Numerical control cutting machine

A technology of cutting machine and stepping motor, which is applied in metal processing and other directions, can solve the problems of low working efficiency, insufficient safety performance and high labor intensity of cutting machine, and achieve the goal of improving production efficiency, obvious energy saving and high degree of automation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

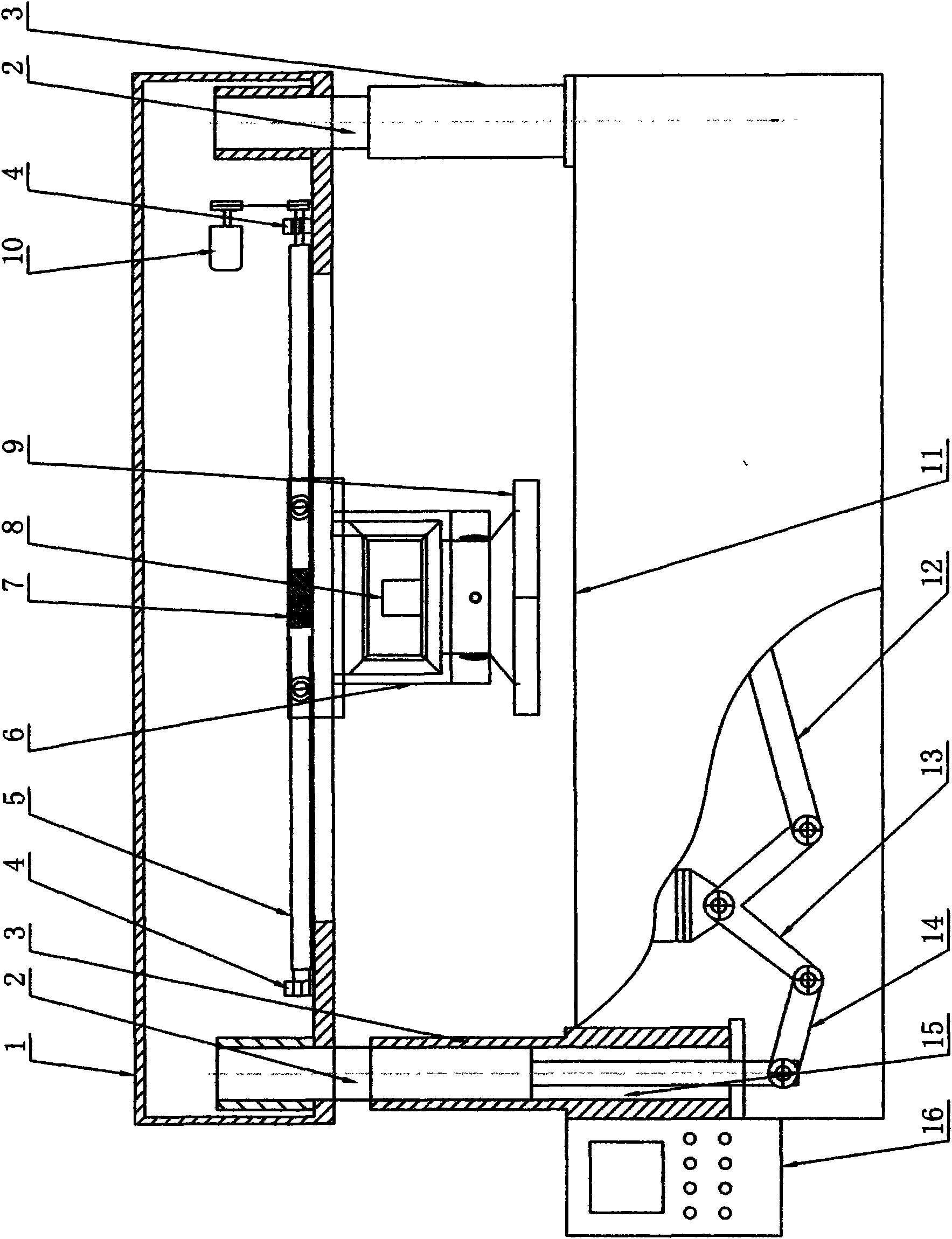

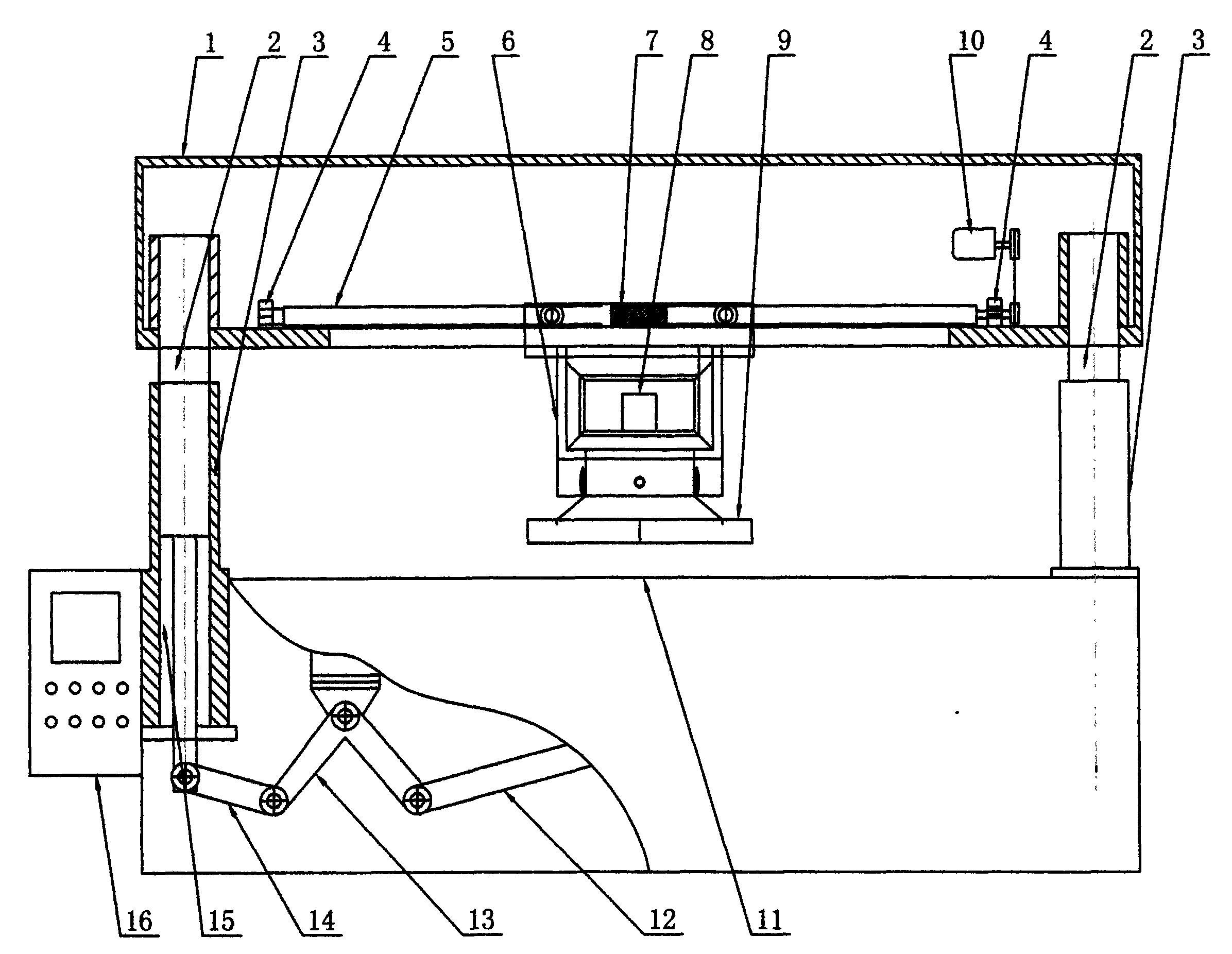

[0011] In the figure: the upper workbench 1 is a rectangular shape, two guide pillars 2 are arranged at the center of the two tops of the bottom surface to connect with the two guide sleeves 3 above the workbench 11, and the upper workbench 1 is provided with a ball screw 5 inside, The screw support base 4 is arranged on the two top ends of the ball screw 5, and the ball screw 5 protrudes from one end of the screw support base 4, and a sprocket is provided on the sprocket, and a chain is arranged on the sprocket to connect with the sprocket on the servo motor 10. , the upper end of the numerically controlled moving head 6 is provided with a connecting seat 7, the connecting seat 7 is connected with the ball screw 5, a stepping motor 8 is provided at the center of the numerically controlled moving head 6, and a rotary mold base 9 is provided at the lower end of the numerically controlled moving head 6, The top of the rotary mold base 9 is provided with a cutting die, the lower p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com