Efficient cloth spreading equipment for clothing materials for garment processing

A high-efficiency technology for clothing materials, applied in the field of high-efficiency spreading equipment for clothing materials for clothing processing, can solve the problems of easy deviation and wrinkling of fabrics, taking a long time, reducing work efficiency, etc., to enhance device stability and enhance stability. , Improve the effect of cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a high-efficiency spreading equipment for clothing materials for garment processing includes a support column 1, a workbench 2, a moving mechanism 3, a fabric pulling mechanism 4, and a cutting mechanism 5. The bottom of the workbench 2 is symmetrically and evenly spaced with support columns 1 , The top of the workbench 2 is provided with a moving mechanism 3, the moving mechanism 3 is provided with a pulling mechanism 4, and the pulling mechanism 4 is provided with a cutting mechanism 5.

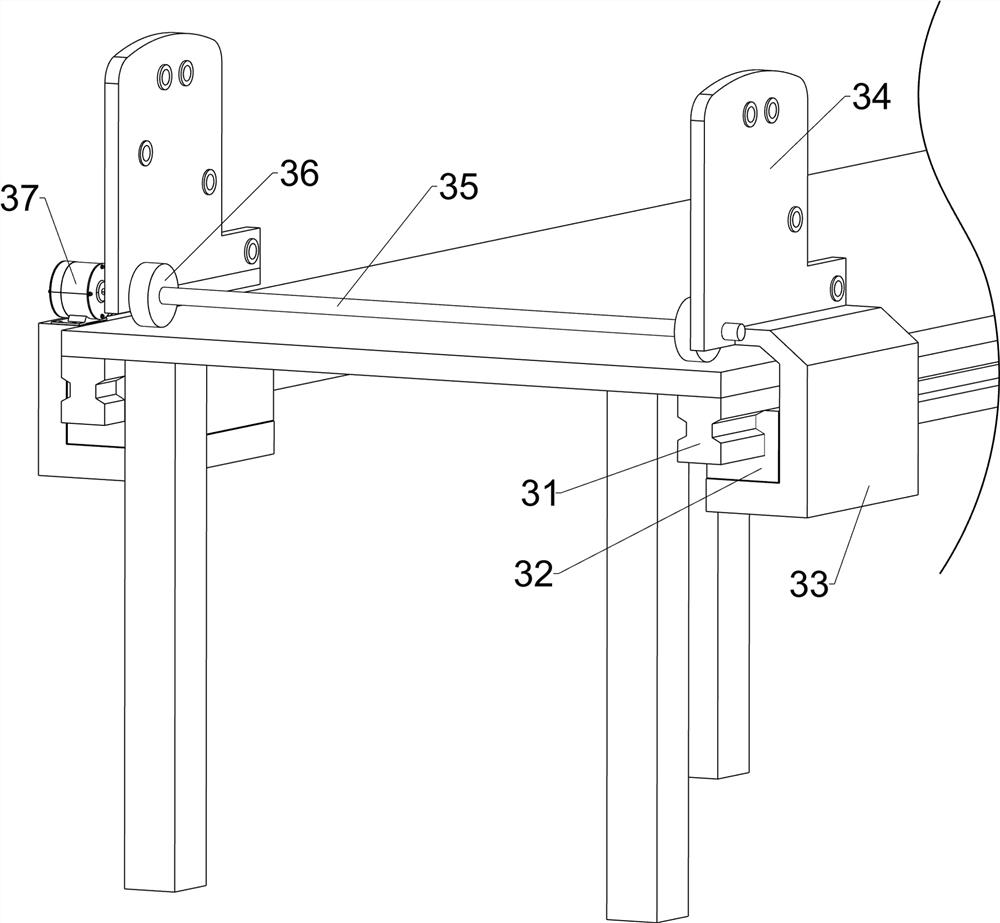

[0028] The moving mechanism 3 includes a slide rail 31, a slide table 32, a connecting frame 33, a first side plate 34, a first rotating shaft 35, a roller 36 and a first servo motor 37. A sliding platform 32 is provided on the rail 31, a connecting frame 33 is provided on the sliding platform 32, a first side plate 34 is provided on the top of the connecting frame 33, and a first side plate 34 is arranged on the bott...

Embodiment 2

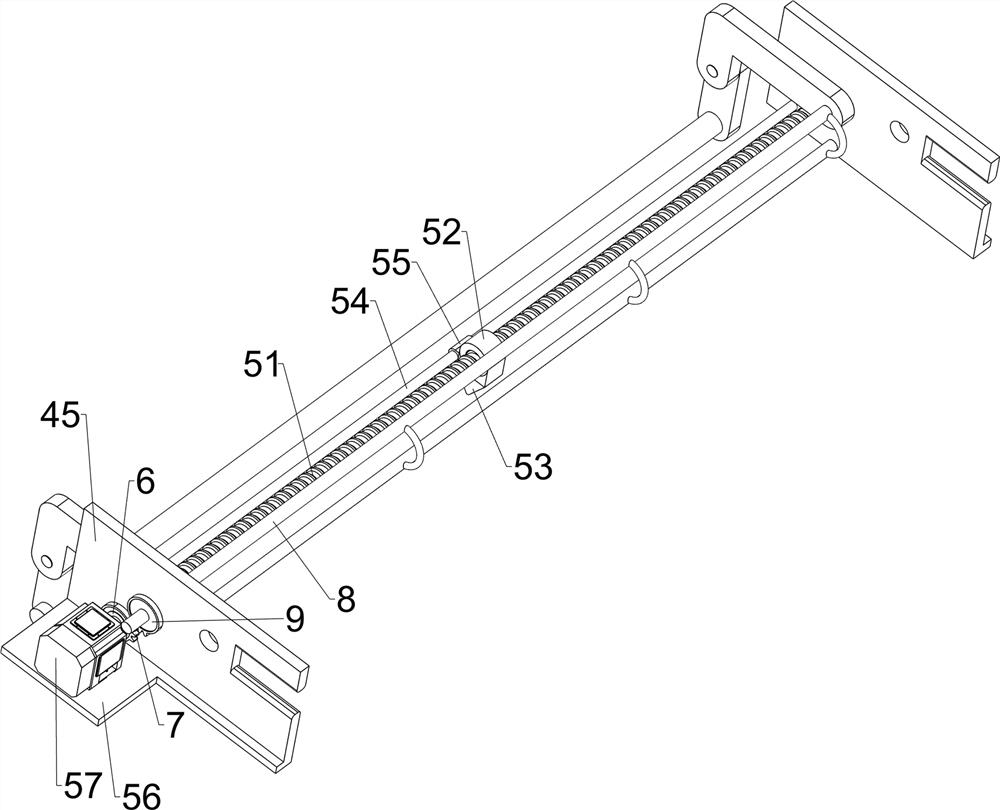

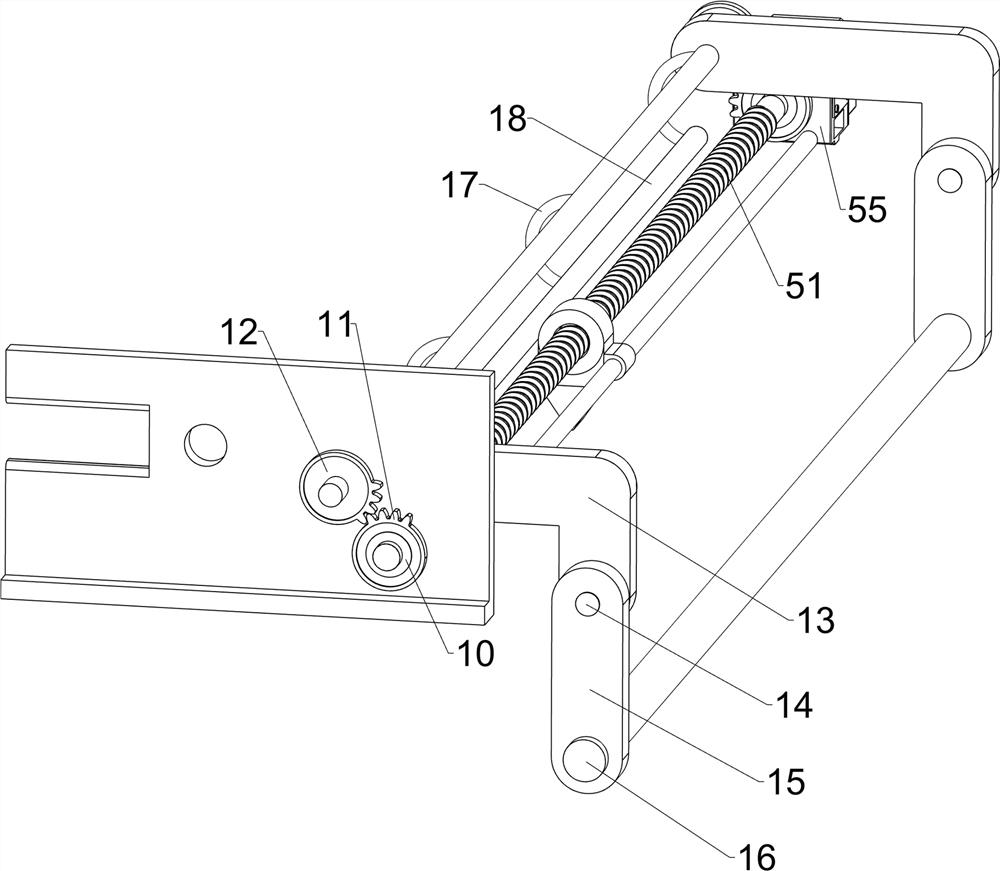

[0033] Such as Figure 4 , Figure 5 , Figure 6 and Figure 7 Shown, on the basis of embodiment 1, a kind of clothing material efficient spreading equipment for garment processing also includes the third one-way bearing 6, the first missing gear 7, the fifth rotating shaft 8, the second missing gear 9, the first Four one-way bearings 10, the third missing gear 11, the fourth missing gear 12, swing bar 13, latch 14, connecting rod 15, first pressing bar 16, bending bar 17 and second pressing bar 18, screw mandrel 51 right-hand ends are arranged There is a third one-way bearing 6, the outer ring of the third one-way bearing 6 is provided with a first missing gear 7, and a fifth rotating shaft 8 is arranged between the two second side plates 45 close to the position of the screw rod 51, and the fifth The end of the rotating shaft 8 close to the first missing gear 7 is provided with a second missing gear 9, the second missing gear 9 meshes with the first missing gear 7, the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com