Automatic cutting and conveying device of trademark paper of woven bags or mesh bags

A technology of conveying device and trademark paper, which is applied in the directions of transportation and packaging, textile and papermaking, and cutting of textile materials, etc., can solve the problems of increasing labor costs and time costs, increasing production costs, and the packaging is not beautiful enough to save labor costs. and time cost, beautiful appearance, and the effect of ensuring cutting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

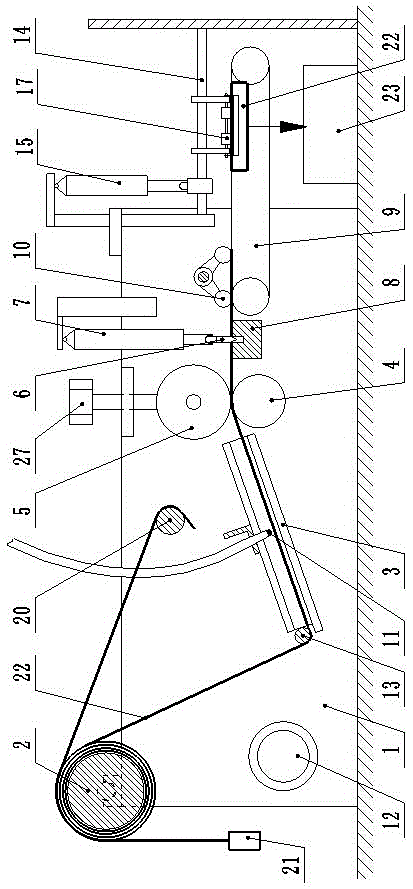

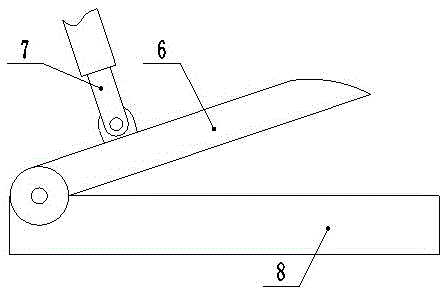

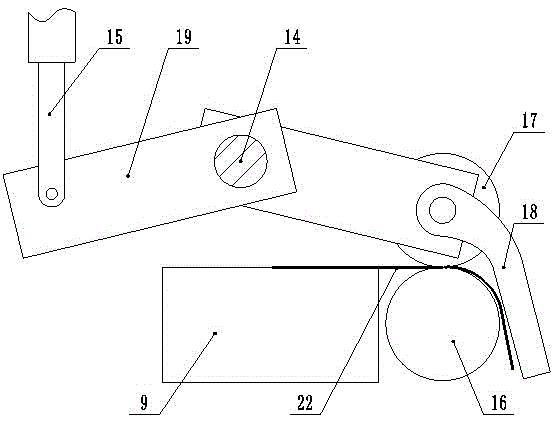

[0024] Such as Figure 1-4 As shown, the woven bag or mesh bag trademark paper automatic cutting and conveying device of the present invention includes a box body 1, a paper reel 2, a fixed frame 3, a conveying driving wheel 4, a first pressure wheel 5, a cutting device, and a conveyor belt 9 , the second pressure roller 10, the unloading device, the detection head 11, the motor 12 and the control center, the paper reel 2 is installed at one end of the box body 1, the fixed frame 3 is fixedly installed inside the box body 1 and it is close to the paper reel 2 One side of one side is provided with reversing round bar 13, and fixed frame 3 opposite sides are installed with active conveying wheel 4, cutting device, conveyer belt 9 and unloading device successively, and conveying driving wheel 4 is close to the outlet end of fixed frame 3 and its The matching first pressure roller 5 is installed above, the conveyor belt 9 is close to the outlet end of the cutting device and the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com