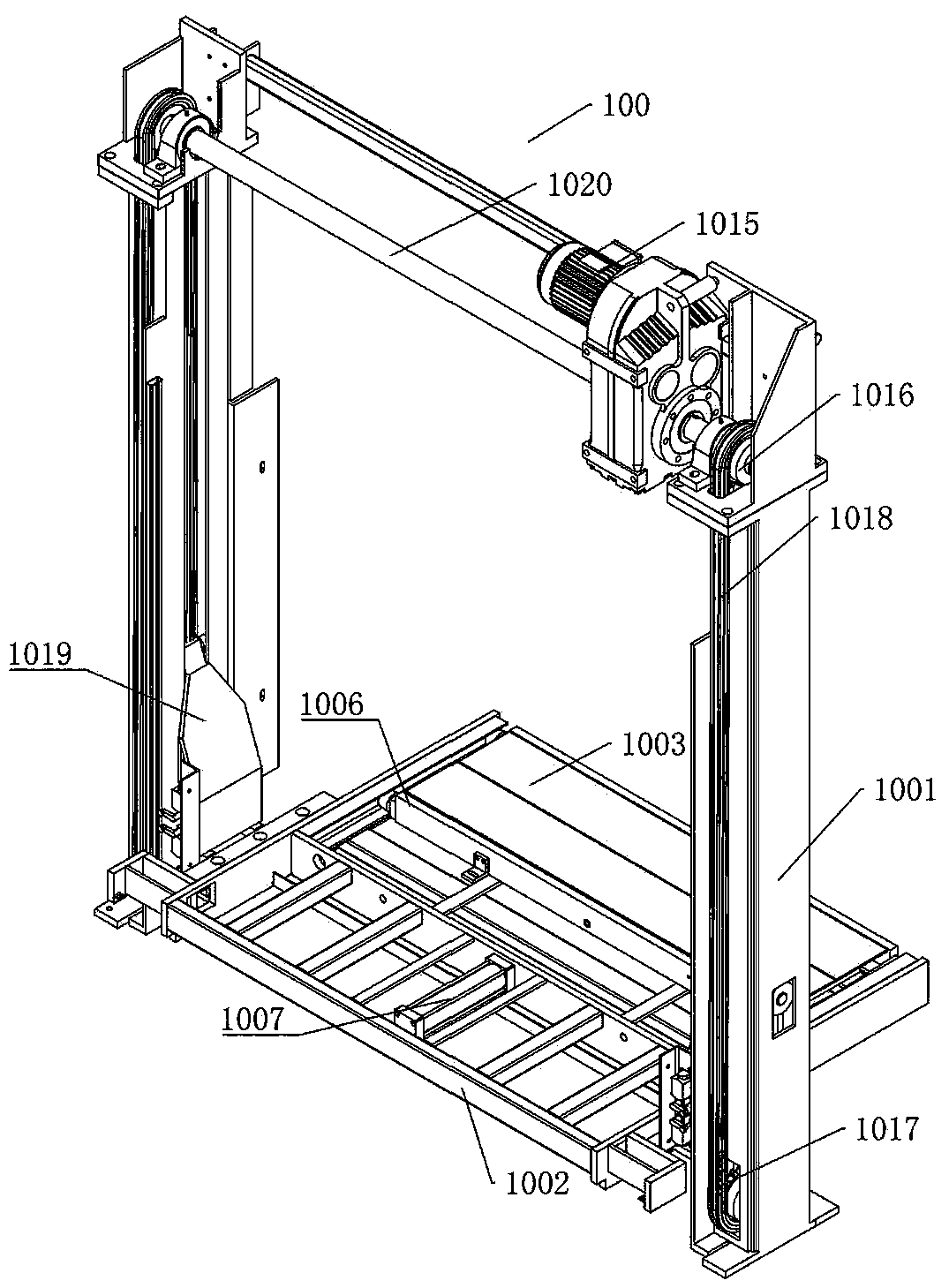

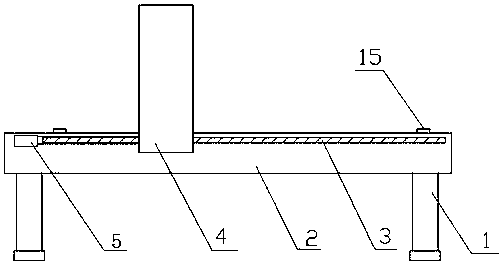

Guide rail type cutting machine

PendingCN108724339ANovel structureRealize automatic croppingMetal working apparatusEngineeringMechanical engineering

The invention discloses a guide rail type cutting machine which comprises a rack and a controller. A worktable is fixedly arranged on the rack; guide rails in horizontal direction are arranged on twosides of the worktable; columns are slidably arranged on the guide rails; the columns are in transmission connection to a driving device I; vertical chutes are formed in opposite side faces of the twocolumns; an upper pressure plate is arranged between the two columns; the upper pressure plate is slidably arranged between the columns through the chutes; the upper pressure plate is in transmissionconnection to a driving device II; a sliding track is arranged on the lower end surface of the upper pressure plate; a cutting head is slidably arranged on the sliding track; the cutting head is in transmission connection to a driving device III; and the driving devices I, II and III are electrically connected to the controller. The guide rail type cutting machine disclosed by the invention is novel in structure. The position of the cutting head can be adjusted, so that any positions of a material on the worktable can be cut. The material needs not to be moved frequently, so that the work efficiency is improved effectively.

Owner:江苏华驰机械有限公司

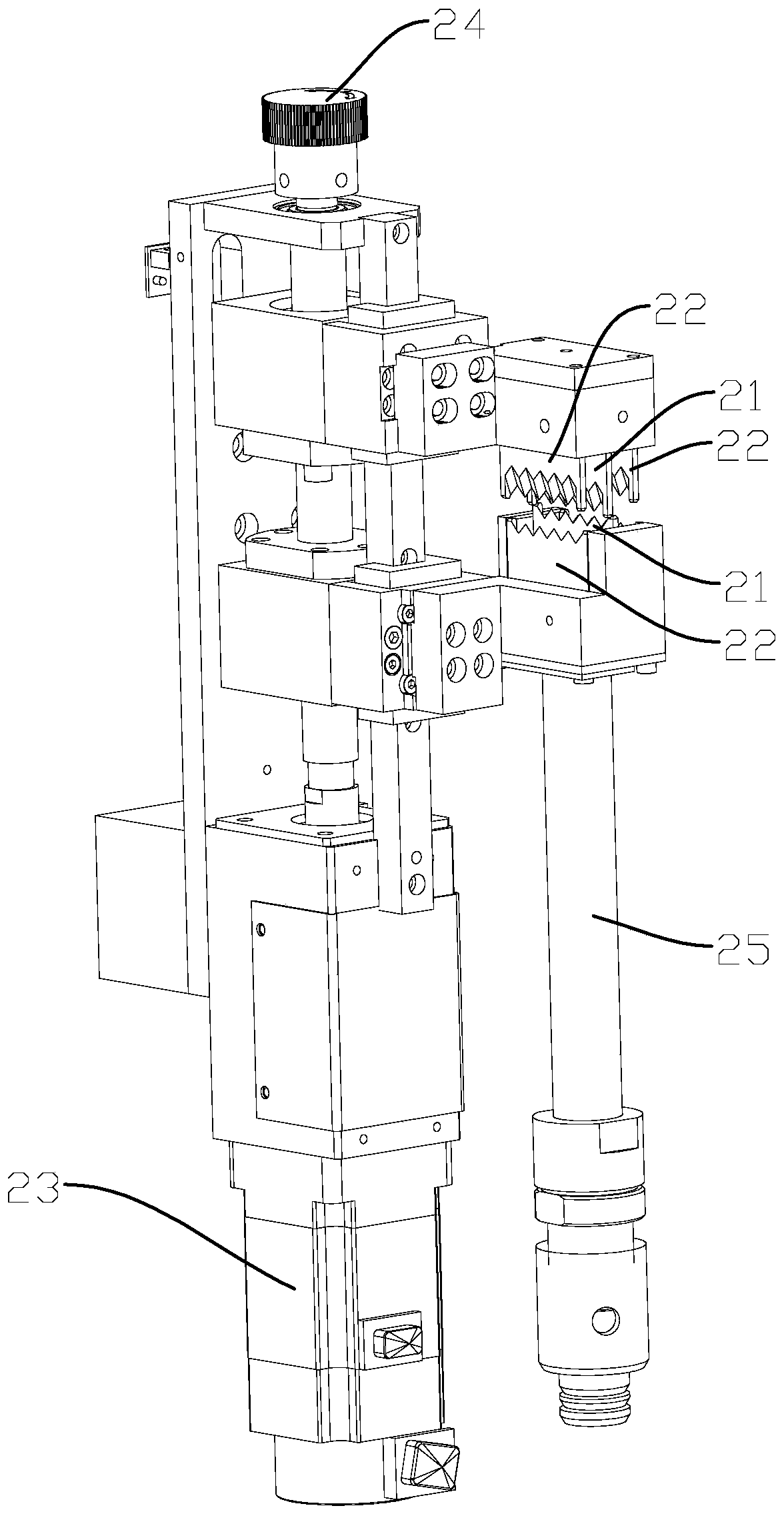

Double-headed terminal installer

InactiveCN110247275ARealize automatic croppingReduce labor intensityConnection formation by deformationEngineeringUltimate tensile strength

The invention discloses a double-headed terminal installer comprising a frame; a cutting device for cutting off a wire and a wire skin; a first terminal-installing device and a second terminal-installing device, wherein the first terminal-installing device is used for installing a terminal on the wire end behind the fracture surface of the wire, and the second terminal-installing device is used for installing a terminal on the wire end ahead of the fracture surface of the wire; and a first wire moving device and a second wire moving device, wherein the first wire moving device can clamp the wire behind the cutting device, can move the wire in the front-rear direction, and can move the wire thereon to the first terminal-installing device; the second wire moving device can clamp the wire ahead of the cutting device, can move the wire in the front-rear direction, and can move the wire thereon to the second terminal-installing device; and the wire on the first wire moving device can be transferred to the second wire moving device. The double-headed terminal installer can realize the automatic cutting, the peeling and the double-headed terminal installation of the wire, can improve the production efficiency and reduce the labor intensity of workers.

Owner:ZHONGSHAN YATAI MACHINERY

Packaging bag cutting machine

InactiveCN106626528ARealize automatic croppingBag making operationsPaper-makingEngineeringMechanical engineering

Owner:WENZHOU RUIZHI PACKING MACHINERY

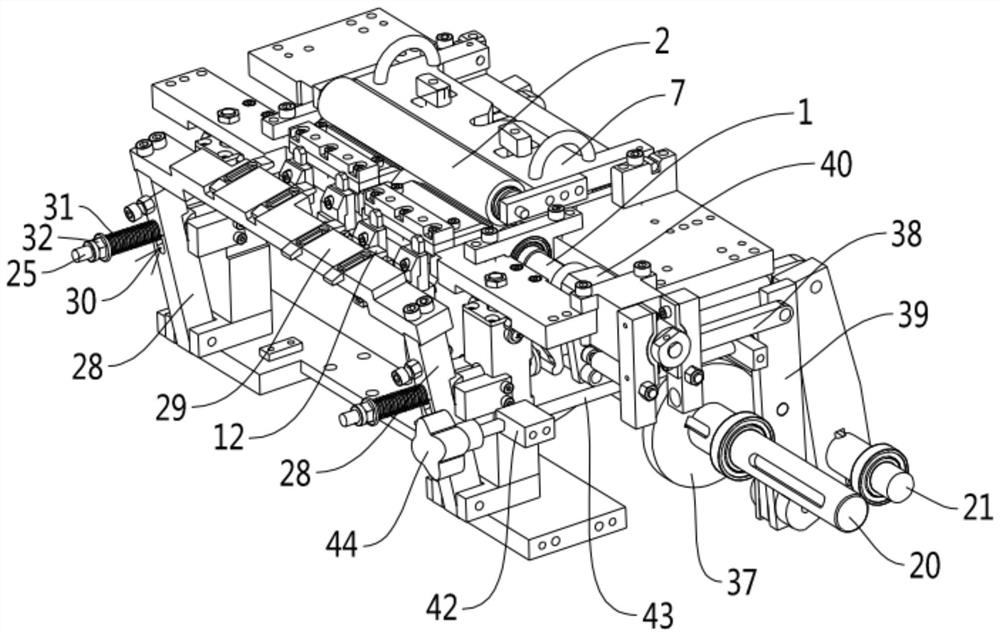

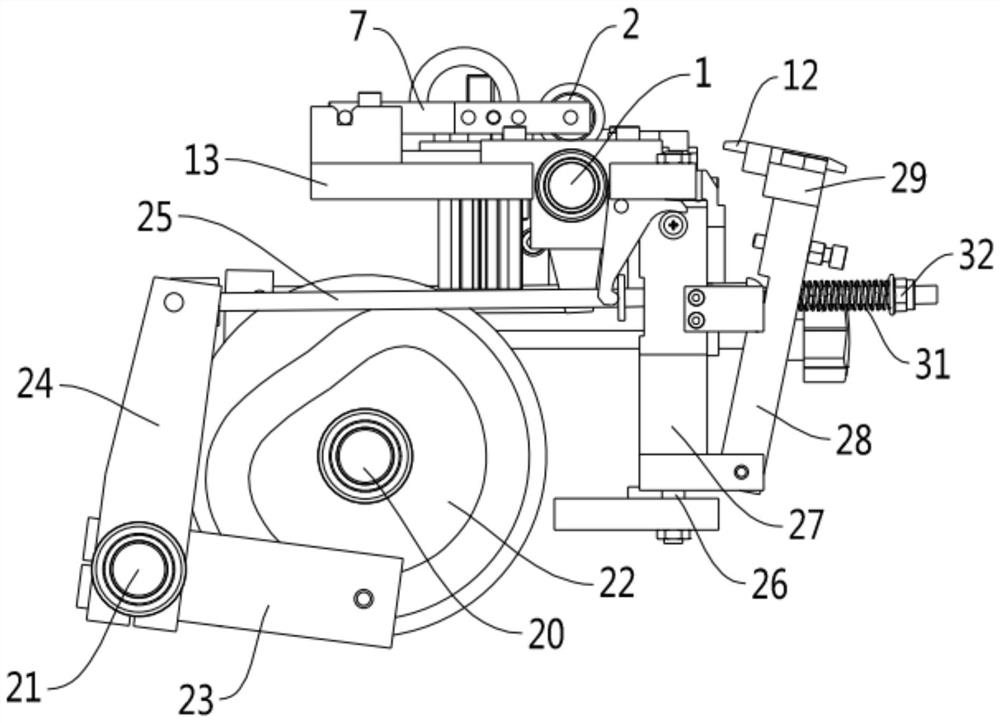

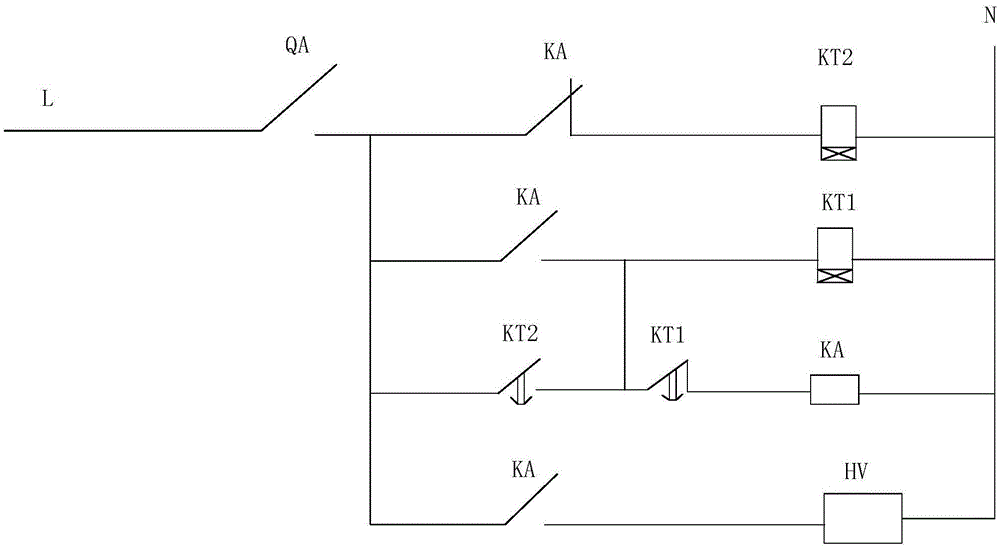

A communication relay high-speed cam type contact sheet silver wire spot welding feeding silver wire cutting mechanism

ActiveCN110911230BRealize automatic croppingHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesWire cuttingEngineering

The invention discloses a communication relay high-speed cam type contact plate silver wire spot welding silver wire feeding and cutting mechanism, which includes a lower roller shaft and an upper roller shaft, and a front upper stopper and a front lower stopper are arranged in front of the lower roller shaft. The back of the lower roller shaft is provided with a rear upper stopper and a rear lower stopper, and above the rear upper stopper is an upper roller plate that is raised relative to it. The upper roller shaft is connected to the upper roller plate in rotation. There is also a wire frame, the wire frame is provided with a wire frame shaft, and the front of the lower drum shaft is also provided with a lower electrode located in the output direction of the front upper stopper and the front lower stopper, and a blanking groove is provided on the upper end of the lower electrode , also comprises the cutting knife that is made close to or away from front upper stopper and front lower stopper, and silver wire part is cut off when cutting knife is close to front upper stopper and front lower stopper and falls into the discharge groove. The mechanism adopts two sets of cam structures to realize the characteristics of single power source input and double power source output, and completes the function of automatically cutting silver wire, and is easy to maintain and use as a whole.

Owner:嘉兴市宇钛自动化科技有限公司

Packaging material cutting machine

The invention belongs to the cutting machine field, and especially relates to a packaging material cutting machine characterized in that a frame platform is provided with a packaging material port; a packaging material storage tank is arranged below the packaging material port; a packaging material cutting groove comprises a side wall, a first bottom wall and a second bottom wall; the first and second bottom walls are plugged between the side wall and the frame platform; the first and second bottom walls are arranged above the packaging material port; a first bottom wall cylinder is connected with the first bottom wall; a second bottom wall cylinder is connected with the second bottom wall; a first pressure plate is connected with a first pressure plate cylinder; a second pressure plate is connected with a second pressure plate cylinder; a packaging material cutter cylinder and a packaging material punching cylinder are fixed on a slide track; a packaging material cutter is connected with the packaging material cutter cylinder; a packaging material punching die is connected with the packaging material punching cylinder.

Owner:天津三源鑫泰科技有限公司

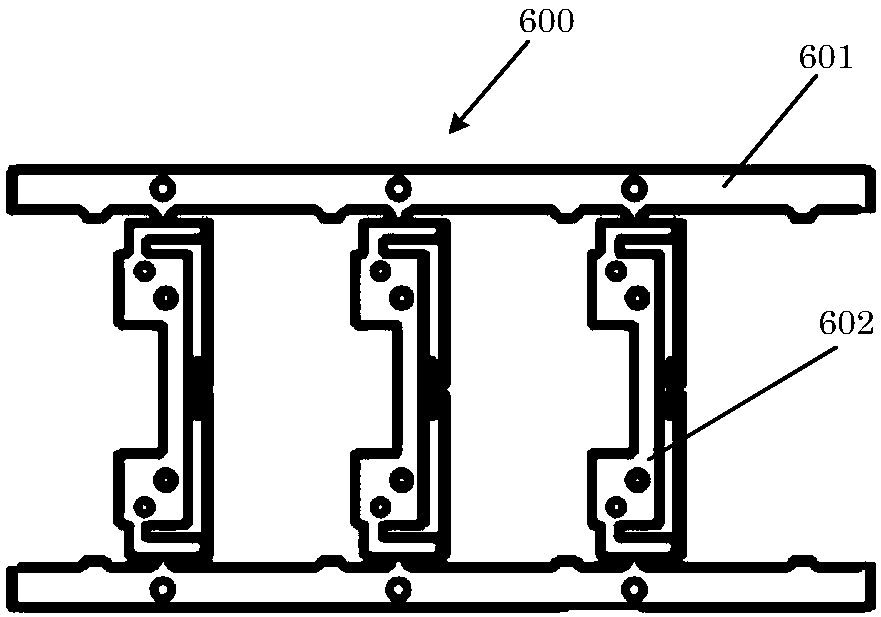

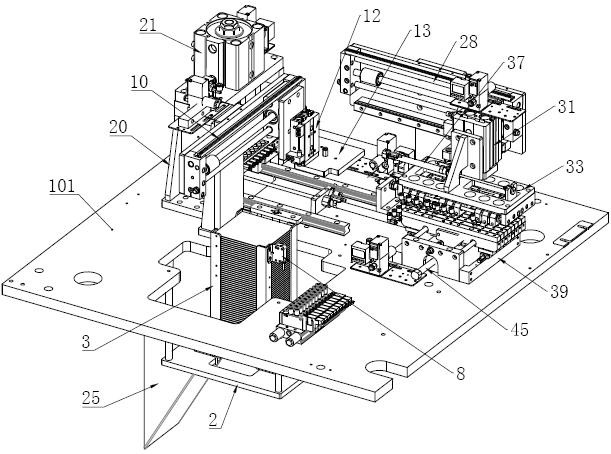

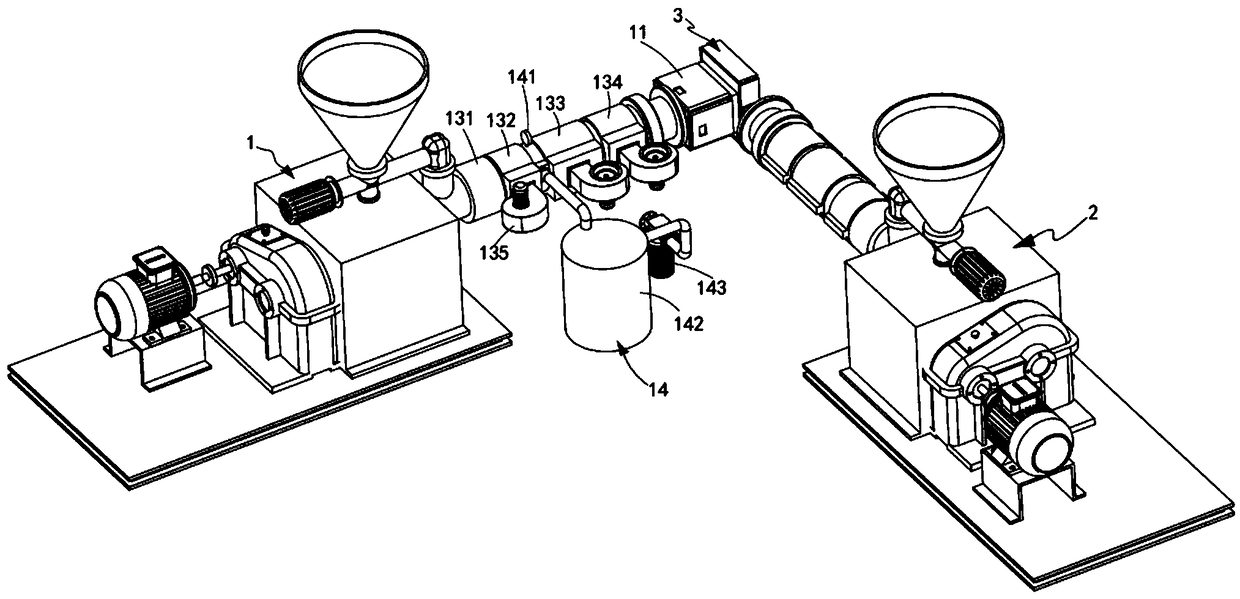

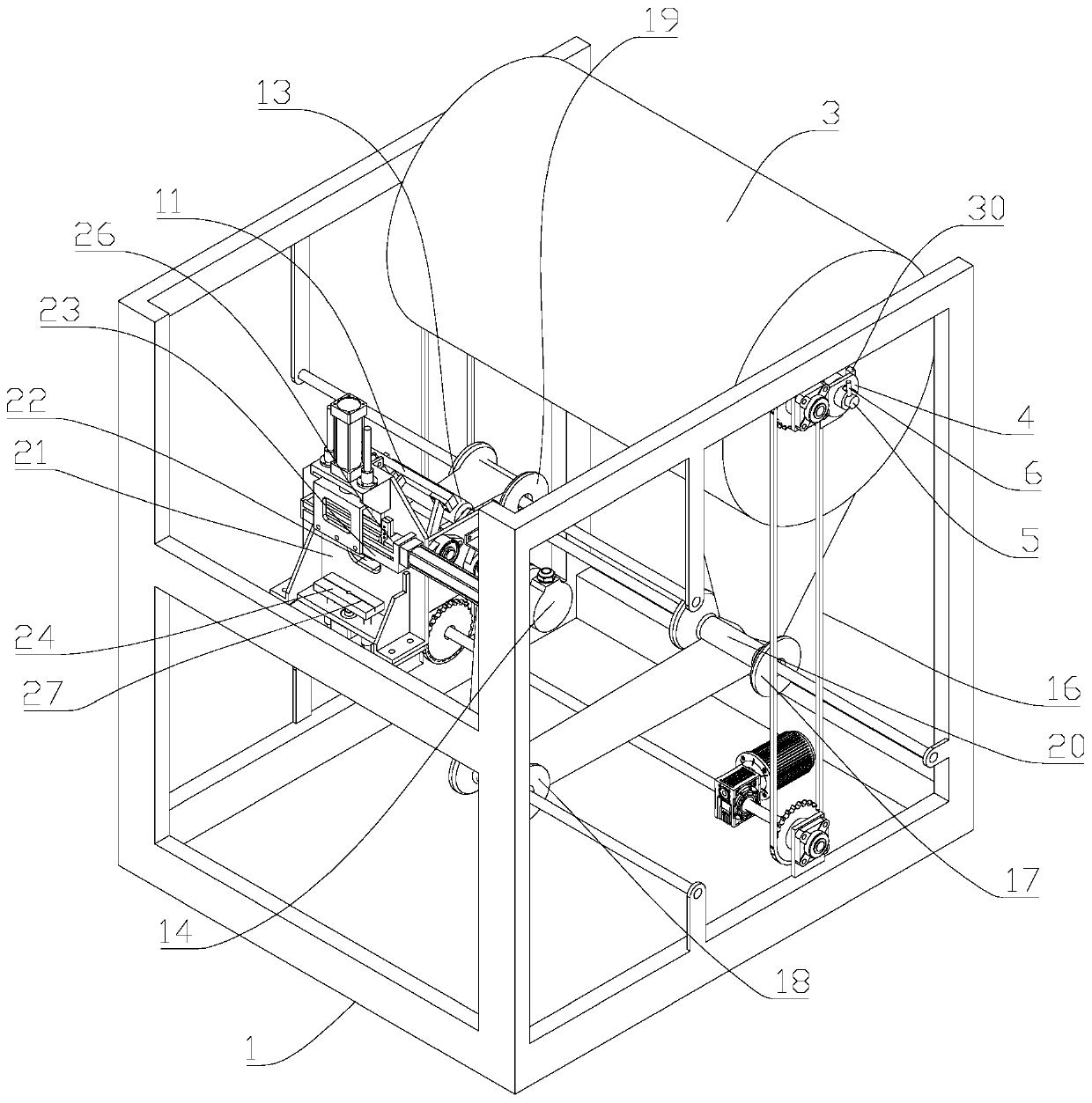

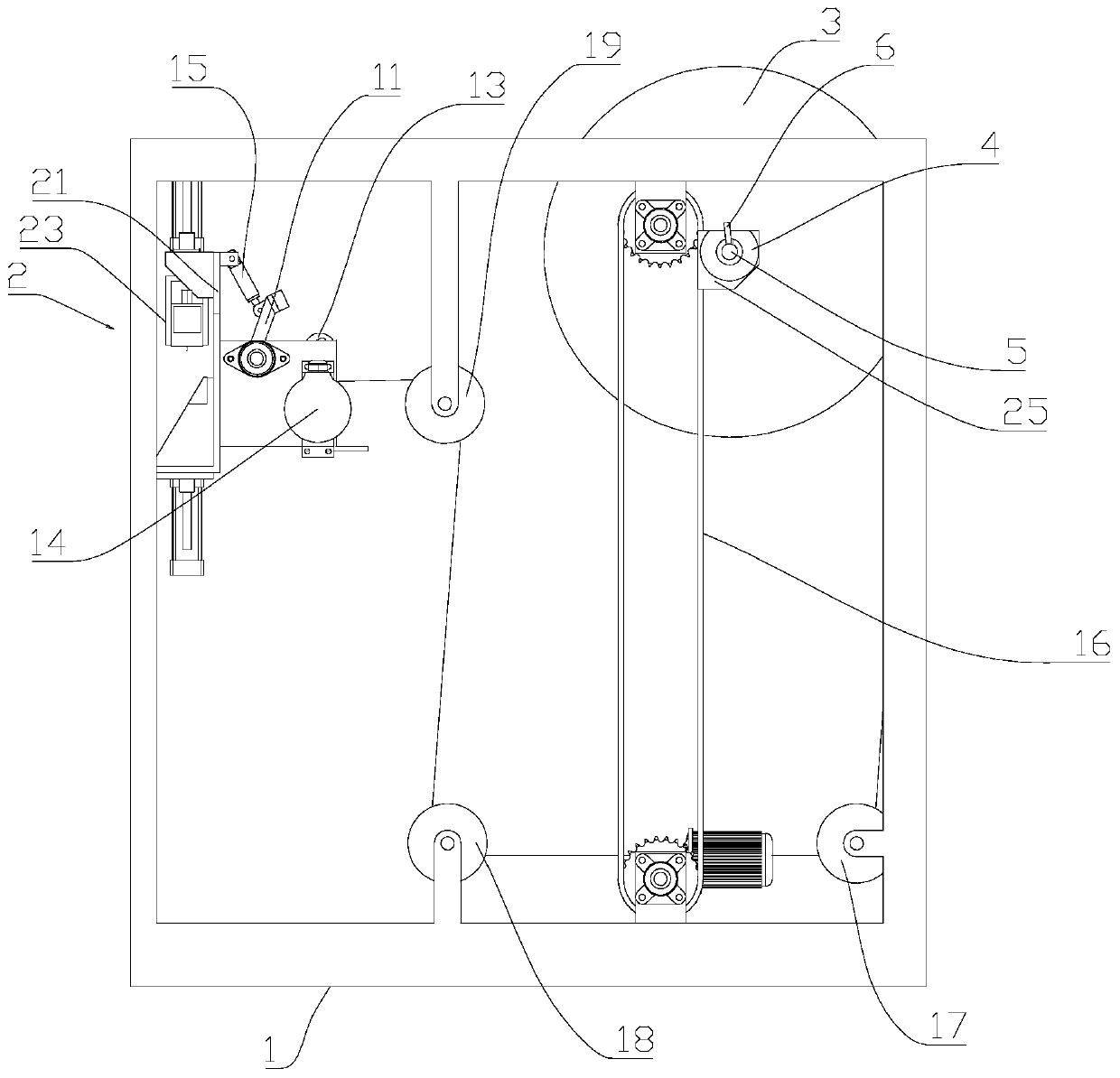

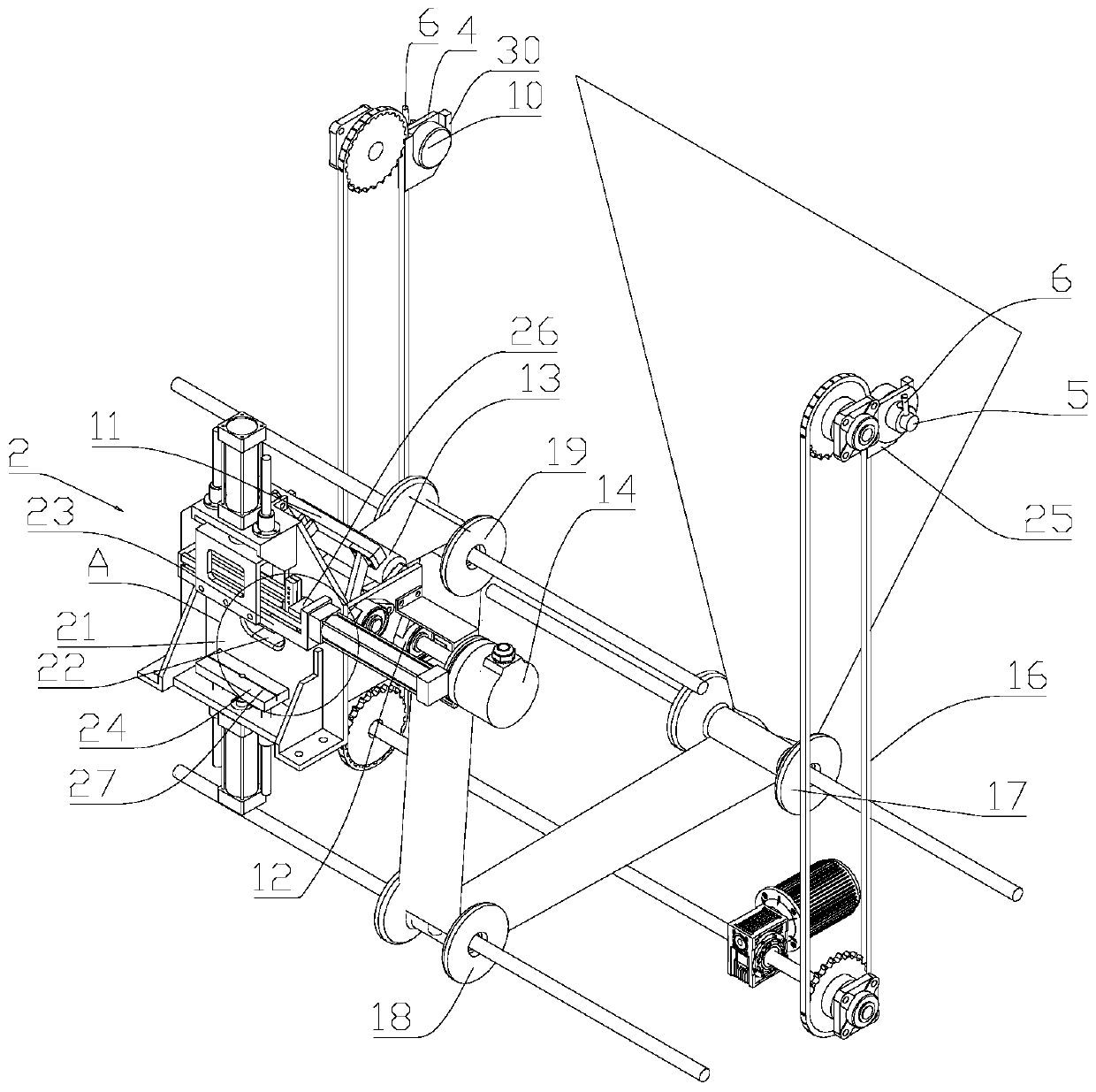

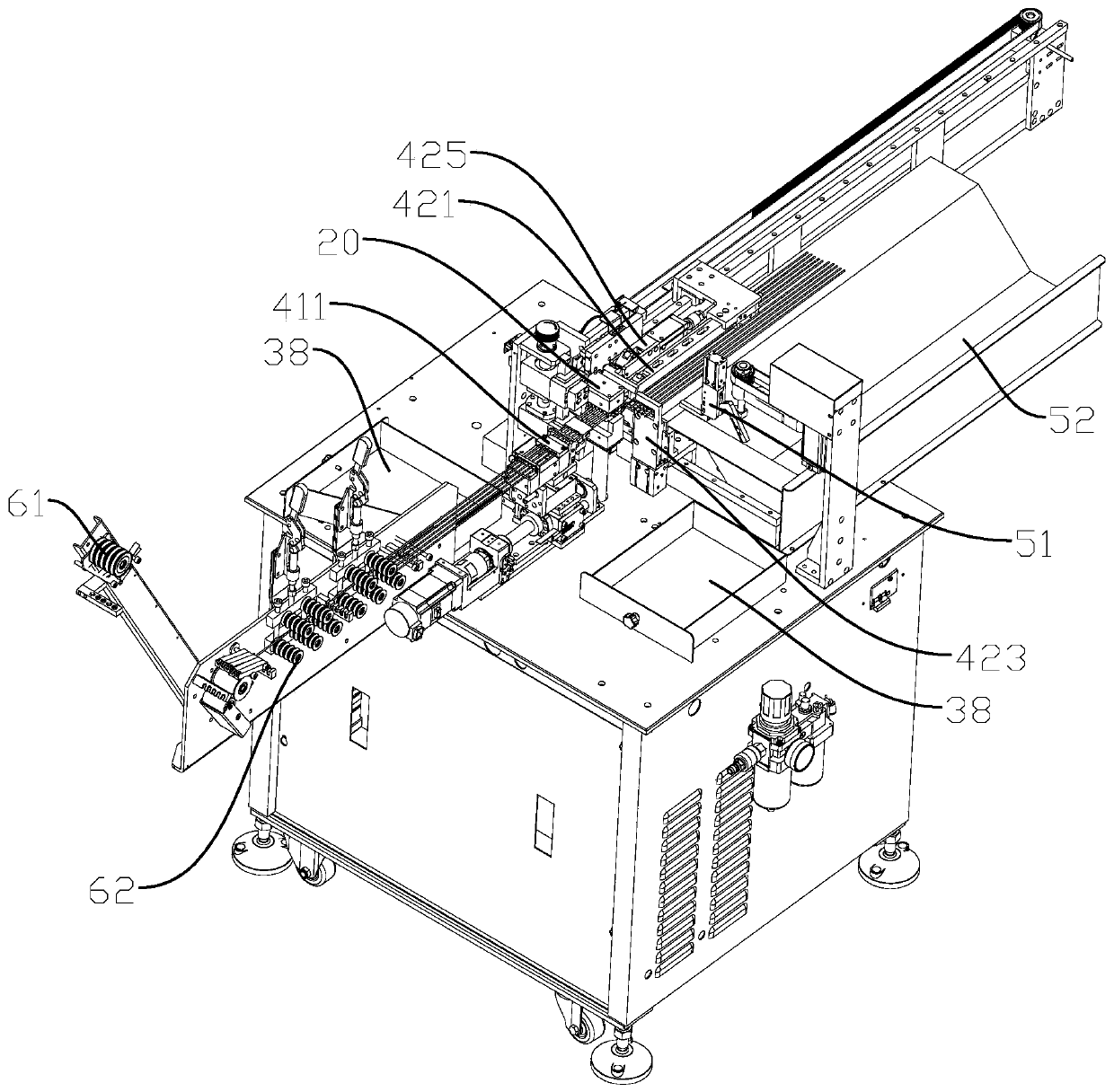

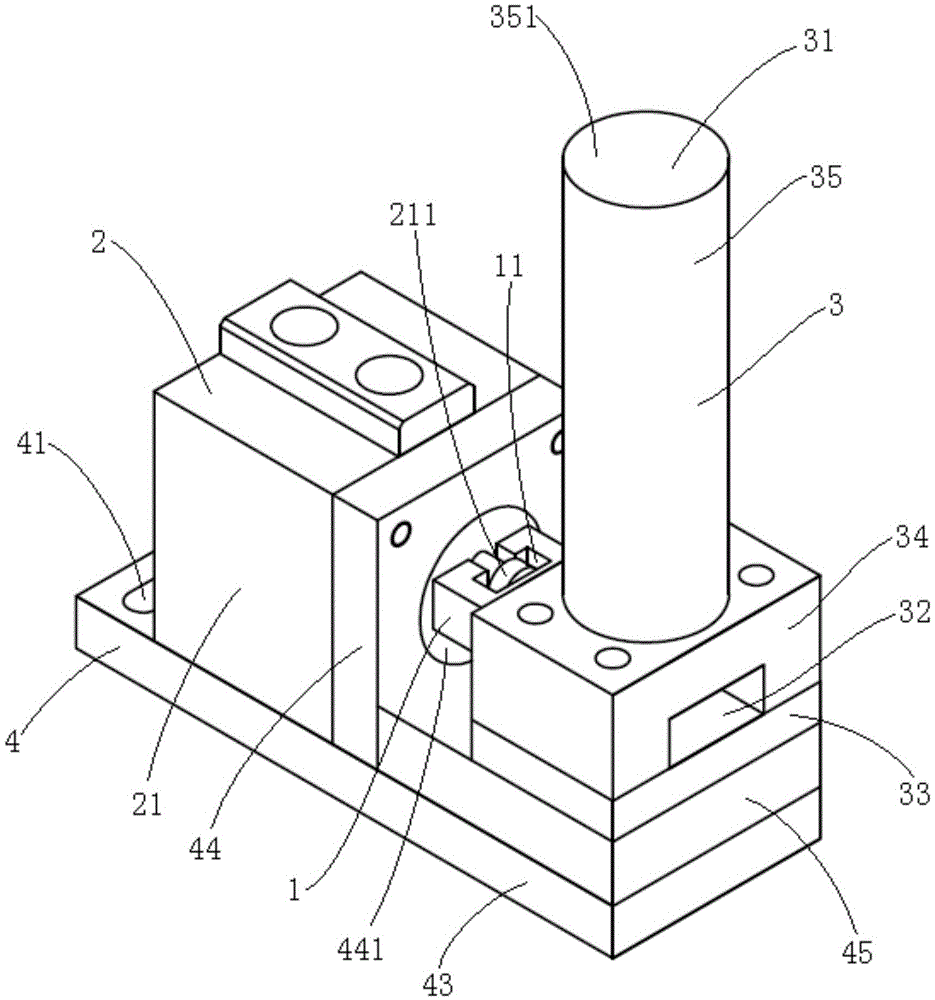

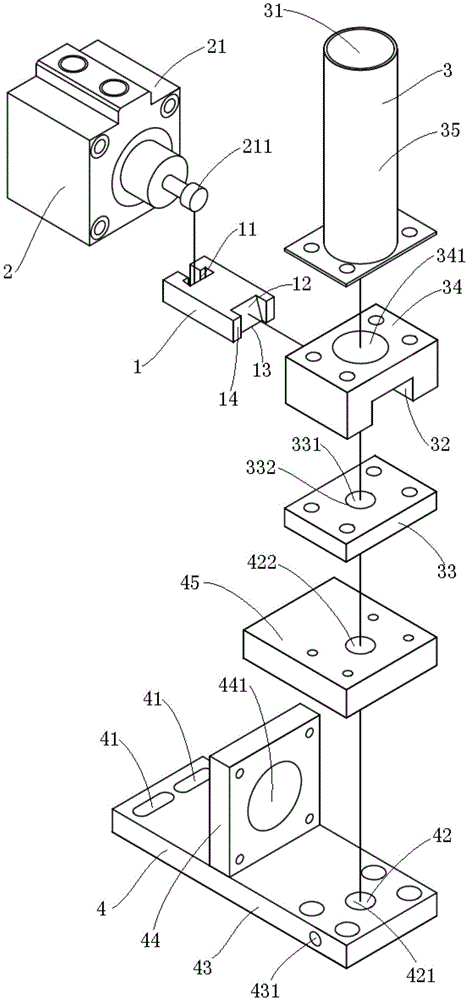

A geogrid welding machine

ActiveCN103056564BRealize automatic feedingRealize automatic croppingWelding/cutting auxillary devicesOther manufacturing equipments/toolsStopped workEngineering

The invention discloses a geogrid welding machine. When a feeder transversely sends materials, the materials are fed into a second clamping device along a leading device; when the materials reach a preset position in the second clamping device, the feeder stops working under control of a controller. At the same time, a first clamping device and the second clamping device can respectively clamp the two ends of the materials, then the controller controls a trimming device to cut off the materials, afterwards, the controller controls a first cylinder to enable the first clamping device and the second clamping device to move along their own guide rails and enable the materials to be disposed right above a lower die and right under an upper die. At this moment, a second cylinder moves under control of the controller to enable the upper die to depress the materials down on the lower die. Then a plum joint under control of the controller welds the tap of a transverse strip belt and a longitudinal strip belt. The geogrid welding machine has the advantages of automatic feeding, automatic cutting and automatic welding.

Owner:SUZHOU KEBER PRECISION MACHINERY

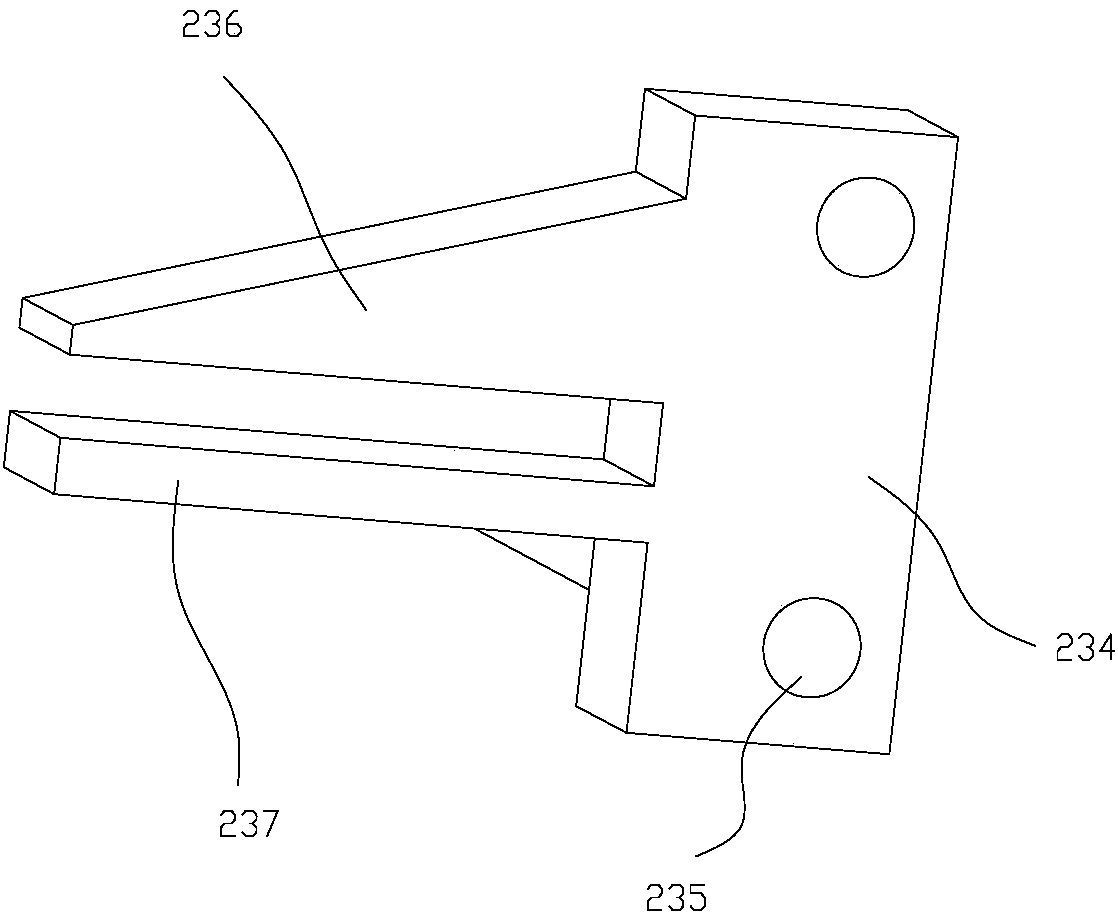

A garment multifunctional sewing machine

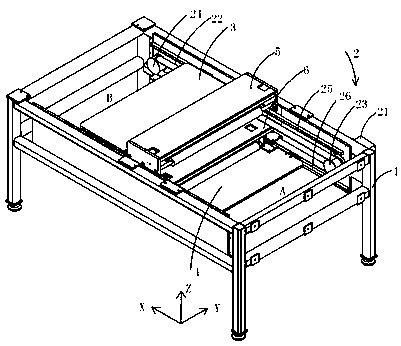

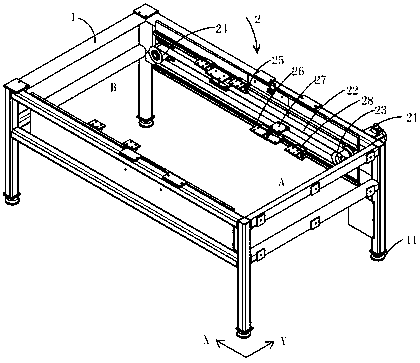

ActiveCN105887369BMeet different process requirementsImprove efficiencyWorkpiece carriersWork-feeding meansControl systemEngineering

The invention discloses a multifunctional garment sewing machine which comprises a rack and a control system, wherein a worktable and a rotating mechanism are arranged on the rack; a plurality of working areas are formed in the worktable; the rotating mechanism comprises a rotating disc; the rotating disc is arranged in the middle of the worktable; a first rotating shaft which rotates along the rotating disc is longitudinally arranged on the rotating disc; the first rotating shaft is composed of a plurality of equally divided intervals; the number of the intervals is equal to that of the working areas; the bottom of each interval is connected with the rotating disc by virtue of a Y-axis transmission mechanism so as to realize Y-direction movement of the intervals on the rotating disc; a second rotating shaft is transversely arranged on each interval; a plurality of working groups with different using functions are arranged on the second rotating shaft; the plurality of working groups are respectively uniformly and fixedly distributed on the second rotating shaft by taking the second rotating shaft as an axis and are positioned just above the worktable; and function switching of the working groups is realized by virtue of rotation of the second rotating shaft. According to the invention, the rotating mechanism is combined with the plurality of working groups, so that function selection diversity and automatic operation are realized.

Owner:南京润泽华针纺织科技发展有限公司

Automatic cutting device for terminal waste materials

InactiveCN105458386ARealize automatic croppingSimple structureShearing machinesShearing machine accessoriesReciprocating motionWaste material

The invention provides an automatic cutting device for terminal waste materials. The automatic cutting device comprises a movable cutting knife, a driving unit connected with the movable cutting knife and a guiding unit with a waste material guiding channel. The waste material guiding channel is used for allowing the continuous terminal waste materials to pass through. A cutting knife guide groove communicated with the waste material guiding channel in a crossed mode is arranged in the guiding unit. The cutting end of the movable cutting knife is embedded in the cutting knife guide groove, and the movable cutting knife can move back and forth in the cutting knife guide groove. When the automatic cutting device for the terminal waste materials is used, the continuous strip-shaped terminal waste materials flow downwards along the waste material guiding channel; meanwhile, under the action of the driving unit, the movable cutting knife is driven to feed forward; accordingly, the continuous strip-shaped terminal waste materials are cut off, and automatic cutting conducted on the terminal waste materials is achieved. In addition, the automatic cutting device is simple in structure, low in production cost and convenient to popularize and use.

Owner:上海元一电子有限公司

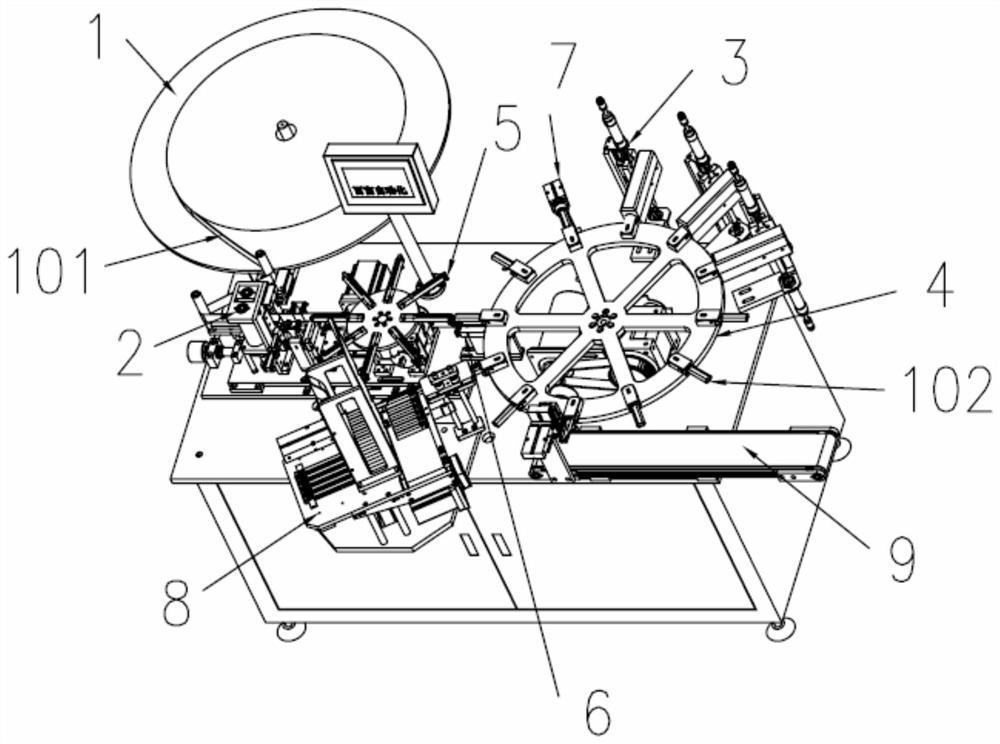

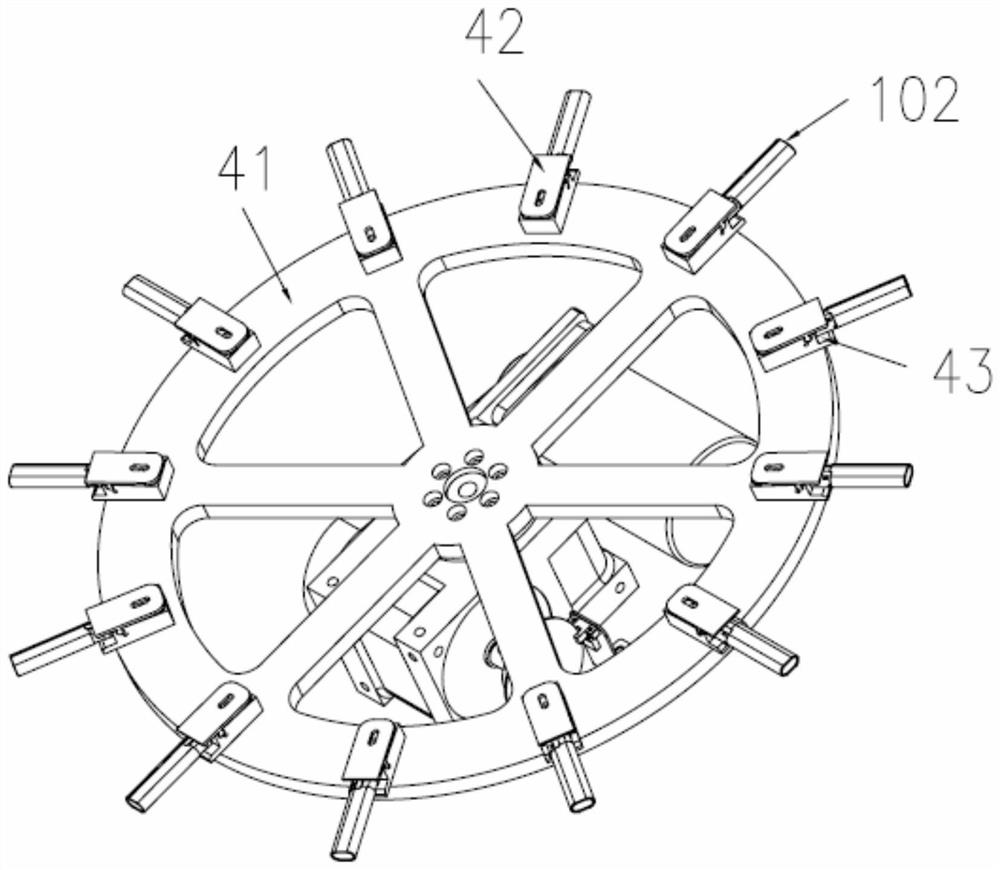

A fully automatic assembly machine for lighter heat-shrinkable sleeves

ActiveCN109986346BRealize automatic croppingImplement automatic assemblyMetal working apparatusProcess engineeringIndustrial engineering

The invention discloses a fully-automatic assembling machine of a lighter heat shrinking tube sleeve. The fully-automatic assembling machine of the lighter heat shrinking tube sleeve includes a feeding tray mechanism, a material belt automatic feeding mechanism, a steam baking mechanism, a lighter feeding rotating tray mechanism, a tube sleeve feeding rotating tray mechanism, a material sleeving assembly, a lighter fully-automatic distributing mechanism, a finished product discharging mechanism, so that fully-automatic assembling of the lighter heat shrinking tube sleeve is realized, the workefficiency and quality are improved, and the manual cost is also lowered.

Owner:龚培生

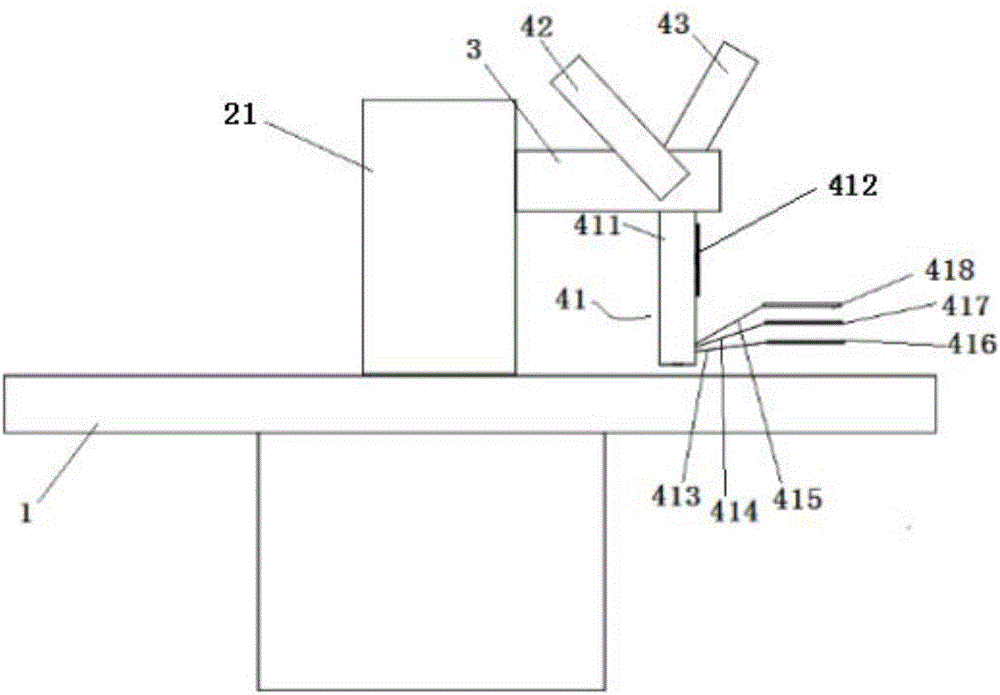

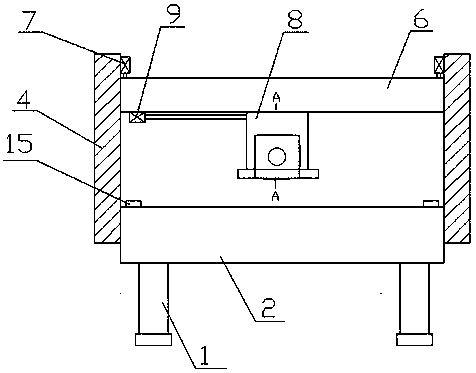

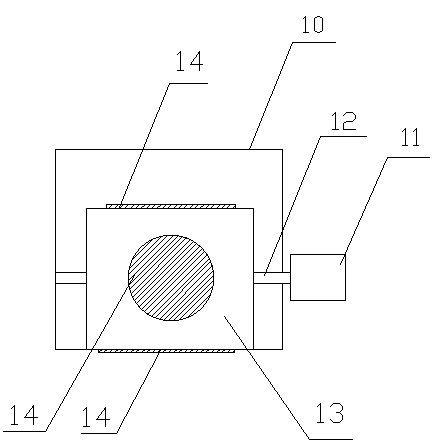

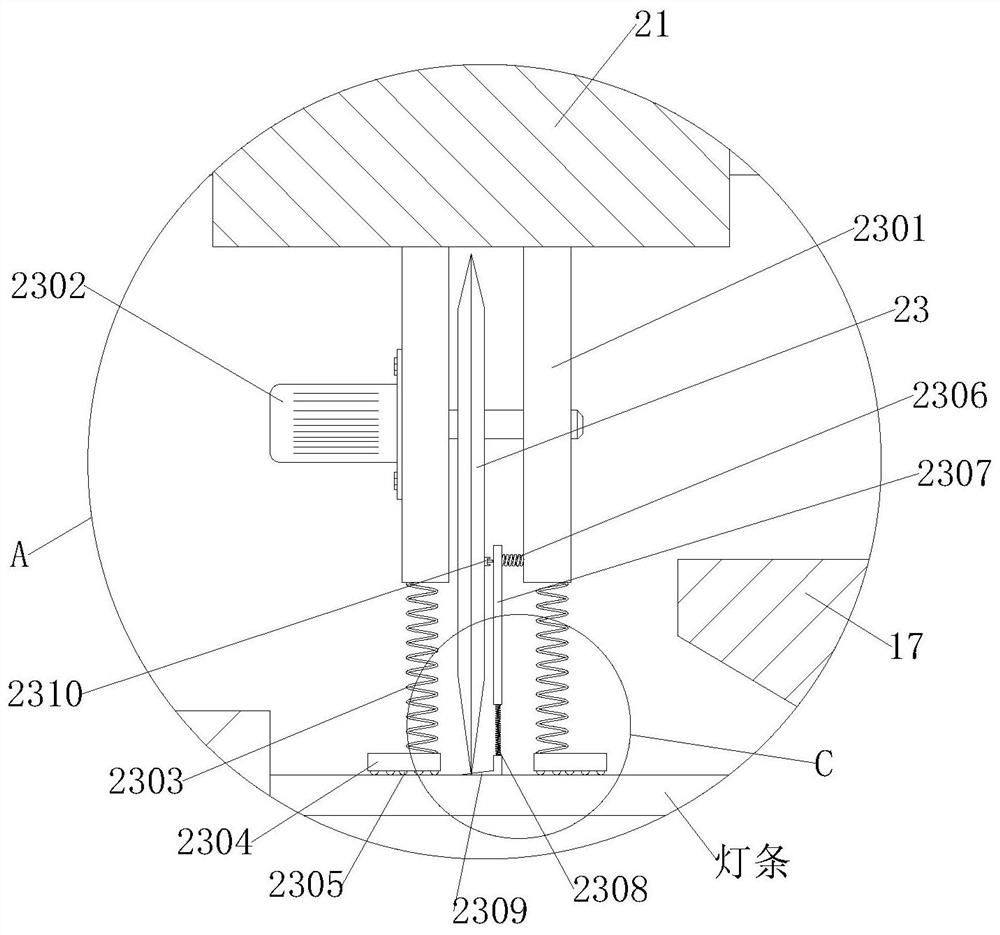

LED light-emitting bulb production and machining technology

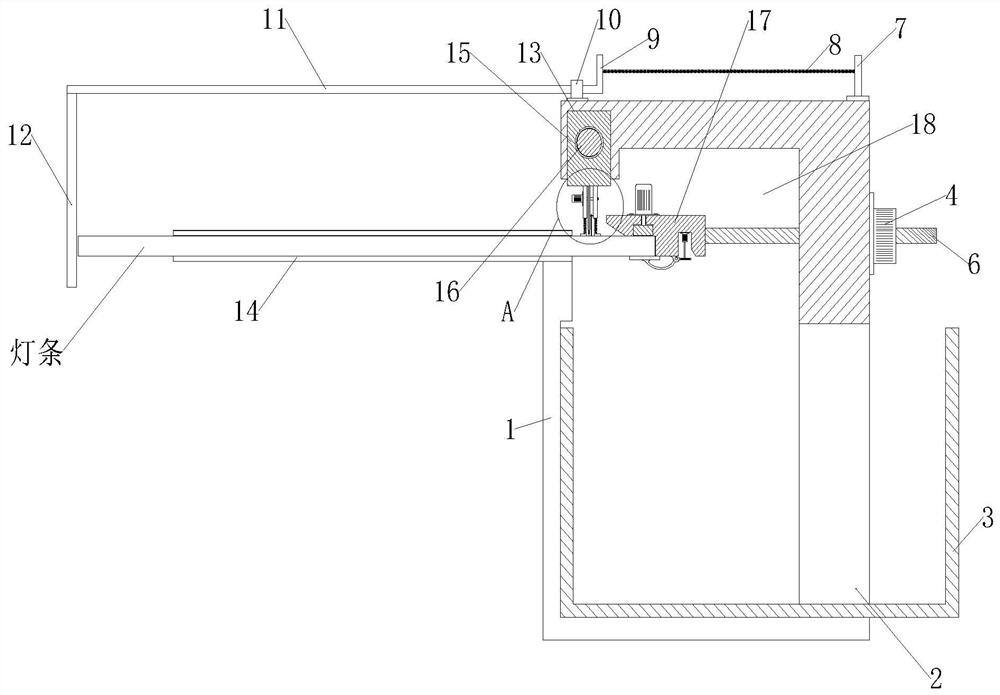

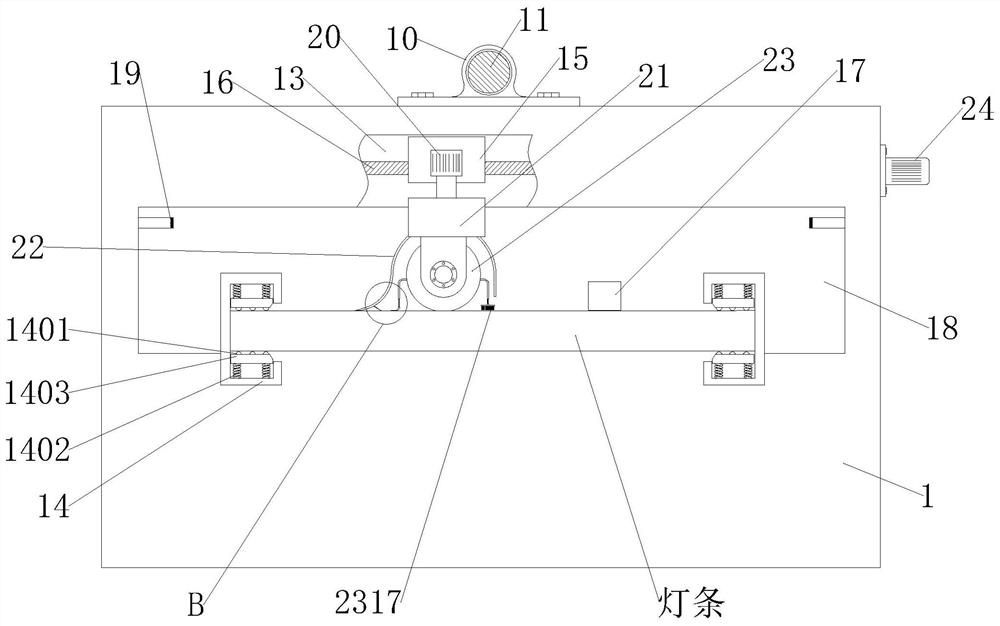

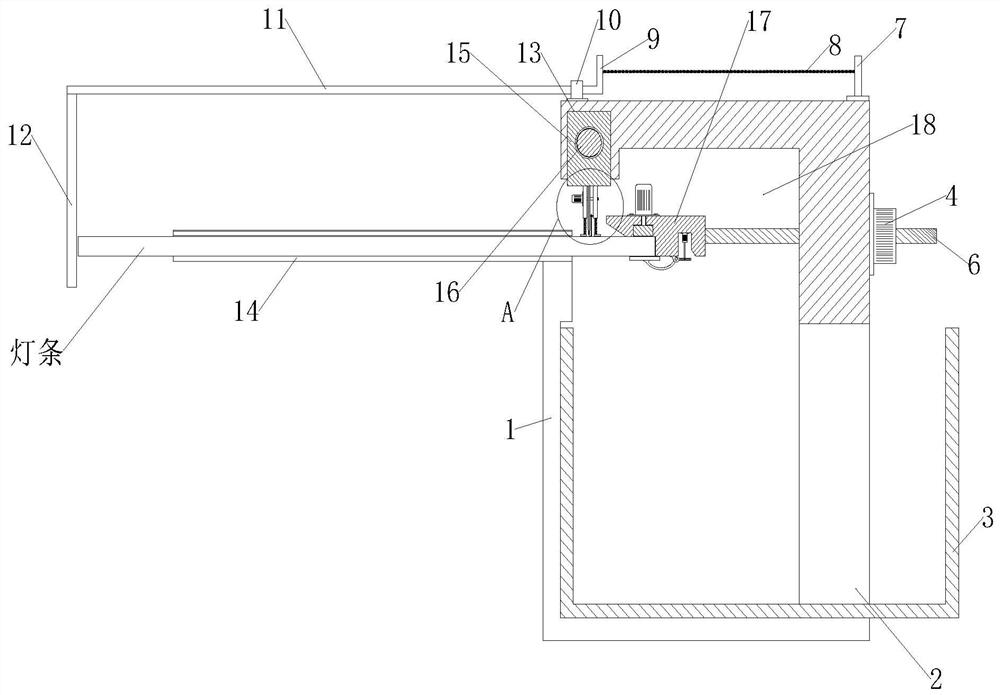

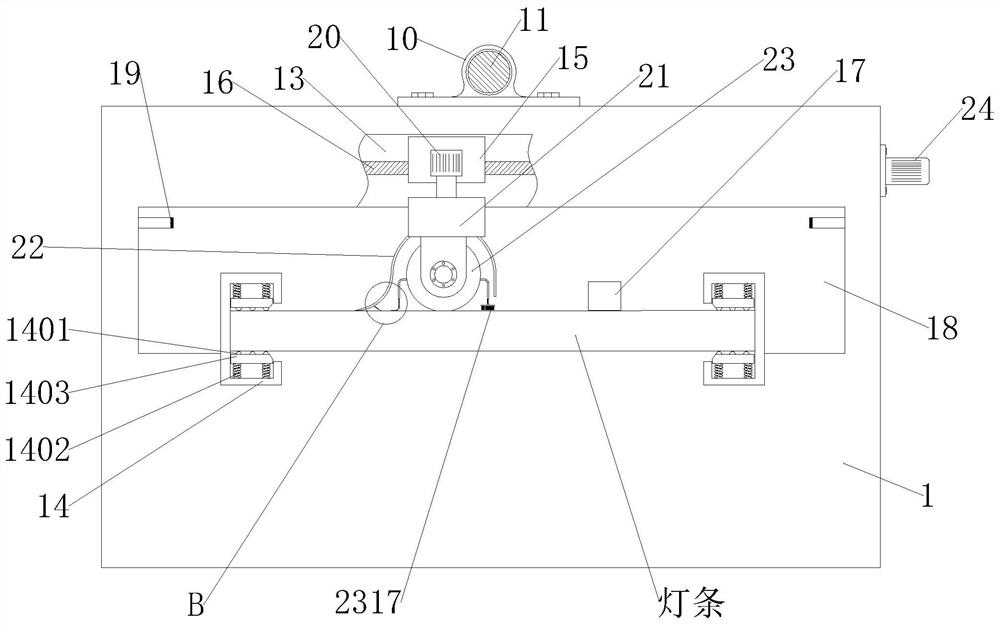

ActiveCN112549102AHigh continuous production efficiencyHigh positioning accuracyMetal working apparatusEngineeringMachining

The invention provides an LED light-emitting bulb production and machining technology and relates to the technical field of LED light-emitting bulbs. The LED light-emitting bulb production and machining technology is completed by cooperation of an LED light-emitting bulb production and machining device. The LED light-emitting bulb production and machining device comprises a cutting machine, and the cutting machine is a square box body with a hollow middle part. A cutting opening is formed in the position, close to the top end of the cutting machine, of the left end of the cutting machine, a storage notch is formed in the bottom of the right end of the cutting machine, and a storage box is installed in the storage notch in a sliding connection mode. According to the LED light-emitting bulbproduction and machining technology, multiple second balls of ball structures are arranged on the bottom faces of pressing feet at equal intervals, so that the pressing feet roll at the top end of a light bar, scratches of the pressing feet to the surface of the light bar are reduced, the pressing feet slide more stably on the surface of the light bar through the second balls, and therefore vibration generated on the surface of the light bar when the pressing feet slide on the surface of the light bar is reduced, and the cutting precision of a cutting knife is further improved.

Owner:金华橙果环保科技有限公司

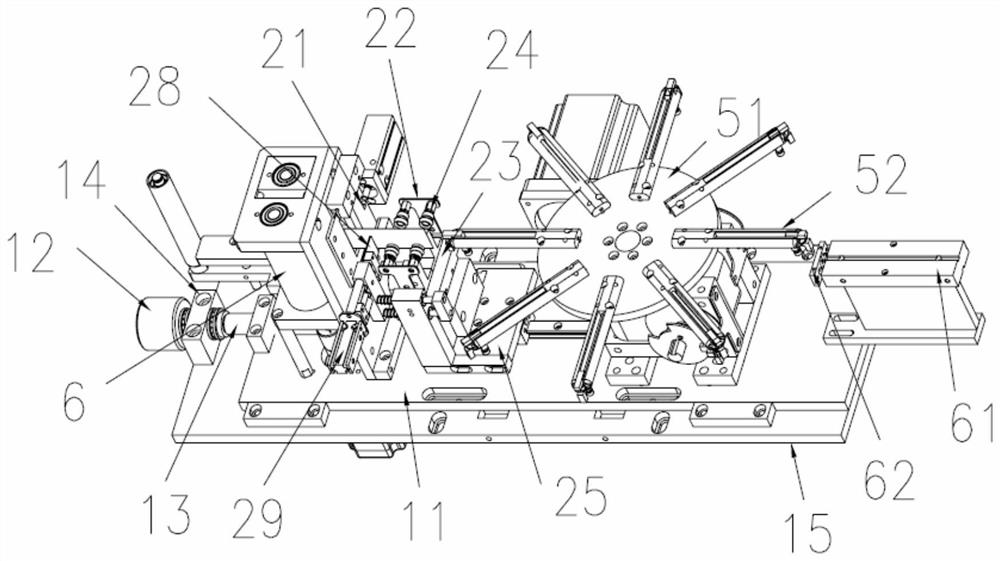

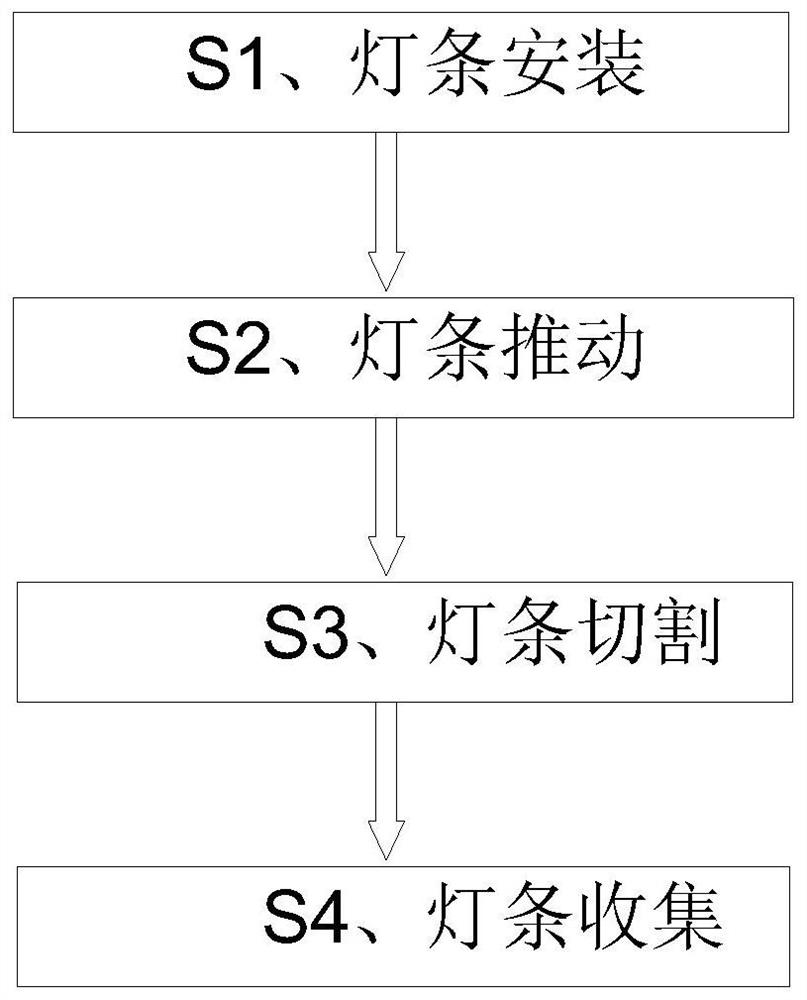

A kind of LED light strip production and processing equipment and processing method thereof

ActiveCN112372731BHigh continuous production efficiencyHigh positioning accuracyMetal working apparatusEngineeringMaterial storage

The invention provides a LED light bar production and processing equipment and a processing method thereof, and relates to the technical field of LED light bulbs. The LED light bulb production and processing process is completed by a LED light bulb production and processing device. The LED light bulb production and processing device Including a cutting machine, the cutting machine is a hollow square box in the middle, a cutting opening is opened at the left end of the cutting machine close to the top of the cutting machine, a storage slot is opened at the bottom of the right end of the cutting machine, and a storage slot is opened in the storage slot A material storage box is installed through a sliding connection; the bottom surface of the pressing foot of the present invention is equidistantly provided with several second balls with a spherical structure, so that the pressing foot rolls on the top of the light bar, reducing the pressure on the sole of the pressing foot facing the light bar Scratching on the surface, through several second balls, the pressing foot slides more smoothly on the surface of the light bar, thereby reducing the vibration on the surface of the light bar when the pressing foot slides on the surface of the light bar, and further improving the cutting accuracy of the cutting knife Spend.

Owner:金华橙果环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com