Patents

Literature

128results about How to "Realize automatic picking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Robot picking implementation method and device, and electronic equipment

ActiveCN108537841AAccurate estimateRealize automatic pickingProgramme-controlled manipulatorImage enhancementMachine visionComputer graphics (images)

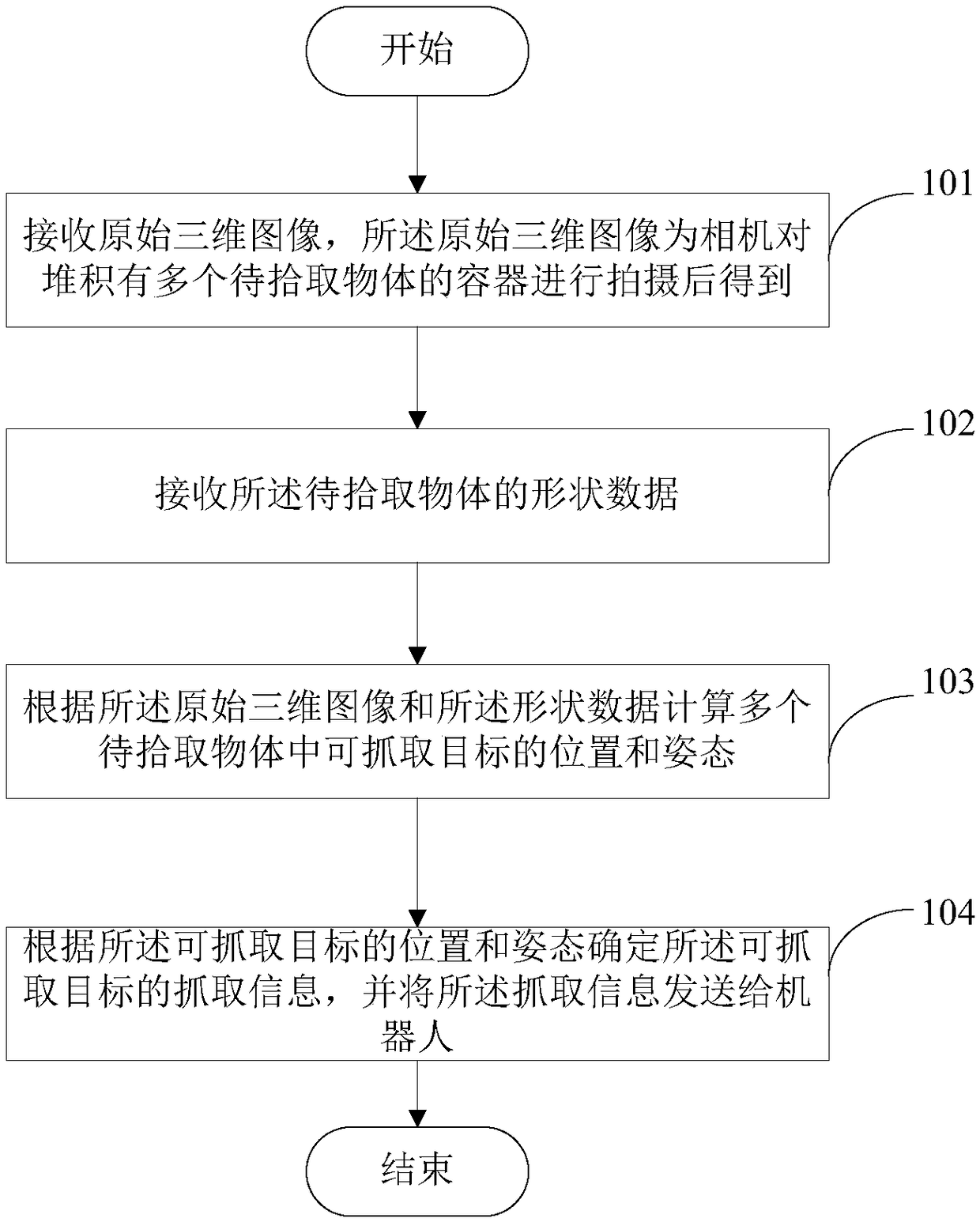

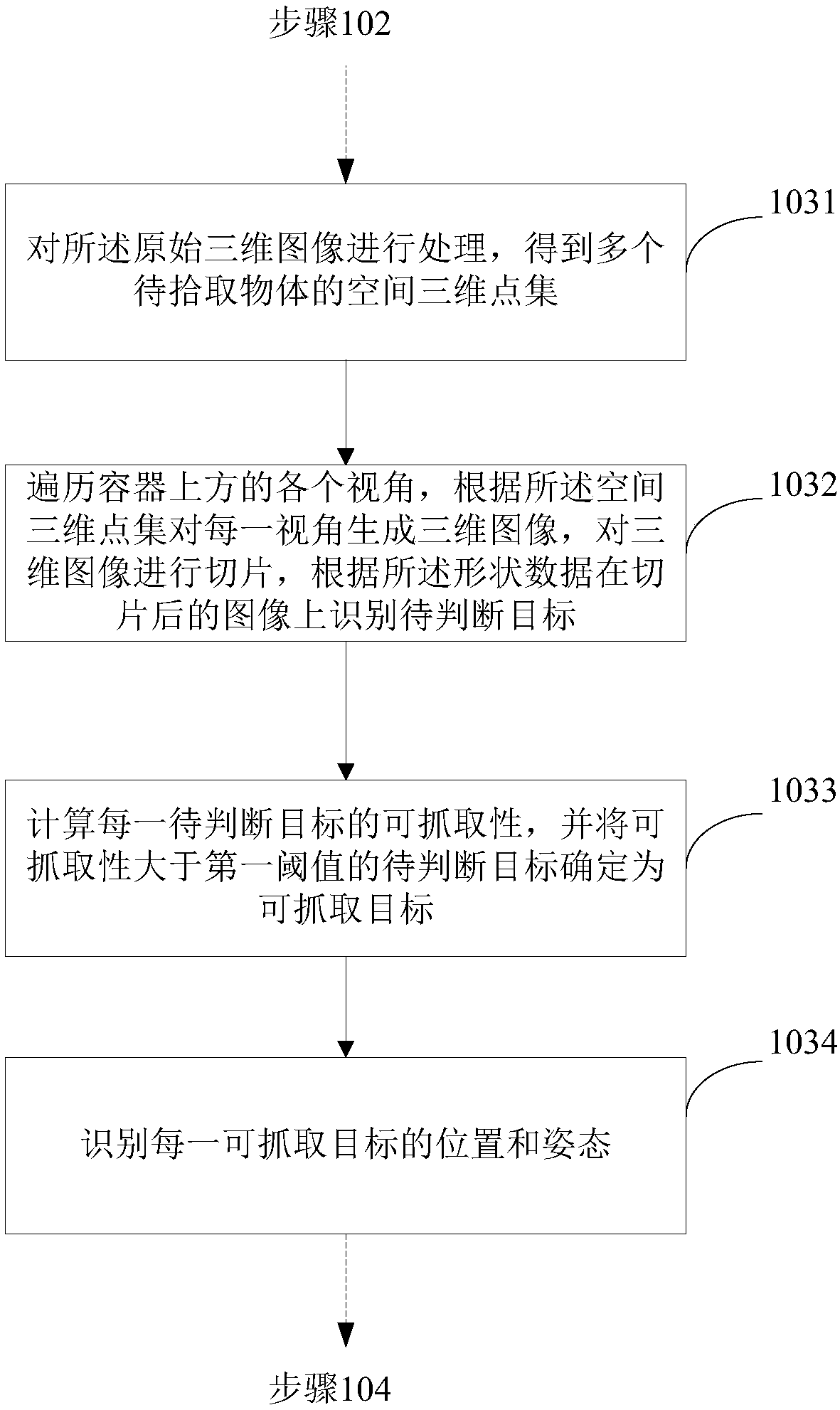

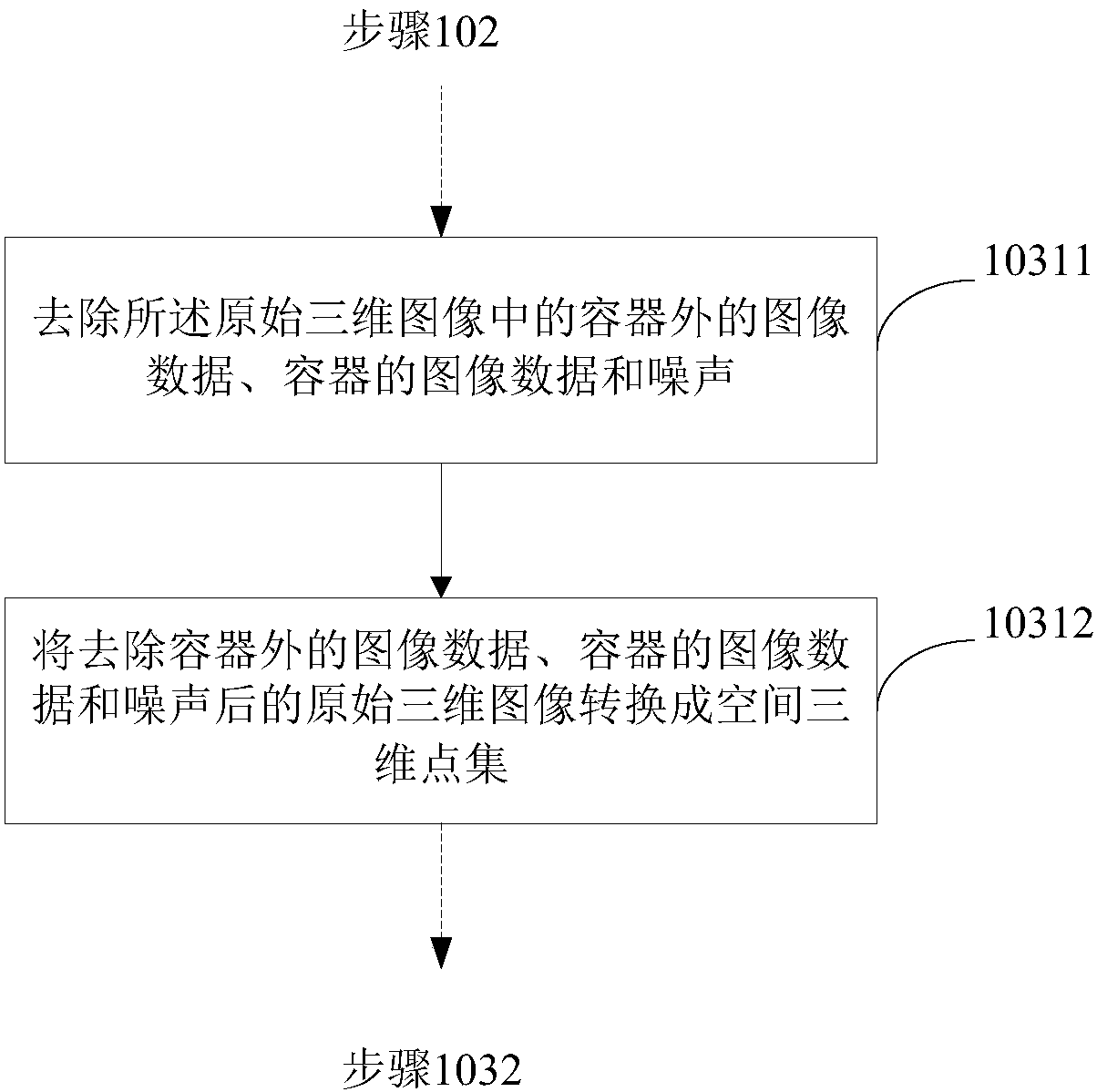

The invention provides a robot picking implementation method and device, and electronic equipment and belongs to the machine vision field. The method comprises steps that an original three-dimensionalimage is received, and the original three-dimensional image is acquired by a camera photographing a container in which multiple to-be-picked objects are stacked; shape data of the to-be-picked objects is received; the position and the posture of a graspable target among the multiple to-be-picked objects is calculated according to the original three-dimensional image and the shape data; the grab information of the graspable target is determined according to the position and the posture of the graspable target, and the grab information is sent to the robot so that the robot picks up the graspable target according to the grab information. The robot picking implementation method is advantaged in that an object having the hollow portion, a shell-like object and an object that is likely to be entangled can be automatically picked by the robot.

Owner:RICOH KK

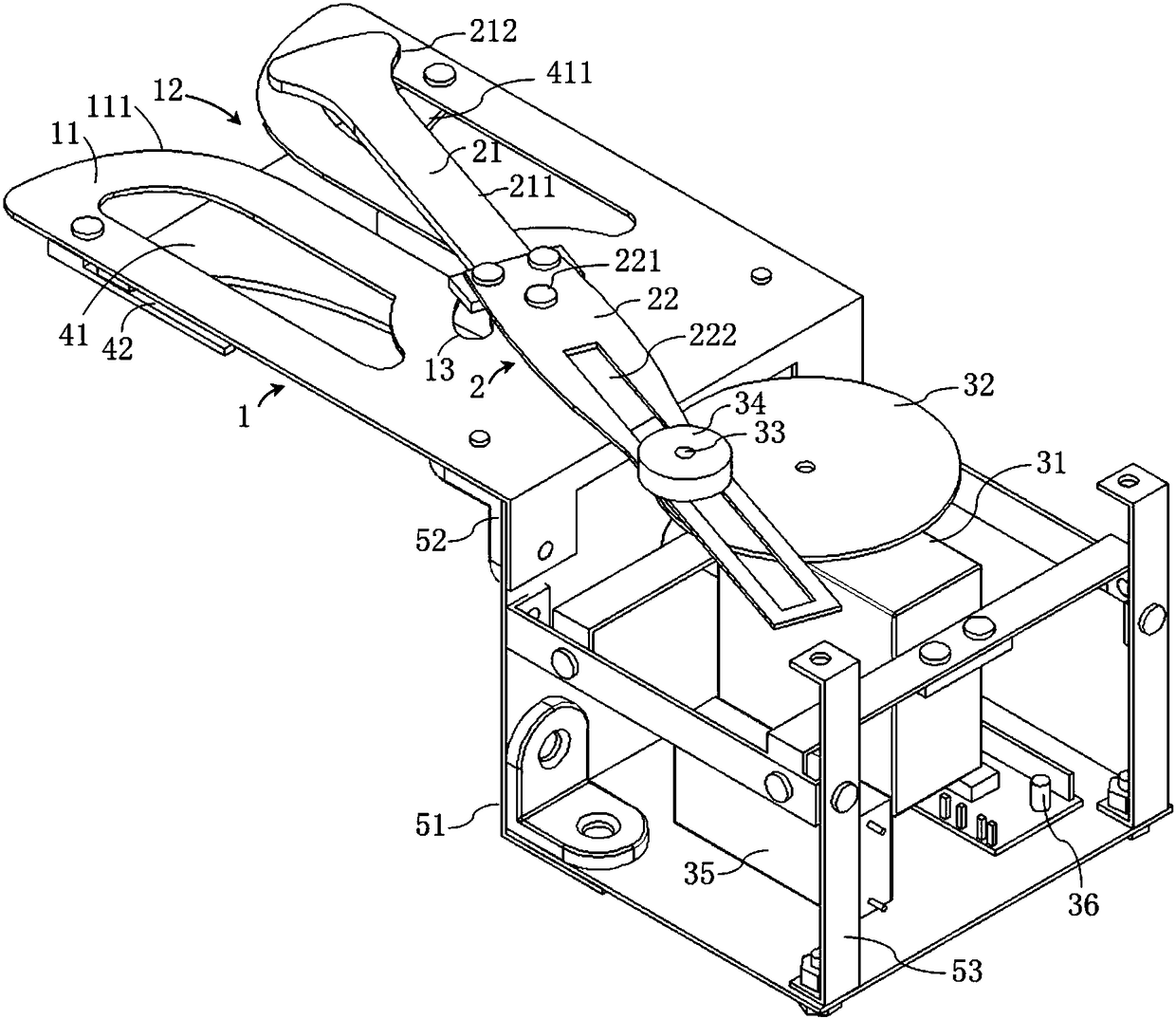

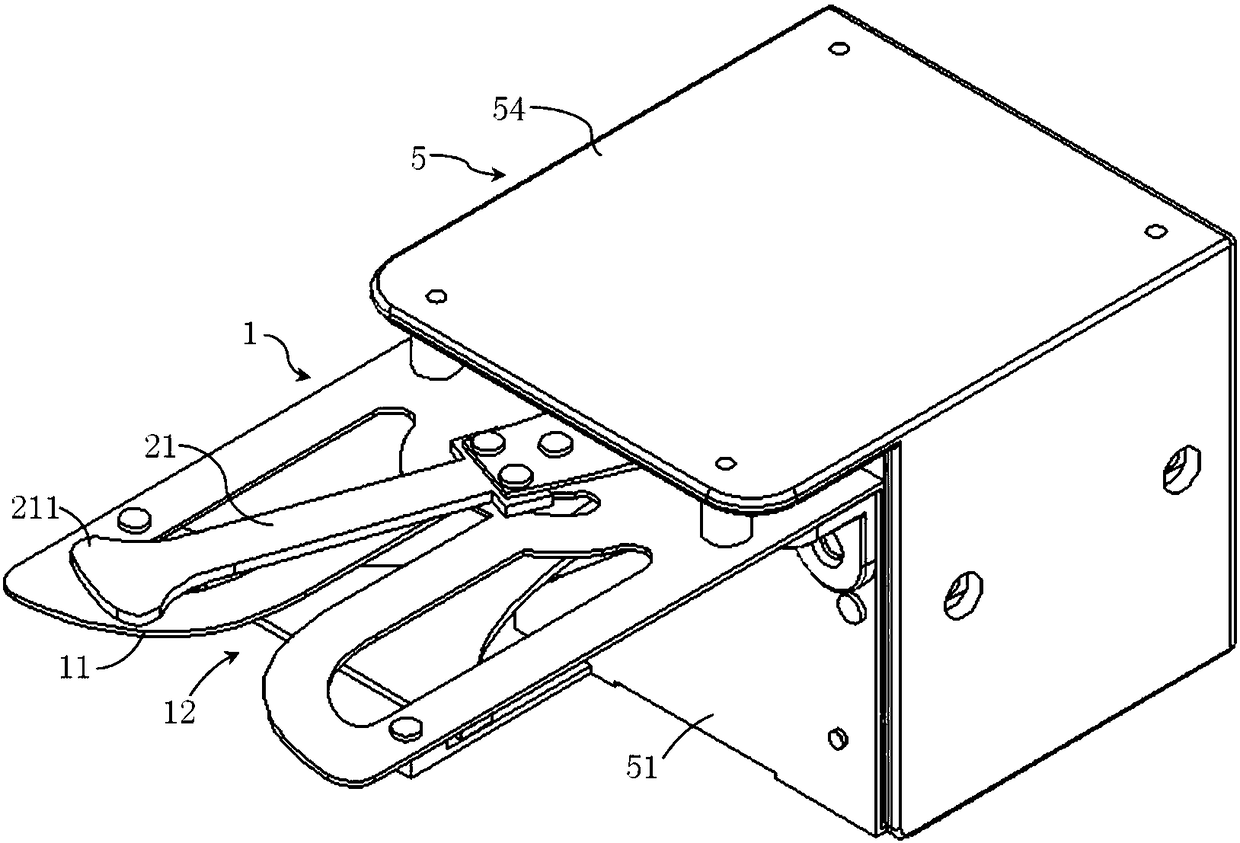

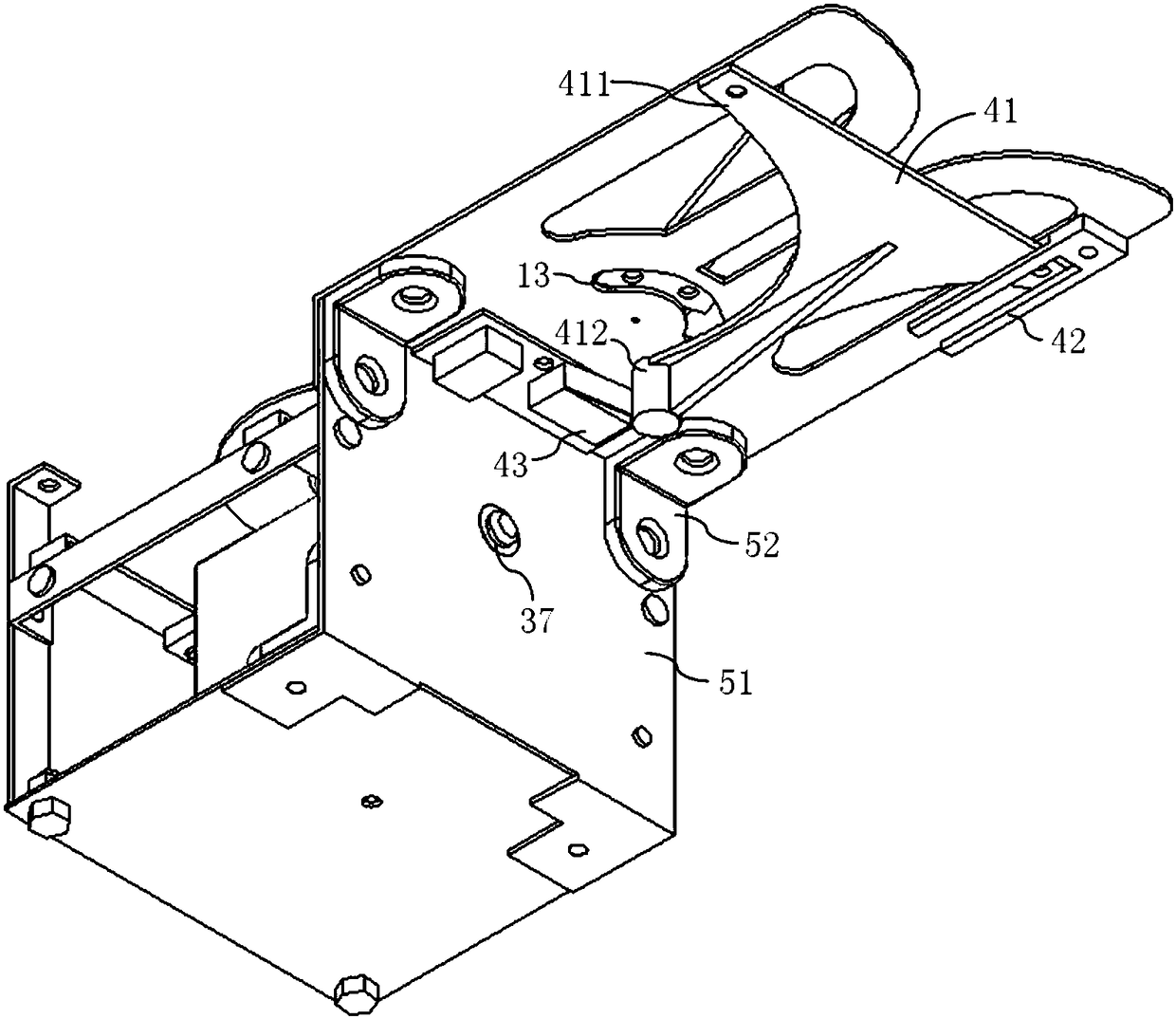

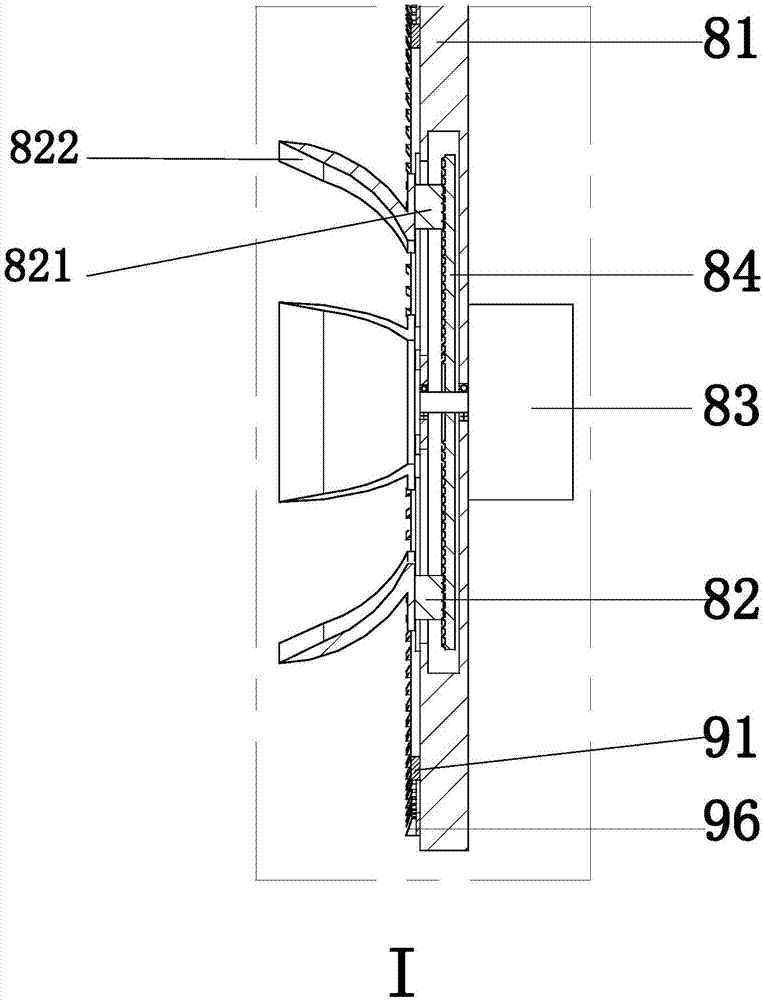

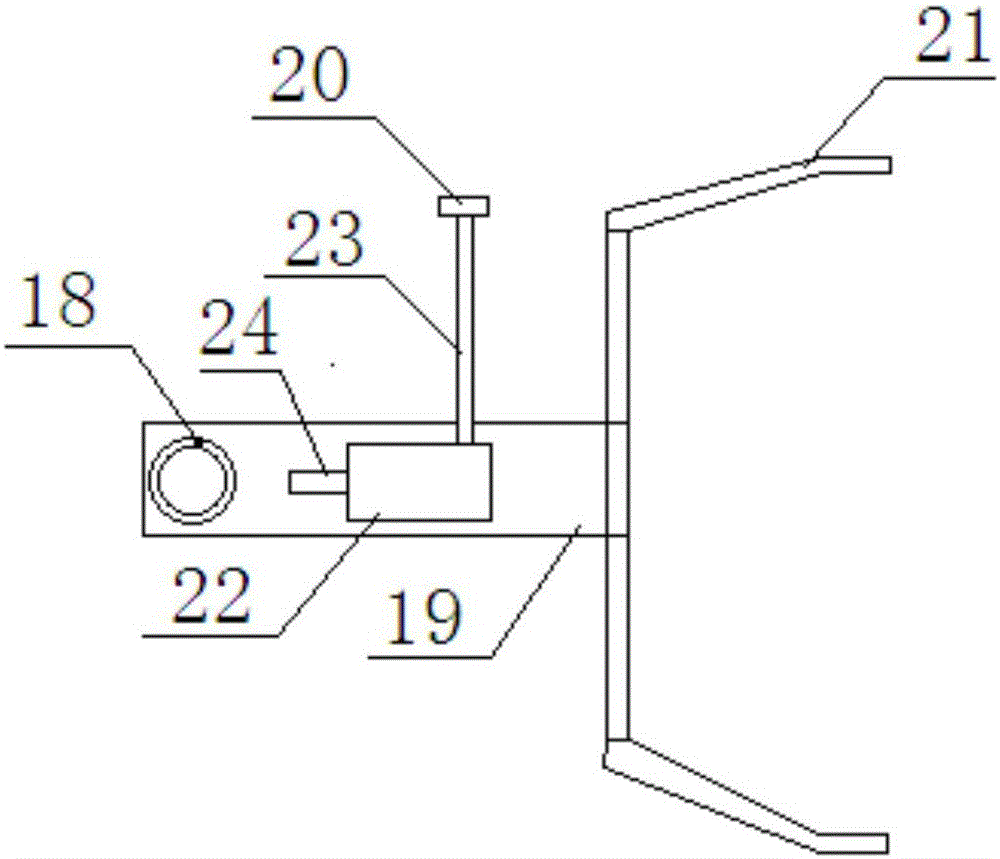

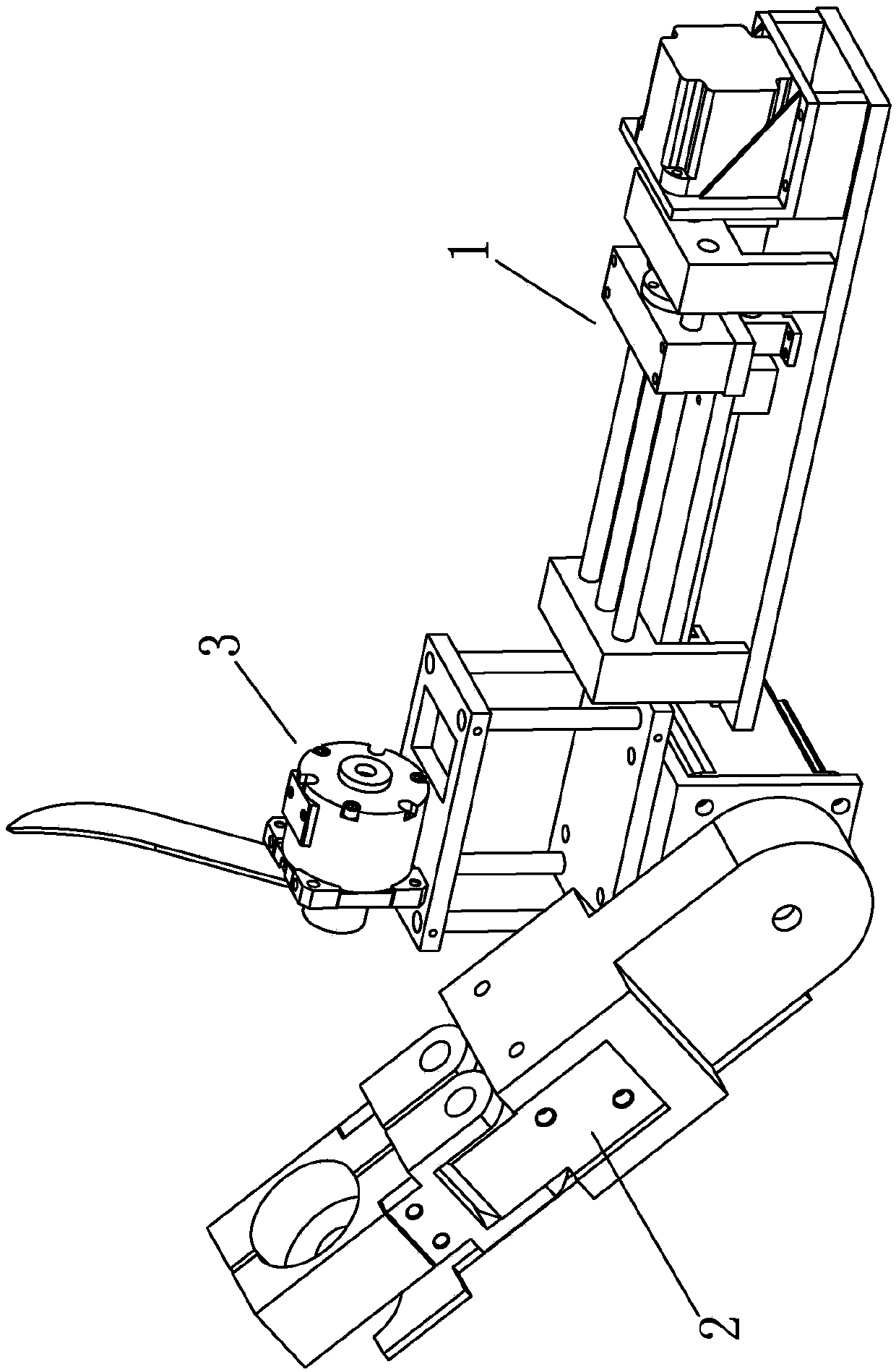

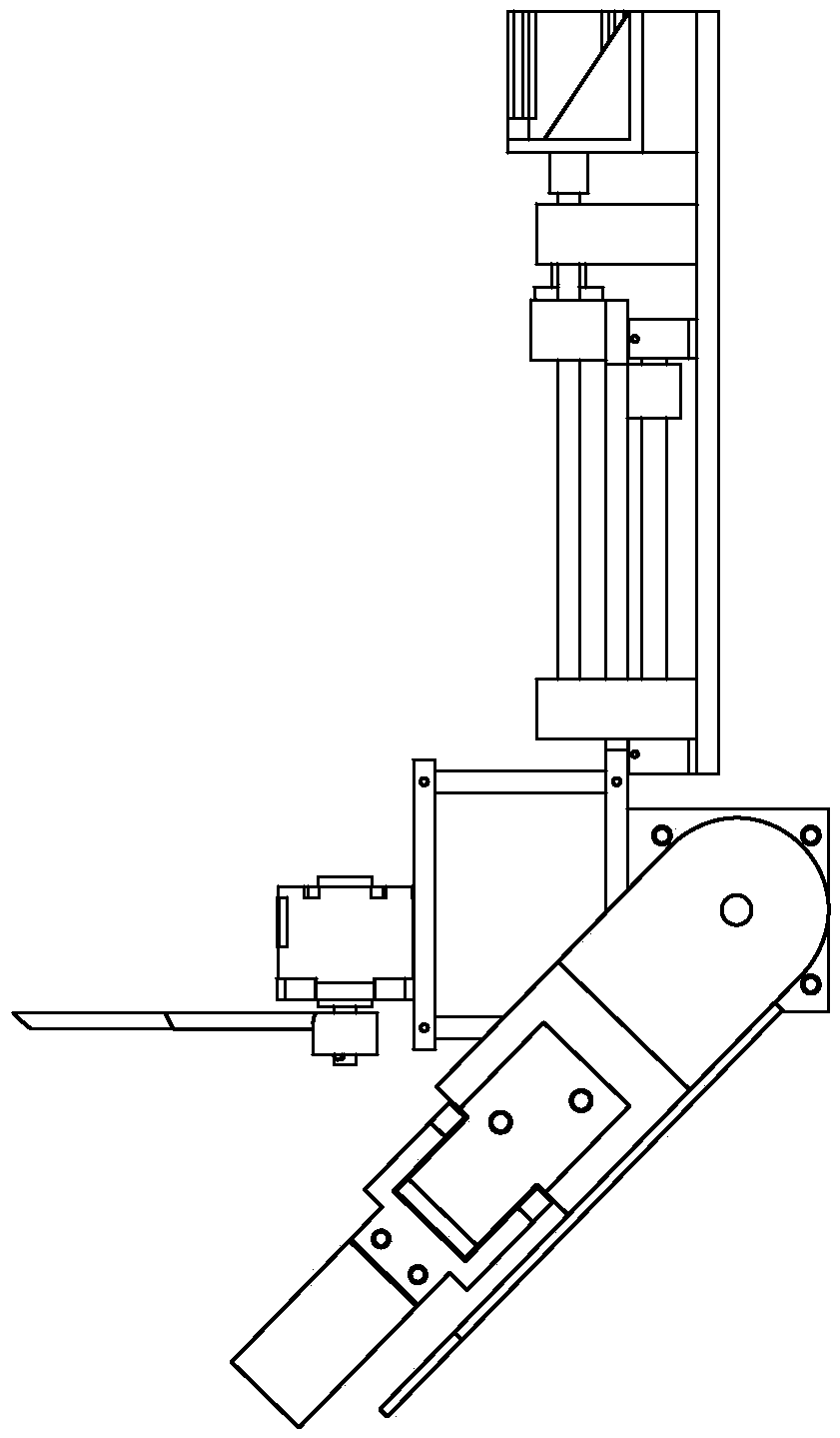

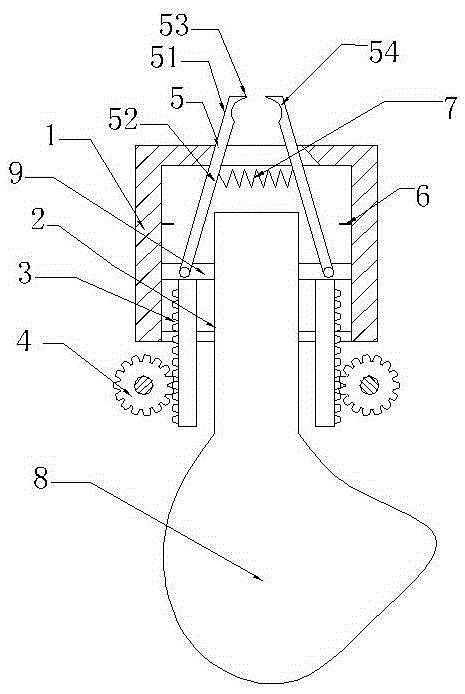

Efficient fruit picking end effector, fruit picker and picking vehicle

PendingCN108419520ARealize automatic pickingImprove picking efficiencyPicking devicesBlade plateSwitching signal

The invention discloses an efficient fruit picking end effector, a fruit picker and a picking vehicle, belonging to the field of picking devices. The fruit picking end effector disclosed by the invention comprises a blade, a triggering actuating lever, an actuating device and a controller, wherein the blade is hinged to a cutting board through a shaft rod, and the cutting edge of the blade cooperates with the fixed cutting board of the cutting board to form a shearing opening; the triggering actuating lever is movably installed on the cutting board, one end is positioned at the shearing opening, and the other end is provided with a limiting switch; the controller is in signal connection with the limiting switch and the actuating device and used for receiving a limiting switch signal and sending an execution signal to the actuating device. The actuating device drives the blade to swing around the shaft rod, and the shearing opening is closed to perform shearing operation, so that the automatic picking of fruit is realized. In the process of operation, the manual intervention of the blade is not required, and the fruit picking end effector is practical, convenient and fast, thereby improving the picking efficiency greatly.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

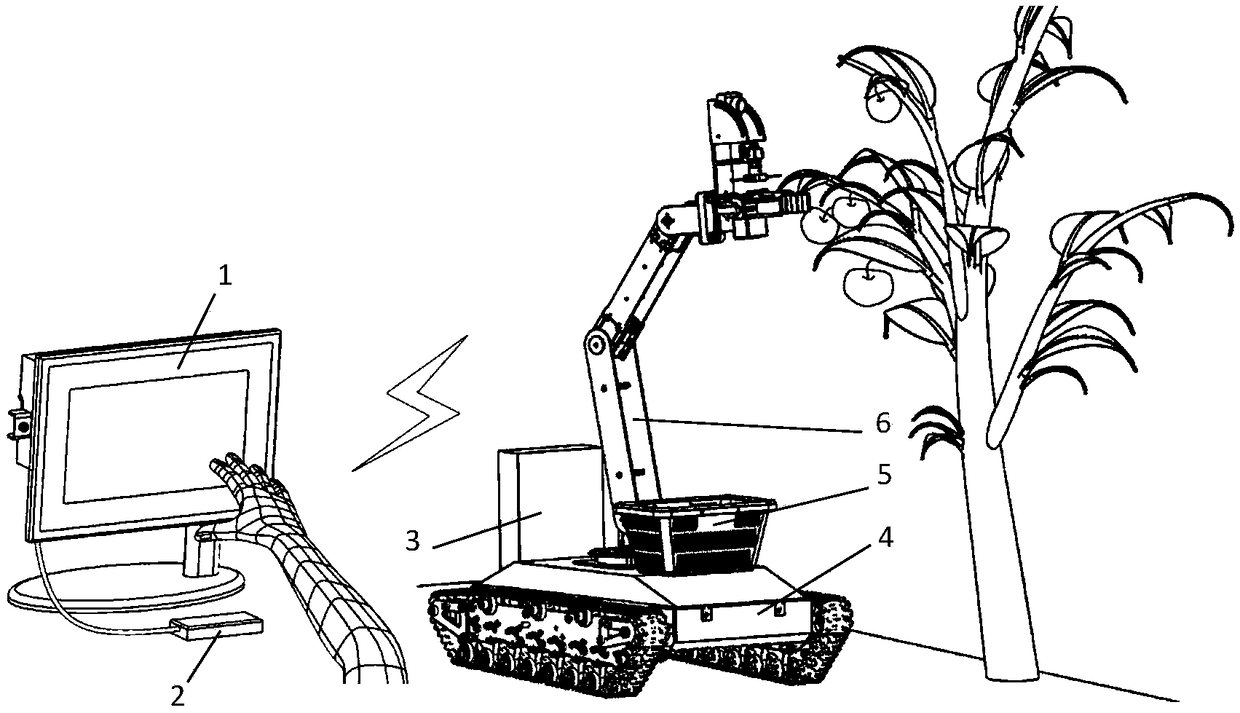

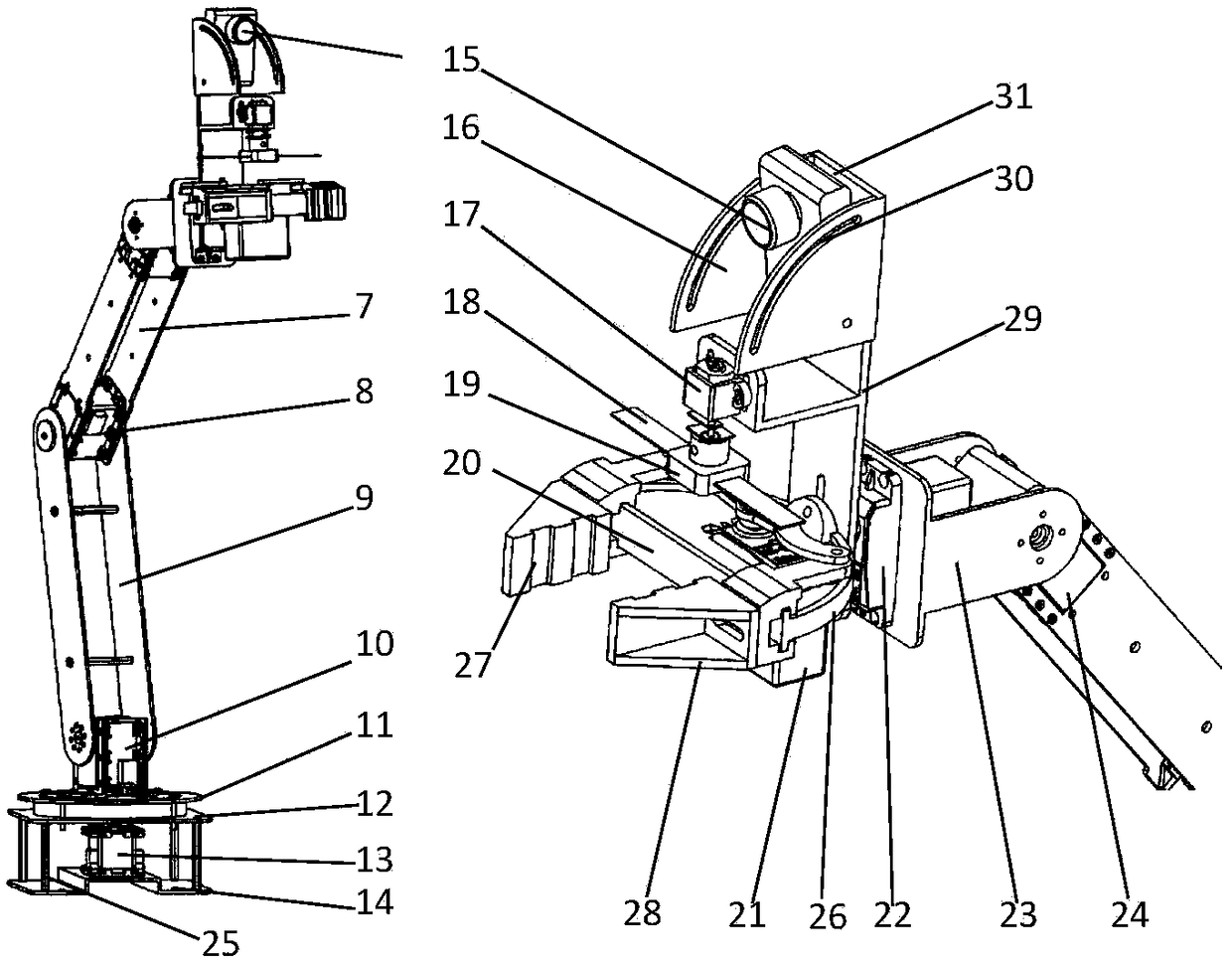

Human-machine cooperative picking robot based on Leap Motion and machine vision and control method thereof

InactiveCN109202848AHigh degree of intelligenceReduce interventionProgramme-controlled manipulatorGripping headsManipulatorElectricity

The invention discloses a human-machine cooperative picking robot based on Leap Motion and machine vision and a control method thereof. The human-machine cooperative picking robot comprises a walkingmechanism and a picking mechanical arm. A power source, a picking collecting basket and a robot controller are fixedly arranged on the walking mechanism, and the picking mechanical arm is arranged onthe walking mechanism. A picking mechanical hand is arranged on the picking mechanical arm. The human-machine cooperative picking robot also comprises a remote control system, and the remote control system comprises a computer and a Leap Motion somatosensory sensor, the Leap Motion somatosensory sensor communicates with the computer, and the computer communicates with the robot controller. A camera is arranged on the picking mechanical hand and communicates with the robot controller, and the camera and the robot controller are electrically connected with the power source. The human-machine cooperative picking robot can recognize objects to be picked in a complex background environment by using the excellent visual system of a human and is remotely controlled to move to pick fruits by the non-contact somatosensory sensor.

Owner:SOUTHWEST UNIVERSITY

Sunflower disc automated picking robot

InactiveCN106856825ASolve labor intensitySolve efficiency problemsPicking devicesEngineeringHelianthus

The invention relates to an automatic picking robot for sunflower discs, which comprises a bottom plate, a collection box is installed on the bottom plate, a position adjustment device is installed in the middle of the bottom plate, an angle adjustment device is installed at the front end of the position adjustment device, and a lifting device is installed at the lower end of the angle adjustment device. device, and a shearing device is installed on the outside of the No. 1 lifting device, a moving device is installed at the lower end of the angle adjustment device, and a No. 2 lifting device is installed at the lower end of the moving device, and the angle adjustment device, the moving device, the No. 2 lifting device, No. 1 lifting device, shearing device, position adjustment device, guiding device, and collection box are used together to complete the sunflower automatic picking process. The invention can solve the problems existing in the existing process of picking sunflower flower disks manually, such as high labor intensity, low picking efficiency, damage to sunflower flower disks by mechanized picking, unfavorable use of sunflower flower disks, waste of resources, etc., and can realize automatic picking of sunflower flower disks Function.

Owner:储小燕

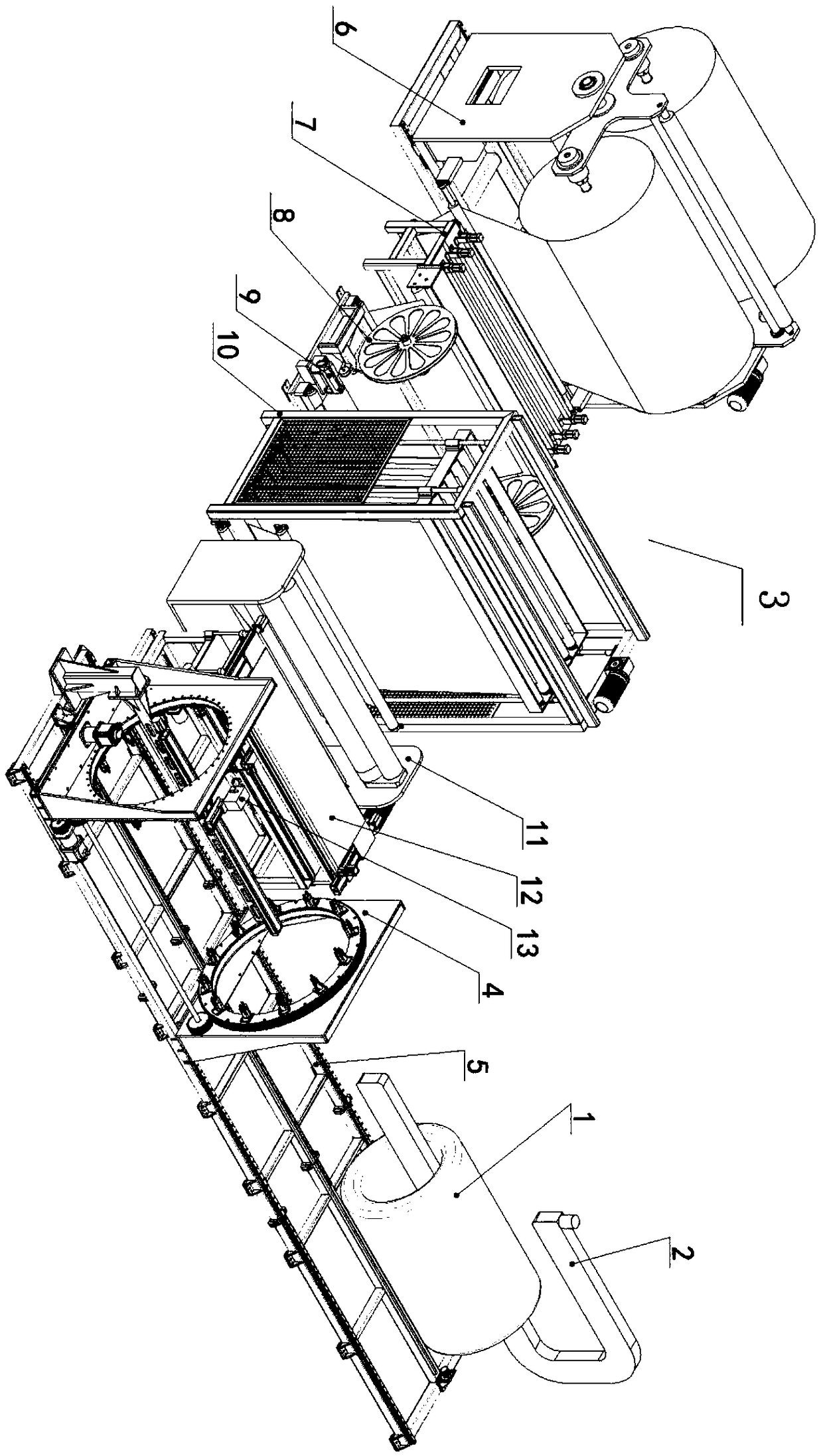

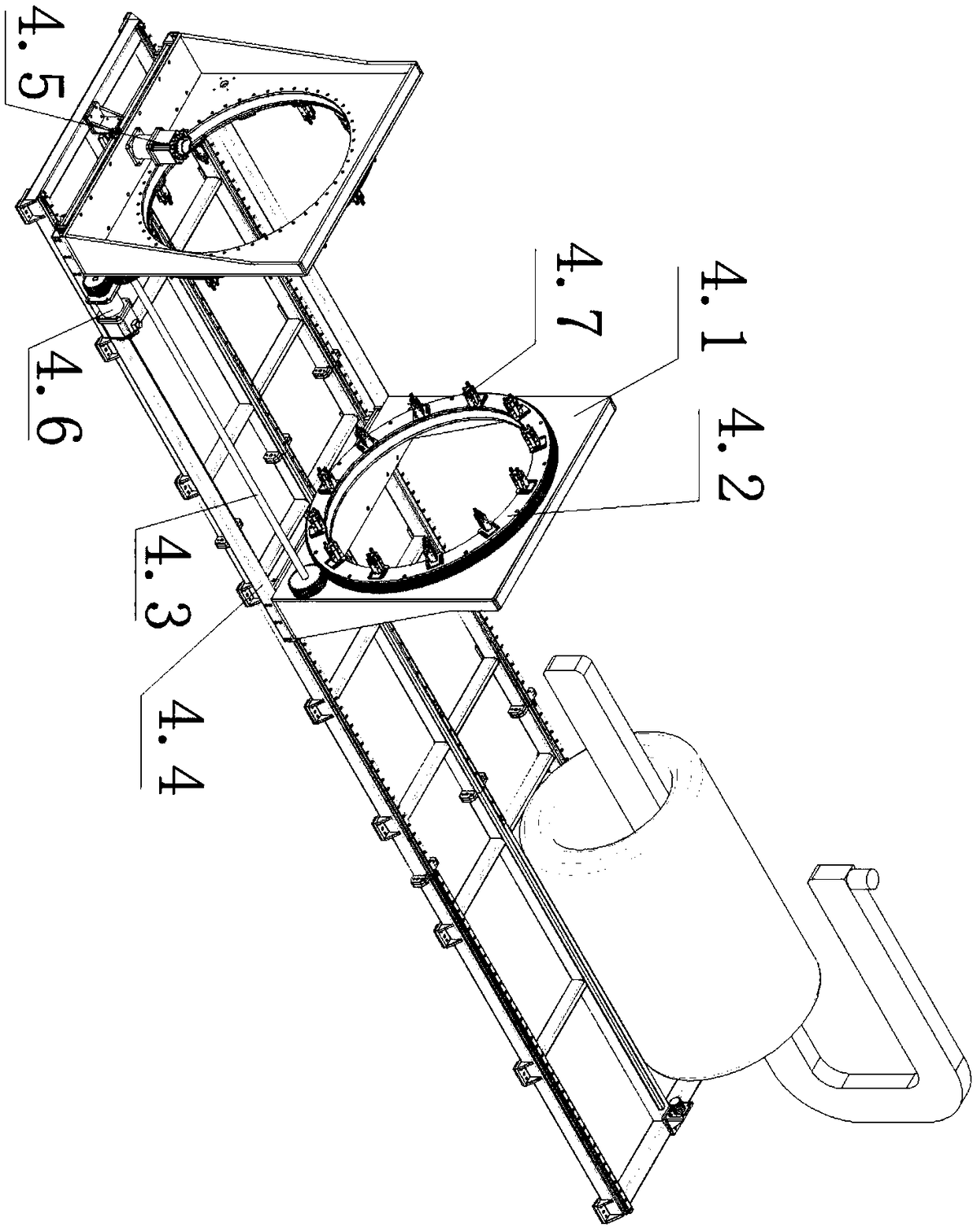

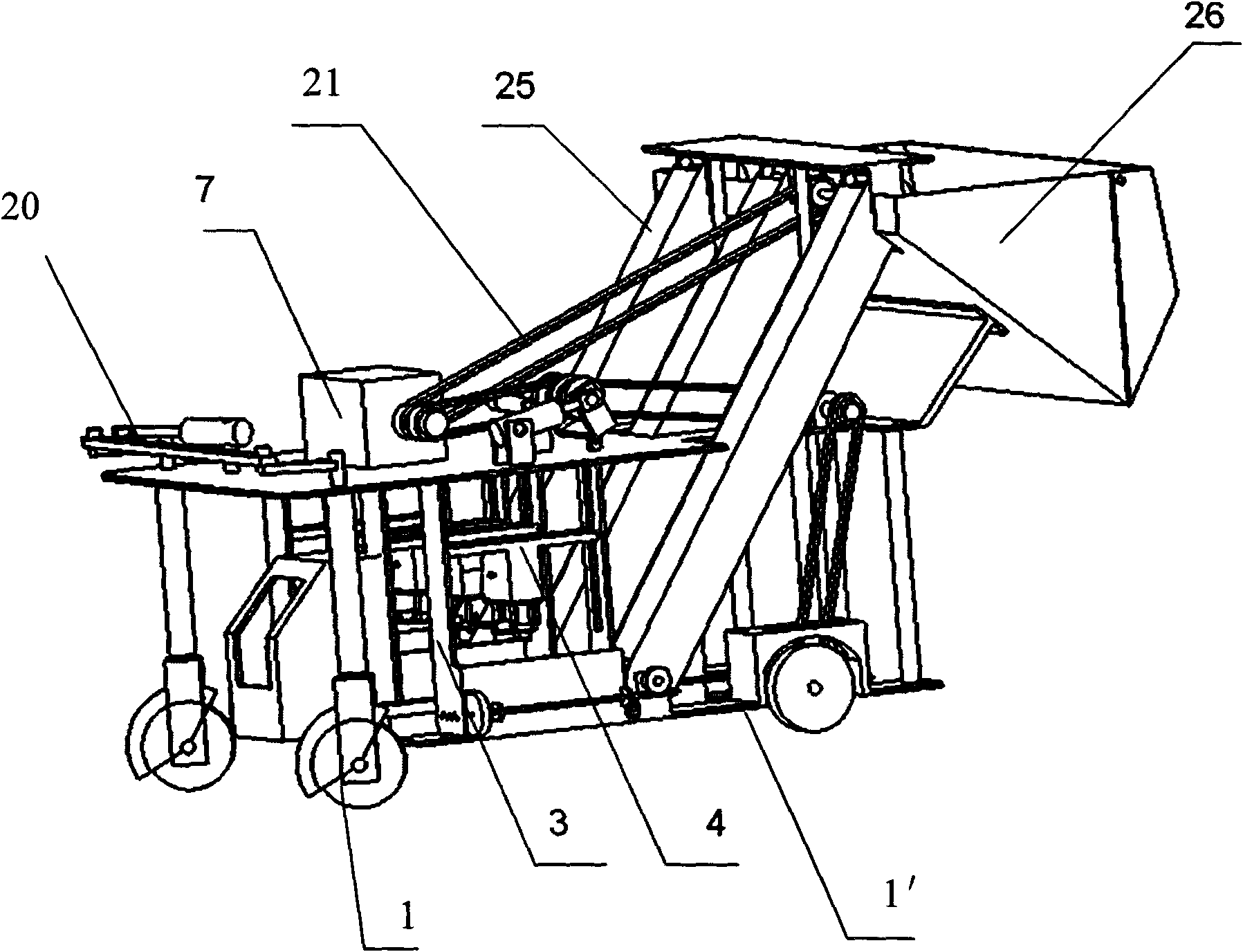

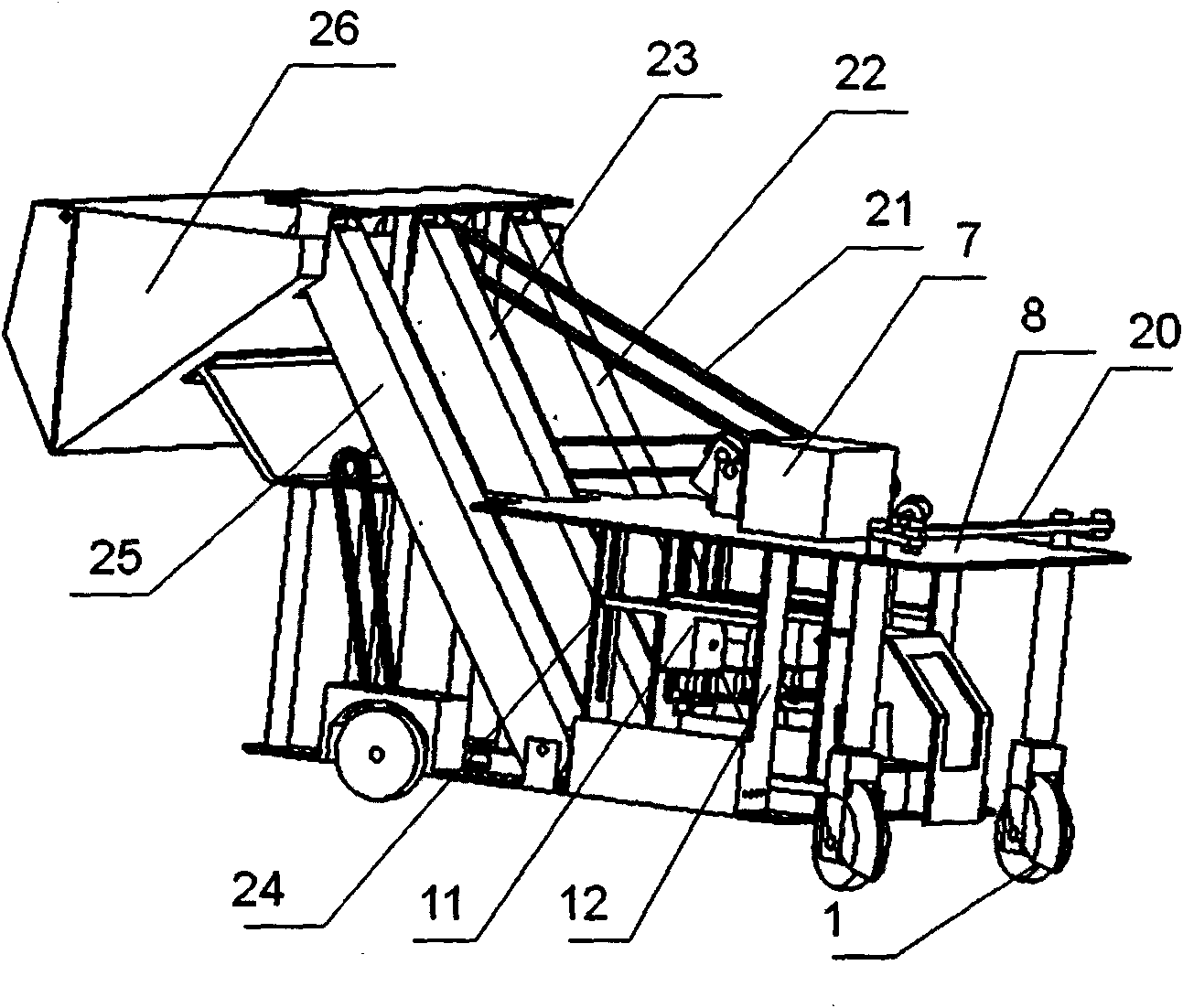

Traction type all-in-one machine integrating forest residue picking, crushing and compression

InactiveCN106718119AEasy to collectSimple device structureHops/wine cultivationTurf growingEngineeringForest road

The invention discloses a traction type all-in-one machine integrating forest residue picking, crushing and compression, belongs to the field of forestry machinery and aims at solving the problems of insufficient picking in the traditional forest residue picking and conveying process, high requirements for rigidity and stability of mechanical equipment due to rough forest roads, and damage to a crushing or compression device due to easiness in picking up stones and soils. According to the traction type all-in-one machine integrating forest residue picking, crushing and compression, conveying is realized through a conveyor belt; through twice separation by a filter plate and a cyclone separator, gravels and sands are effectively filtered out, and useless objects such as stones doped in the residues are prevented from being picked up to cause low picking efficiency; and in addition, the residues such as fallen leaves and the like can be crushed, thicker residues such as branches and the like can also be manually fed into the crushing device through a side feeding hole, and crushed materials can be primarily compressed by the compression device directly. The traction type all-in-one machine integrating forest residue picking, crushing and compression is suitable for picking up the forest residues.

Owner:NORTHEAST FORESTRY UNIVERSITY

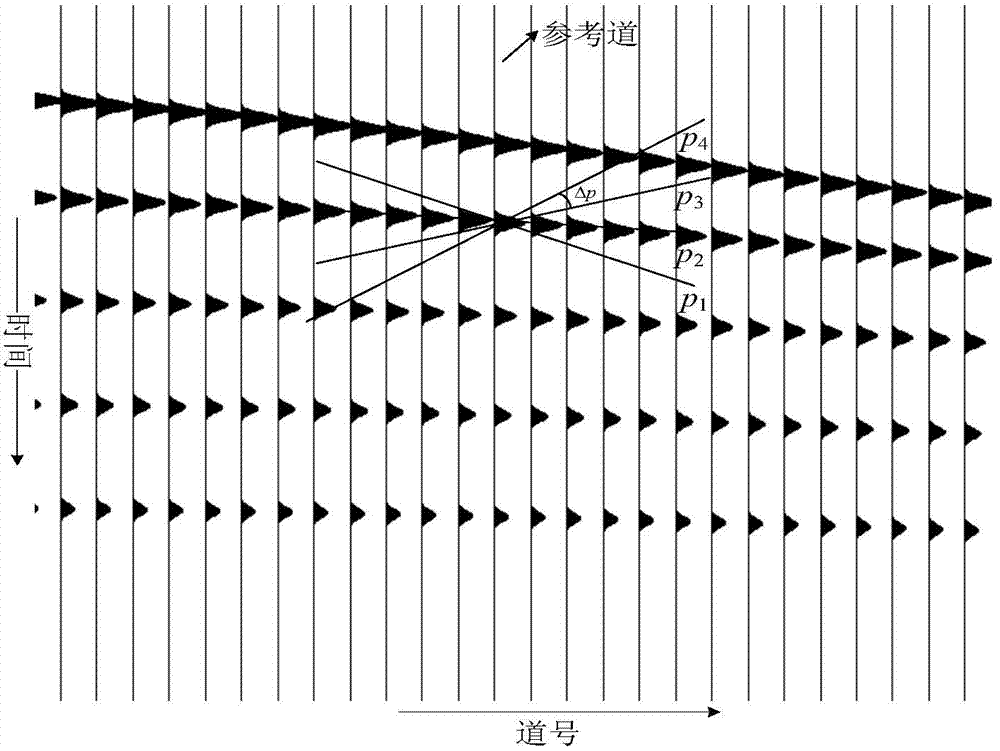

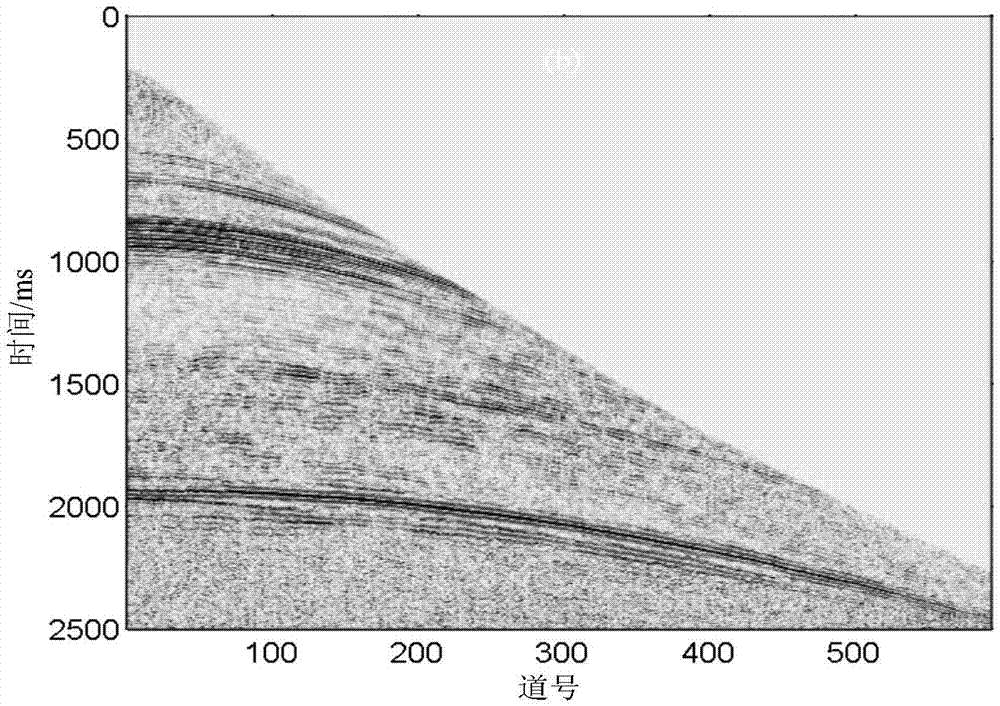

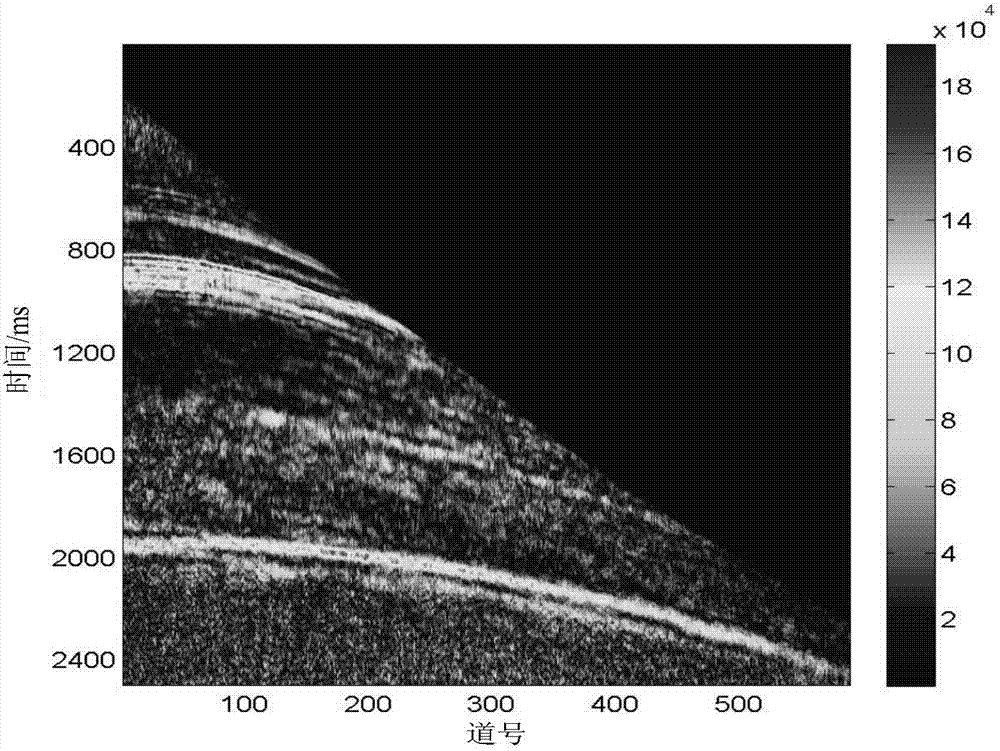

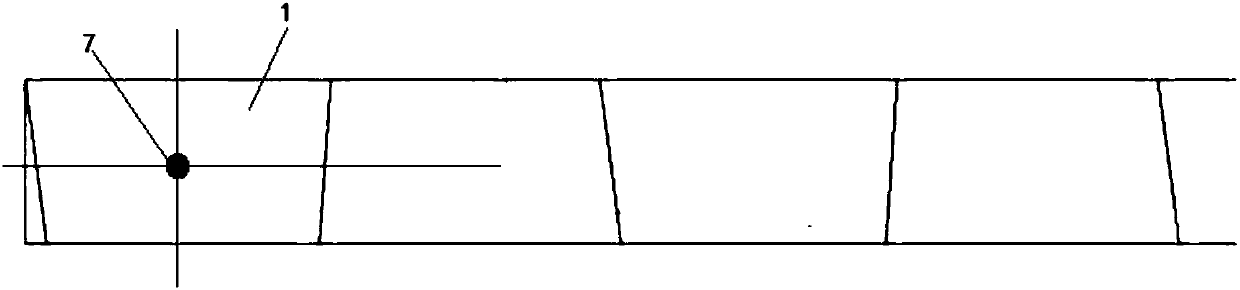

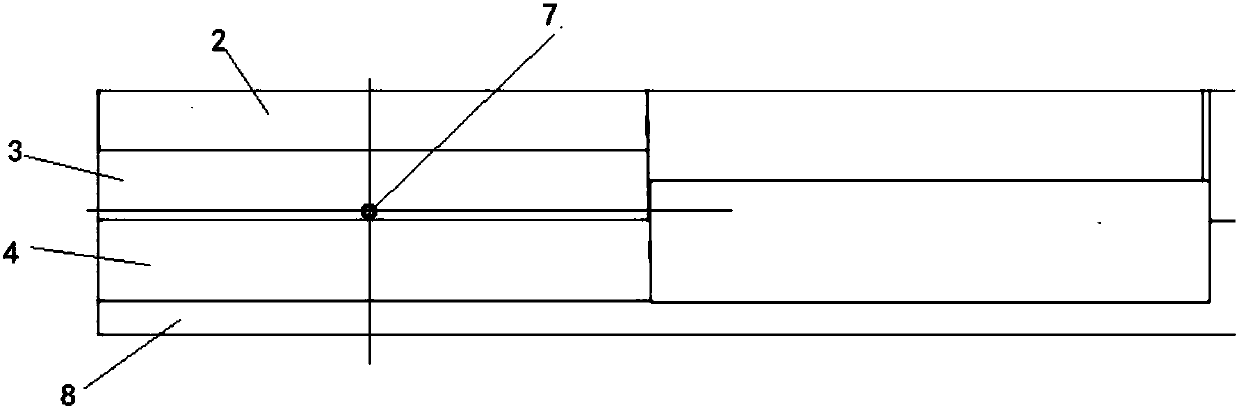

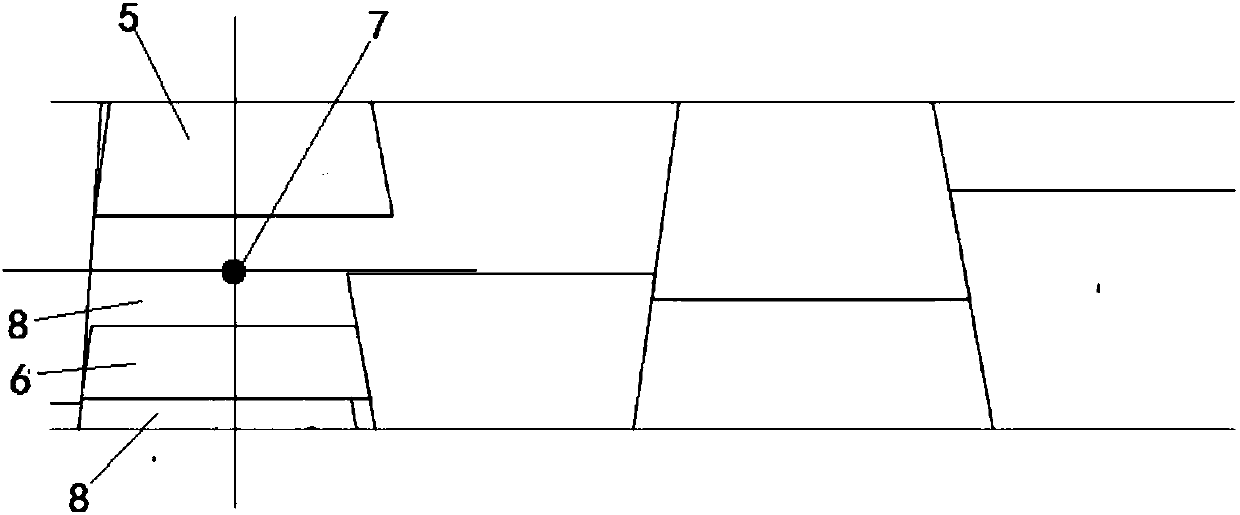

Oblique stacking peak amplitude portion edge detecting method for event automatic picking

ActiveCN104714251AImprove signal-to-noise ratioRealize automatic pickingSeismic signal processingOffset distancePeak value

The invention provides an oblique stacking peak amplitude portion edge detecting method for event automatic picking. The method comprises the steps that 1. pre-stacking CSP data are used for wavelet transforming, and a signal analysis part is obtained; 2. according to the analysis part obtained in the step 1, signal instant amplitude is obtained; 3. local linear Radon conversion is carried out on a profile of the instant amplitude, the peak amplitude of instant amplitude is picked, and an oblique stacking peak amplitude profile is obtained; and 4. based on the oblique stacking peak amplitude profile, an edge detection profile is obtained, and event and travel time picking is carried out on the edge detection profile. Oblique stacking conversion is carried out on an instant amplitude profile, the instant amplitude profile is smooth compared with original seismic recording, a plurality of low-frequency components are contained, a part of high-frequency glitch noise can be filtered away, and the event positions of the two parts are the same. Noise is effectively suppressed, the problem that continuous events cannot be picked in a large offset distance easily through an existing method is overcome, operation is convenient, and event automatic picking is achieved.

Owner:XI AN JIAOTONG UNIV

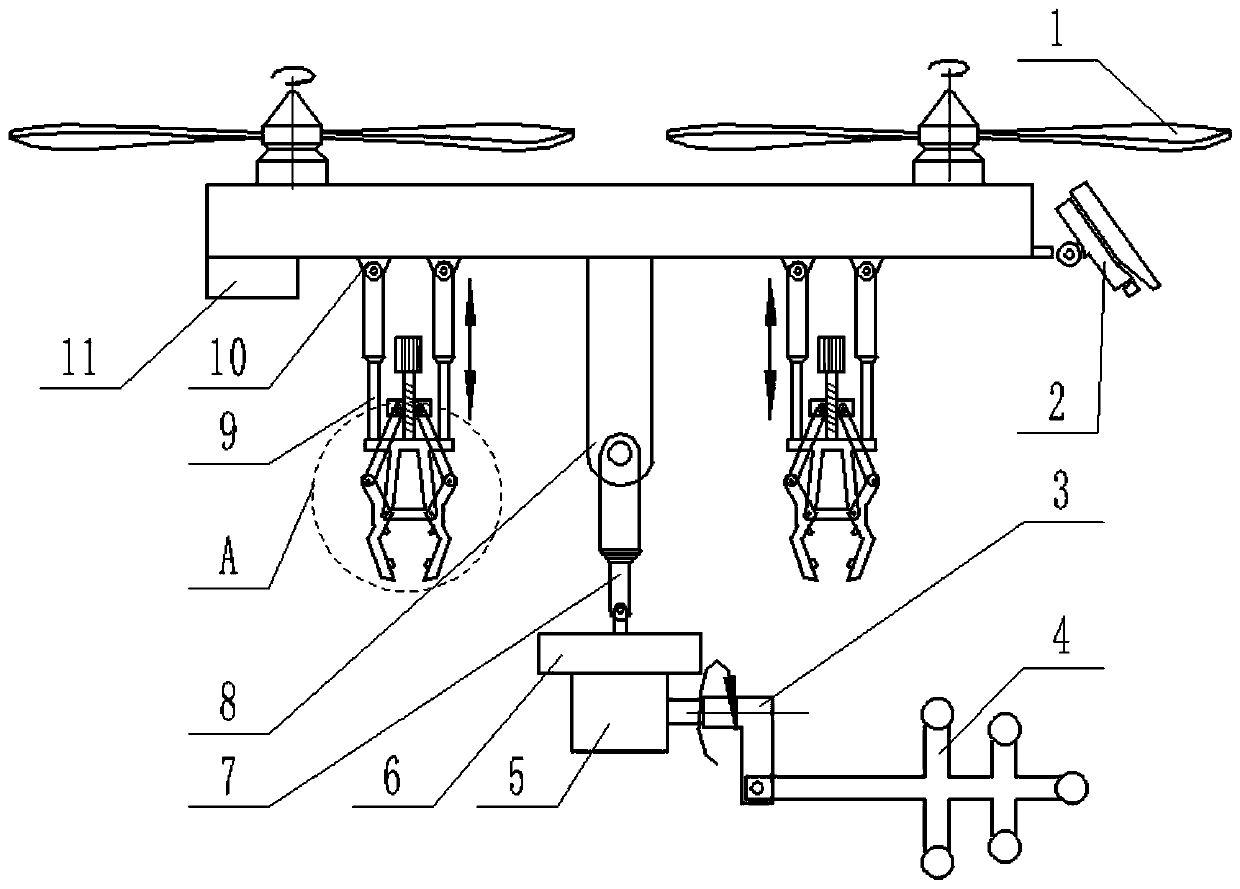

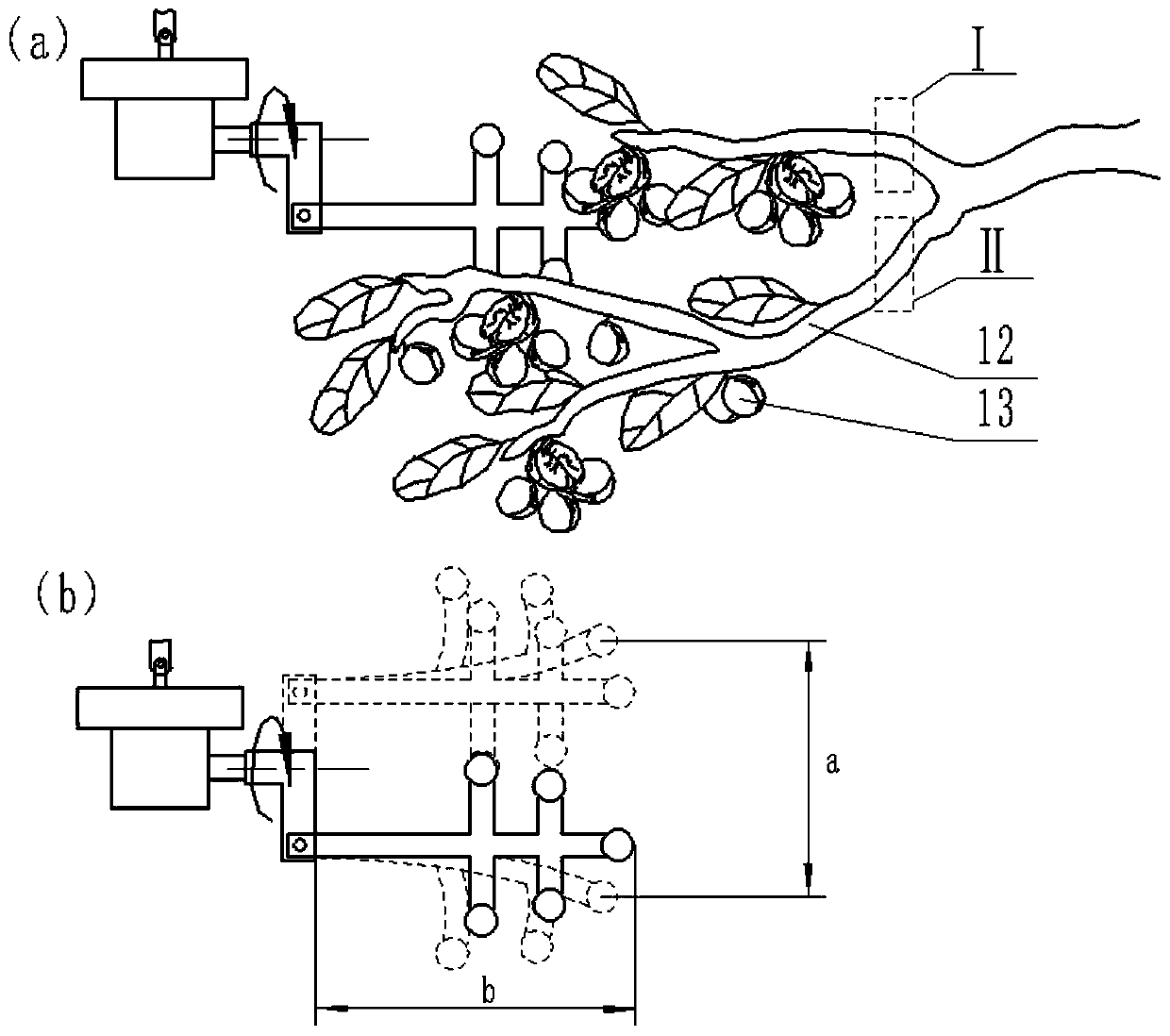

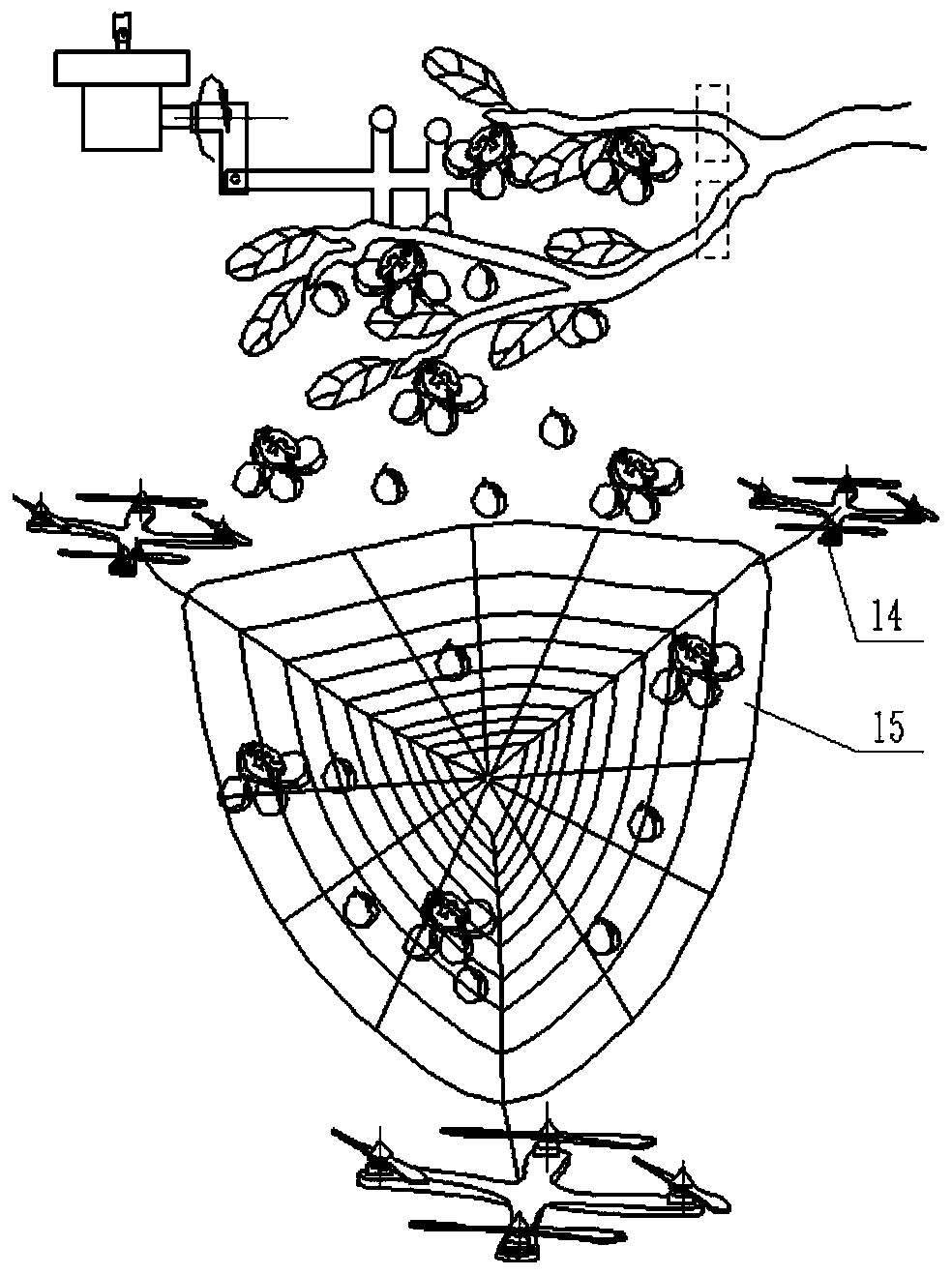

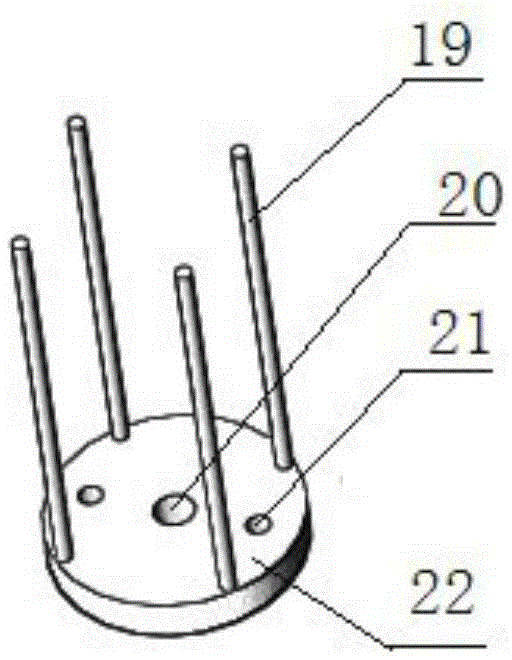

Chinese walnut picking and collecting device and method based on unmanned aerial vehicle

ActiveCN110192471AAvoid safety hazardsExtended working hoursAircraft componentsPicking devicesGlass fiberWalnut Nut

The invention discloses a Chinese walnut picking and collecting device and method based on an unmanned aerial vehicle, and belongs to the technical field of picking devices. The Chinese walnut pickingand collecting device comprises a picking unmanned aerial vehicle device, a recognizing and positioning system, a fixing device, a picking device, a collecting device and a control center. The recognizing and positioning system is located on the upper side of the picking unmanned aerial vehicle device. The fixing device and the picking device are both located on the lower side of the picking unmanned aerial vehicle device. The picking unmanned aerial vehicle device flies to a designated position according to the recognizing and positioning system, and the fixing device is composed of two stretching automatic telescopic clamping claws for clamping two branch fixing machine bodies. The eccentric variable-speed rotary striking of a glass fiber rod is realized by the picking device through aservo motor, the variable-force, variable-position and variable-angle striking of Chinese walnut branches is realized, and it is ensured that Chinese walnuts are struck down. A collecting unmanned aerial vehicle is connected with a collecting net, the struck-down Chinese walnuts fall into the collecting net, and a pressure sensor is arranged in the collecting unmanned aerial vehicle. The picking and collecting can be integrated, the picking unmanned aerial vehicle stops working in the striking process, and the electric energy consumption is reduced.

Owner:DALIAN UNIV OF TECH

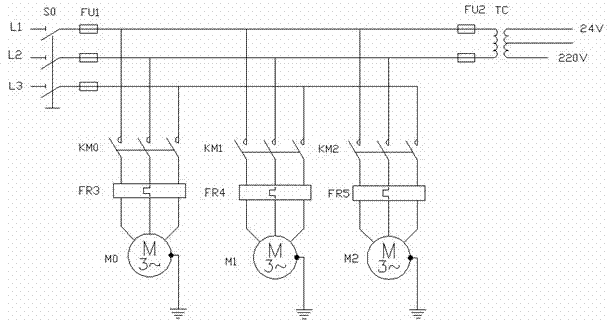

Automatic fruit-picking and leave-removing device

InactiveCN103609258ARealize automatic pickingRealize automatic picking and removing leavesPicking devicesImaging processingProgrammable logic controller

The invention relates to an automatic fruit-picking and leave-removing device, and belongs to the technical field of agricultural mechanical equipment. The automatic fruit-picking and leave-removing device comprises a manipulator, a monitoring scanner, a mechanical arm I, a rotary fulcrum, a rotary shaft, a receiver, an opening and closing valve, a shock absorber, a buffer device, an image processing device, a mechanical arm II, a leave cutting knife, a conveying belt, a container, an oil tank, a brake, a shock absorber II, a driving motor I, a relay I, a PLC (programmable logic controller), a transmission shaft, a relay II, a relay III, wheels, a driving motor II, a vehicle body, a driving motor III and a supporting rod. The automatic fruit-picking and leave-removing device is convenient to operate; and leaves can be removed effectively after fruits are automatically picked, the picking cost is saved, the picking efficiency is improved, and the fruit picking quality is guaranteed.

Owner:KUNMING UNIV OF SCI & TECH

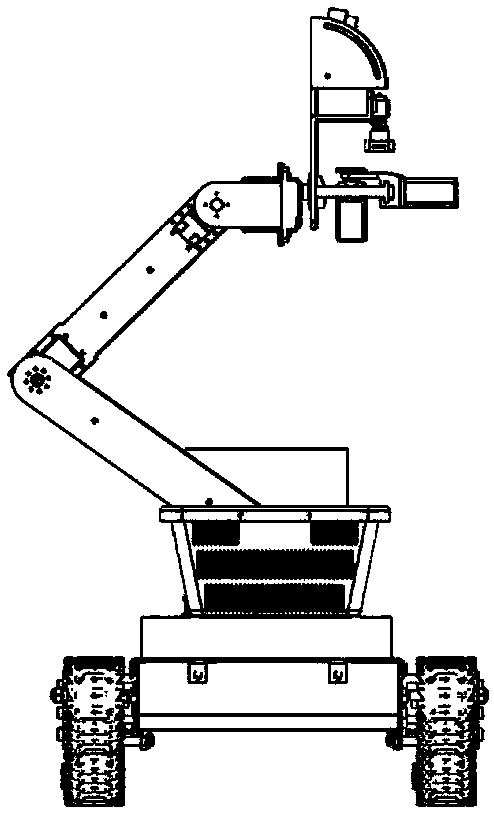

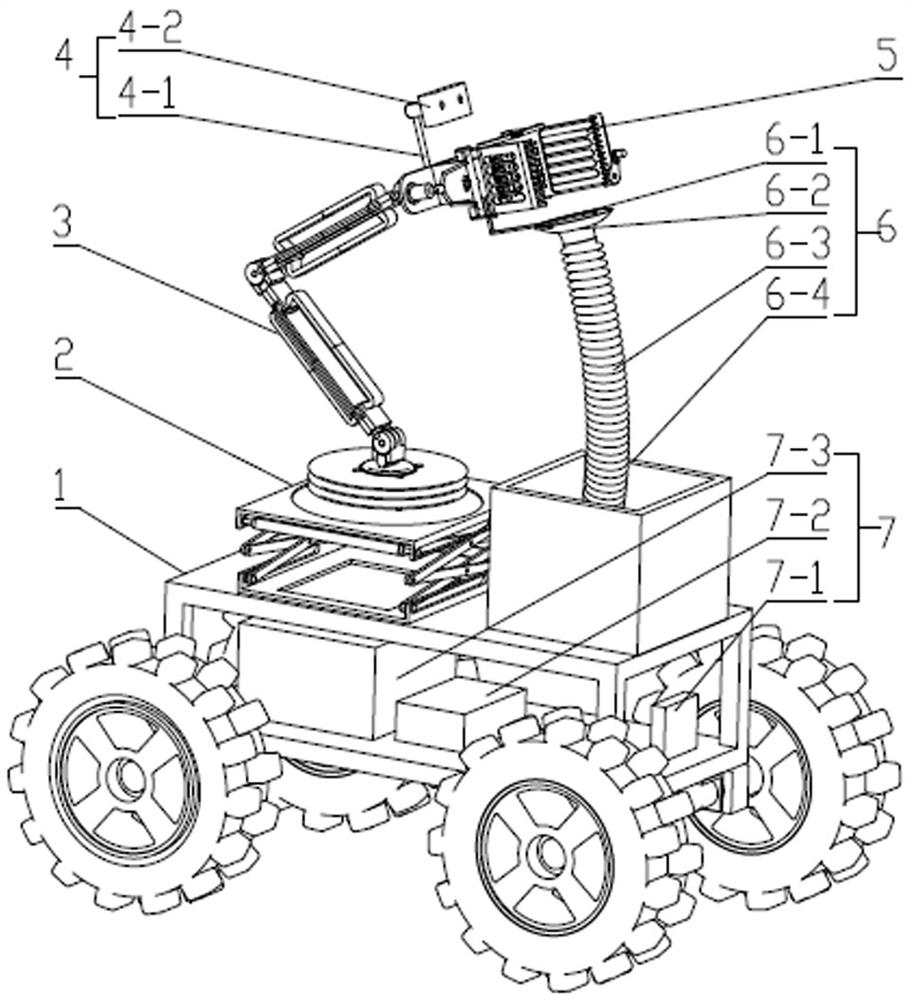

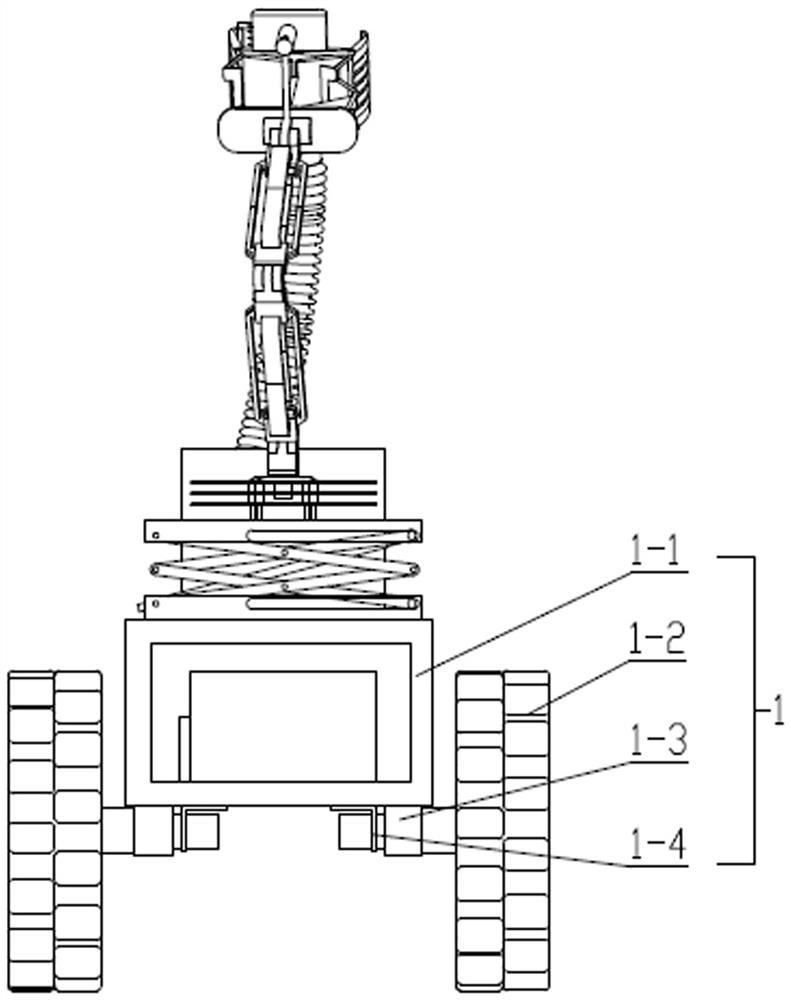

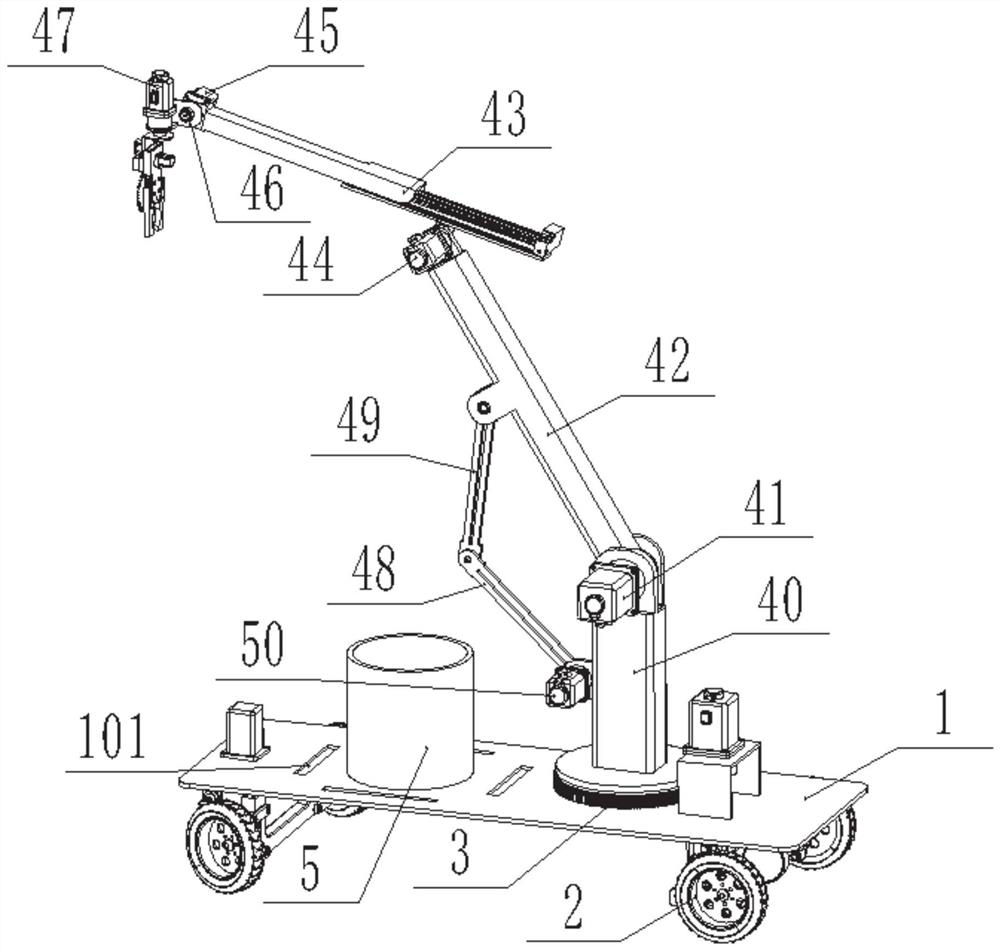

Spherical fruit picking robot and picking method

PendingCN114402806ALabor savingGood versatilityPicking devicesRenewable energy machinesElectric machineryACTINIDIA POLYGAMA FRUIT

The invention discloses a spherical fruit picking robot and a picking method.The spherical fruit picking robot comprises a moving trolley, an electric shear type lifting platform, a mechanical arm, an end effector, a visual device, a collecting device and a control device.The moving trolley comprises a double-layer frame, driving wheels, a driving motor and a motor connecting piece; the mechanical arm comprises a base, a rotating motor, a rear arm motor, a mechanical rear arm, a front arm motor, a mechanical front arm, a wrist motor and a mechanical wrist, the end effector is composed of a T-shaped base, an electric push rod, a hydraulic supporting rod, a clamping mechanism, a cutting mechanism, a sliding block mechanism and a pressure sensor, and the vision device comprises a depth camera and a camera support. The control device comprises a controller, a processor and a storage battery, a visual guidance picking method is further combined, automatic picking of the spherical fruits such as apples, oranges and kiwi fruits can be achieved, and the automatic picking device has the remarkable advantages of being high in automation degree, high in universality, high in efficiency, low in damage and the like.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

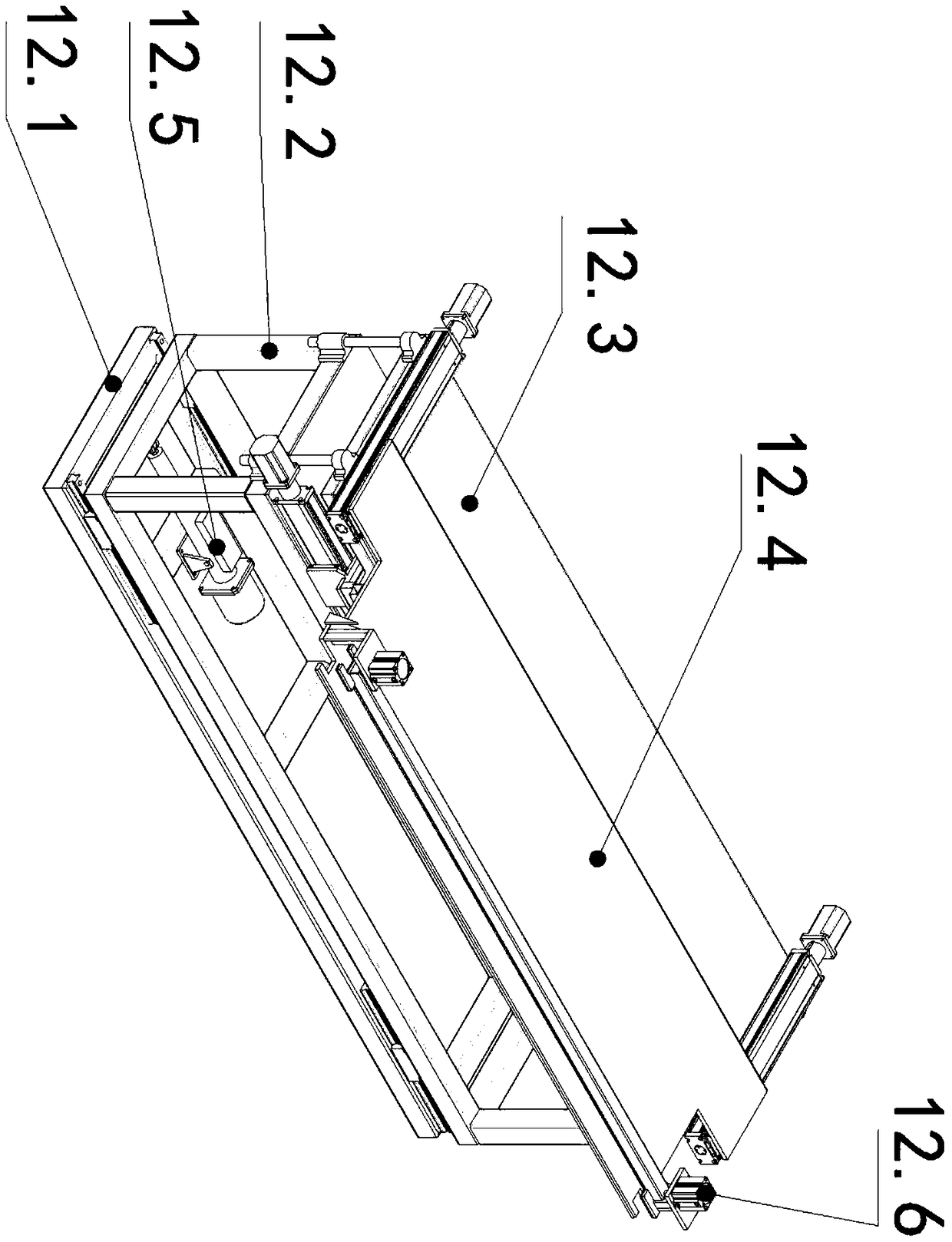

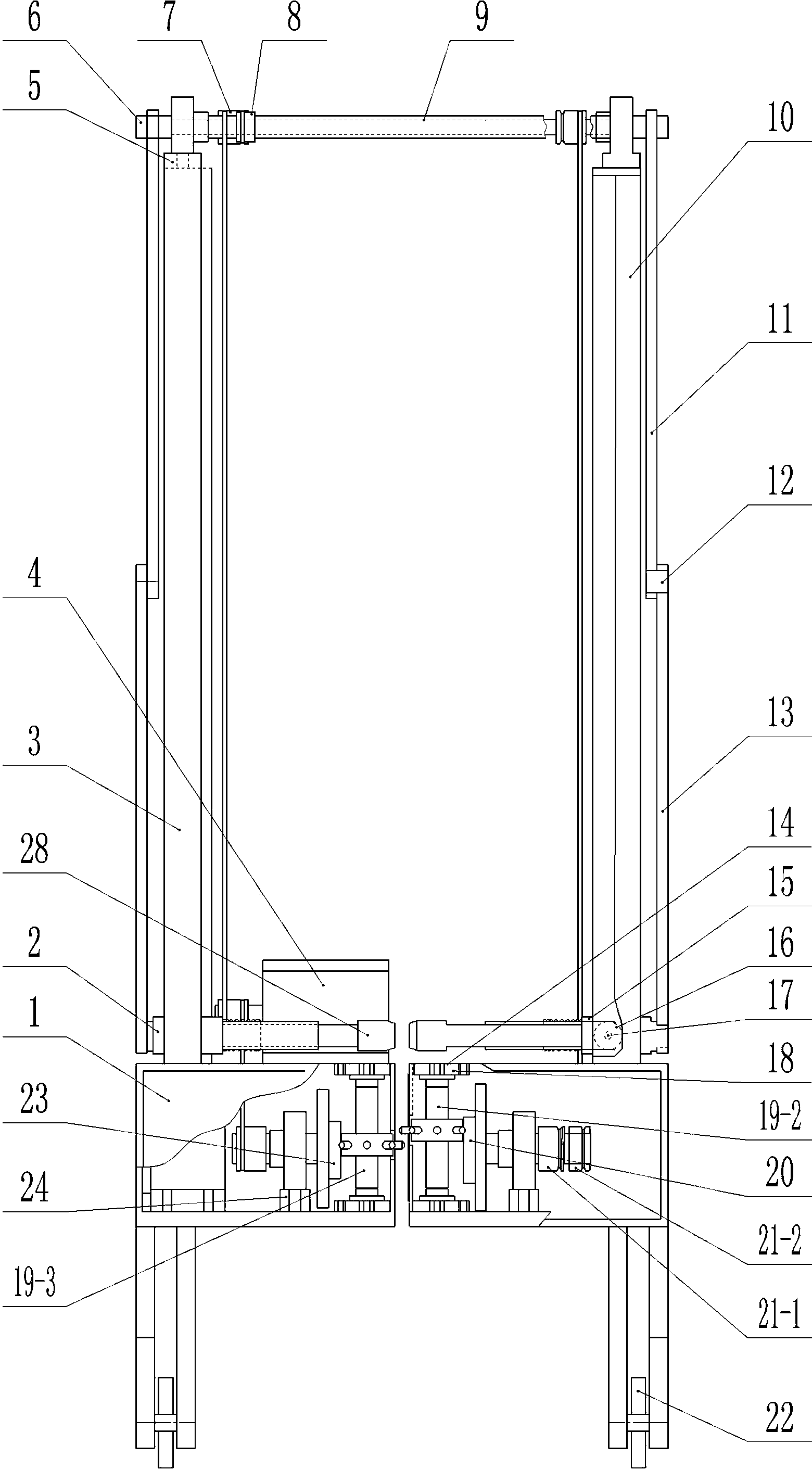

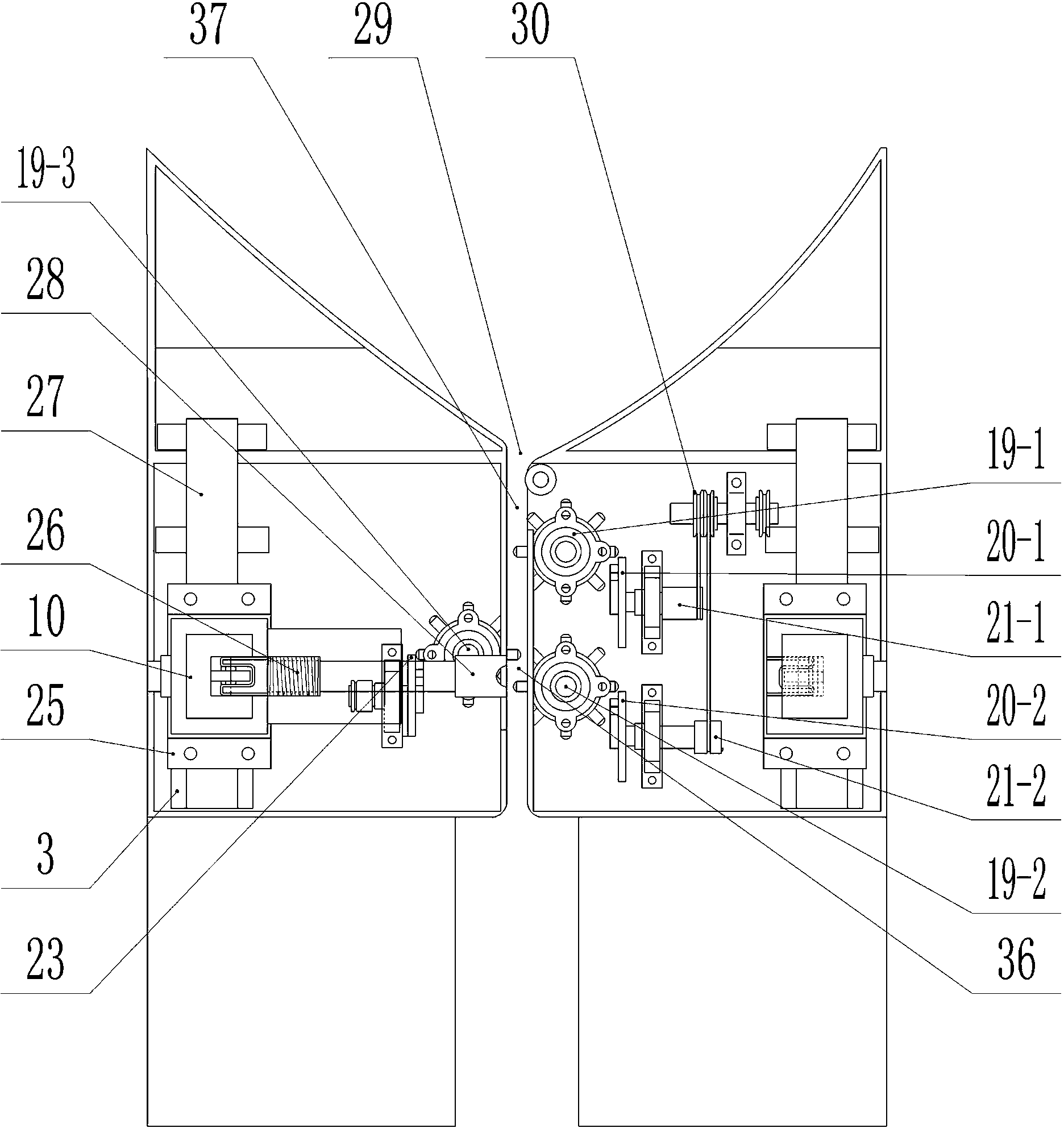

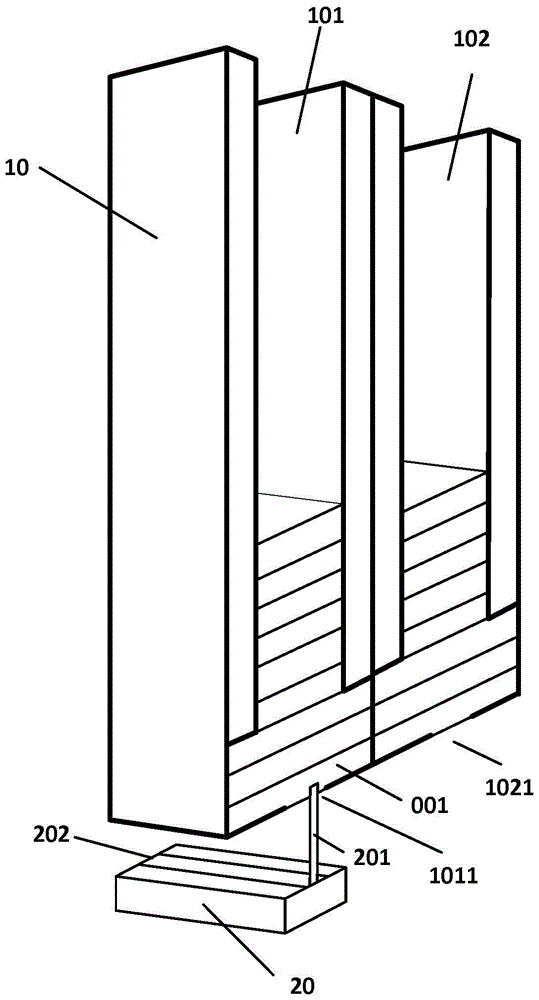

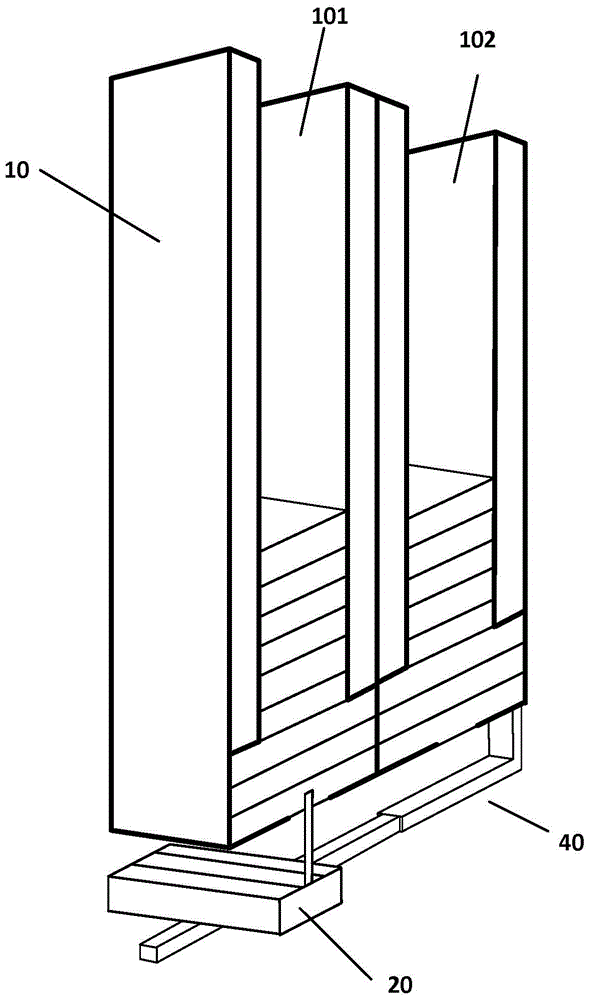

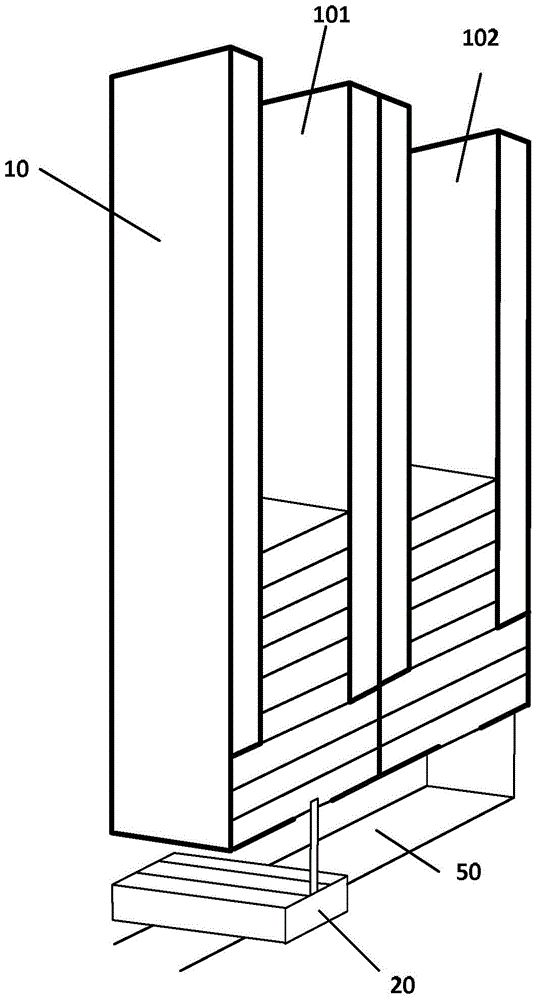

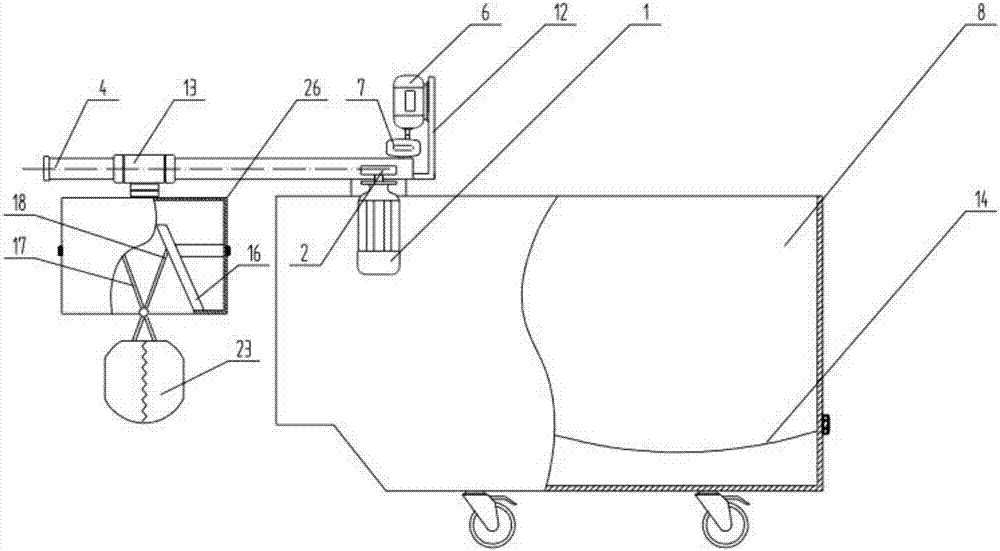

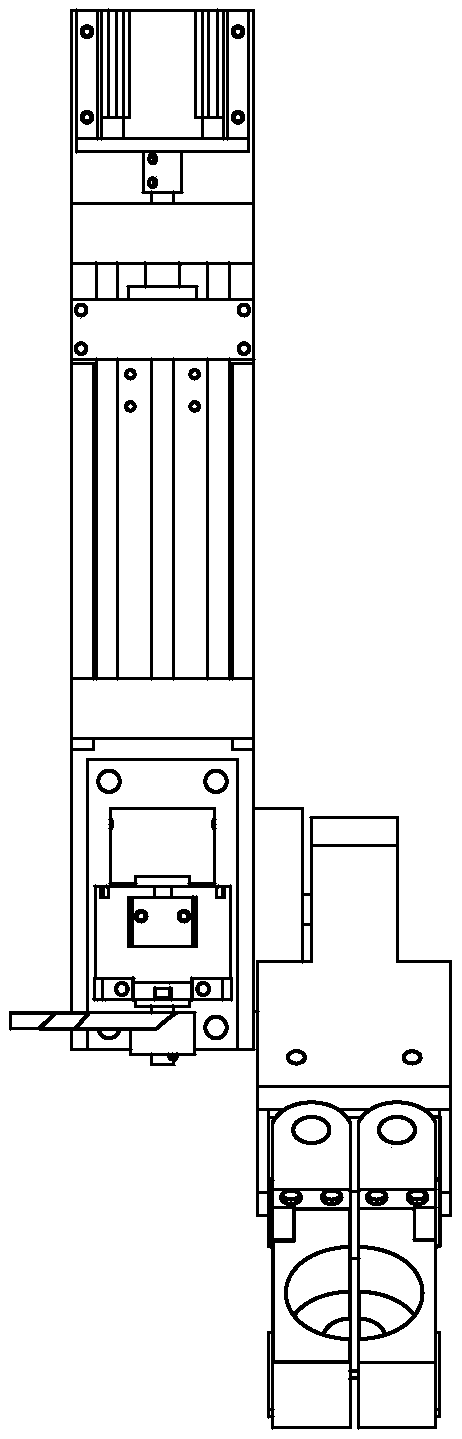

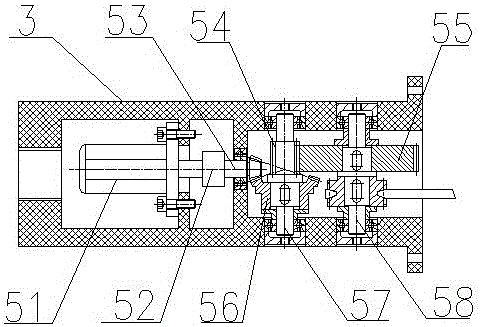

Intelligent bagging device for rod wire rolls

PendingCN108820355AWork tempo matching is reasonableRealize automatic pickingIndividual articlesWorking environmentEngineering

The invention discloses an intelligent bagging device for rod wire rolls. The intelligent bagging device comprises a crane used for storing the rod wire rolls, a bag forming line used for manufacturing and forming woven bags, an automatic bagging device used for sleeving the formed woven bags to the rod wire rolls, and a ground rail. The bag forming line is sequentially provided with an automaticroll releasing and deviation rectifying device used for automatically switching and feeding the woven bags, an automatic splicing device used for connecting two rolls of woven bags in a seamless manner, an elastic cord sewing device used for sewing and closing up the two ends of each woven bag, and a woven bag welding machine used for sewing and splitting the woven bags. The crane and the automatic bagging device are arranged on the ground rail. The automatic bagging device is arranged right ahead of the crane. The initial position of the automatic bagging device stops at the left end of the ground rail. The automatic bagging device moves on the ground rail back and forth to achieve bagging of the rod wire rolls. The intelligent bagging device can achieve the unmanned automatic fast bagging function, the working environment of workers is improved, and the working efficiency is improved.

Owner:江苏中科云控智能工业装备有限公司

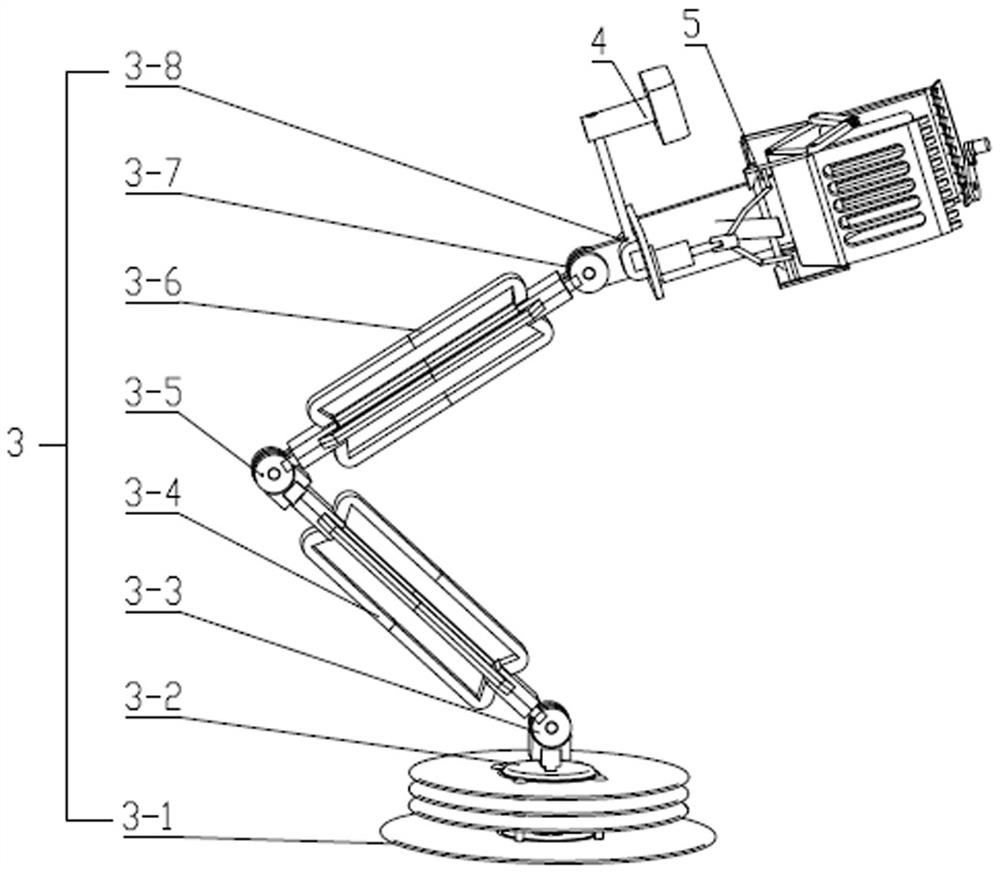

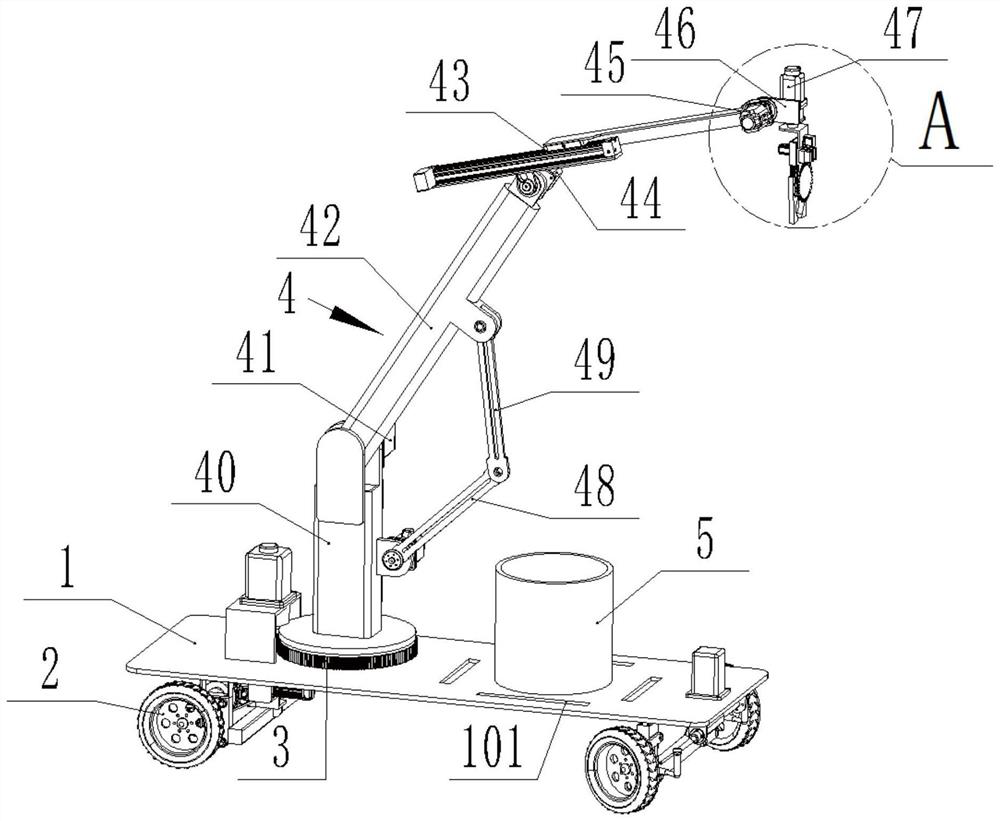

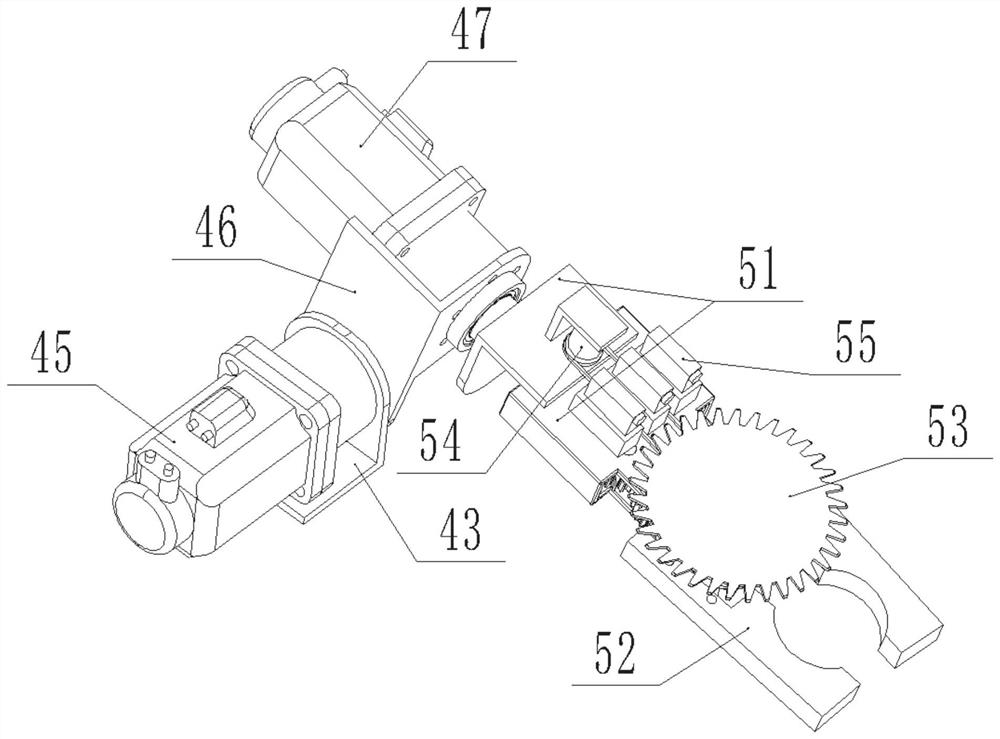

Picking manipulator and intelligent fruit picker

InactiveCN111656960AWide range of operationsEasy to usePicking devicesMechanical engineeringControl engineering

The invention discloses a picking manipulator. The picking manipulator comprises a base, a large arm, a telescopic forearm, an oscillating wrist, a palm, grabbing fingers, a cutting blade, a first rotary drive assembly, a second rotary drive assembly, a third rotary drive assembly, a fourth rotary drive assembly, a fifth rotary drive assembly, a sixth rotary drive assembly, a first transmission assembly, a second transmission assembly, a first connecting rod and an oscillating gear. The invention further discloses an intelligent fruit picker. The intelligent fruit picker comprises a base plate, a walking mechanism, a swing mechanism, a fruit containing barrel and the picking manipulator, wherein the walking mechanism is arranged below the base plate; the swing mechanism is arranged at theupper part of the base plate; the lower end of the base is connected with the swing mechanism; and the fruit containing barrel is placed at the upper part of the base plate. According to the picking manipulator and the intelligent fruit picker, automatic picking of fruits is achieved, the fruit picking effect is greatly improved, manpower is saved and the artificial labor intensity is reduced.

Owner:湖南翰坤实业有限公司

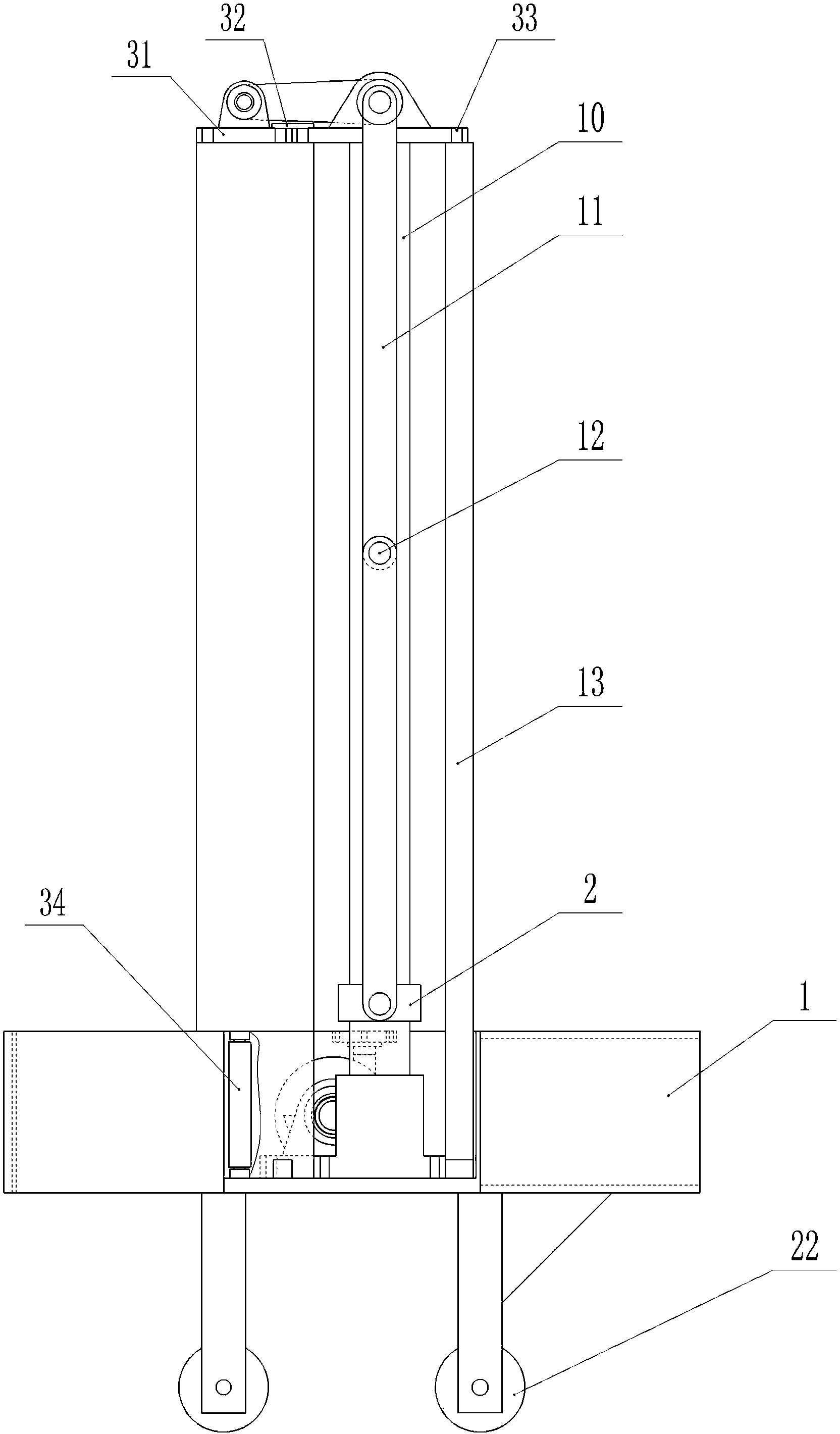

Robot capable of automatically picking up eggs

InactiveCN105145407ARealize automatic pickingSave manpower and material resourcesBird housingsMaterial resourcesEngineering

The invention provides a robot capable of automatically picking up eggs and belongs to the field of poultry breeding. The robot comprises a robot body and a motion assembly. The motion assembly comprises a sliding plate and a fixed sliding rail. The robot body is installed on the sliding plate. Sliding rail bodies are arranged on the fixed sliding rail. The robot is characterized by further comprising a square egg barrel assembly and an egg rack assembly; the lower end of the robot body is connected with the motion assembly, and the square egg barrel assembly is arranged at the upper end of the robot body, the egg rack assembly is arranged on a coop. The effect of automatically picking up the eggs can be achieved, and a large quantity of manpower and material resources are saved.

Owner:SHANGHAI ZHONGHONG ELECTRONICS TECH

Fabric cutting and fetching method

ActiveCN107724052ARealize automatic croppingRealize automatic pickingSevering textilesMetal working apparatusFiberControl system

The invention belongs to the field of complex fiber fabric processing and particularly relates to a cloth cutting method for complex fiber fabrics. The method specifically comprises the steps that distribution design is conducted on multiple shapes of pieces to be cut in a complementary way, distribution design results are imported into a cutting machine control system; the control system segmentsthe distribution design, wherein each segment can be completely covered by the cutting range of a cutting machine in the cutting process, and it is ensured that only one row of pieces exists in eachsegment in the fabric conveying direction; positioning points of the segments are determined and need to coincide with the central line of the cutting range of the cutting machine; the control systemcontrols a device to operate and achieves fabric positioning in the conveying process in the mode that the positioning points coincide with the central line, and cutting is performed by using the distribution design of each segment as a motion trail after positioning is completed. By adopting the fabric cutting and fetching method, automatic fabric cutting and taking can be achieved, the working efficiency is effectively improved, and the labor cost is reduced.

Owner:NEWTRY COMPOSITE

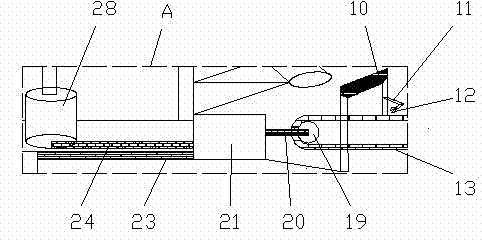

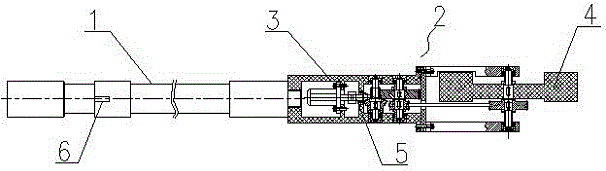

Tobacco harvesting machine with roller cutter head

InactiveCN102334402ARealize automatic pickingRealize automatic collectionHarvestersCamMechanical engineering

The invention discloses a tobacco harvesting machine with a roller cutter head, comprising a frame and a driving part, wherein the frame is provided with a tobacco leaf collecting box and a tobacco leaf harvesting cutter box; a motor is arranged in the tobacco leaf harvesting cutter box; a main shaft of the motor is connected with a cam supporting shaft through a coupler; the cam supporting shaftis provided with two cams and two oscillating followers; one end of each oscillating follower is hinged with the tobacco leaf harvesting cutter box; each oscillating follower is respectively in contact with one cam; and the other end of the oscillating follower is connected with a flexible cutter head serving as a roller. By using the tobacco harvesting machine in the technical scheme, automatically picking up tobacco leaves is realized; tobacco leaves with different heights can be collected through adjusting the height of the tobacco leaf harvesting cutter box; and the tobacco harvesting machine has the characteristics of high harvesting efficiency, high pick-up rate and the like. Compared with an aboard machine, the tobacco harvesting machine has a simple structure and lower cost.

Owner:HENAN AGRICULTURAL UNIVERSITY

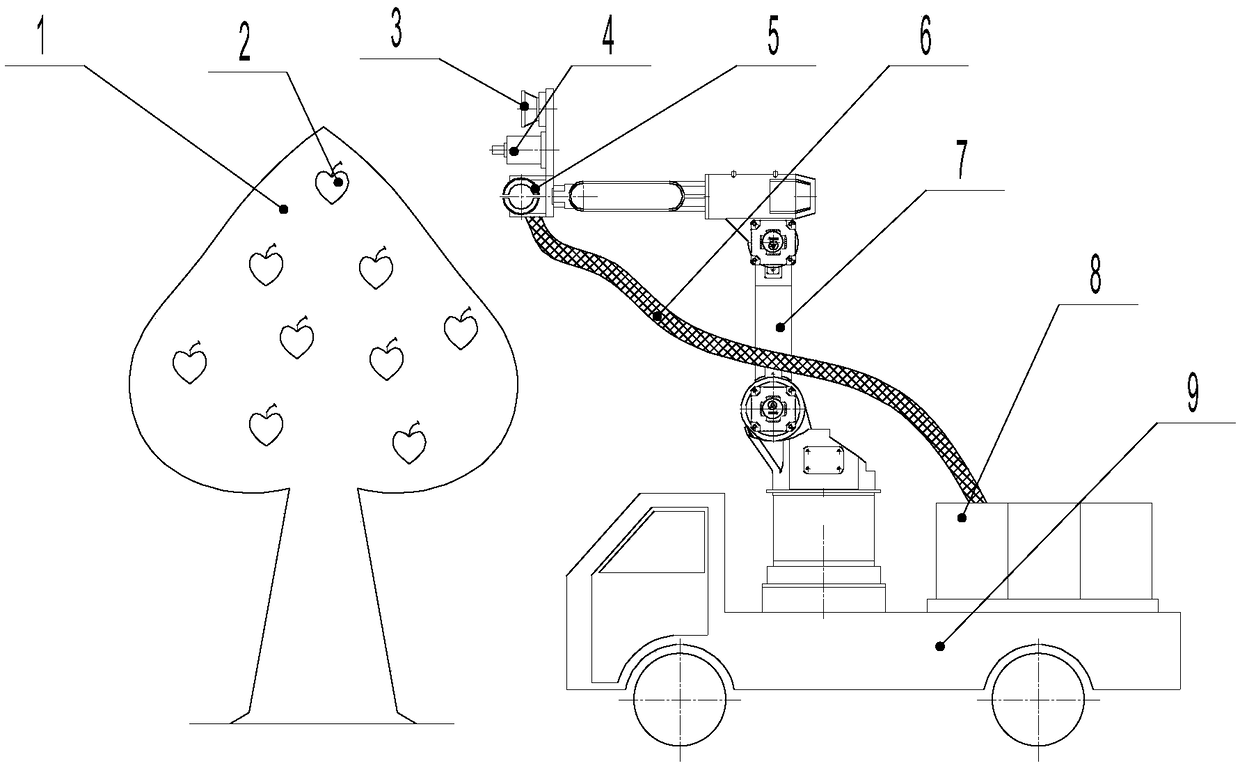

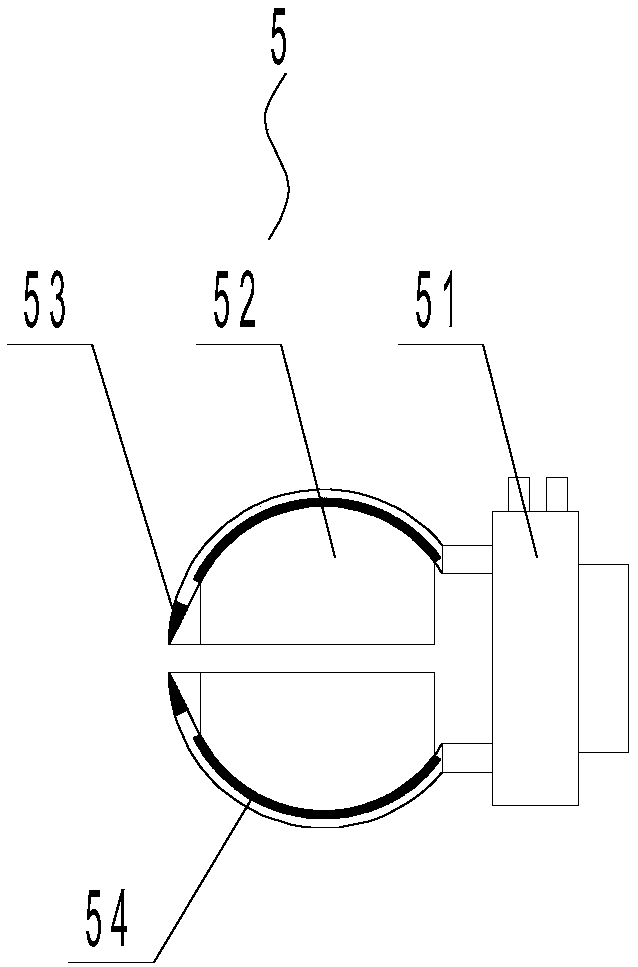

Automatic fruit picking device based on information traceability and method thereof

InactiveCN109005920ARealize automatic pickingAutomate the picking processProgramme control in sequence/logic controllersPicking devicesFruit treePattern recognition

An automatic fruit picking device based on information traceability relates to a picking device and a method. The device comprises a visual recognition device, a QR code pasting device, an automatic picking device and a fruit picking robot, wherein the automatic picking device is connected with a fruit collection box through a conveying hose, the visual recognition device, the QR code pasting device and the automatic picking device are respectively installed on the fruit picking robot; the visual recognition device is connected with the input end of the fruit picking robot, and the output endof the fruit picking robot is respectively connected with the QR code pasting device and automatic picking device. The method includes the steps of determining the position and maturity of the fruit on a fruit tree by the visual recognition device, activating the QR code pasting device to paste planting information, starting the automatic picking device to pick the fruit, and conveying the pickedfruit through the conveying hose to the fruit collection box. The invention can realize automatic picking and quality tracing of fruits, and has great promotion value.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

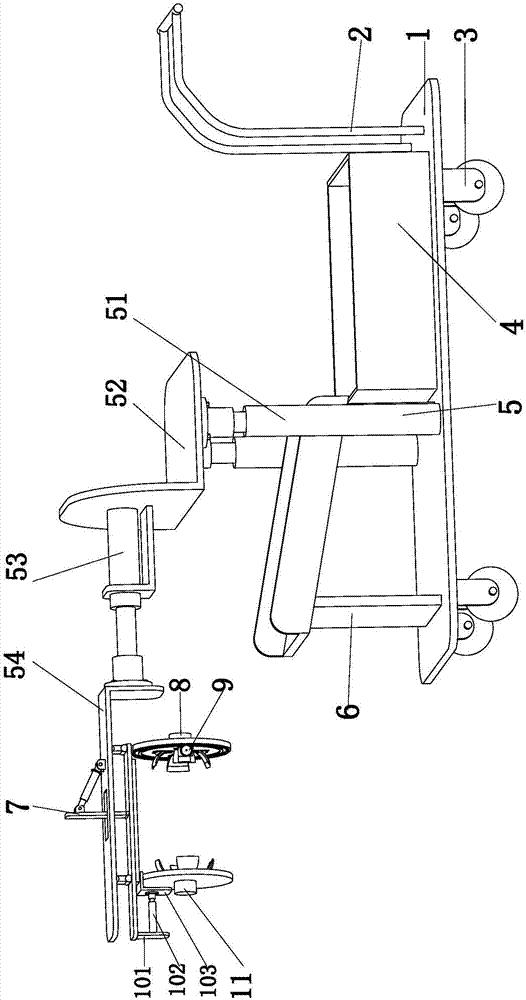

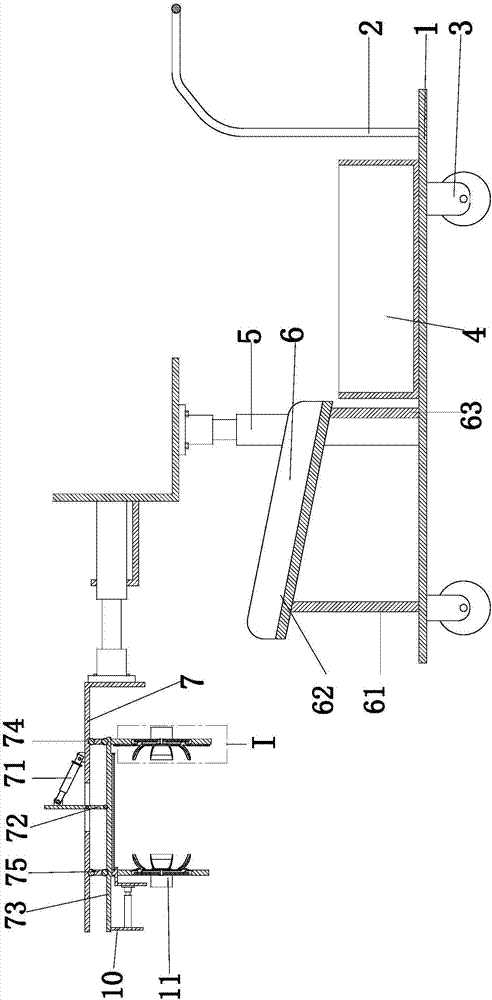

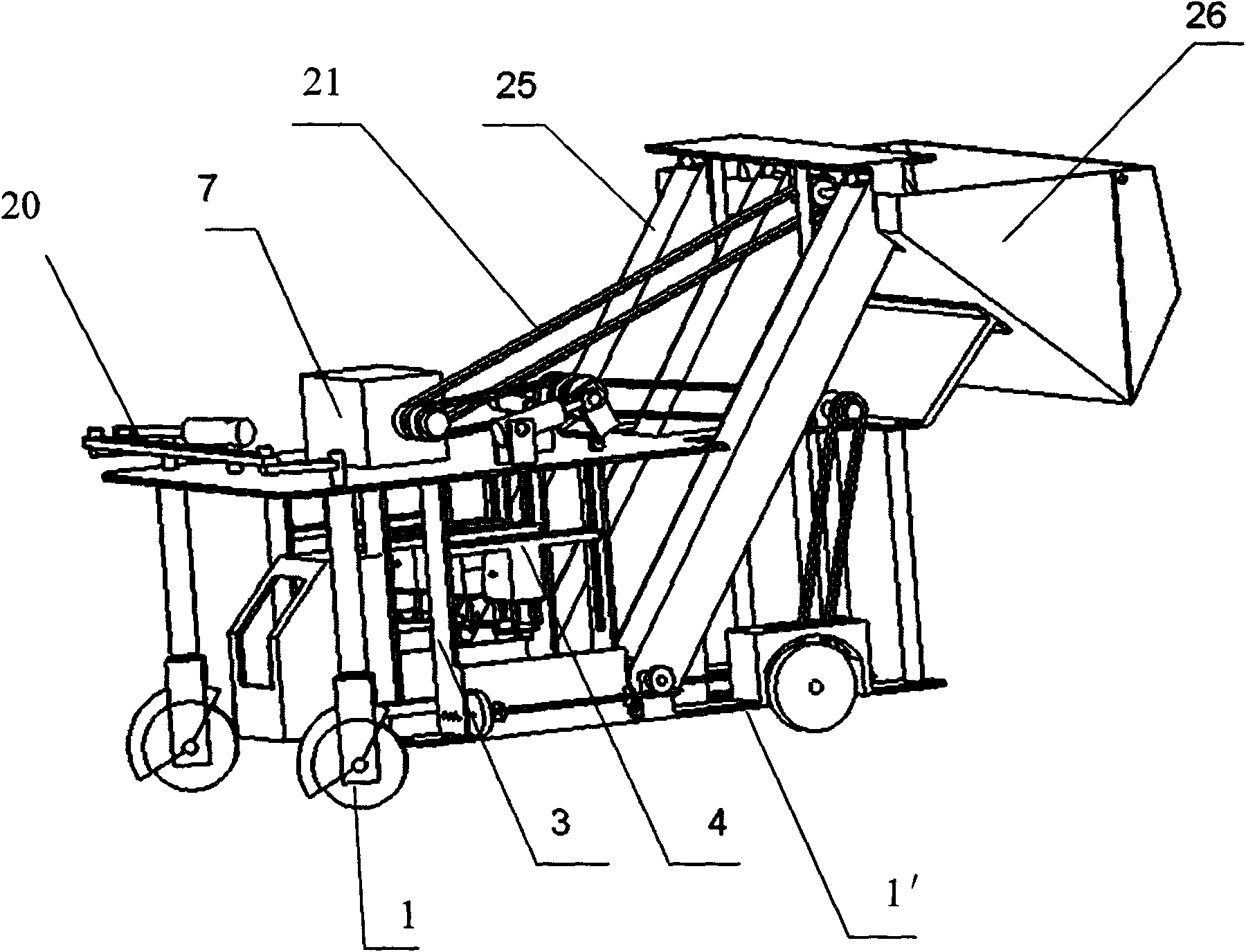

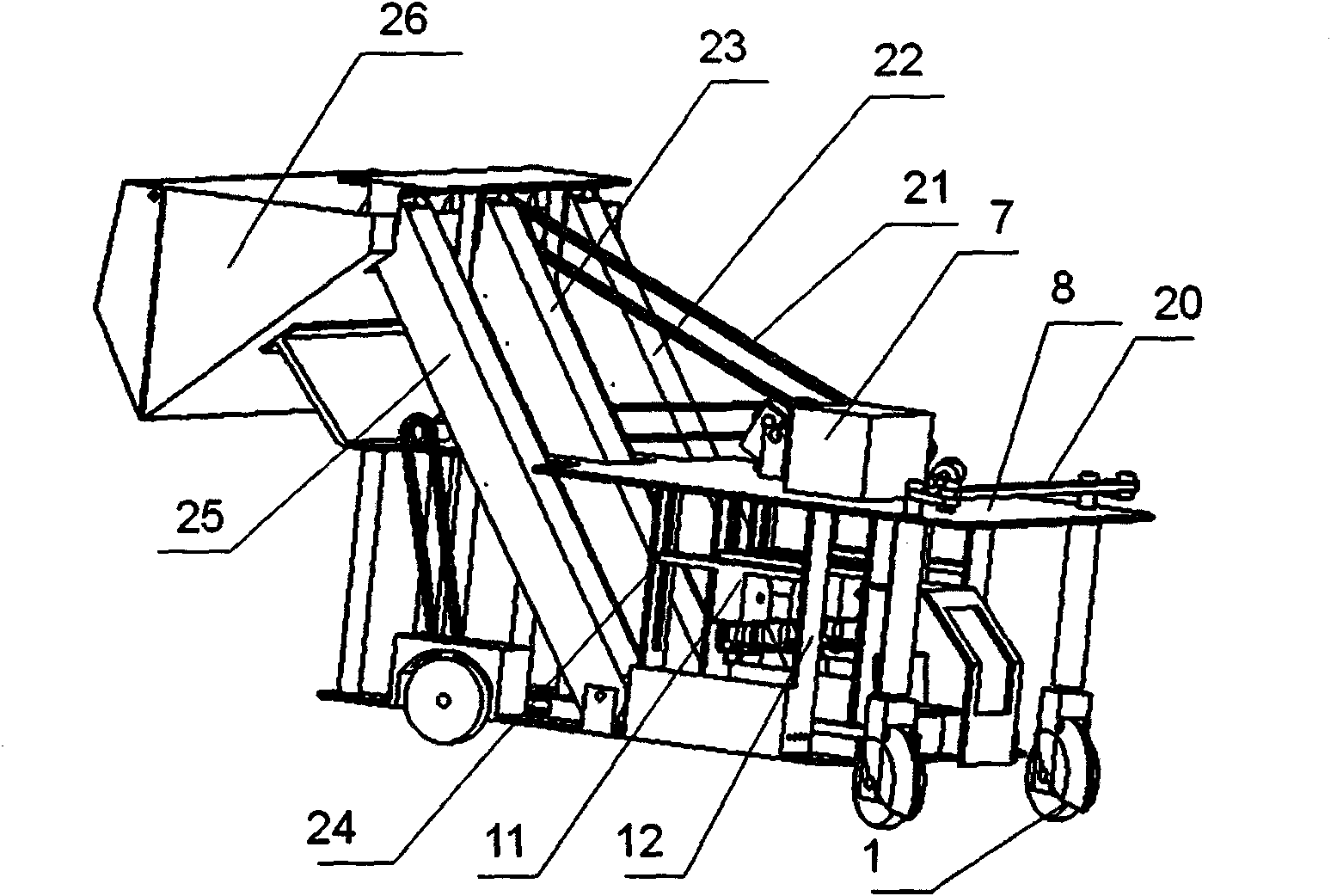

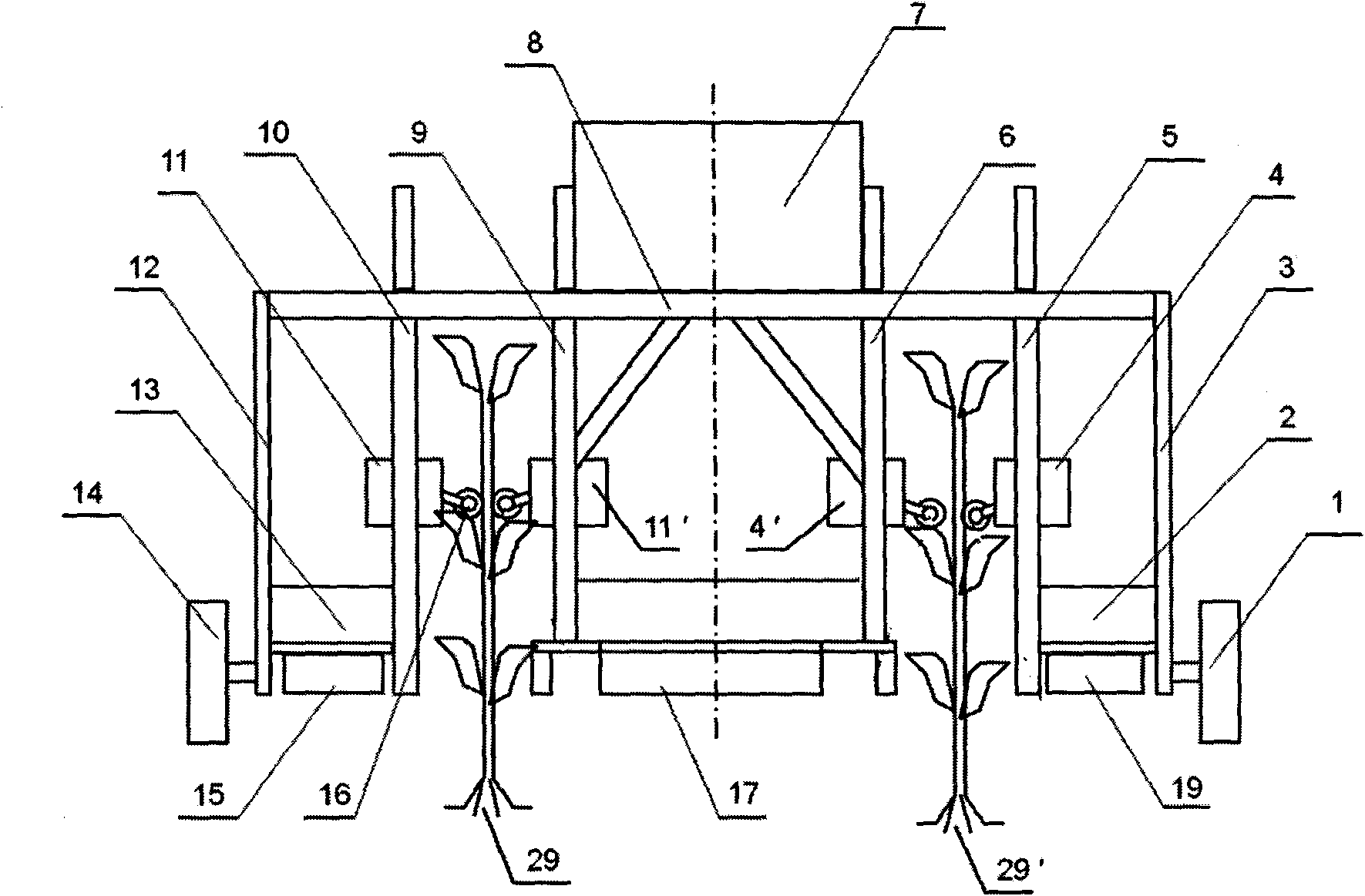

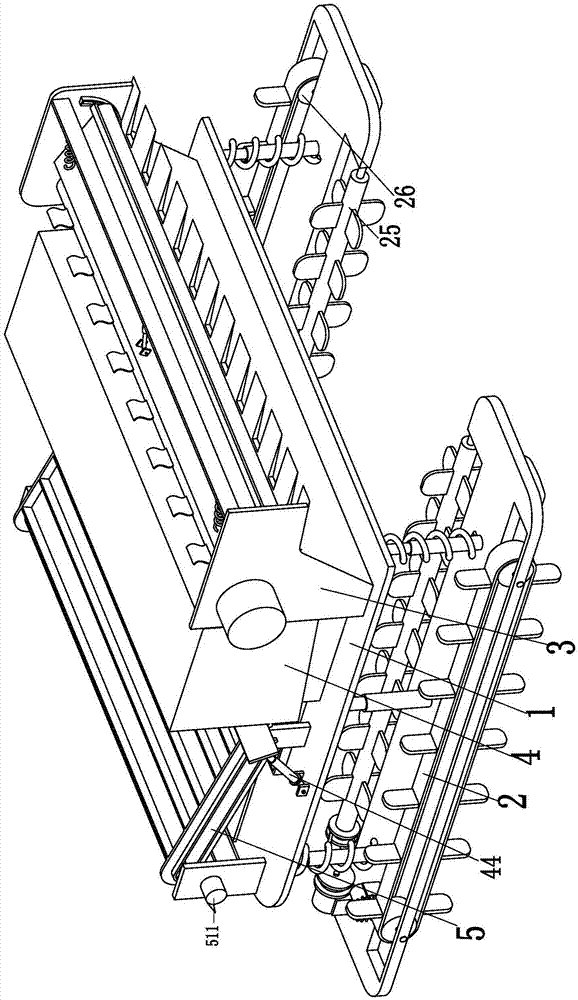

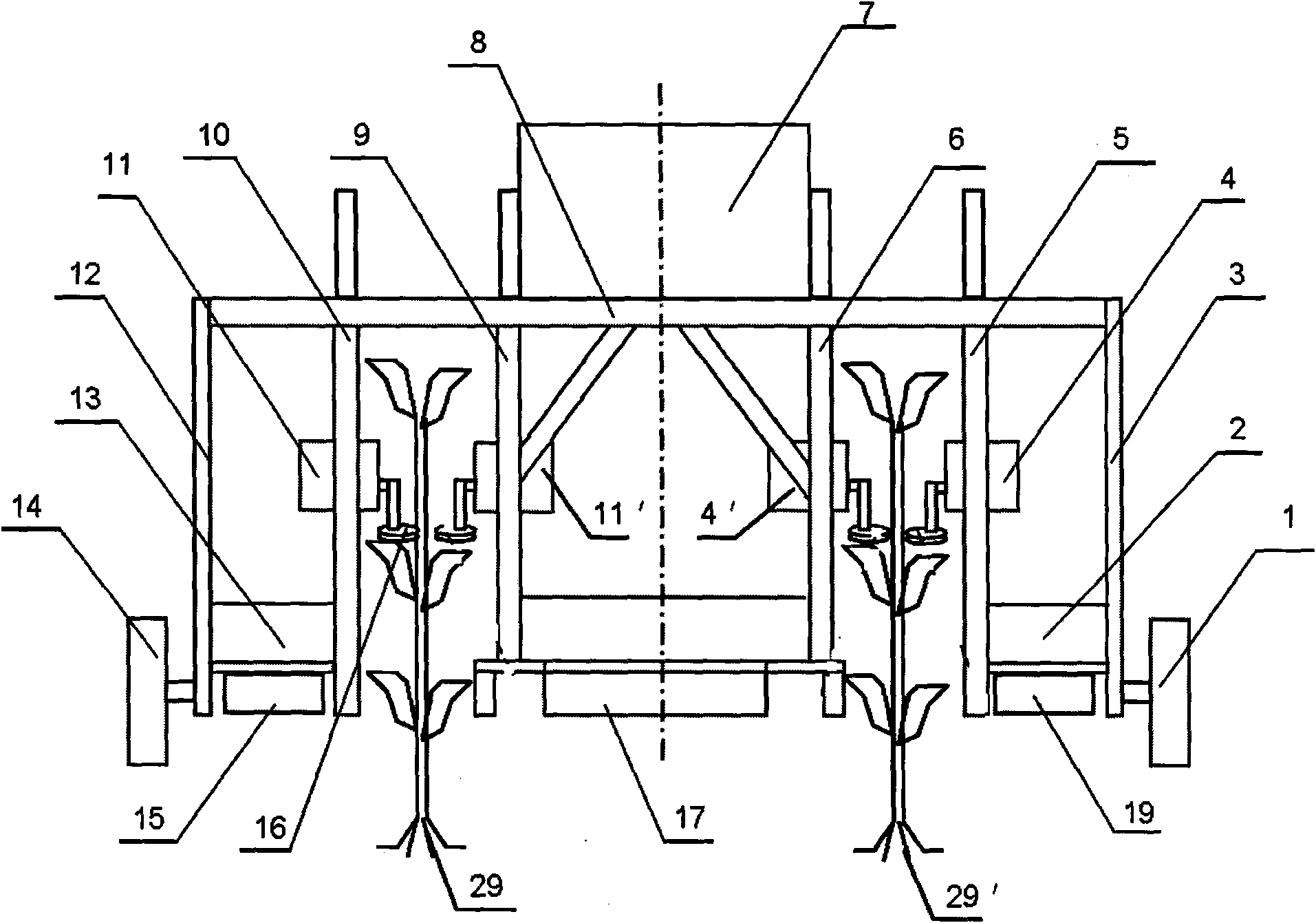

Automatic folium mori picking machine driven in rocker arm mode

The invention discloses an automatic folium mori picking machine driven in a rocker arm mode. The automatic folium mori picking machine comprises a travelling device and is characterized by comprising a base device, a ramulus mori poking and positioning device, a rocker arm device and a folium mori picking device. The base device is arranged on the travelling device, the ramulus mori poking and positioning device is arranged in a box body of the base device, two hook-shaped guide rails of the folium mori picking device are symmetrically and vertically arranged on the base device, a ramulus mori positioning wheel of the ramulus mori poking and positioning device is arranged behind a folium mori inlet of the base device, cutters at the front ends of two cutter bar shafts of the folium mori picking device are arranged above the ramulus mori positioning wheel, the rears of the cutter bar shafts are sleeved with guide rail sliding blocks, the tail ends of the guide rail sliding blocks are hinged to a connecting rod of the rocker arm device, a rocker arm of the rocker arm device is fixedly connected with a driven shaft at the upper ends of the hook-shaped guide rails, and the driven shaft is connected with a power mechanism. The automatic folium mori picking machine can reduce labor intensity of folium mori planters, improve folium mori picking speed and the picking rate and reduce labor cost and is convenient to use.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

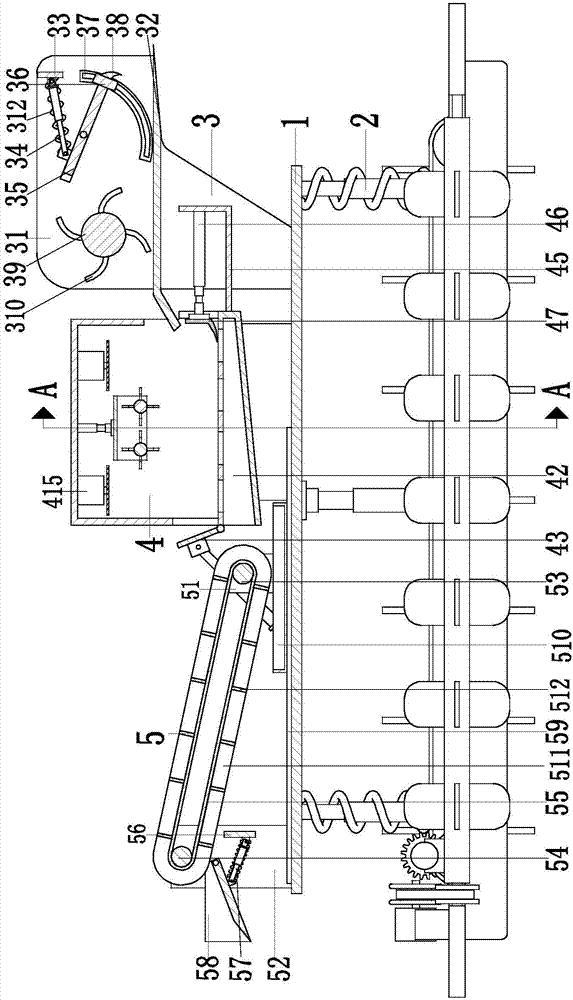

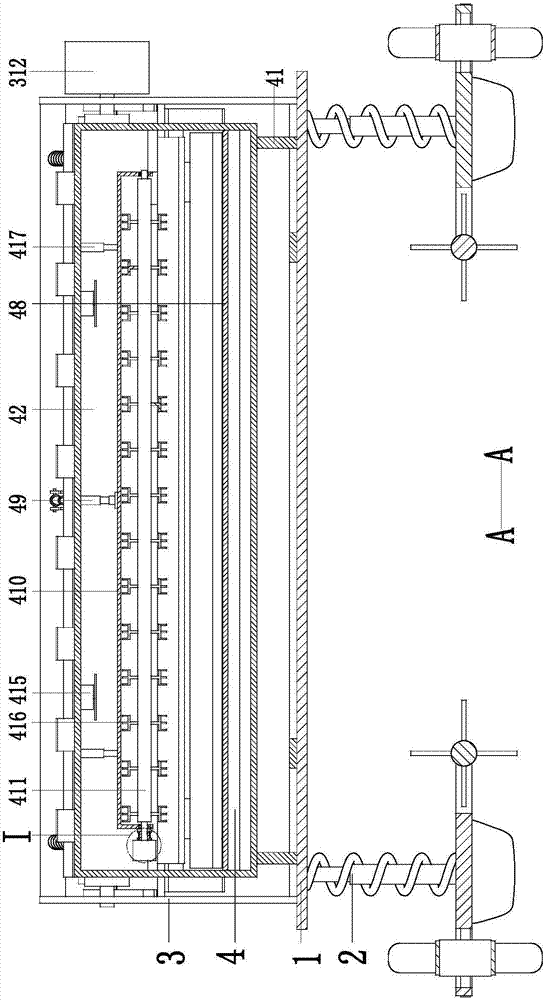

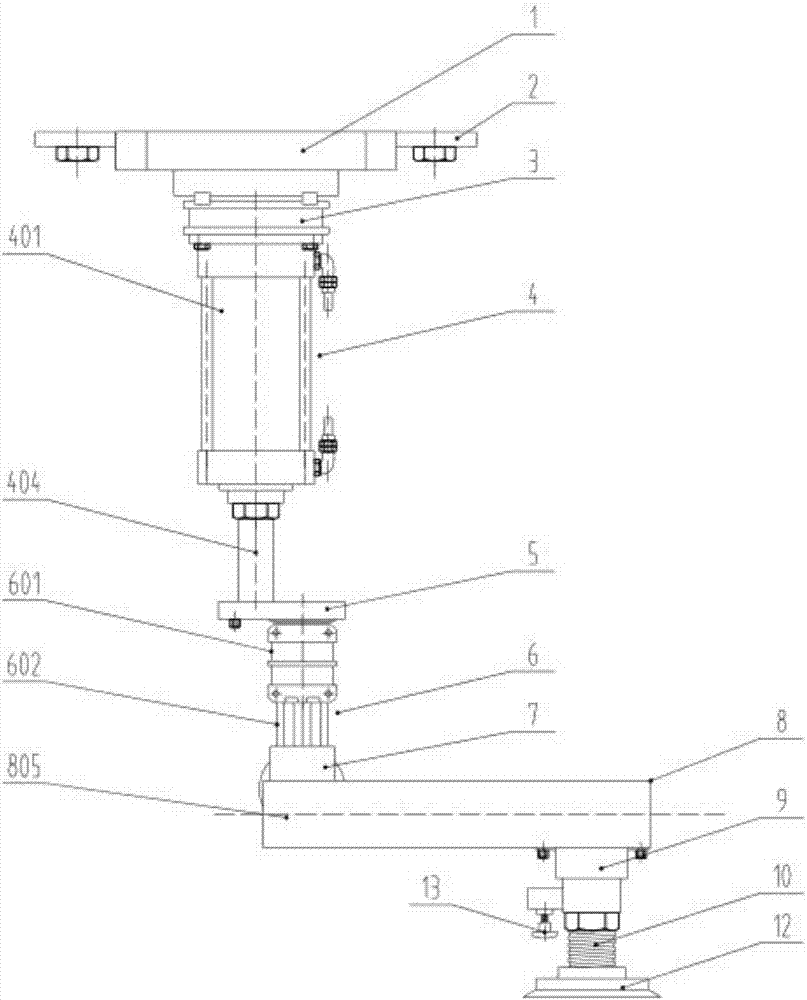

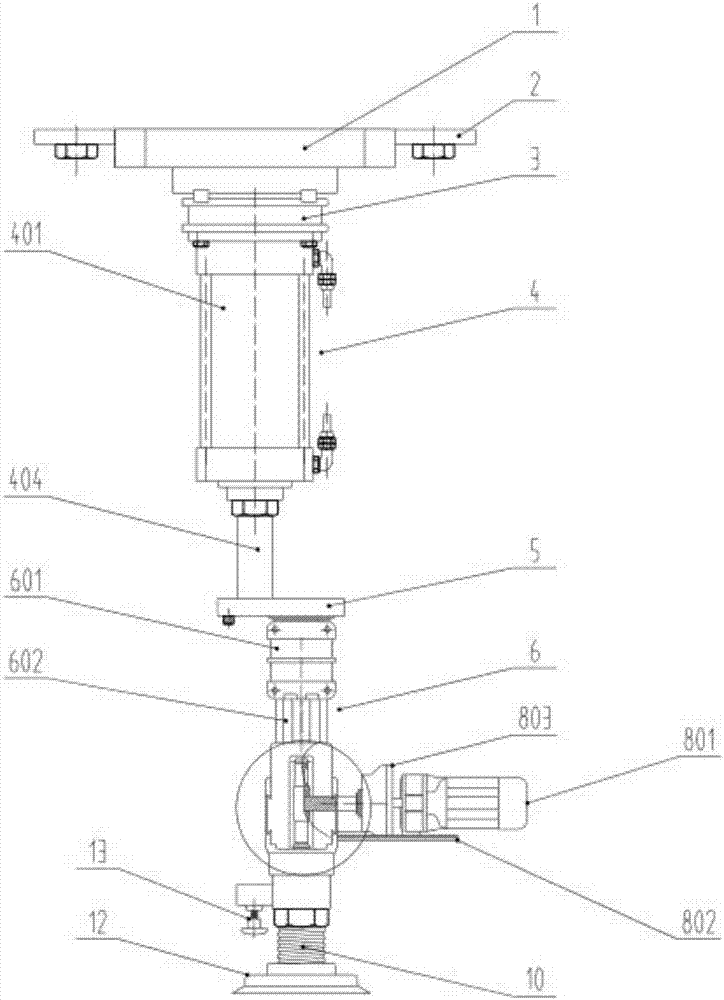

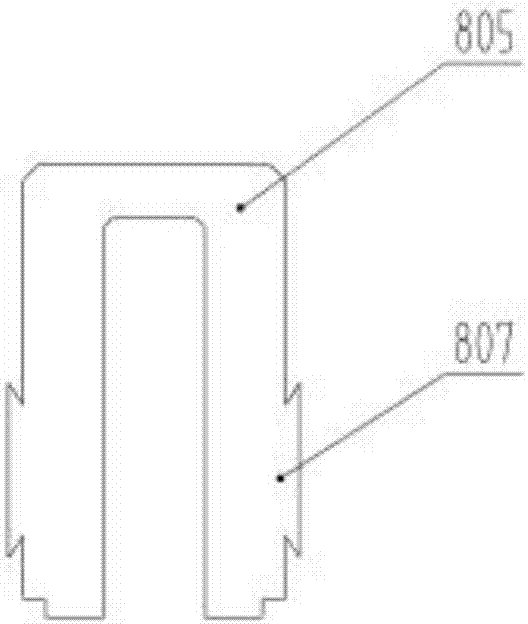

Picking and delivering robot used for ecological floating bed rod-shaped agricultural fruits

InactiveCN107258230ARealize automatic pickingIncrease flexibilityPicking devicesEngineeringUltimate tensile strength

The invention relates to a picking and conveying robot for rod-shaped agricultural fruits on an ecological floating bed. There is a separation device, and a conveying device is installed on the rear side of the support plate. The mobile floating device, the picking device, the separating device and the conveying device are used in conjunction with each other to complete the process of automatic picking and conveying of rod-shaped fruits on the floating bed. The present invention can solve the problems existing in the fruit picking process of rod-shaped plants on the existing ecological floating bed that the mature rod-shaped fruit needs to be manually picked, the impurities in the rod-shaped fruit need to be picked manually, and the picked rod-shaped fruit needs to be manually transported. Manually driven water mobile equipment has poor flexibility, manual picking and transporting of rod-shaped fruits is complicated, complicated operation, time-consuming, labor-intensive and low in work efficiency. It can realize the function of automatic picking and conveying of rod-shaped fruits on floating beds.

Owner:合肥集知网信息技术有限公司

Automatic goods sorting system and method

InactiveCN105015995ARealize automatic pickingReduce in quantityStorage devicesDe-stacking articlesEngineeringProbability of error

The invention discloses an automatic goods sorting system and method. The system comprises a sorting device and a control device. The sorting device is used for sorting goods on chutes used for storing the goods and located on a goods shelf and can move among the sorting positions of the chutes on the goods shelf. The control device is used for receiving a sorting command used for indicating the chute where the goods to be sorted are located, controlling the sorting device to move to the sorting position of the assigned chute and controlling the sorting device to execute sorting operation. Therefore, the goods can be automatically sorted, so that the labor cost is greatly reduced, and the probability of errors caused by manual operation is decreased. In addition, due to the fact that the sorting device can move among the sorting positions of the chutes on the goods shelf, each chute does not need to be provided with an independent sorting device, and cost is effectively saved. By the adoption of the automatic goods sorting system and method, operation is easy and the application scenes are wide.

Owner:WUXI GALAXIS AUTOMOTION MANAGEMENT GMBH +1

Watermelon harvesting and loading device

ActiveCN107027424AImprove picking efficiencyReduce labor loadPicking devicesCantilevered beamDrive wheel

The invention discloses a watermelon harvesting and loading device, and belongs to the technical field of agricultural intelligent machines. Both a transverse rod and one end of a cantilever beam are fixed on a driven gear, the transverse rod is parallel to the cantilever beam, and a gap is formed between the transverse rod and the cantilever beam; the cantilever beam is a metal plate piece with the thickness of 1 cm to 3cm, a driving wheel and a driven wheel are arranged on the cantilever beam respectively, and are connected through a belt; a second motor is arranged above the driving wheel, the output end of the second motor is connected with a reducer, and the reducer is connected with the driving wheel; a linear bearing is arranged on the transverse rod, connected with the belt and connected with a harvesting device. The watermelon harvesting and loading device has the advantage that automatic harvesting is achieved in the whole process.

Owner:河北鸿春农业发展有限公司

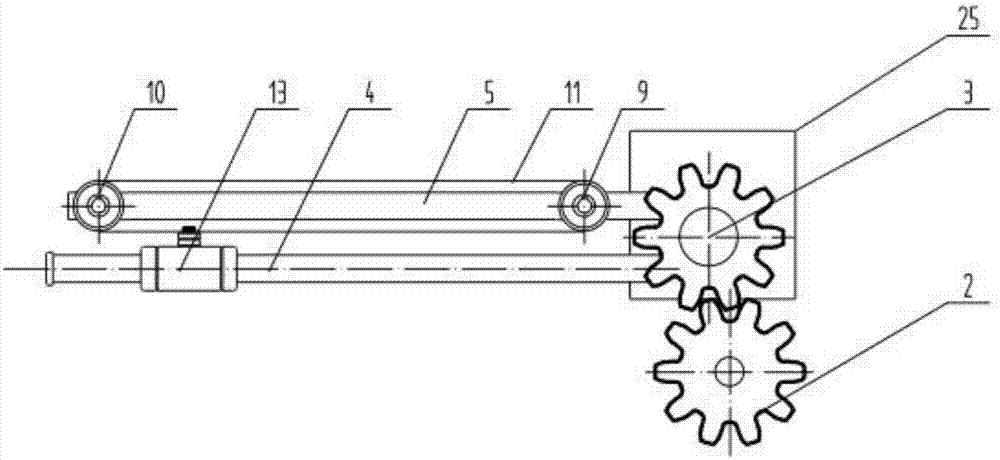

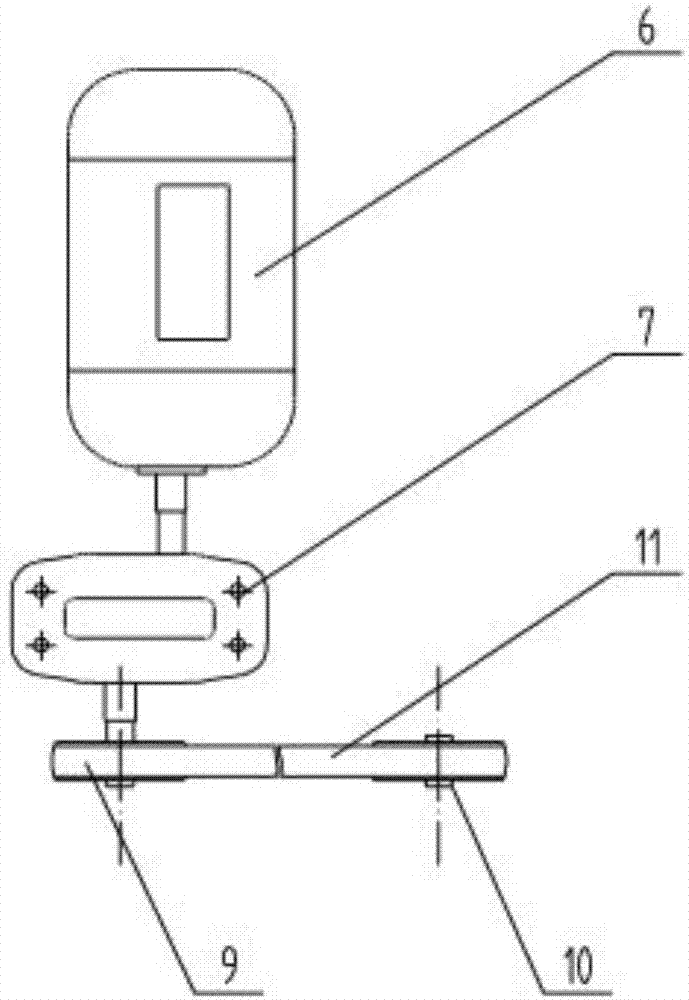

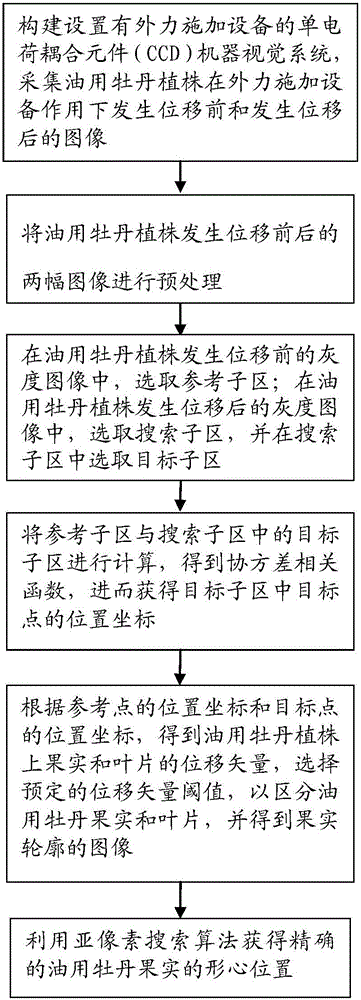

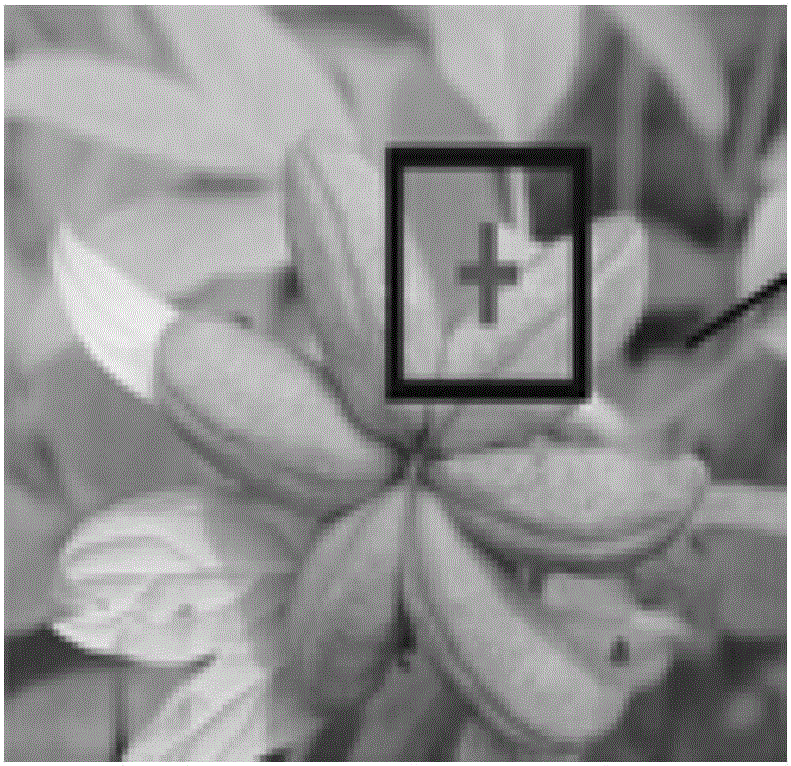

Oil peony fruit image identification method based on stress

InactiveCN105844264APrecise positioningRealize automatic pickingCharacter and pattern recognitionEngineeringHorticulture

The invention provides an oil peony fruit image identification method based on stress. The identification method comprises the following steps: constructing a charge coupling device (CCD) machine visual system with an external force application device, and acquiring images of oil peony plants under the effects of external forces before and after displacement; respectively selecting a reference subarea, a search subarea and an object subarea from the images of the oil peony plants before and after the displacement; performing calculation on the reference subarea and the object subarea, obtaining position coordinates of object points in the object subarea, obtaining displacement vectors of fruits and blades, selecting predetermined displacement vector thresholds, and obtaining images of fruit contours; by use of a sub-pixel search algorithm, obtaining accurate centroid positions of the oil peony fruits; at the same time, establishing an oil peony fruit chroma evolution model; and according to the chroma evolution model, bringing forward feature variables capable of representing maturity change of the oil peony fruits to determine maturity so as to complete positioning identification and maturity determination of the oil peony fruits.

Owner:BEIJING FORESTRY UNIVERSITY

Automatic storage and retrieval system for mails, parcels and single items

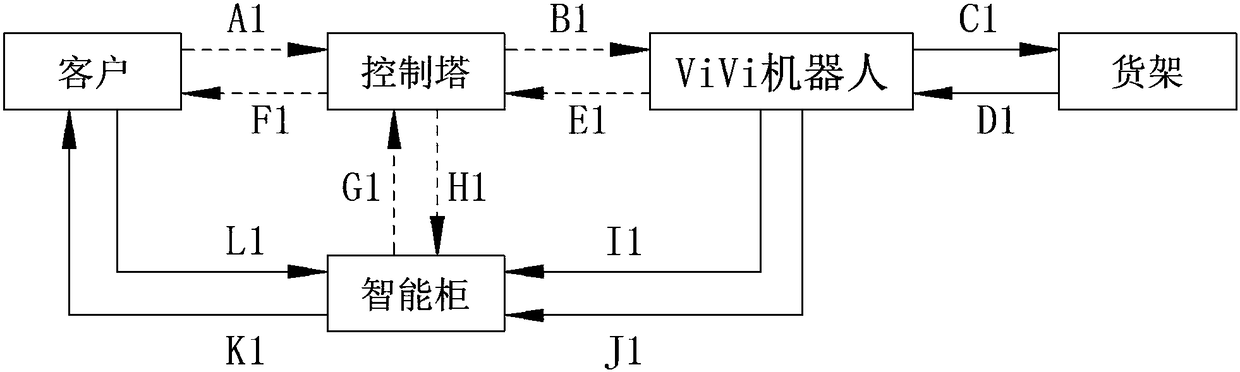

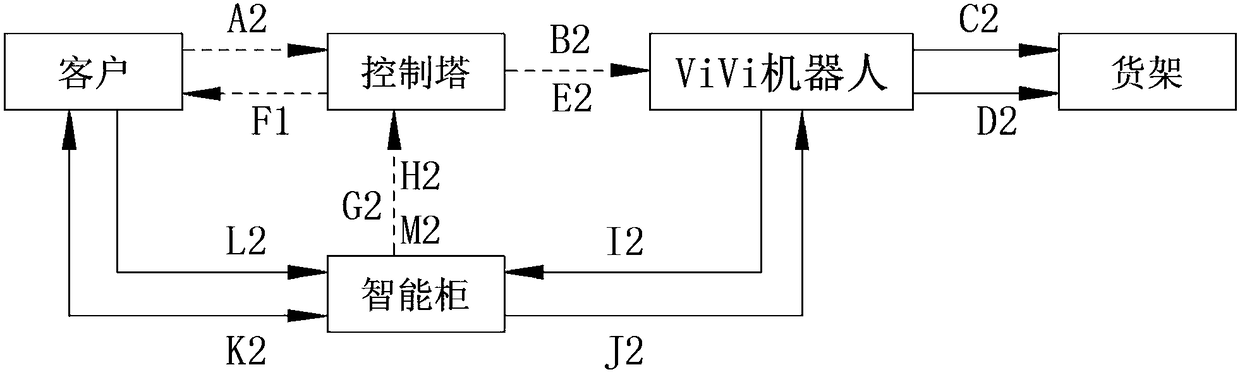

ActiveCN108100547ALarge capacityReduce waiting timeLogisticsStorage devicesLogistics managementInterconnection

The present invention discloses an automatic storage and retrieval system (ASRS) and sales system for mails, parcels and single items and inventory, and mainly relates to the technical field of logistics and new retail. The ASRS comprises a front-end access area, an interconnection operation machine, a back-end storage area and a control tower, a shelf is provided in the back-end storage area, theinterconnection operation machine comprises a ViVi robot, the front-end access area comprises a smart cabinet, and a guiding path adapted to an automatic guided vehicle system is provided between thesmart cabinet and the shelf. The present invention has the beneficial effects that it can realize an all-weather fully automatic access ASRS facility, in the case of fully inside automation, the person only needs to perform access operation from the outside to realize logistics exchange to complete the links required by business flow (sales), the system storage capacity can be greatly expanded, and the service time can be 24*7 to improve the terminal service quality and transit supply chain efficiency.

Owner:郭氢

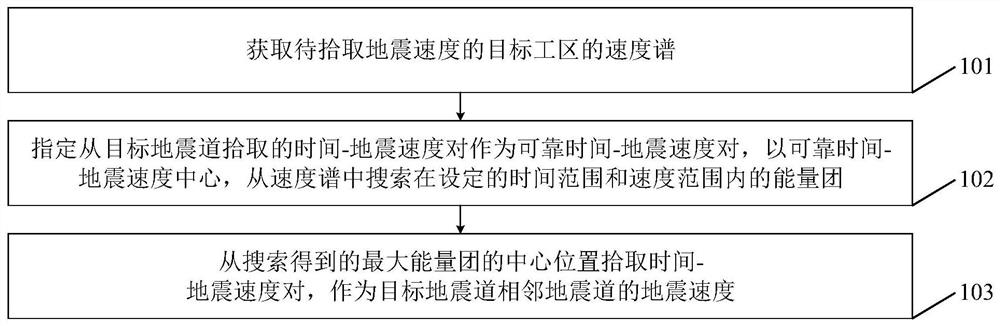

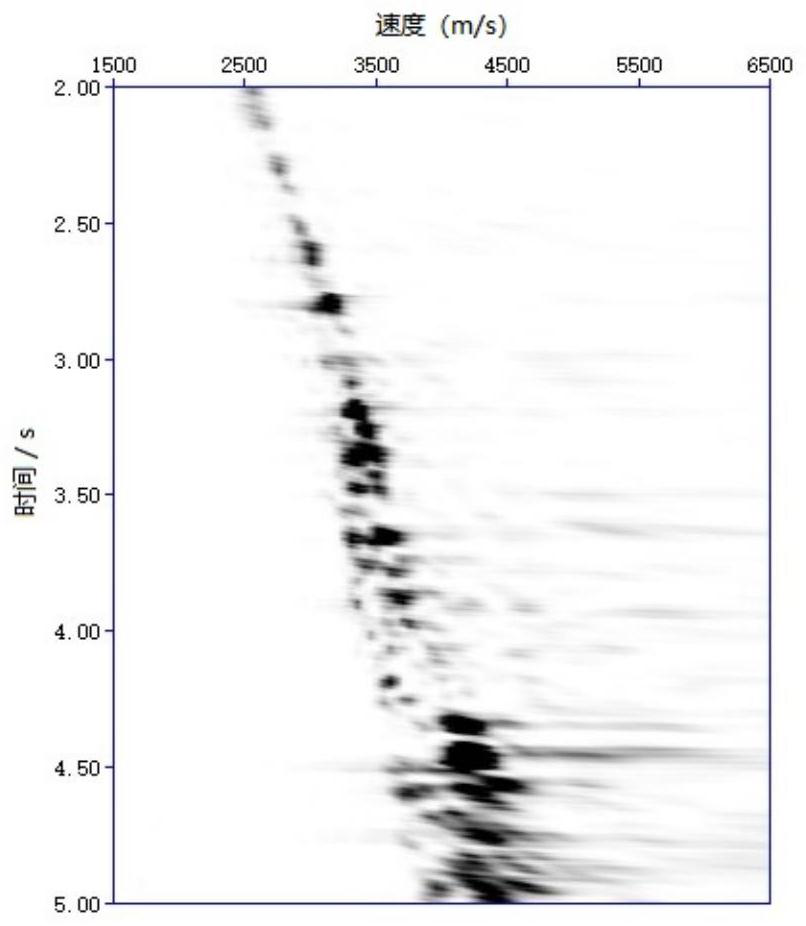

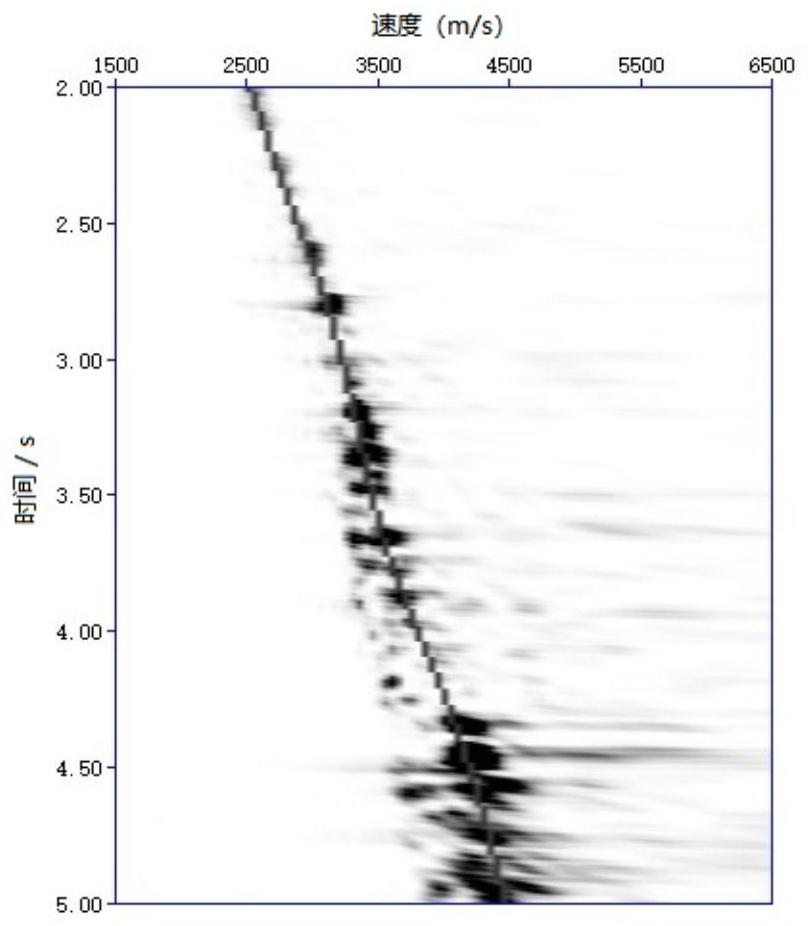

Earthquake speed automatic pickup method and device

ActiveCN111624653ARealize automatic pickingGuaranteed Picking AccuracySeismic signal processingSeismic velocitySeismic trace

The invention discloses an earthquake speed automatic pickup method and device. The method comprises the steps of obtaining a velocity spectrum of a target work area with an earthquake speed to be picked up; specifying a time-seismic velocity pair picked up from a target seismic trace as a reliable time-seismic velocity pair, and searching an energy group in a set time range and a set velocity range from the velocity spectrum by taking the reliable time-seismic velocity pair as a center; and picking up the time-seismic velocity pair from the central position of the searched maximum energy group, and taking the time-seismic velocity pair as the seismic velocity of the seismic trace adjacent to the target seismic trace. According to the invention, on the basis of ensuring the seismic velocity pickup accuracy, the seismic velocity pickup time is reduced, and the seismic velocity pickup efficiency is improved.

Owner:PETROCHINA CO LTD

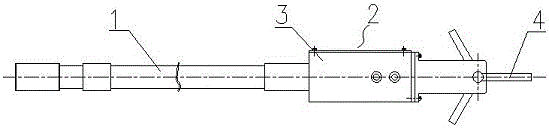

Tobacco harvesting machine with eccentric wheel

InactiveCN102334405ARealize automatic pickingRealize the collectionPicking devicesEngineeringMoving parts

The invention discloses a tobacco harvesting machine with an eccentric wheel. The tobacco harvesting machine comprises a frame and a moving part, wherein the frame is provided with a tobacco leaf collecting box and a tobacco leaf harvesting knife box; the tobacco leaf harvesting knife box is internally provided with a motor; the spindle of the motor is connected with a support shaft through a coupler; the tobacco leaf harvesting knife box is internally provided with a turntable slider mechanism; the turntable of the turntable slider mechanism is installed on the support shaft; the turntable is provided with a turntable outer end pin roll; a rotary slider and the turntable outer end pin roll form a revolute pair connection relation; the rotary slider and a guide rod form a move pair connection relation; the guide rod is located in a sliding groove on the tobacco leaf harvesting knife box; the lower end of the guide rod is connected with a flexible knife head through a chucking disk; and the chucking disk is of a disc shape. The tobacco harvesting machine goes forwards under the driving of the motor and the automatic picking, collecting and basketing of tobacco leaves are realized. The tobacco harvesting machine has the characteristics of high harvesting efficiency, high thoroughly picking rate and the like.

Owner:HENAN AGRICULTURAL UNIVERSITY

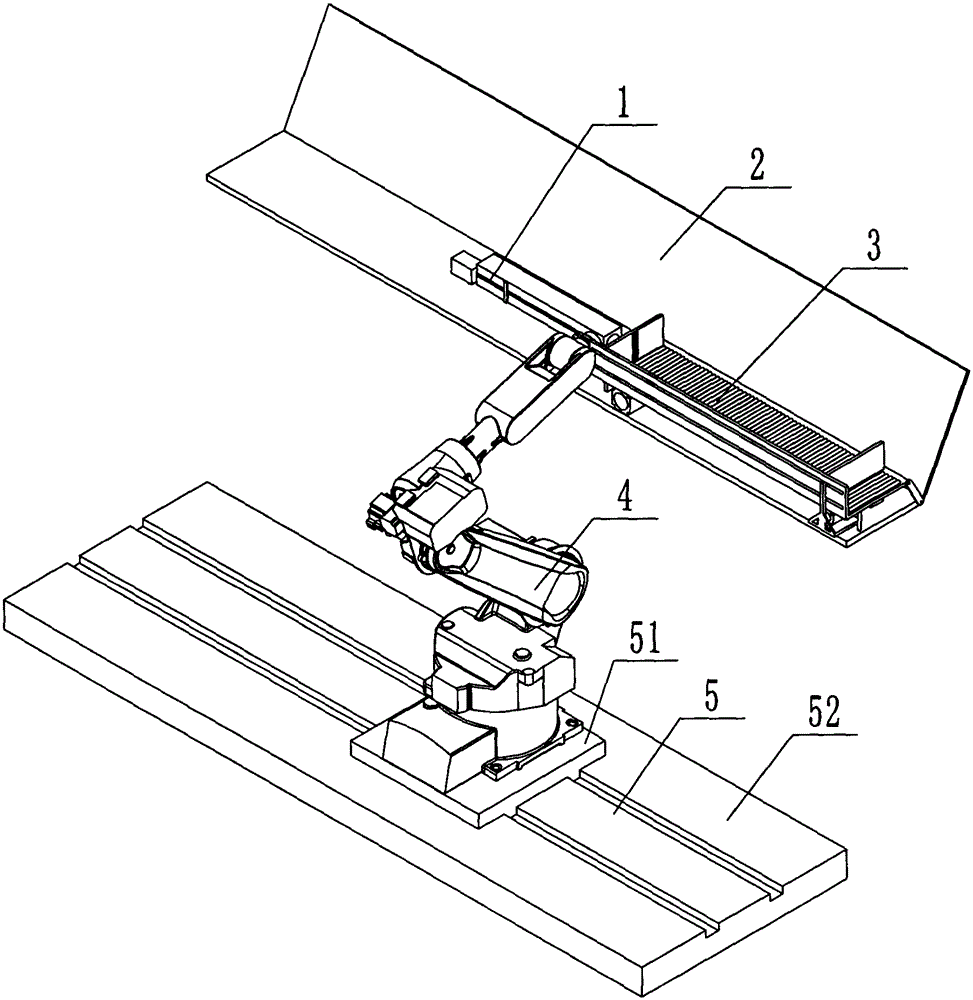

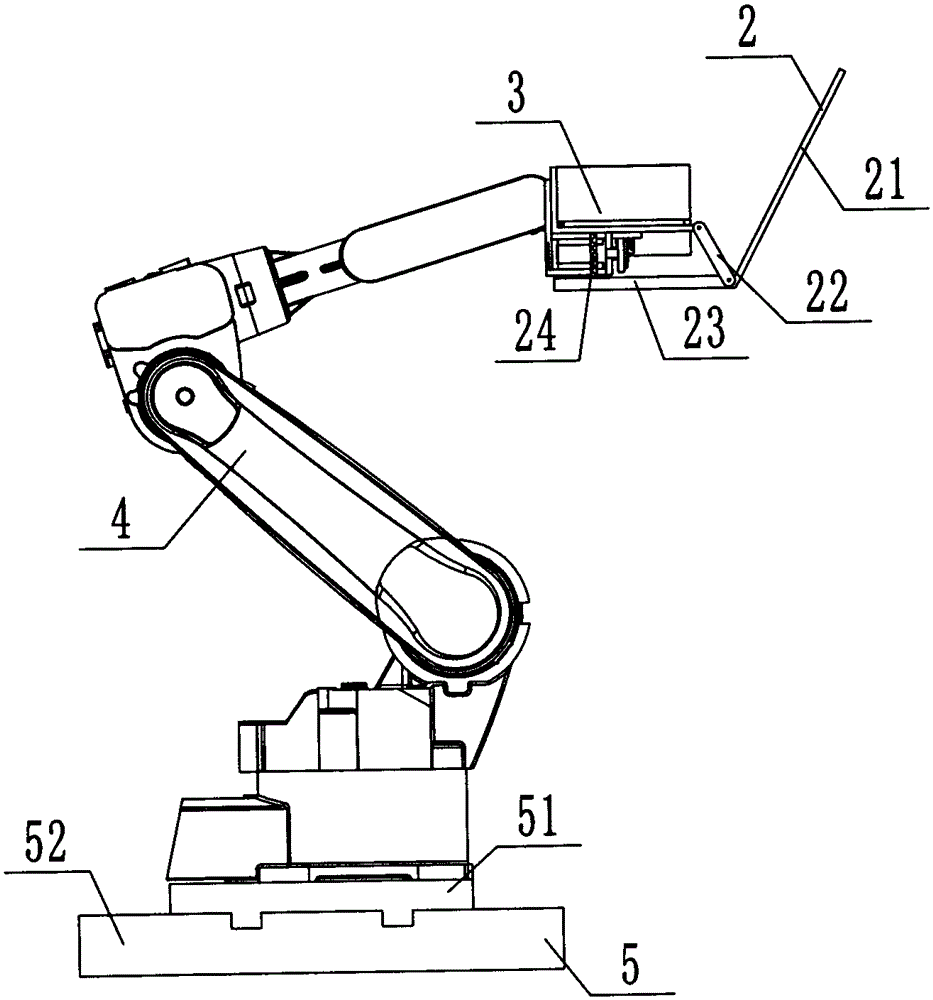

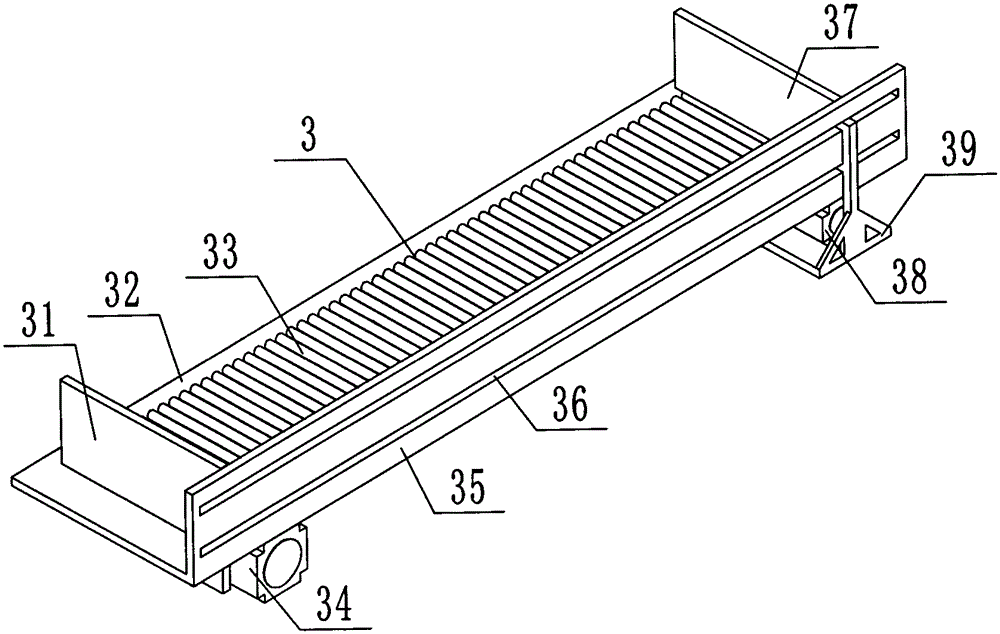

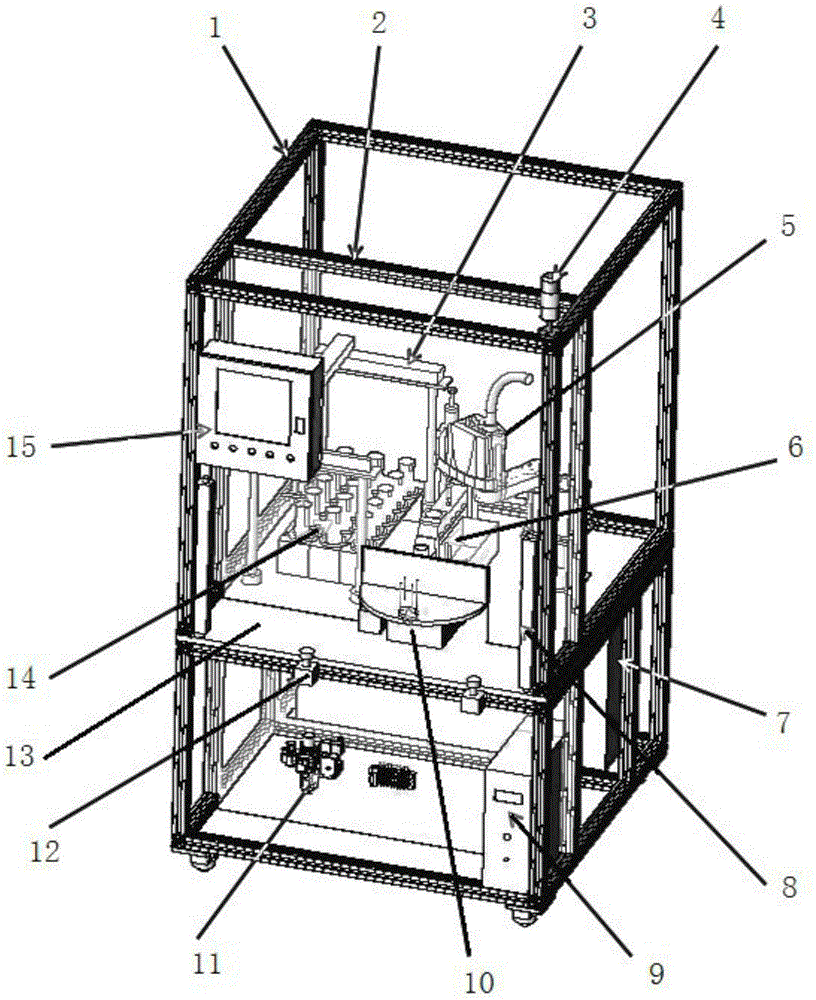

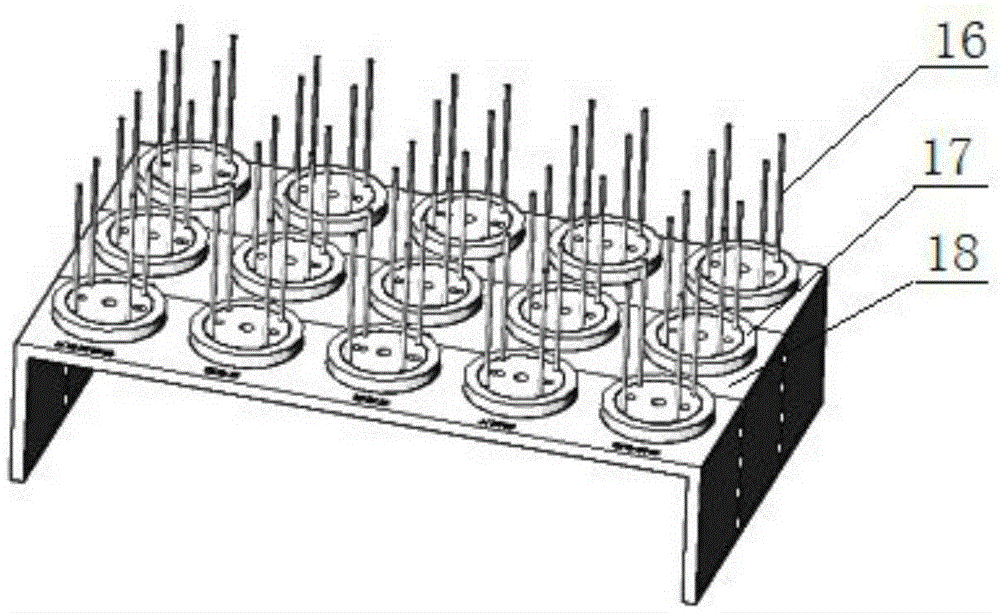

Automatic stacking system for thermal cells

InactiveCN105383942ARealize automatic pickingRealize detectionConveyorsDeferred-action cellsManipulatorEngineering

The invention relates to an automatic stacking system for thermal cells. The automatic stacking system comprises a supporting frame, a pre-arranged tool, a three-coordinate picking mechanism, a visual detecting mechanism, a four-axis manipulator stacking mechanism and a rotating-table feeding and discharging mechanism. The supporting frame is divided into an upper part and a lower part by a workbench, and the pre-arranged tool is mounted on the left side of the top face of the workbench; the three-coordinate picking mechanism is mounted on the workbench through supporting columns and located above the pre-arranged tool, the visual detecting mechanism is mounted on the workbench and located at the right side of the pre-arranged tool, and the four-axis manipulator stacking mechanism is mounted on the workbench and located at the right side of the visual detecting mechanism. A safe transparent isolating plate is mounted on the front face of the supporting frame, an opening is formed in the safe transparent isolating plate and located above the workbench, the rotating-table feeding and discharging mechanism is mounted on the workbench and located in the position of the opening, and an electric control cabinet, an industrial personal computer, a gas source assembly and an electromagnetic valve are mounted in the supporting frame and located below the workbench. By means of the automatic stacking system, single cells of a cell stack are picked, detected, stacked, fed and discharged automatically.

Owner:TIANJIN BATERY MACHINERY AUTOMATION TECH

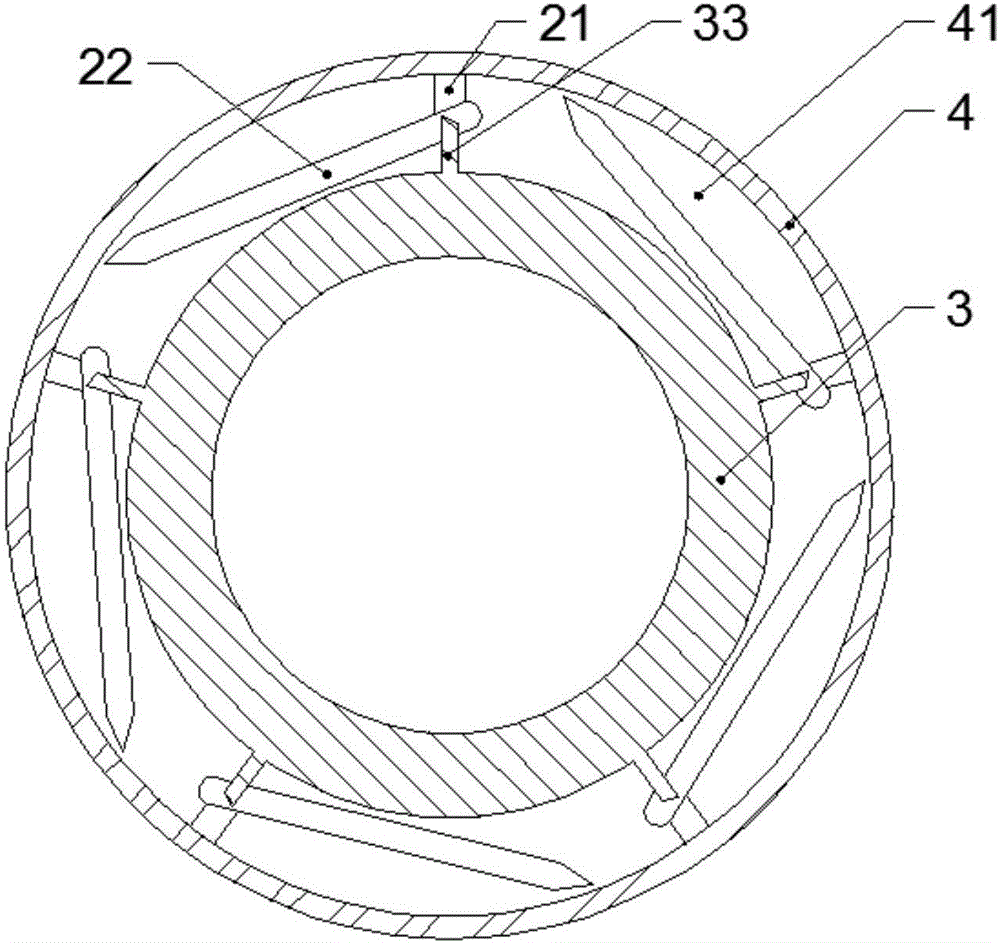

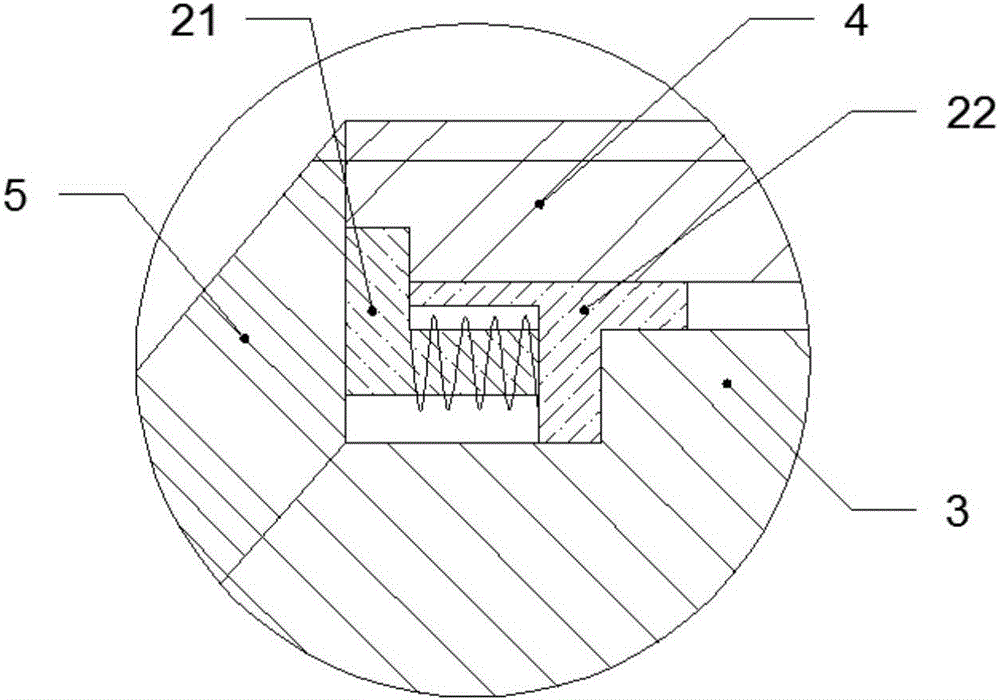

Automatic grabbing device for injection-molded blades

InactiveCN106865214ARealize automatic pickingReduce labor intensityConveyor partsEngineeringUltimate tensile strength

Owner:苏州晟炅精密电子有限公司

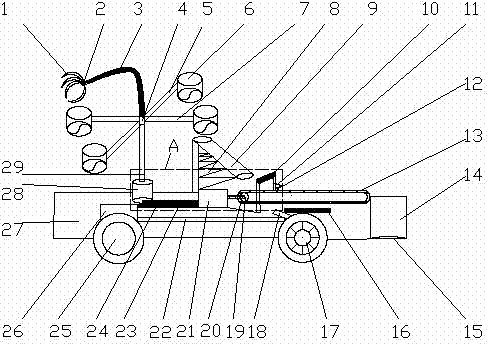

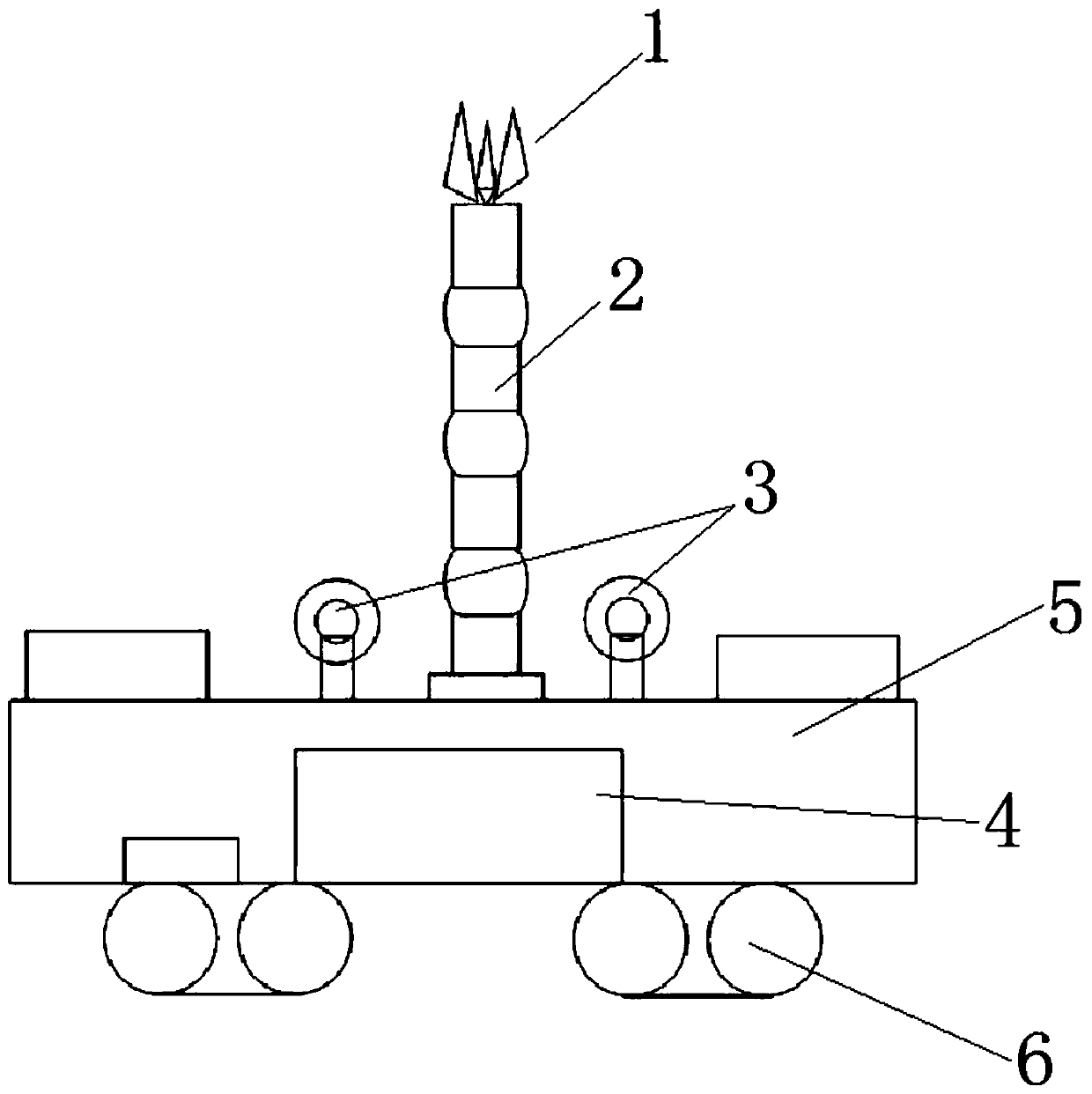

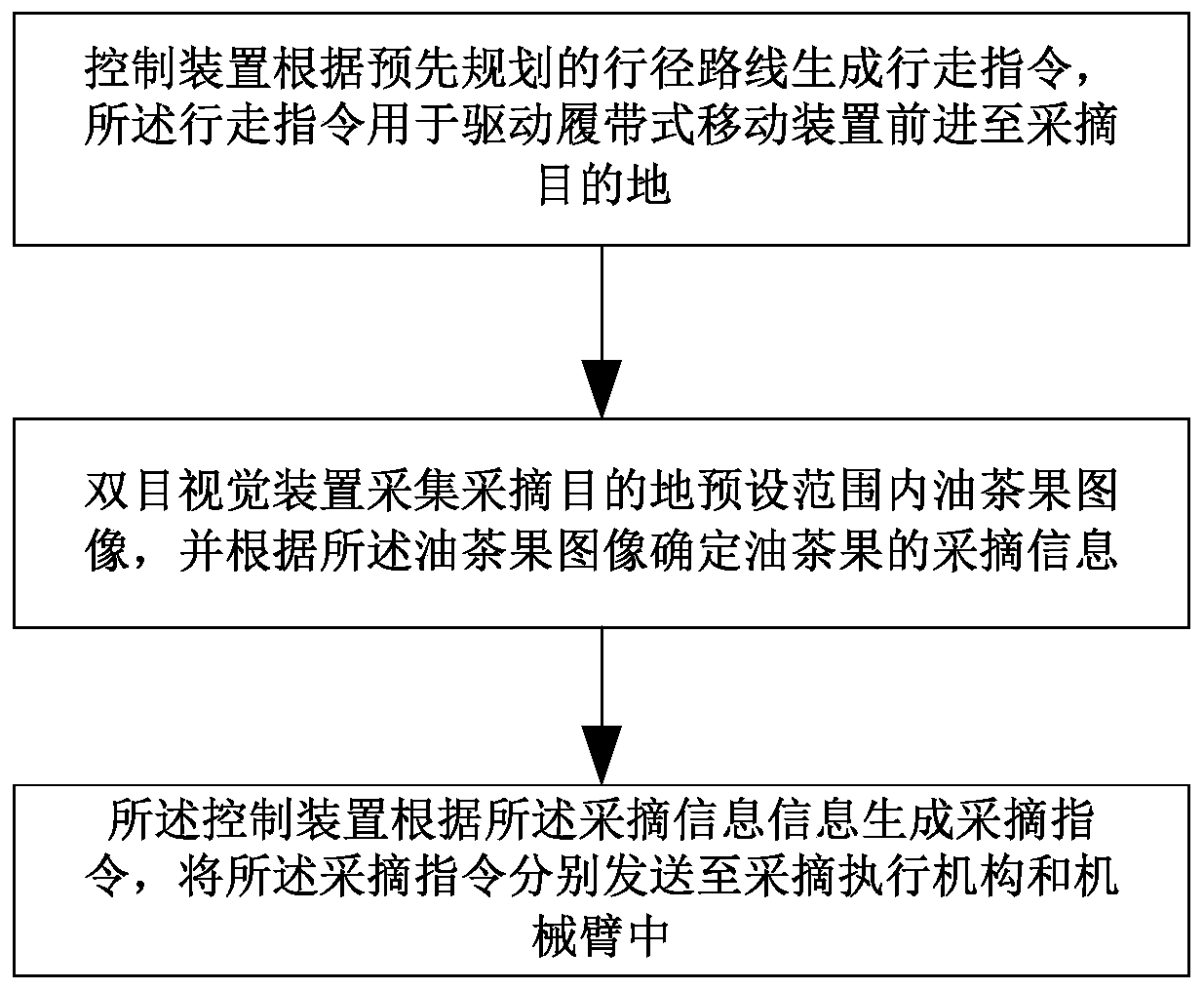

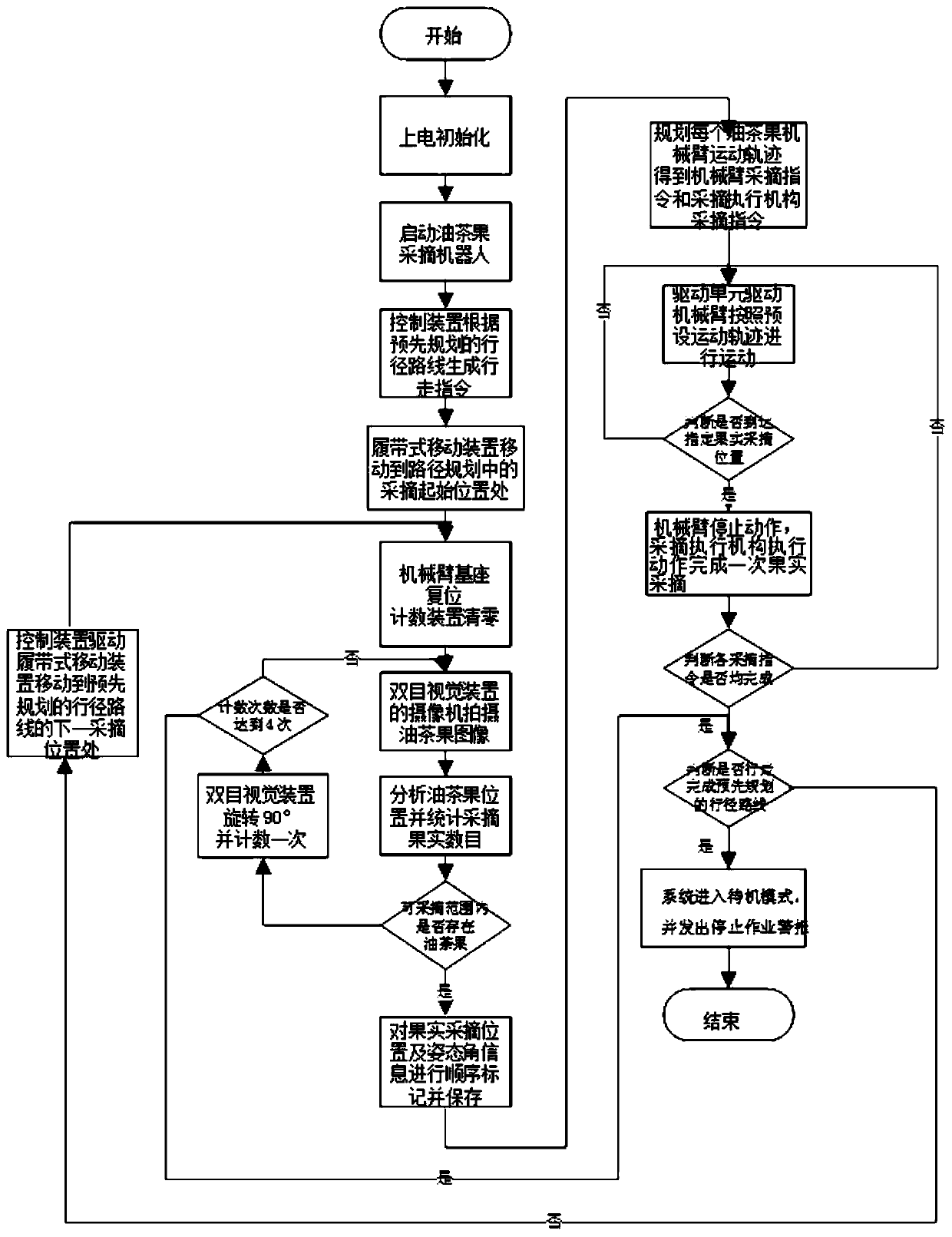

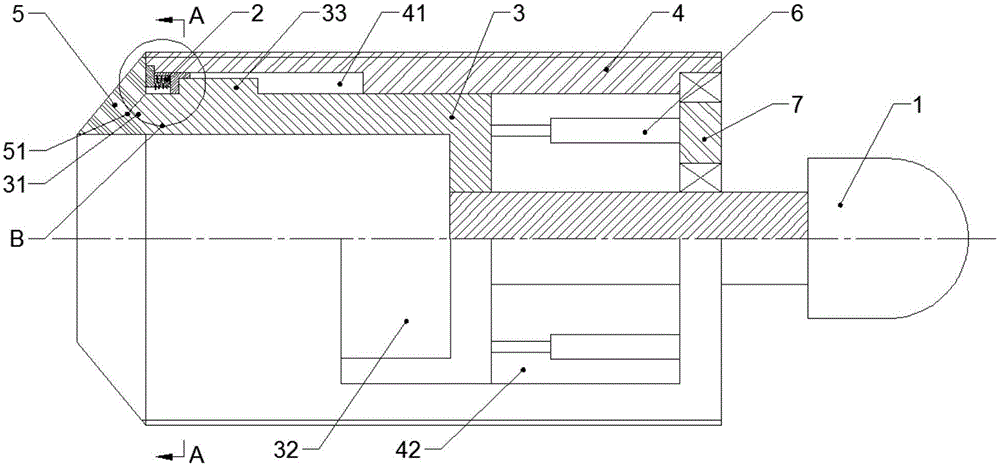

Binocular-vision-based oil tea fruit picking system and control method

PendingCN109729835ARealize automatic pickingSave human effortPicking devicesRenewable energy machinesBase oilMobile device

The invention provides a binocular-vision-based oil tea fruit picking system and a control method. The method comprises the steps: generating a walking instruction by a control device according to a walking route planned in advance, wherein the walking instruction is used for driving a crawler-type mobile device to advance to picking destinations; acquiring an oil tea fruit image by a binocular vision device, and determining picking information of the oil tea fruit according to the oil tea fruit image; and generating a picking instruction by the control device according to the picking information, and respectively transmitting the picking instruction to a picking executing mechanism and a mechanical arm. The binocular-vision-based oil tea fruit picking system is capable of walking according to the planned walking route, fruits on the plurality of picking destinations on the walking route are picked, when a person reaches the picking destinations, the oil tea fruit image is acquired bythe binocular vision device and is processed to obtain the picking information, the picking instruction for controlling the picking executing mechanism and the mechanical arm to execute picking is obtained according to the picking information, and then, the automatic picking of oil tea fruits is realized, so that manpower is saved, and the efficiency is increased.

Owner:GUANGXI NORMAL UNIV

Bamboo shoot cutting machine

InactiveCN106550653ARealize automatic pickingImprove picking efficiencyHarvestersBamboo shootElectric machinery

The invention relates to the field of food processing equipment, in particular a bamboo shoot cutting machine. The bamboo shoot cutting machine provided by the invention comprises a motor, a cutting device, a cutter releasing cylinder, a hollow machine body and a hollow drill. The drill is arranged at one end of the machine body; the cutter releasing cylinder is detachably connected to the drill and can slide in the machine body in the axial direction; a driving device for driving the cutter releasing cylinder to slide is arranged on the machine body; a mounting groove which is concave outward in the radial direction is formed in one side, close to the drill, of the machine body; in an initial state, the cutter releasing cylinder closes the mounting groove, the cutting device is accepted in the mounting groove, and under the action of the driving device, the cutter releasing cylinder slides toward the end far from the drill; the mounting groove is opened, and the cutting device is expanded inward in the radial direction. The invention provides the bamboo shoot cutting machine which realizes automatic picking of bamboo shoots so as to improve the bamboo shoot picking efficiency, reduce the work strength of workers, reduce the probability that the bamboo shoots are damaged and improve the economical value of the bamboo shoots.

Owner:巫山县纯源农产品开发有限公司

Greenhouse leaf vegetable harvesting and root cutting manipulator with adjustable front and back positions

The invention relates to an agricultural machine and aims to provide a greenhouse leaf vegetable harvesting and root cutting manipulator with adjustable front and back positions. The manipulator has the advantages of being reliable, stable and efficient. According to the technical scheme, the greenhouse leaf vegetable harvesting and root cutting manipulator with the adjustable front and back positions is characterized by comprising a mechanical arm, a pneumatic gripper and a cutter, wherein the pneumatic gripper and the cutter are arranged on the mechanical arm; the mechanical arm is providedwith an adjusting mechanism for driving the mechanical arm to extend and a rotating motor for driving the pneumatic gripper to rotate; the adjusting mechanism comprises a lead screw assembly, an adjusting motor driving a screw of the lead screw assembly to rotate, a guide rail parallel to the screw of the lead screw assembly, a sliding block capable of sliding along the guide rail and fixed to a nut of the lead screw assembly and a connecting plate fixed to the sliding block. The rotating motor and the cutter are arranged on the connecting plate. The cutter comprises a cutting air cylinder anda cutting tool driven by the cutting air cylinder.

Owner:ZHEJIANG SCI-TECH UNIV

Citrus picking device

InactiveCN105409450APicking achievedImprove the efficiency of fruit pickingPicking devicesFruit treeEngineering

Owner:CHONGQING PINGWEI CHAOYANG AGRI DEV CO LTD

Automatic walnut picking machine

InactiveCN106797756AGuaranteed continuityReduce labor intensityPicking devicesWalnut NutAgricultural engineering

The invention relates to the agricultural machinery and particularly discloses an automatic walnut picking machine. The machine comprises a power module, a harvesting head, a strike body and a support bar, wherein the power module comprises a drive motor and a reducing power transmission device, the harvesting head is provided with a first rotating shaft, and the first rotating shaft drives rotation by a power module, the strike body is installed on the first rotating shaft and rotates synchronously with the first rotating shaft, the trike body comprises at least two blades and the blades distributes along the circumference of the first rotating shaft, the support bar is the hand-held telescoping bar, the harvesting head is connected detachably to one end of the support bar. The machine has the advantages that not only the use of the machine is simple and convenient, and the labor intensity of workers is greatly reduced, but also picking result is very good.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com