Adhesive tape pasting machine

A technology for sticking tape and tape, applied in the directions of sending objects, thin material handling, transportation and packaging, etc., can solve the problems of inaccurate size of cutting, easy movement of position, and reduced work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

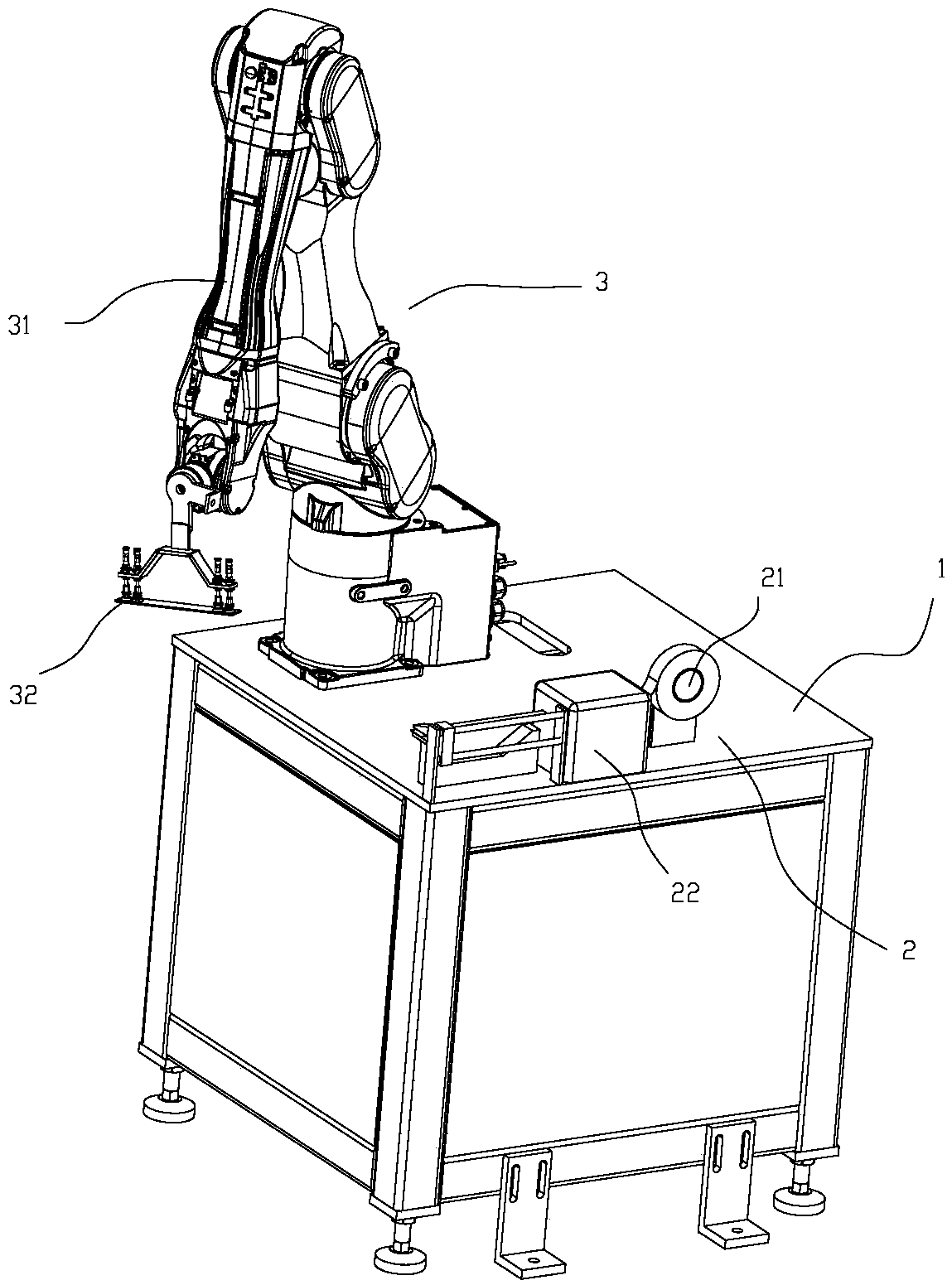

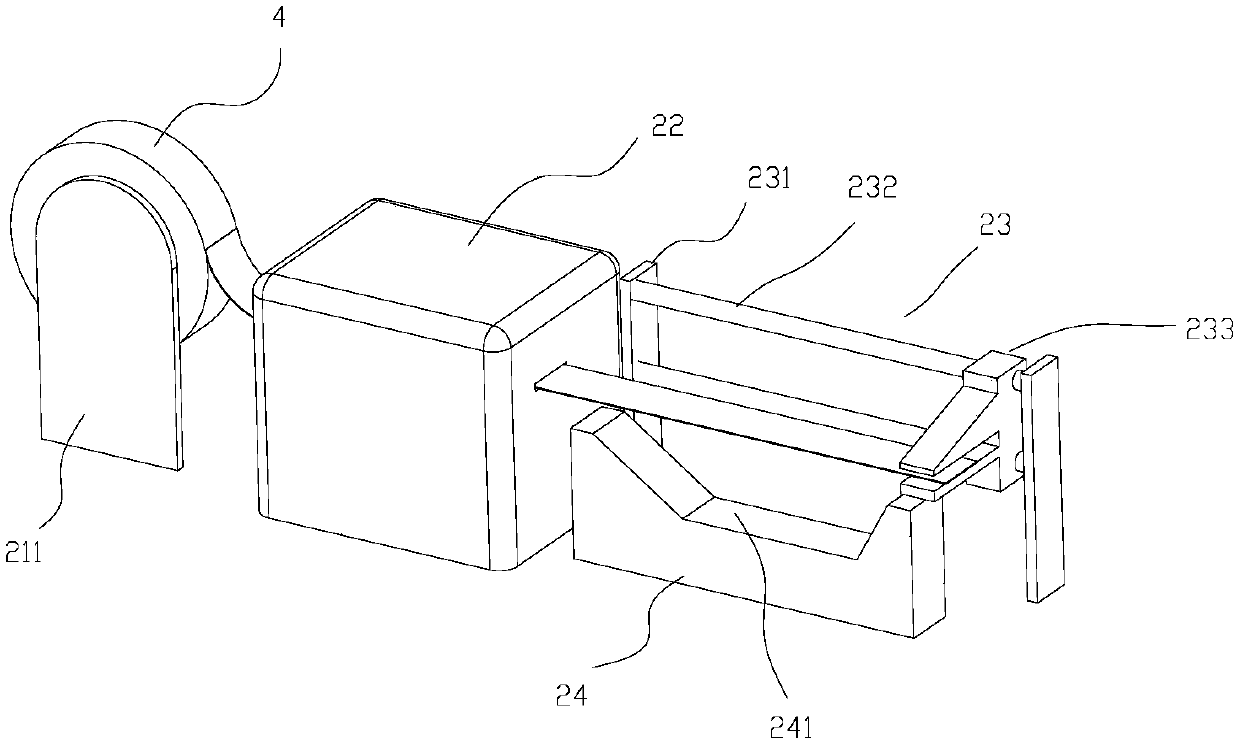

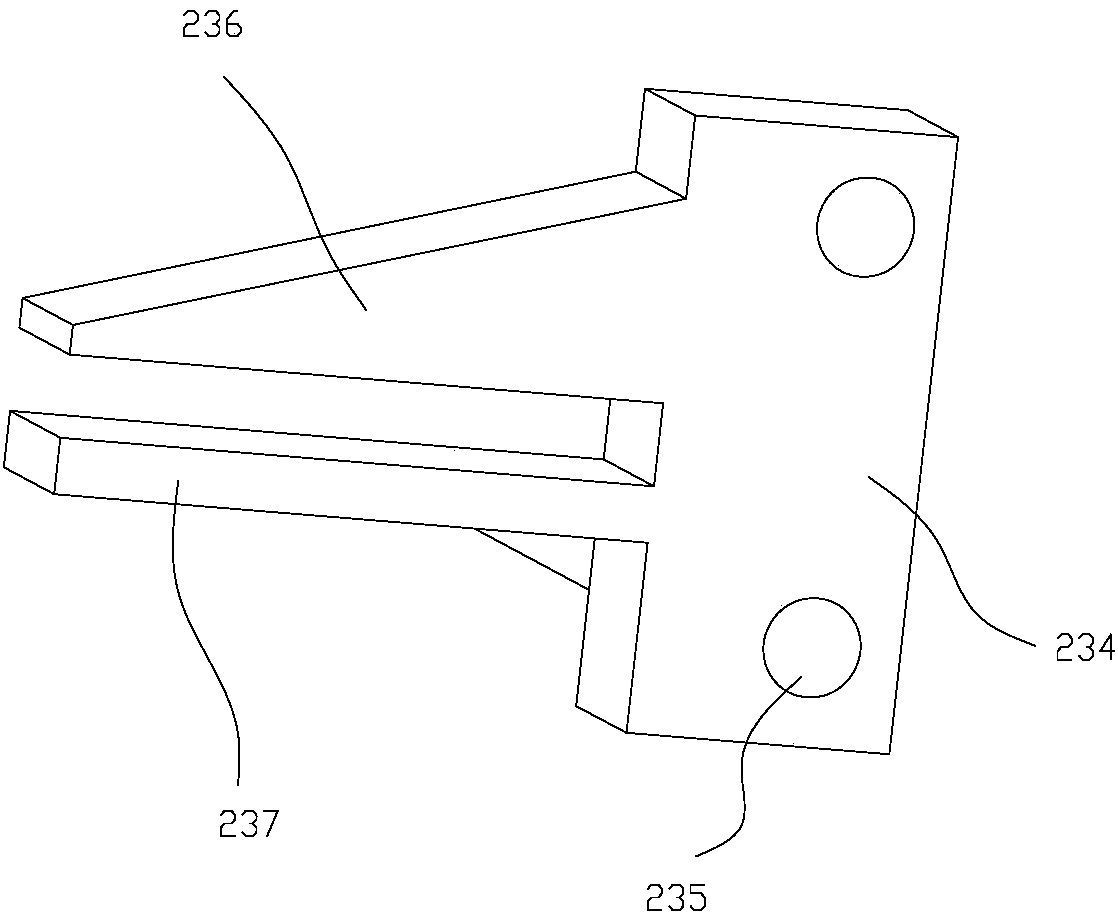

[0017] see Figure 1-Figure 3 , the invention discloses a tape sticking machine, comprising a cutting mechanism 2 and a suction mechanism 3, the cutting mechanism 2 includes a sleeve 21 for winding the tape 4, a supporting part 22 for supporting the tape 4, a The clamping part 23 that is arranged on the downstream of the supporting part 22, the clamping part 23 includes a mounting frame and a clamping claw 233 slidingly connected on the mounting frame, and the clamping claw 233 is used to clamp and stretch the freedom of the adhesive tape 4. end; a cutting knife, the cutting knife is located at the end of the material holding part 22, and the cutting tape 4 is driven by a driver, preferably driven by an air cylinder or an electric cylinder. The suction mechanism 31 includes a manipulator 31 fixed on the workbench 1 and a suction cup 32 connected to the manipulator 31. The manipulator 31 can drive the suction cup 32 to suck and attach the cut tape.

[0018] Specifically, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com