Automatic stacking system for thermal cells

An automatic stacking and thermal battery technology, applied in the direction of primary batteries, stacking of objects, circuits, etc., can solve the problems of many manpower, unstable quality, low battery production efficiency, etc., and achieve the effect of convenient inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

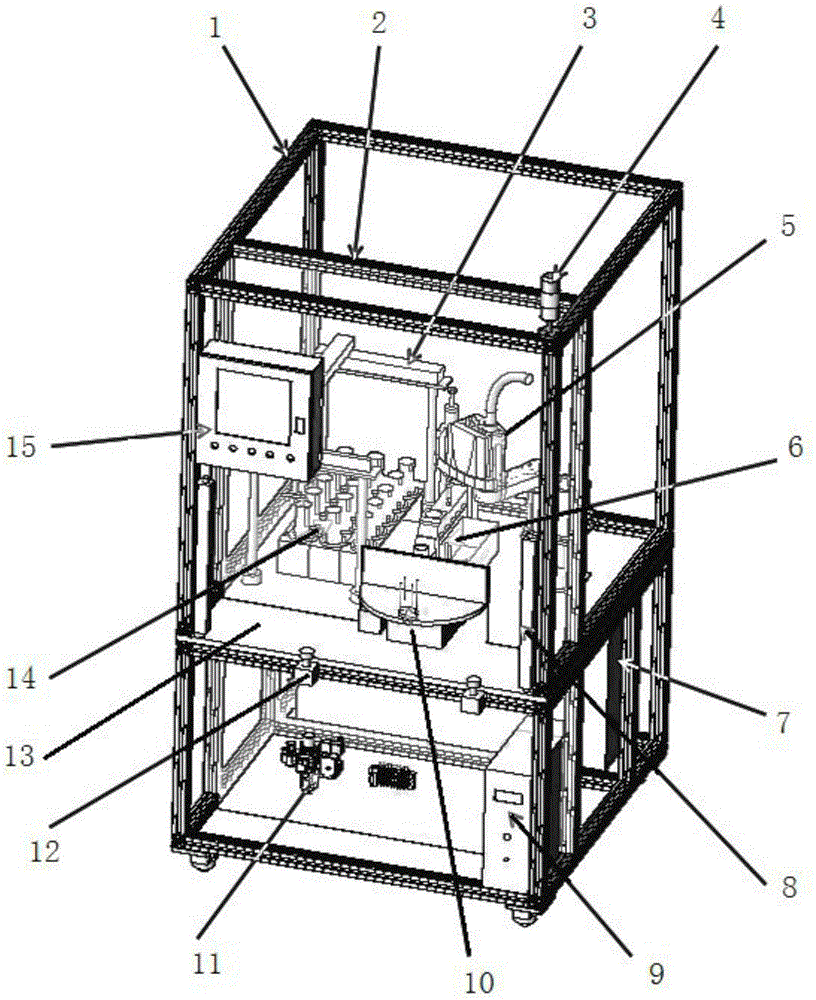

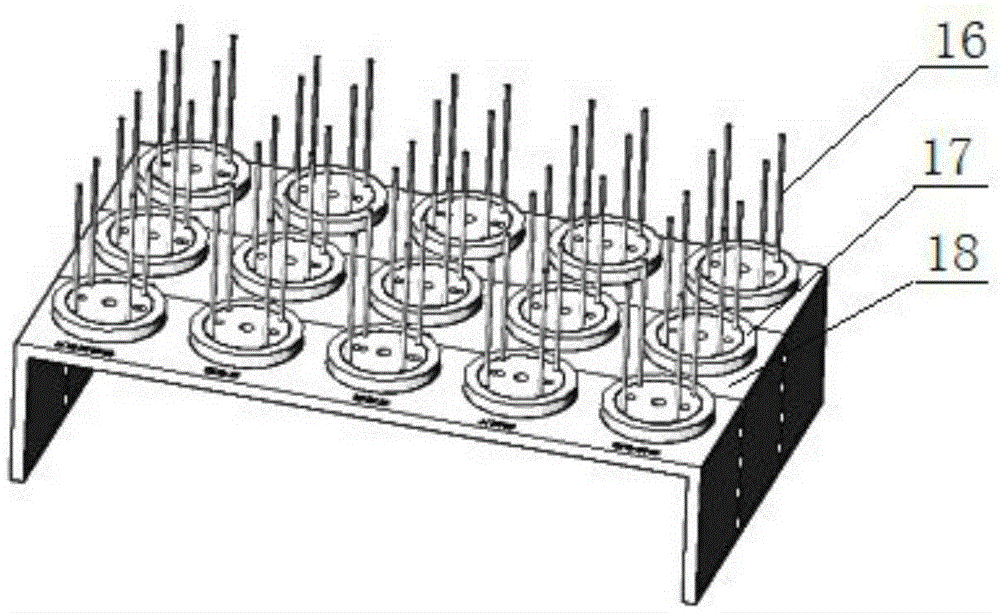

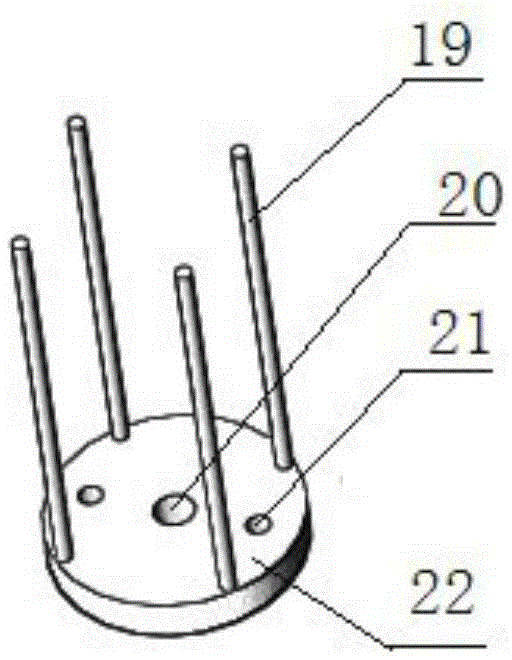

[0030] An automatic stacking system for thermal batteries, comprising a support frame 1, preset tooling 14, a three-coordinate pick-up mechanism 3, a visual inspection mechanism 6, a four-axis manipulator stacking mechanism 5, and a turntable loading and unloading mechanism 10. The support frame is composed of a working The table 13 is divided into upper and lower parts. The preset tooling is installed on the left side of the top surface of the workbench. The three-coordinate pick-up mechanism is installed on the workbench through the pillar above the preset tooling. On the right side of the preset tooling Install the visual inspection mechanism, and install the four-axis manipulator stacking mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com