Patents

Literature

320results about How to "Realize loading and unloading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

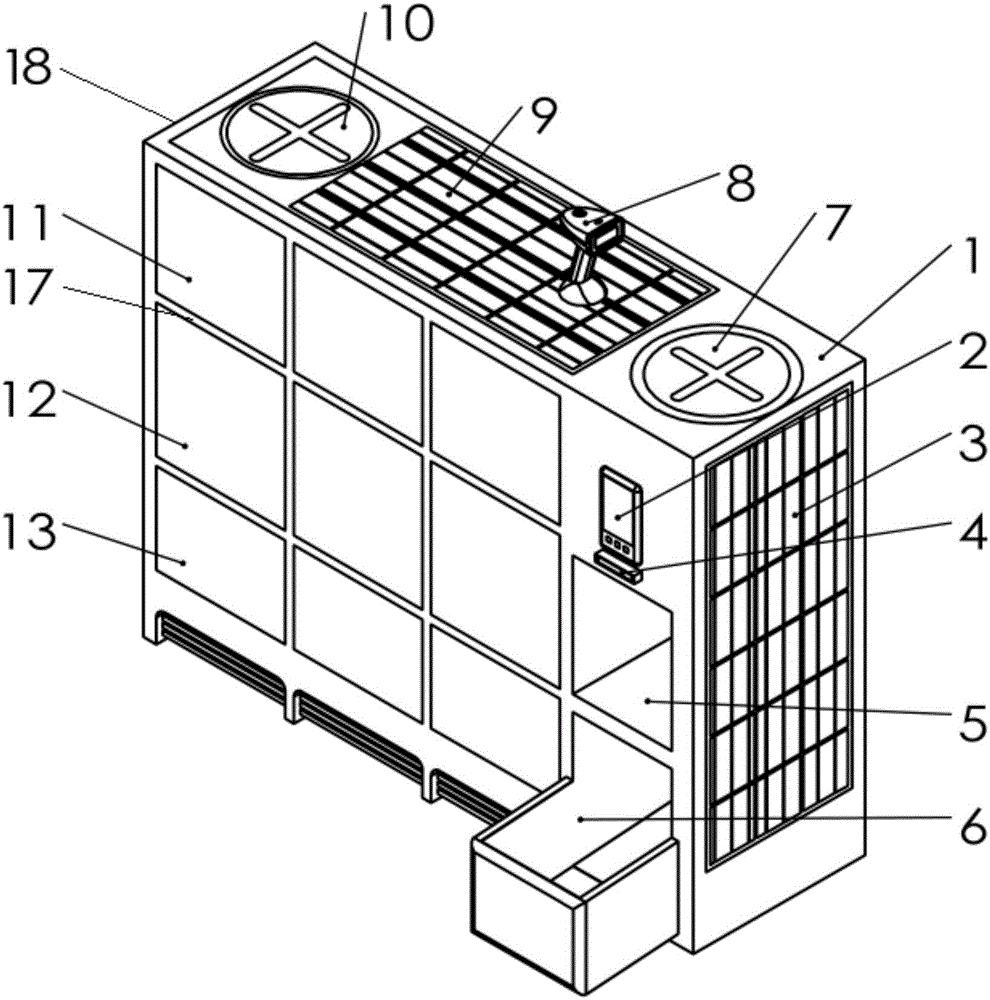

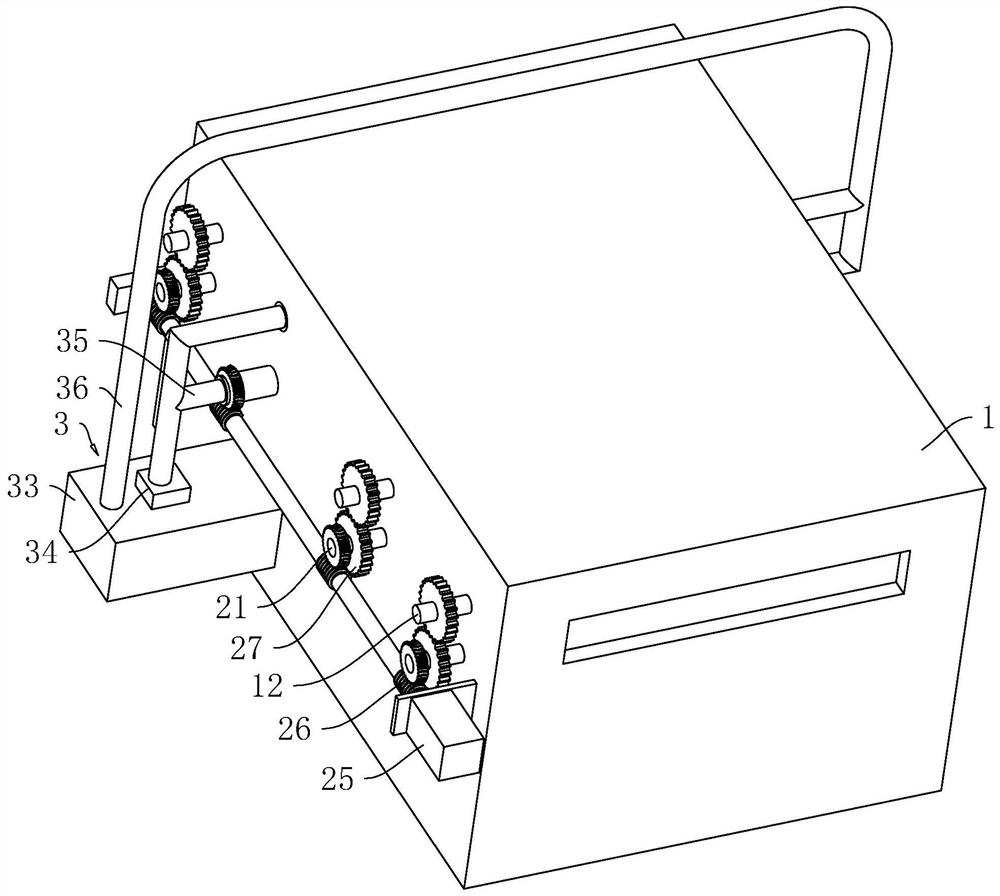

Expressage cabinet and expressage transportation and storage system with same

ActiveCN106493084ARealize loading and unloadingRealize sortingSortingAutomationAerospace engineering

The invention discloses an expressage cabinet which comprises a cabinet body provided with storage zones. The expressage cabinet further comprises an unmanned aerial vehicle recognition part, a bar code obtaining device, a carrying device and a control center; the unmanned aerial vehicle recognition part is used for providing a parking position for an unmanned aerial vehicle and receiving cargoes, and the unmanned aerial vehicle recognition part is arranged on the cabinet body; the bar code obtaining device is used for obtaining cargo information of the cargoes on the unmanned aerial vehicle recognition part and sending the cargo information to the control center; the carrying device is used for moving the cargoes to the storage zones; and the control center is used for controlling the carrying device, and is connected with the carrying device and the bar code obtaining device. The expressage cabinet is mainly used for achieving automation of cargo loading and unloading, sorting, storage, delivering and sending. The unmanned aerial vehicle recognition part is arranged so that parking of the unmanned aerial vehicle is facilitated; the bar code obtaining device scans bar codes on an expressage, so that the cargo information is read and temporally stored. The invention further provides an expressage transportation and storage system comprising the above expressage cabinet.

Owner:GUANGDONG UNIV OF TECH

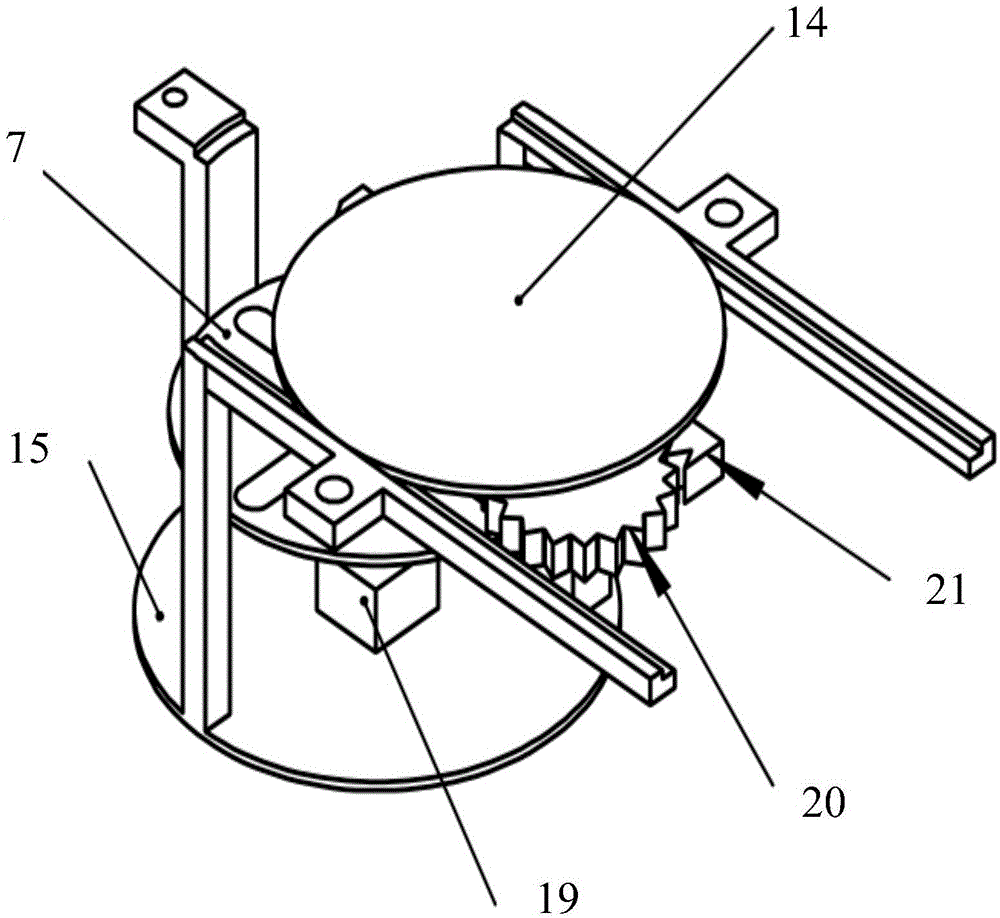

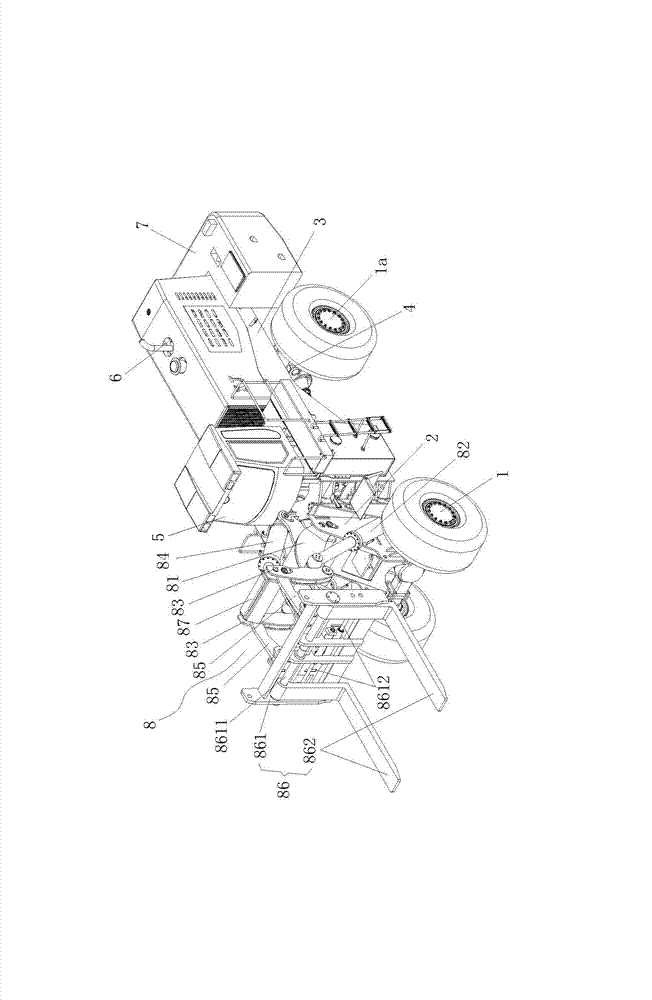

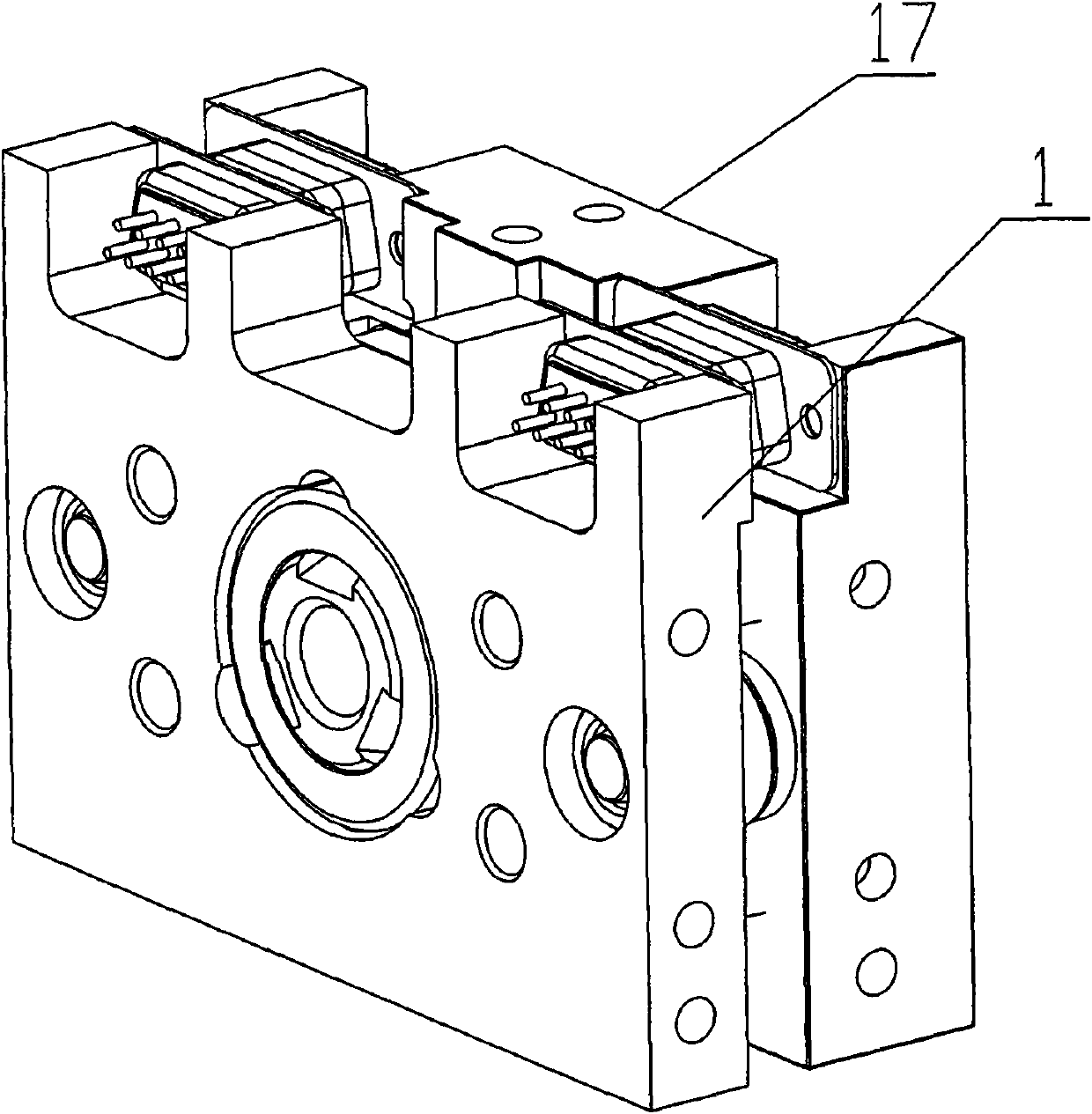

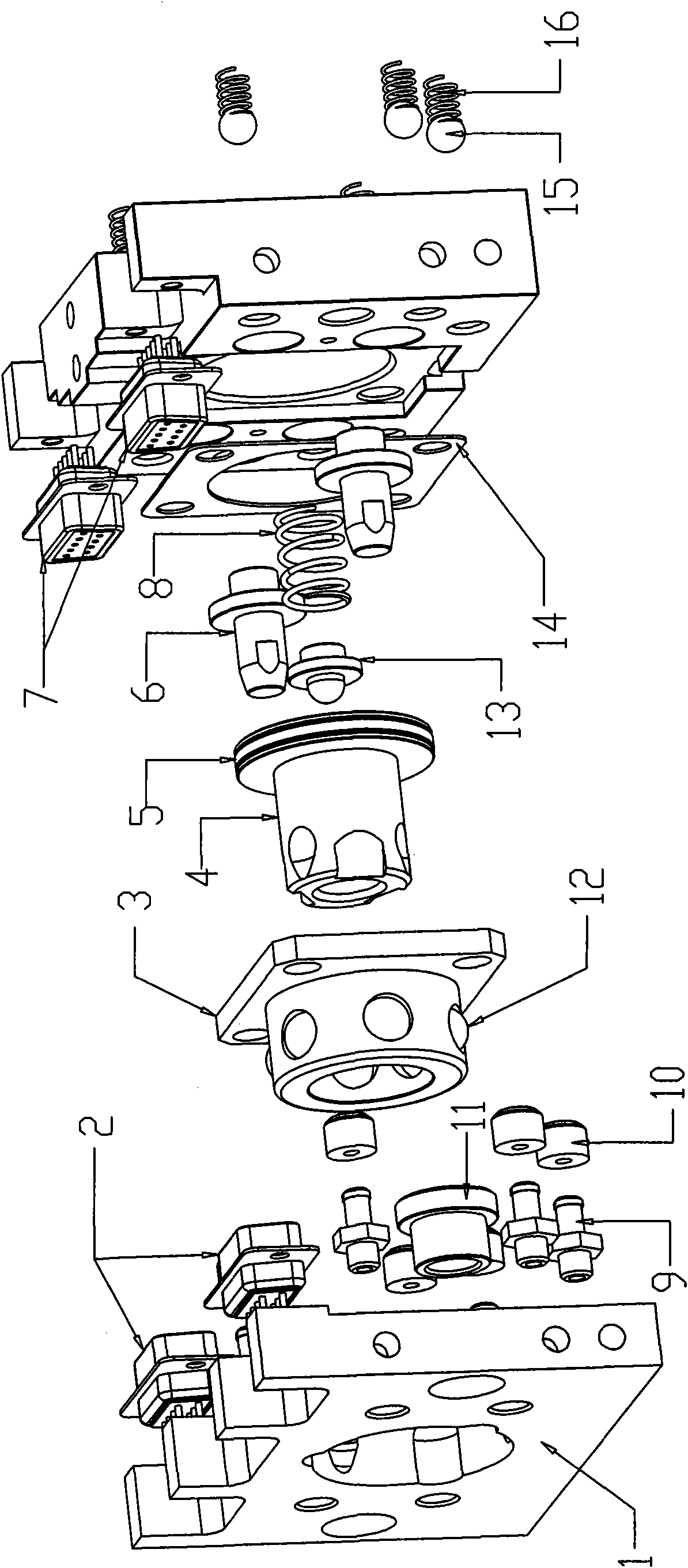

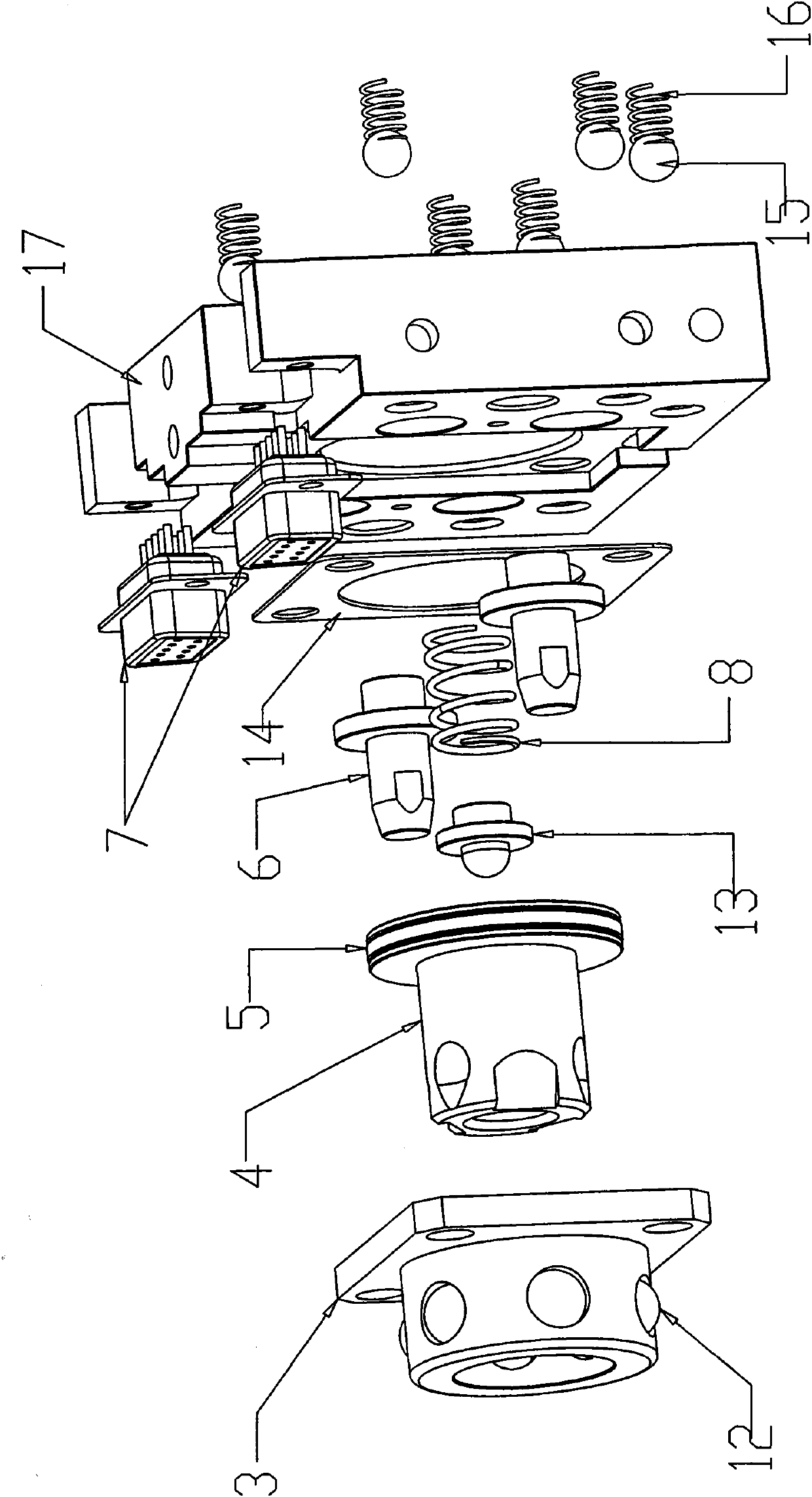

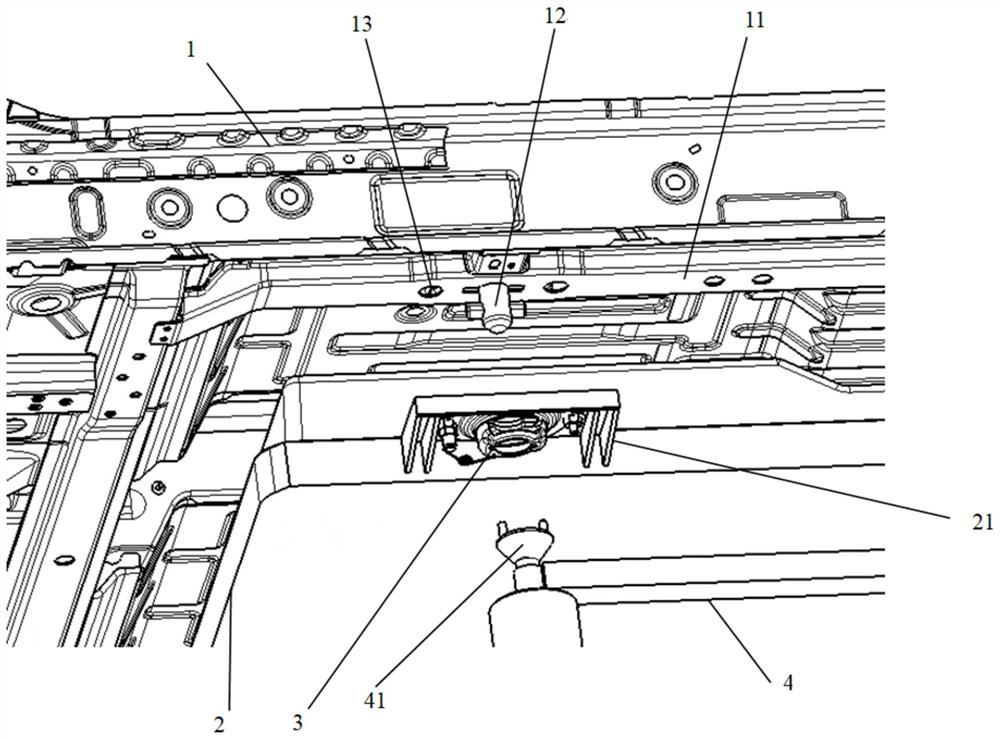

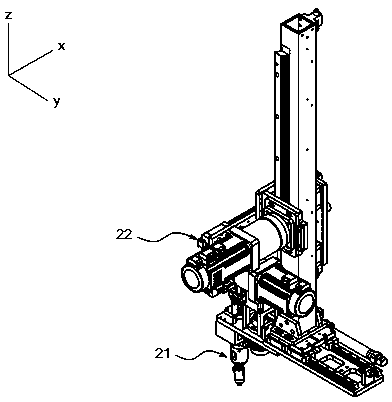

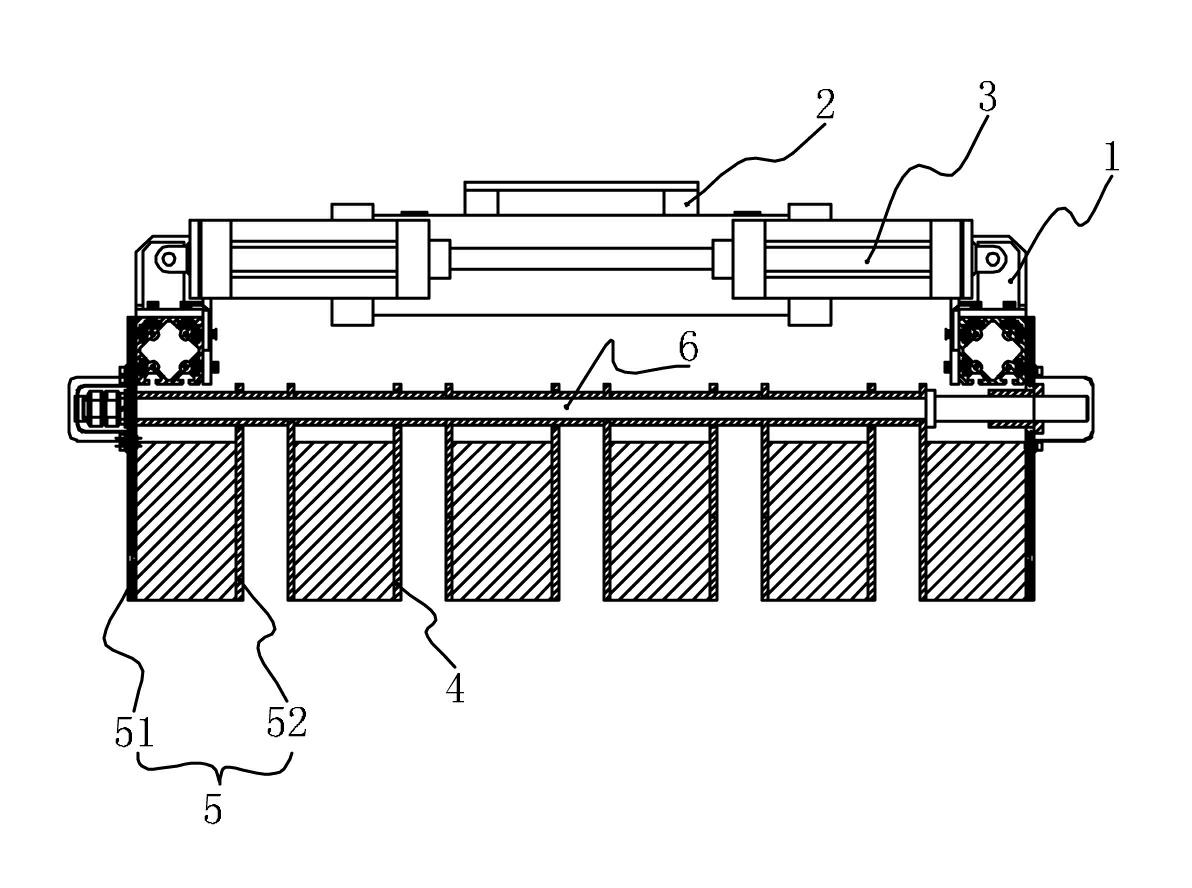

Automatic loading and unloading machine for container twist locks and system with automatic loading and unloading machine

ActiveCN105880989ARealize loading and unloadingAddresses discrepancies in binding positionsMetal working apparatusManipulatorEngineering

The invention provides an automatic loading and unloading machine for container twist locks. The automatic loading and unloading machine comprises a twist lock loading and unloading mechanical arm, a moving sliding disc fixedly connected with the twist lock loading and unloading mechanical arm, a sliding disc supporting mechanism arranged on the moving sliding disc in a sleeving manner, floating mechanisms connected with the sliding disc supporting mechanism, a rotation mechanism which is fixedly connected with the floating mechanisms and drives the twist lock loading and unloading mechanical arm to rotate and a lifting mechanism which is fixedly connected with the rotation mechanism and drives the twist lock loading and unloading mechanical arm to move vertically. The invention further provides an automatic loading and unloading system for the container twist locks. According to the automatic loading and unloading machine for the container twist locks and the system with the automatic loading and unloading machine, by means of the sliding disc supporting mechanism and the floating mechanisms, the twist lock loading and unloading mechanical arm can be adjusted to a certain degree in the horizontal direction and the vertical direction, deviation existing at combination positions during loading and unloading of the different twist locks is eliminated, loading and unloading of the different twist locks are achieved, and the automatic work degree is further increased.

Owner:SANY MARINE HEAVY IND +1

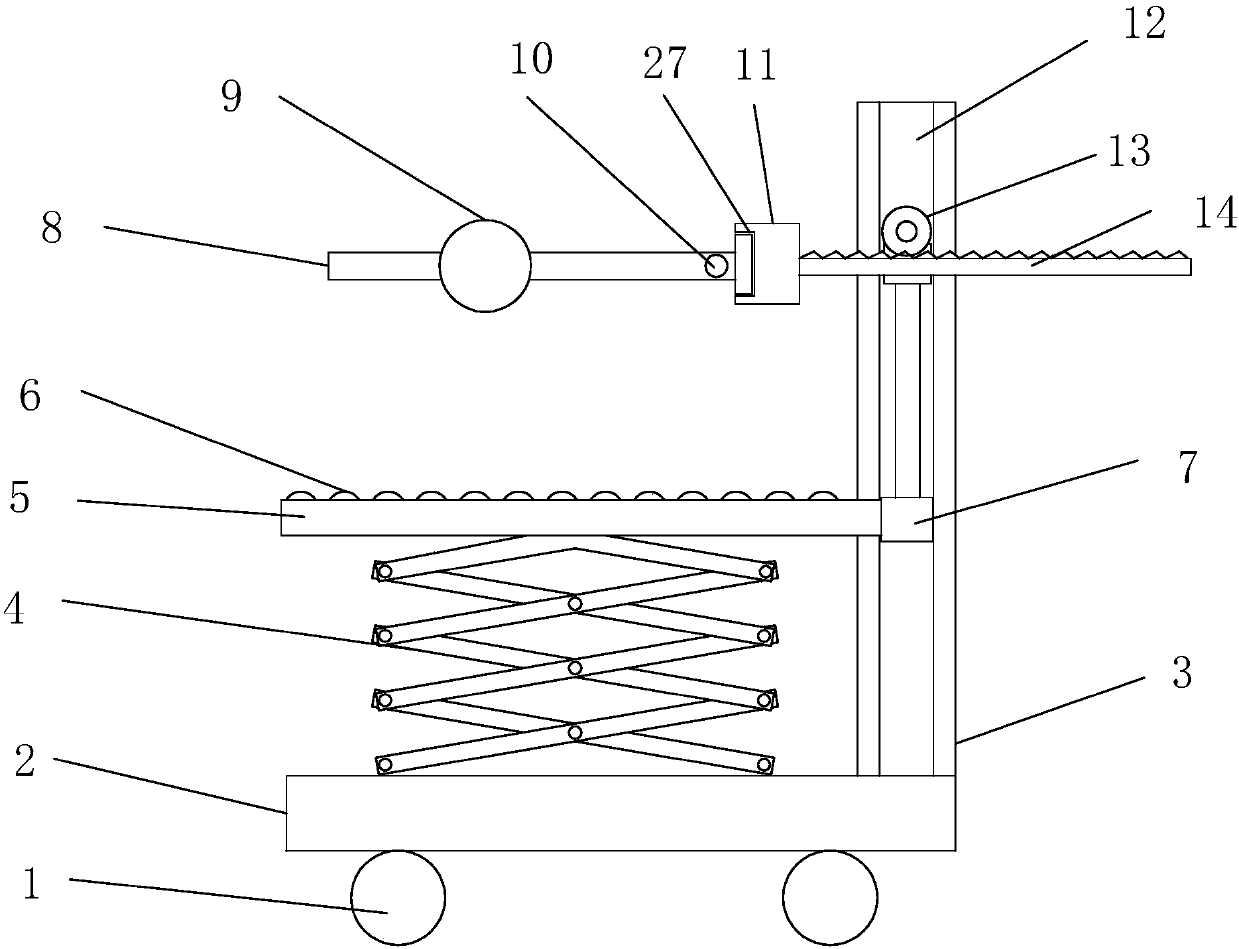

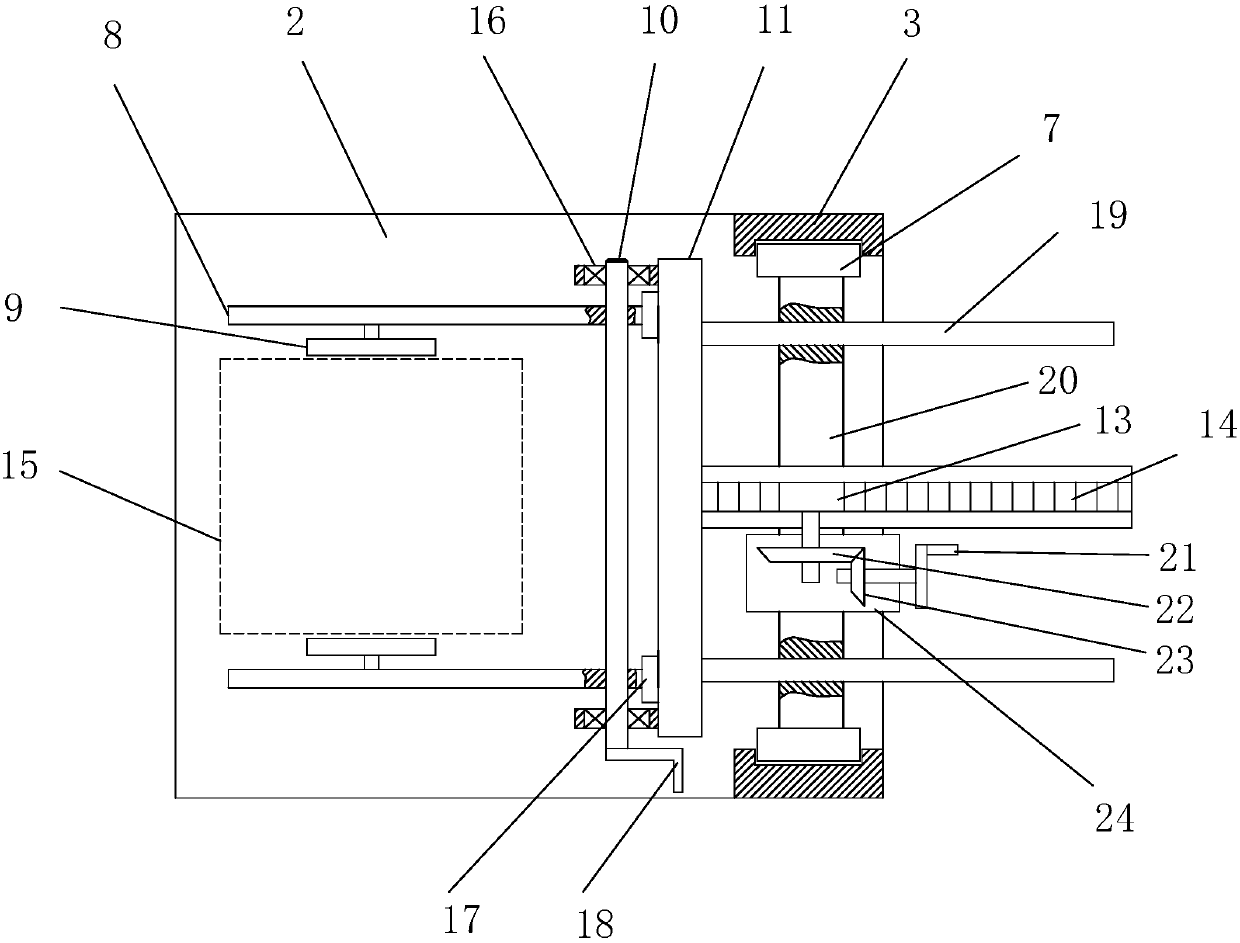

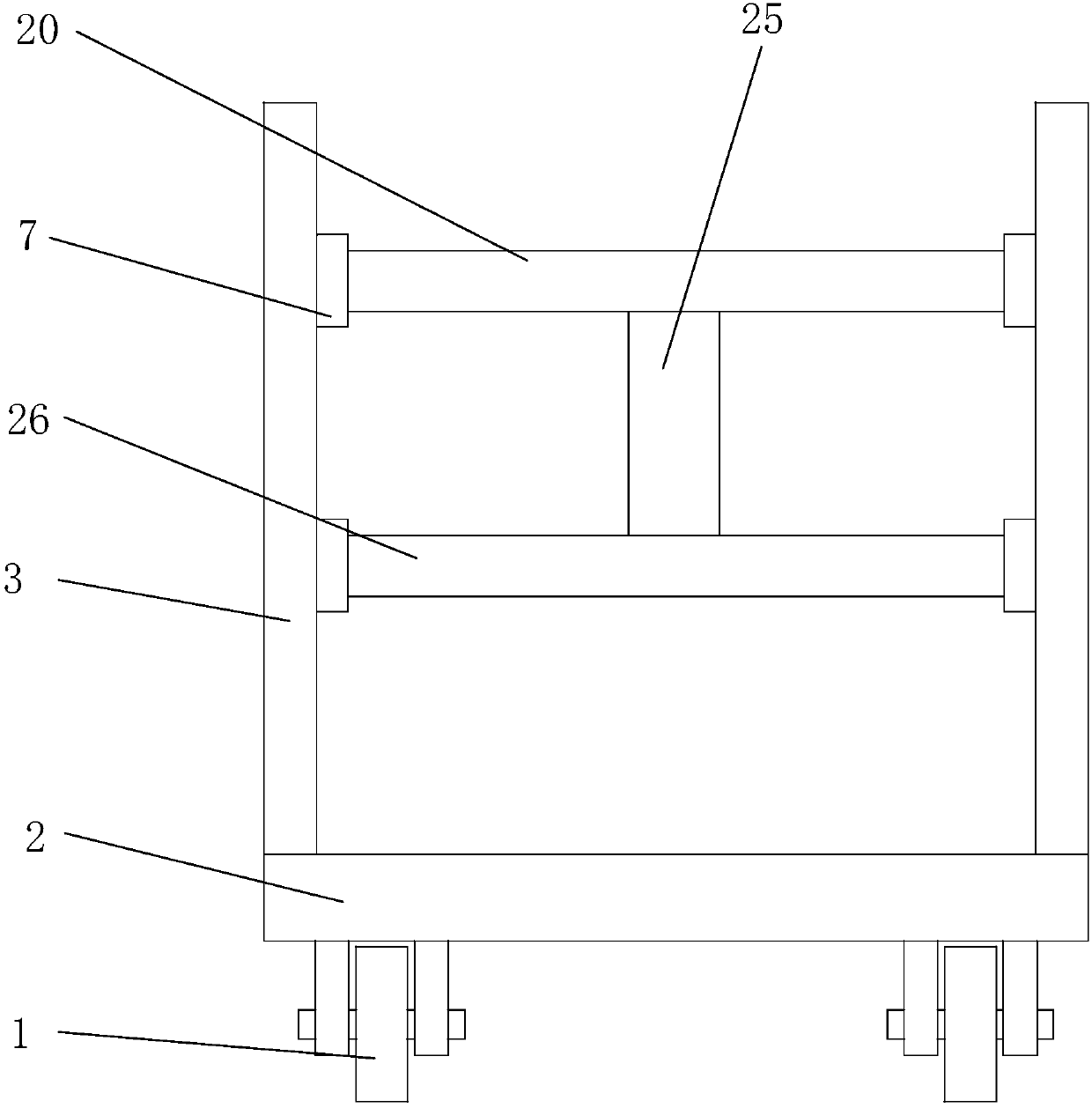

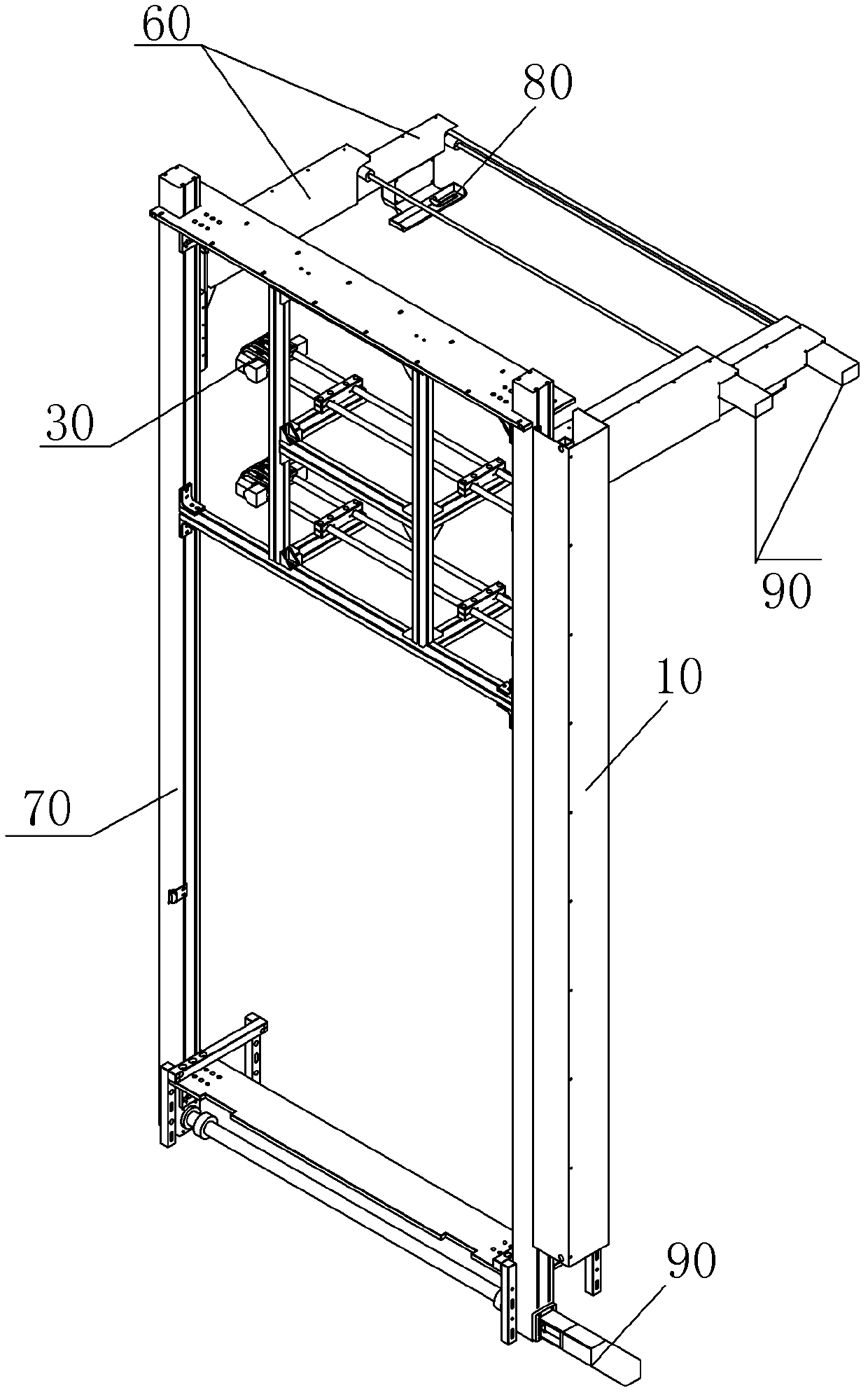

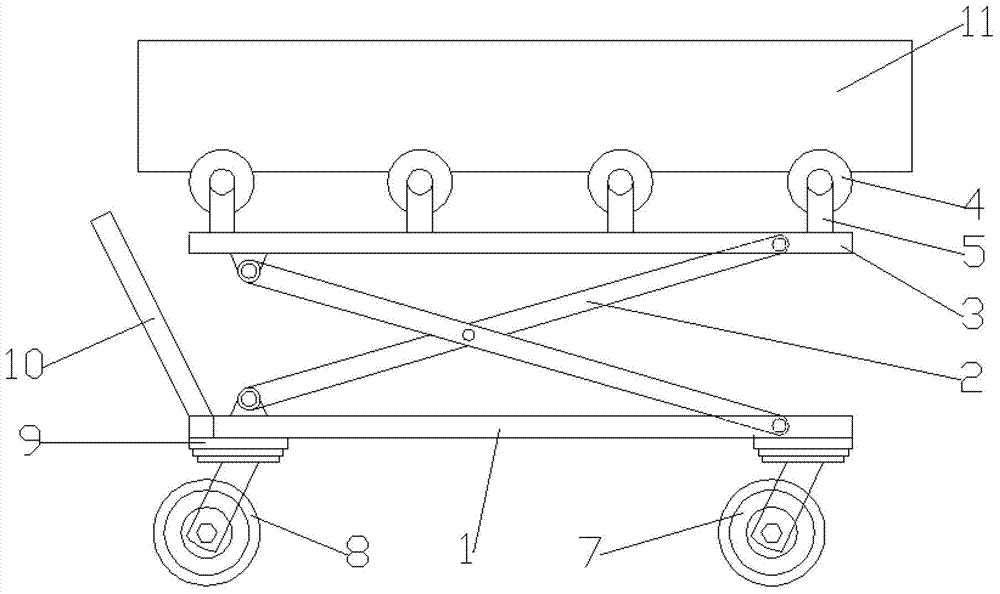

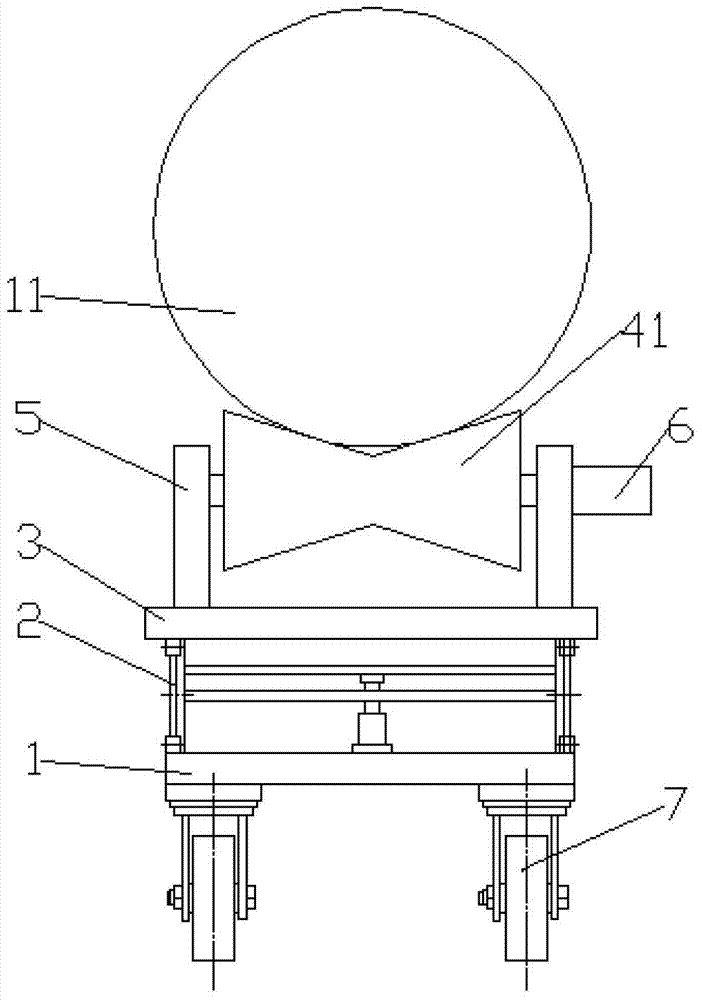

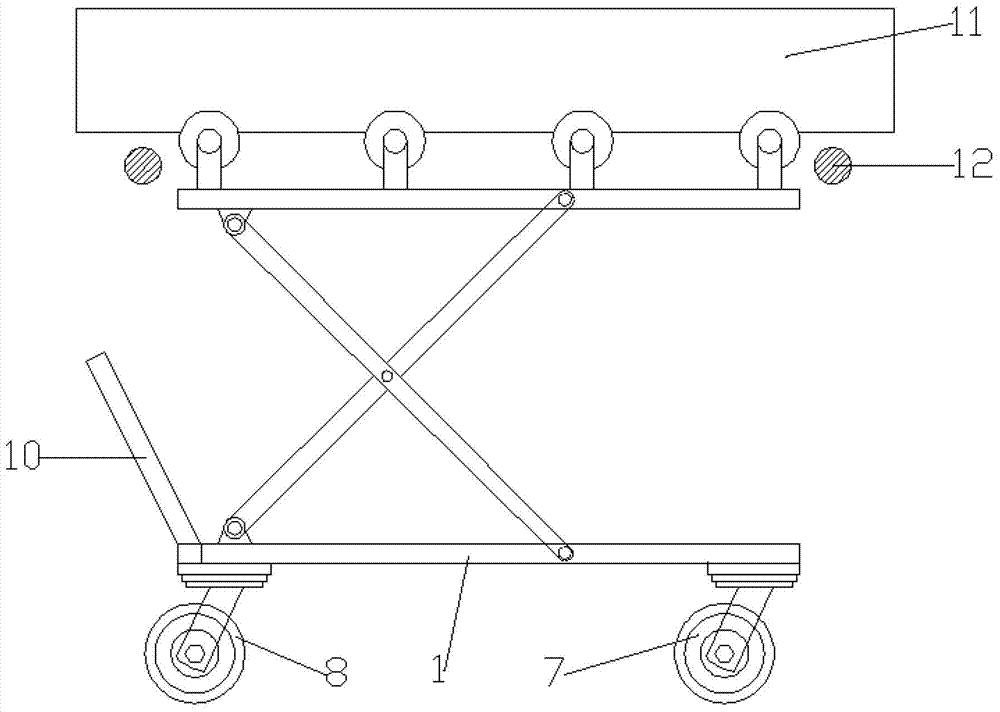

Movable unloading frame for electric power materials

InactiveCN107555190ASimple structureImprove work efficiencyLoading/unloadingConveyor partsEngineeringMechanical engineering

The invention provides a movable unloading frame for electric power materials. The movable unloading frame comprises a trolley body of which the bottom is provided with rolling wheels; a scissors typelifting frame is installed on the trolley body; two vertical columns are arranged at the tail of the trolley body, and vertical slide grooves are formed in the vertical columns; the top of the scissors type lifting frame is connected with a lifting supporting plate, and one end of the lifting supporting plate is connected with a lower transverse beam; an upper transverse beam is arranged above the lower transverse beam, the lower transverse beam and the upper transverse beam are connected through a vertical connection beam, and a rack capable of sliding horizontally is installed on the uppertransverse beam; a gear engaged with the rack is arranged on the rack, and the end of the rack is fixedly connected with a guide beam; and a transverse slide groove is formed in the end face of one side of the guide beam, and a clamping mechanism is installed in the transverse slide groove. The unloading frame is simple in structure, the materials can be conveniently unloaded from the unloading frame or conveniently transferred to the unloading frame through a mechanically auxiliary force applying method, a lot of manpower is not needed in the whole process, personnel casualties can be effectively avoided, and the cargo transferring efficiency is improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO PINGYUAN POWER SUPPLY CO +1

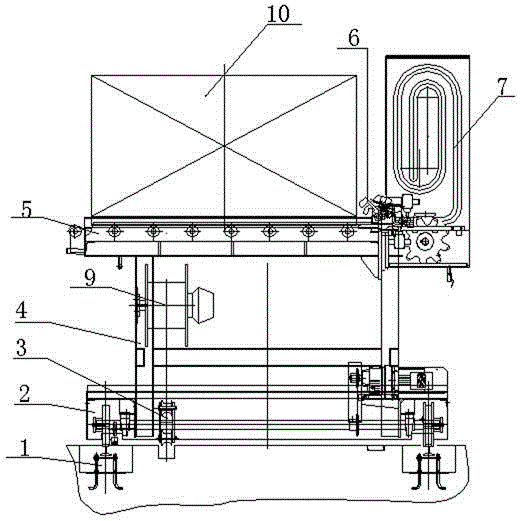

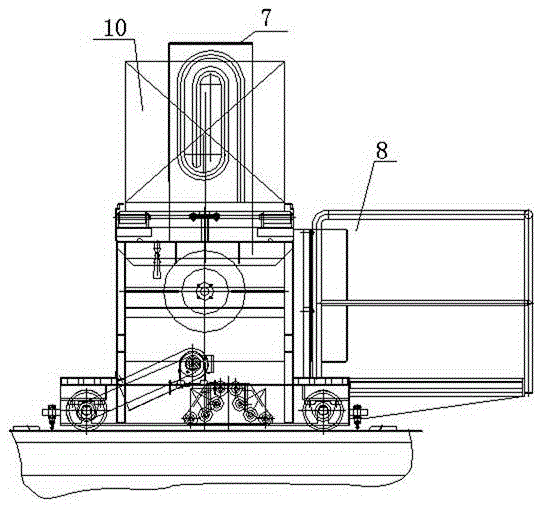

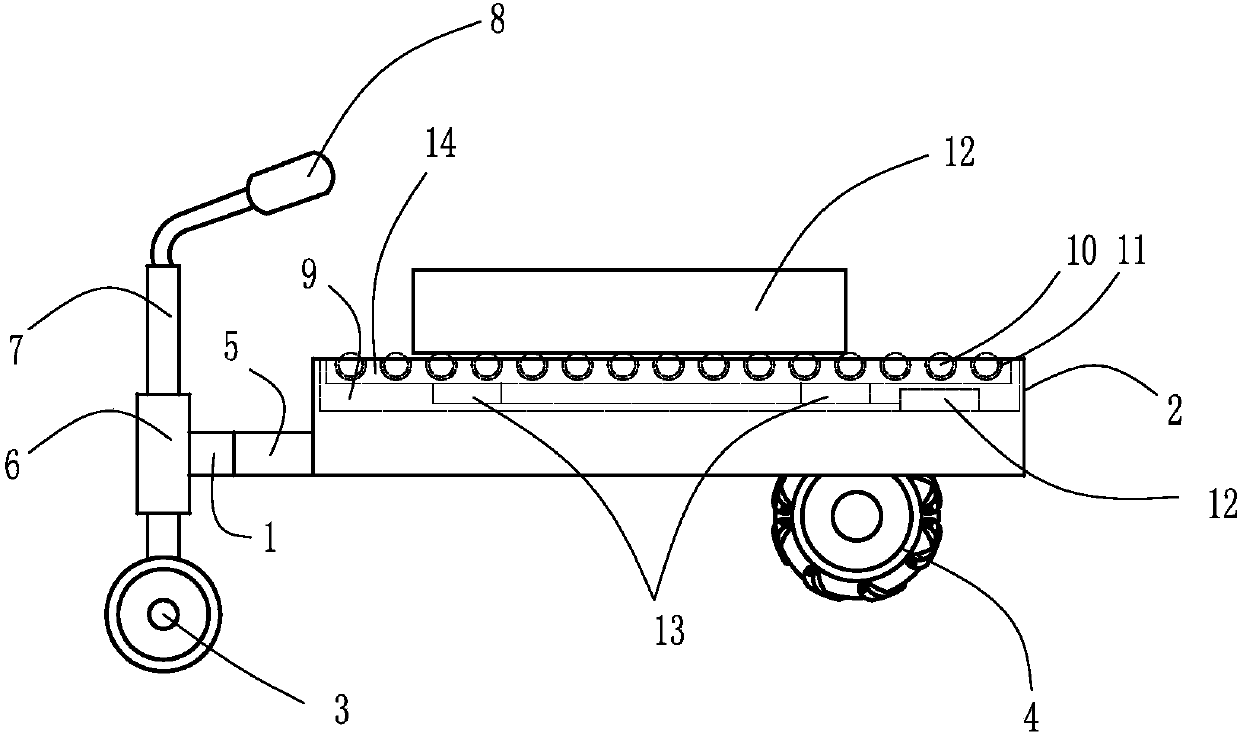

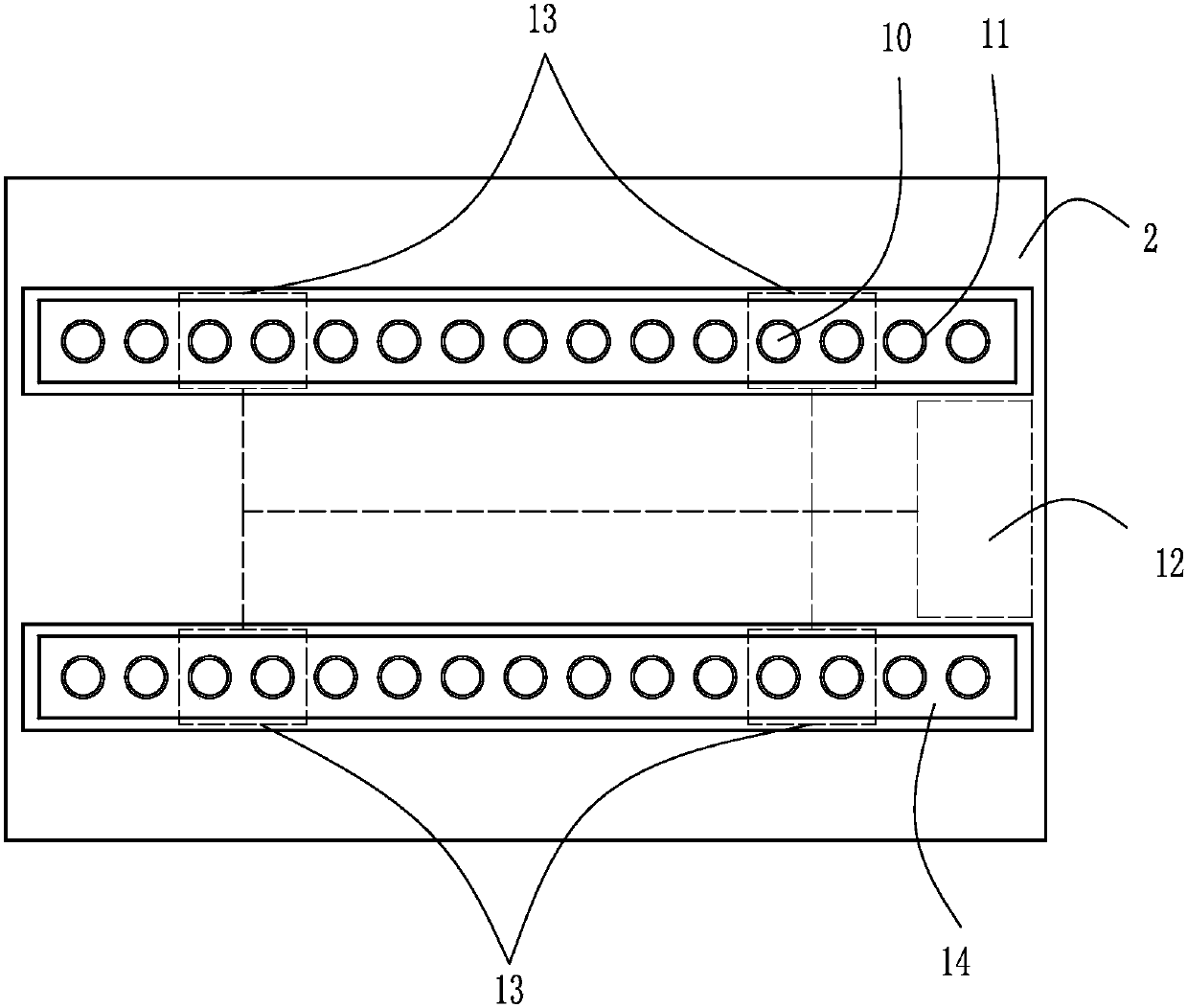

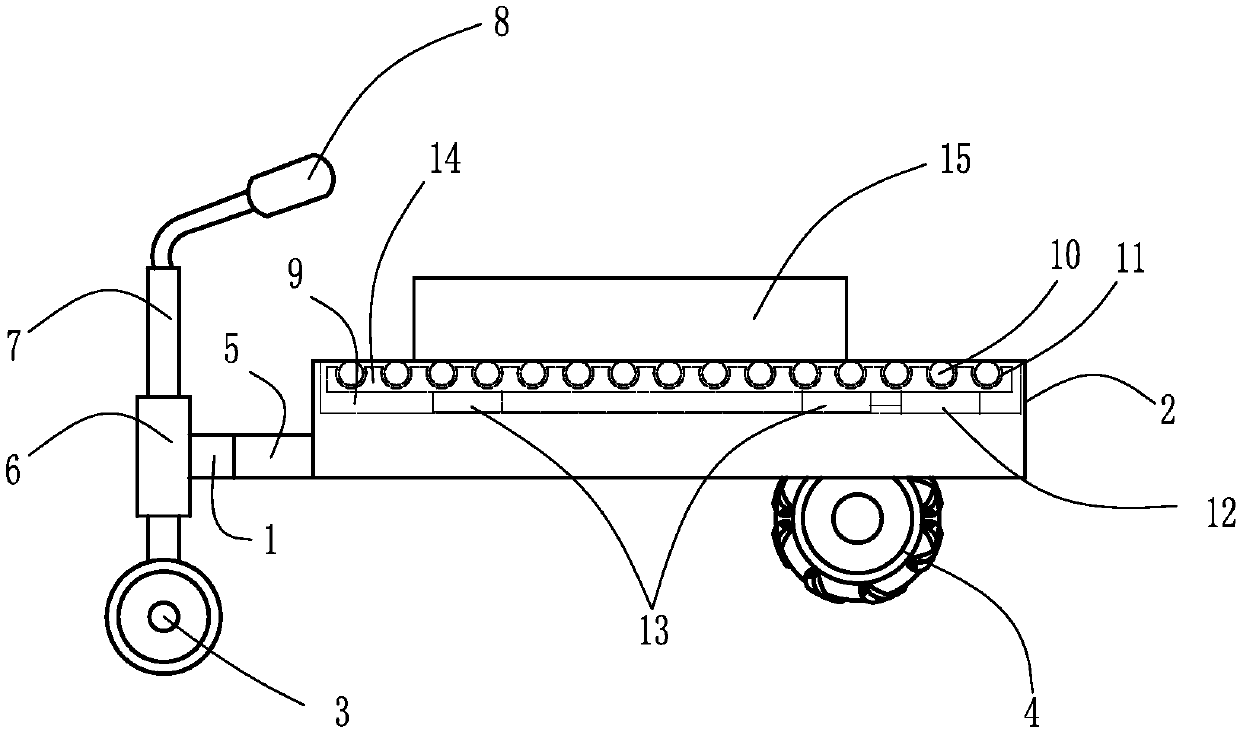

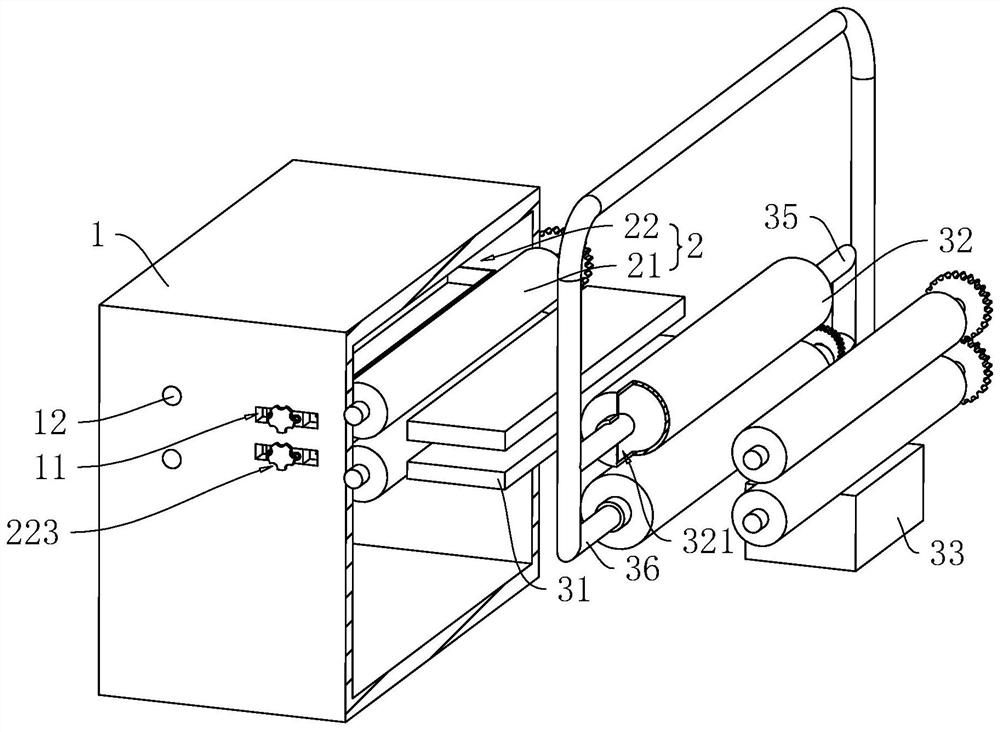

Movable type loading and unloading device for heat treatment products

InactiveCN106477323AWith loading and unloading automation functionPlay the role of loading and unloadingConveyor partsMechanical conveyorsPush pullMovable type

The invention provides a movable type loading and unloading device for heat treatment products. The movable type loading and unloading device comprises a guide rail installed on the ground. A walking trolley is erected on the guide rail. A walking device is arranged in the walking trolley. A support is further arranged on the walking trolley. A roller bed is arranged on the support. One side of the roller bed is aligned with a device entrance, a clamping jaw is arranged at the other end of the roller bed, and the clamping jaw is further connected with a push-pull chain mechanism. A control platform is arranged on the lateral side of the support. The movable type loading and unloading device is usually special for devices such as natural gas energy-saving multipurpose furnaces, push plate furnaces, tempering furnaces and cleaning machines, and has automatic loading and unloading functions, the walking trolley can be driven to convey the thermal treatment products in a long distance to the position of the device entrance, the heat treatment products advance and retreat along the roller bed through the push-pull chain mechanism and the clamping jaw so that the loading and unloading effects can be achieved, the mechanism is simple, control is convenient, and loading and unloading can be quite conveniently and rapidly achieved particularly for thermal treatment of large workpieces.

Owner:HUBEI JINGLIANG HEAT TREATMENT SYST CO LTD

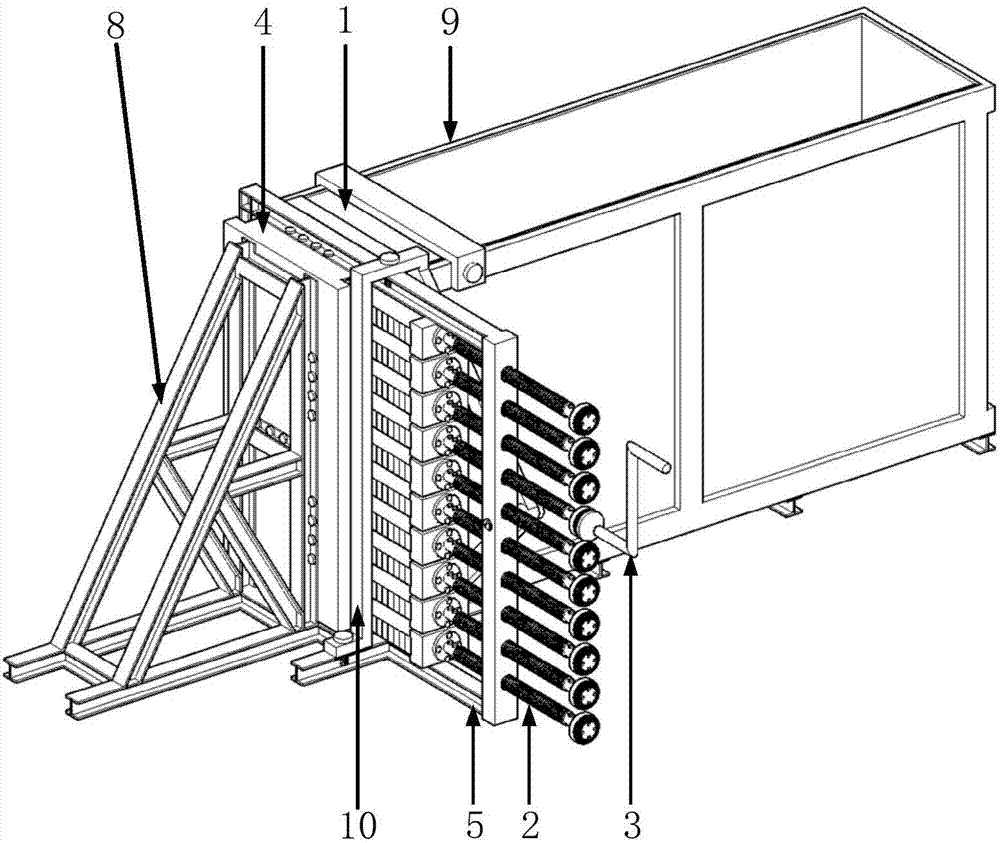

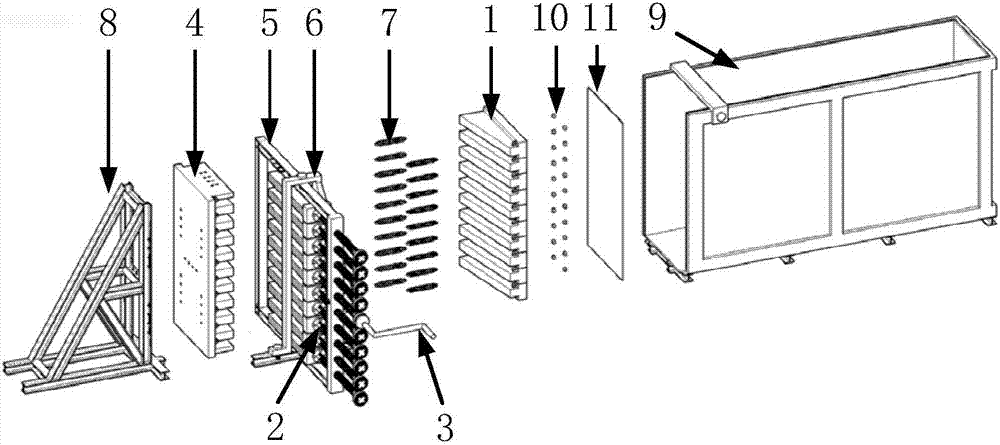

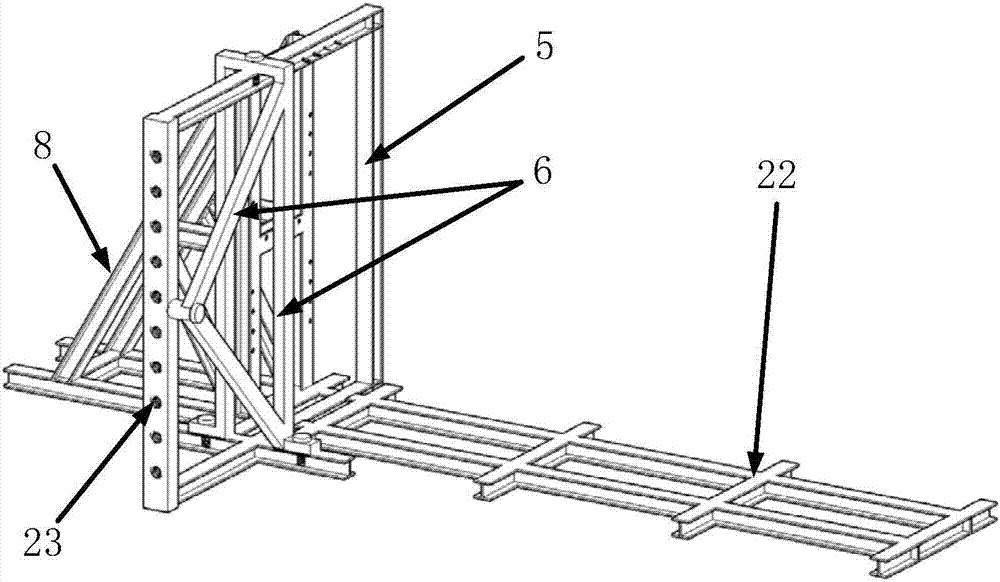

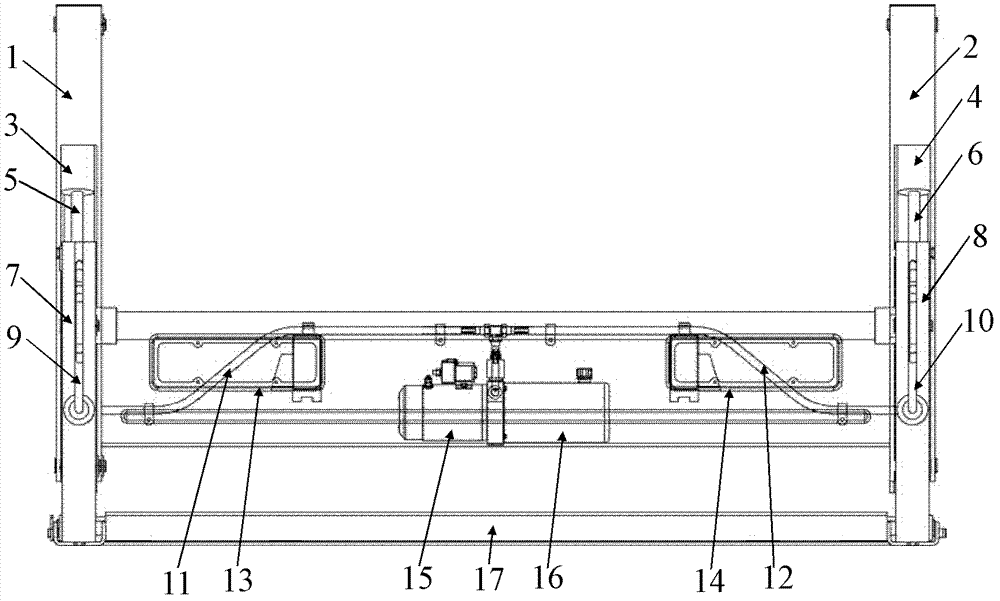

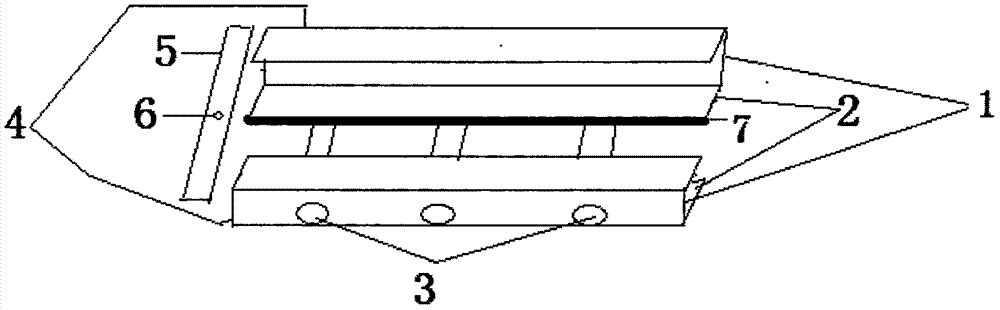

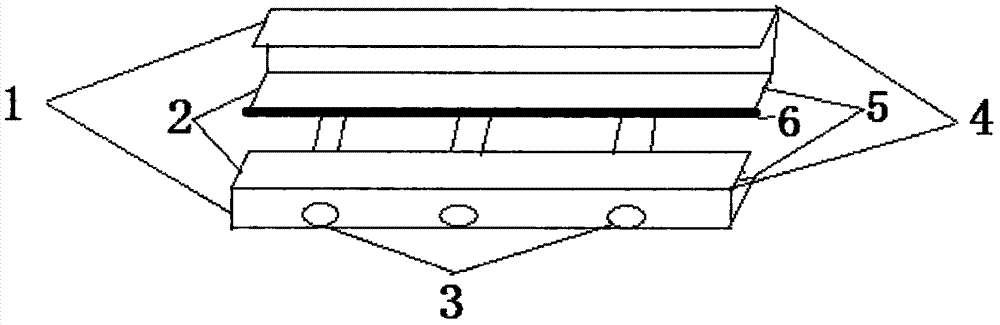

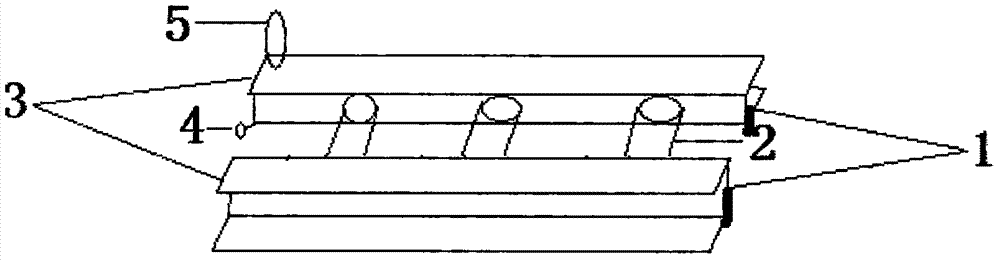

Device for support side pressure testing model during stratified unloading and nonuniform lateral displacement and a method based on device

ActiveCN107389446AThe number of layers is limitedSimulate non-uniform displacement casesMaterial strength using tensile/compressive forcesApparatus for force/torque/work measurementEngineeringDistribution law

The invention provides a device for a support side pressure testing model during stratified unloading and nonuniform lateral displacement and a method based on the device. The device comprises a triangular diagonal bracing rack, a loading frame, a rib slot rack, a loading unit, a loading crutch, a return spring, a spliced retaining wall, a micro-soil pressure sensor, a rubber film and a model box; and the method is based on the device. The device provided by the invention can simulate the lateral pressure of a support structure in a process of stratified excavation and unloading of a foundation pit, provide a basis for engineering design and support, research a distribution law of the lateral pressure of the support structure and a law of variation with displacement during nonuniform displacement, particularly, control the lateral displacement of the retaining wall at each depth accurately, and load the passive displacement of the retaining wall with relatively small loading thrust force.

Owner:SHANGHAI JIAO TONG UNIV

Electric truck facilitating loading and unloading

InactiveCN107738604AEasy loading and unloadingReduce frictionVehicle with rollersVehicle frameEngineering

The invention discloses an electric truck facilitating loading and unloading. The electric truck comprises a front frame, a rear frame and a connecting frame, wherein the front frame and the rear frame are fixedly connected through the connecting frame; rear wheels are installed on the bottom of the rear frame, lifting devices are fixedly arranged in the rear frame, at least two longitudinal grooves are formed in the upper surface of the rear frame, rolling belts are arranged in the grooves in a vertically-rolling mode, the bottoms of the rolling belts are connected with the lifting devices, ball grooves are formed in the upper surfaces of the rolling belts, rolling balls are restrained in the ball grooves, and the distance between the center of each rolling ball and the upper surface of the corresponding ball groove is smaller than the radius of the rolling ball, so that when cargoes are loaded, the lifting devices drive the rolling belts up, the upper surfaces of the ball grooves coincide with the upper surface of the rear frame, and the cargoes can roll on the rolling balls, so that friction force is greatly reduced, and during transportation, the lifting devices make the rolling belts down, and the cargoes are in contact with the upper surface of the rear frame again, so that friction force is increased, and then the cargoes do not slide during transportation. Therefore, loading and unloading of the cargoes are conveniently achieved.

Owner:WEIFANG HONGSHIXING MACHINERY PROCESSING CO LTD

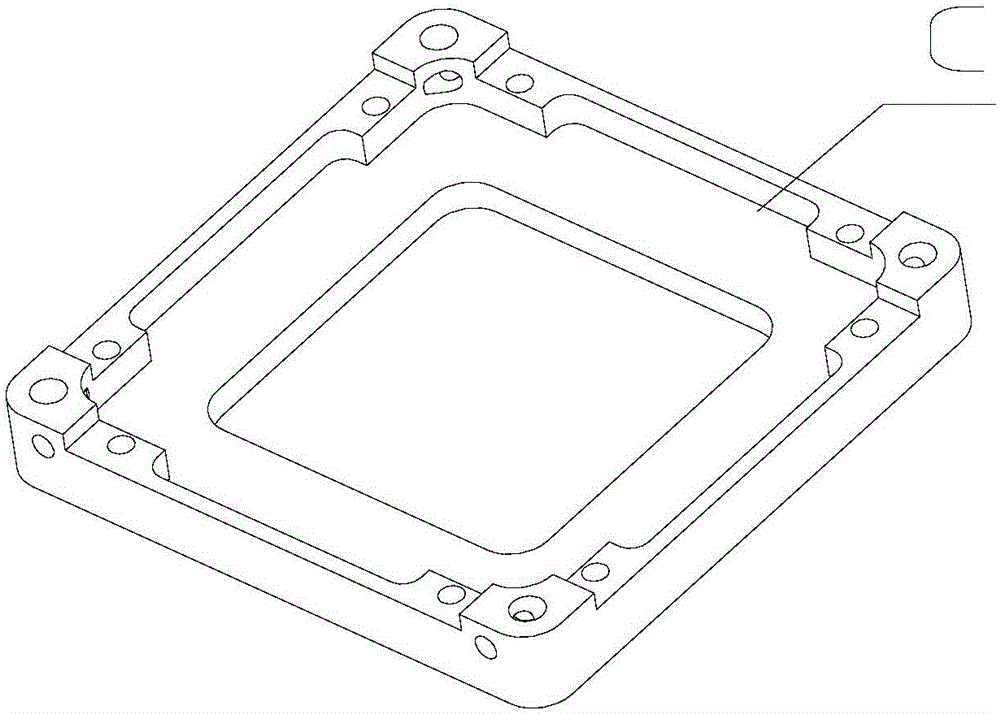

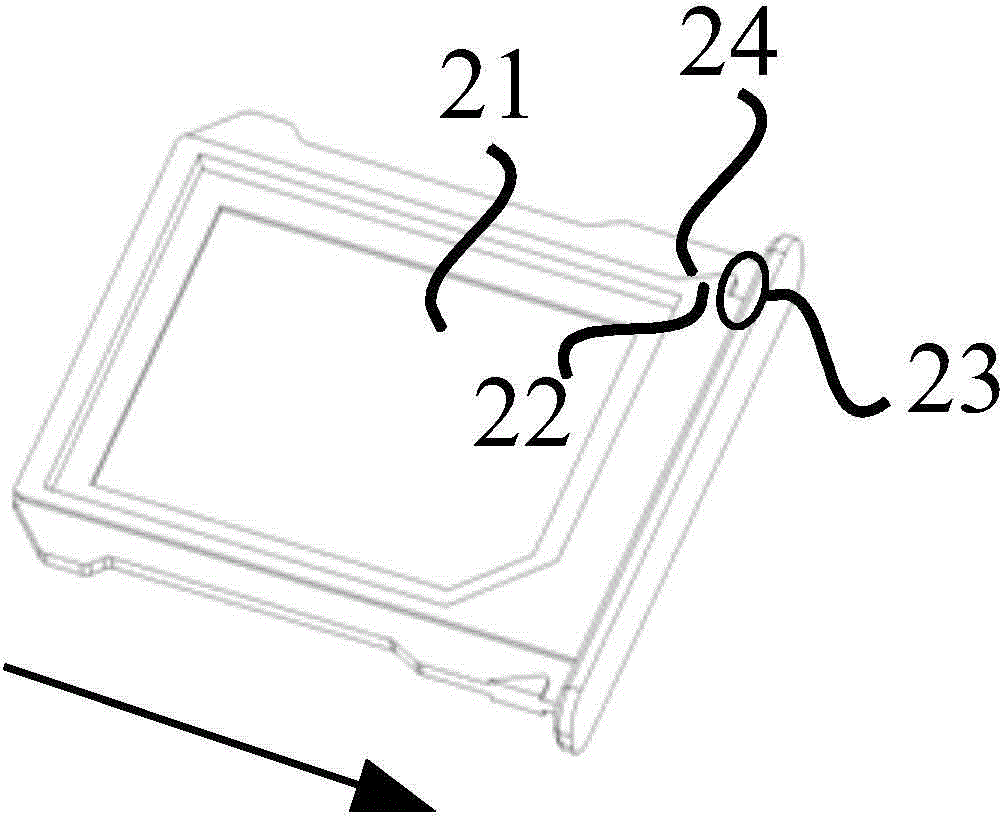

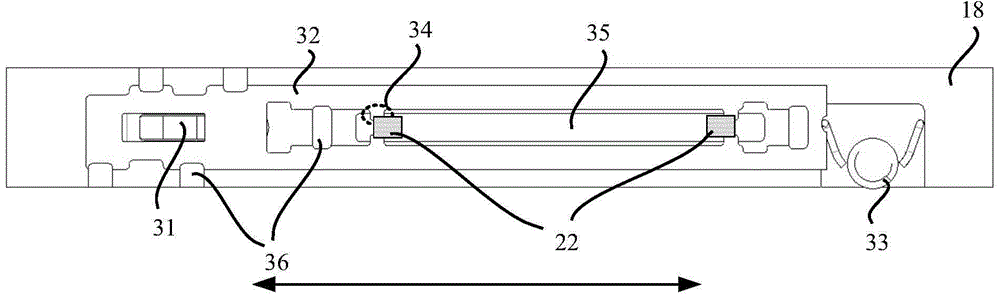

SIM card fixing device and mobile terminal

ActiveCN105635351AEasy loading and unloadingRealize loading and unloadingTransmissionTelephone set constructionsCard holderComputer terminal

The invention relates to an SIM card fixing device and a mobile terminal, and the device is disposed in the terminal. The device comprises a card holder for bearing an SIM card, a card seat for bearing the card holder, and a holder locking mechanism which is used for fixing the card holder. The card seat is provided with a first elastic part, and the first elastic part is used for applying an outward pushing force to the card holder when the SIM card withdraws. The holder locking mechanism comprises a press part, a locking rod, and a second elastic part. The locking rod is provided with a locking buckle, and the card holder is provided with a locking piece. When the card holder is assembled in the terminal, the locking buckle and the locking piece cooperatively abut against each other, thereby preventing the card holder from withdrawing. The press part is provided with a first force applying surface making contact with the locking rod, and the first force applying surface is used for pushing the locking rod to move when the press part is pressed, thereby driving the locking buckle on the locking rod to move and achieving the withdrawing of the card holder. The second elastic part is connected with the locking rod, and is used for achieving the resetting of the locking rod when the card holder withdraws. According to the embodiment of the invention, the device achieves the convenient assembly and disassembly of the SIM card.

Owner:XIAOMI INC

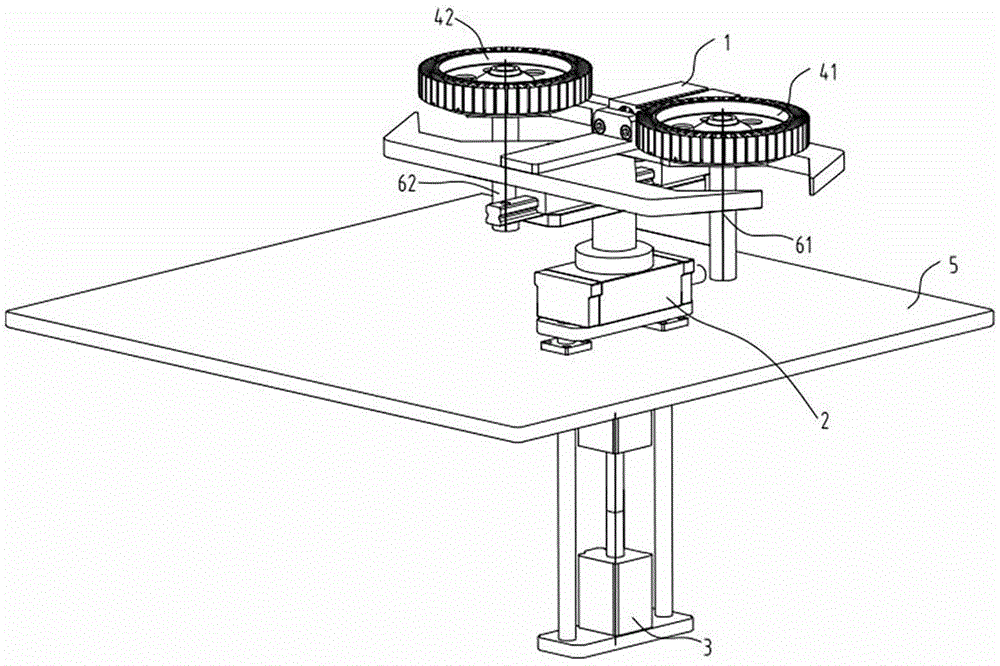

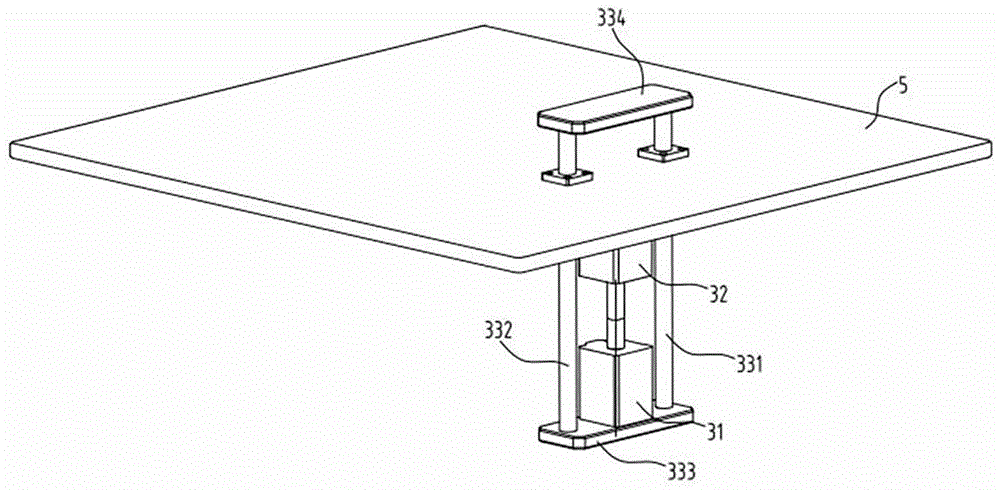

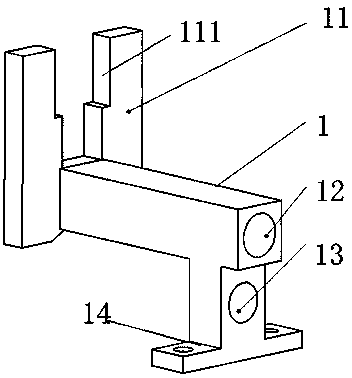

Double-station feeding and discharging device

ActiveCN105836538AIncrease productivityRealize manipulator loading and unloadingFilament handlingManipulatorStator

The invention belongs to the field of machining and discloses a double-station feeding and discharging device. The double-station feeding and discharging device comprises a workbench, a clamping mechanism with double clamping openings, an indexing mechanism for driving the clamping mechanism to rotate, and a lifting mechanism for driving the indexing mechanism and the clamping mechanism to ascend and descend. The clamping mechanism is arranged on a rotating component of the indexing mechanism. A fixing component of the indexing mechanism is arranged on a lifting component of the lifting mechanism. A fixing component of the lifting mechanism is arranged on the workbench. The two clamping openings of the clamping mechanism are in central symmetry with respect to the rotating axis of the indexing mechanism. Through the double-station feeding and discharging device, motor stators are fed and discharged alternately in a reciprocating mode, winding production efficiency is improved, and implementation of feeding and discharging with manipulators is facilitated.

Owner:HANGZHOU TIANMING TECH CO LTD

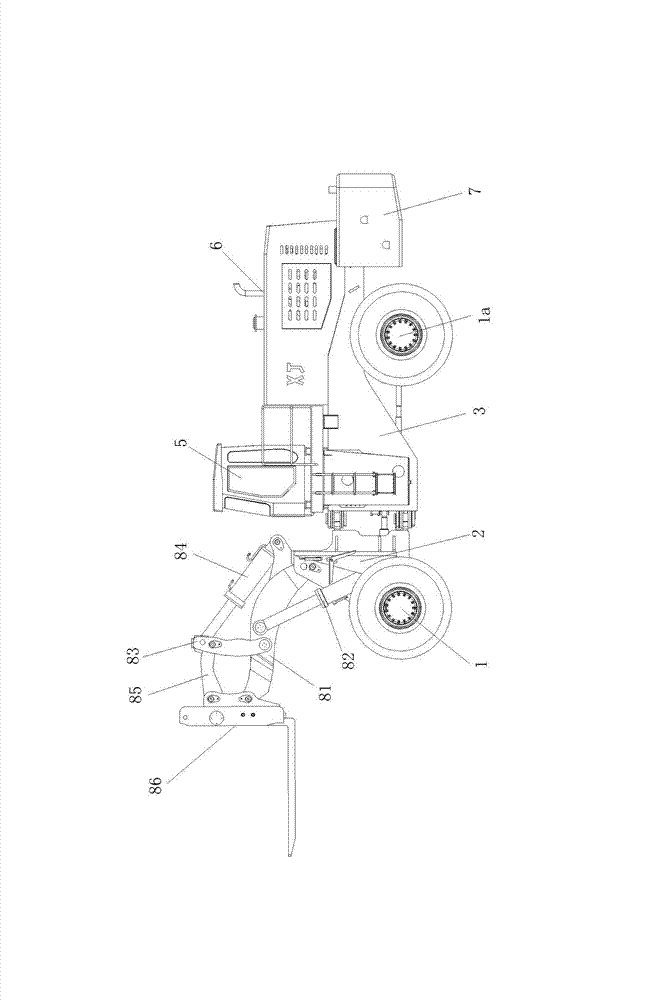

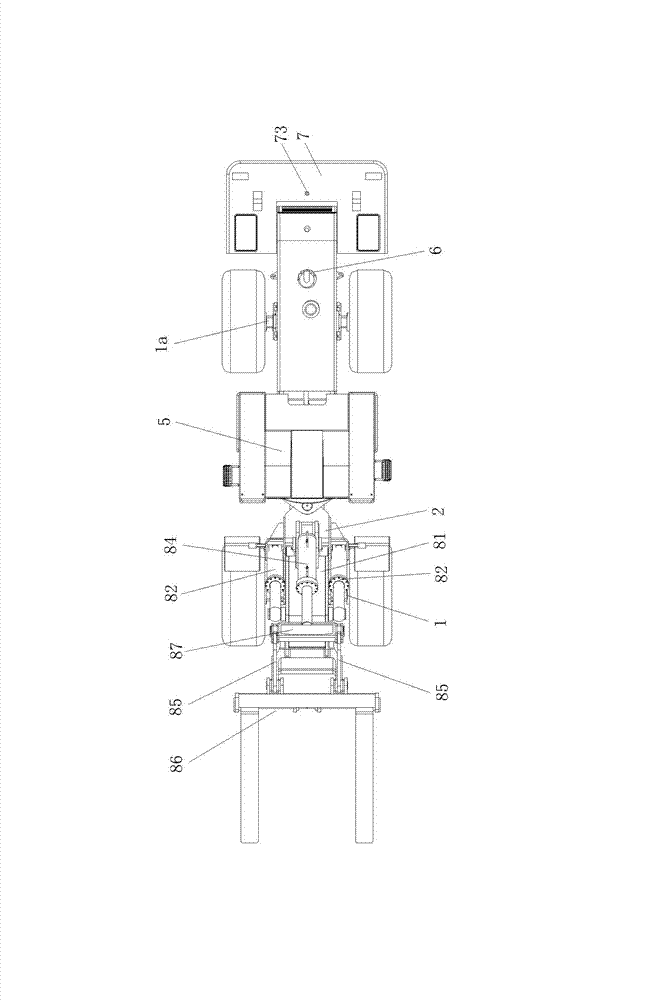

Telescopic handler

ActiveCN103043565AStrong torsion resistanceStrong bending resistanceLifting devicesTractor-trailer combinationsEngineeringLarge size

The invention discloses a telescopic handler which comprises a front driving axle and a back driving axle which are provided with tires, a front frame, a back frame, an auxiliary frame, a cab, an engine, a counter weight block and a working device. The working device comprises a movable arm, two movable arm oil cylinders, two rocker arms, a rotating bucket oil cylinder, two pull rods and an object fork. The lower end of the movable arm is hinged on the upper portion of the front frame, the upper end of the movable arm is hinged on the back lower portion of the object fork, the lower ends of the two movable arm oil cylinders are respectively hinged on two sides of the lower portion of the front frame, and the upper ends of the two movable arm oil cylinders are hinged on two sides of the middle of the movable arm. The lower ends of the two rocker arms are hinged on two sides of the middle of the movable arm, the lower end of the rotating bucket oil cylinder is hinged on the upper side of the lower portion of the movable arm, the upper end of the rotating bucket oil cylinder is hinged with the upper ends of the two rocker arms through a connection rod, one ends of the two pull rods are hinged at the position of the rocker arms close to the upper end, and the other ends of the two pull rods are respectively hinged on the back upper portion of the object fork. The telescopic handler is capable of forking materials with large size and weight, long in unloading distance, large in unloading angle and flexible to operate.

Owner:XIAMEN XIAJIN MACHINERY

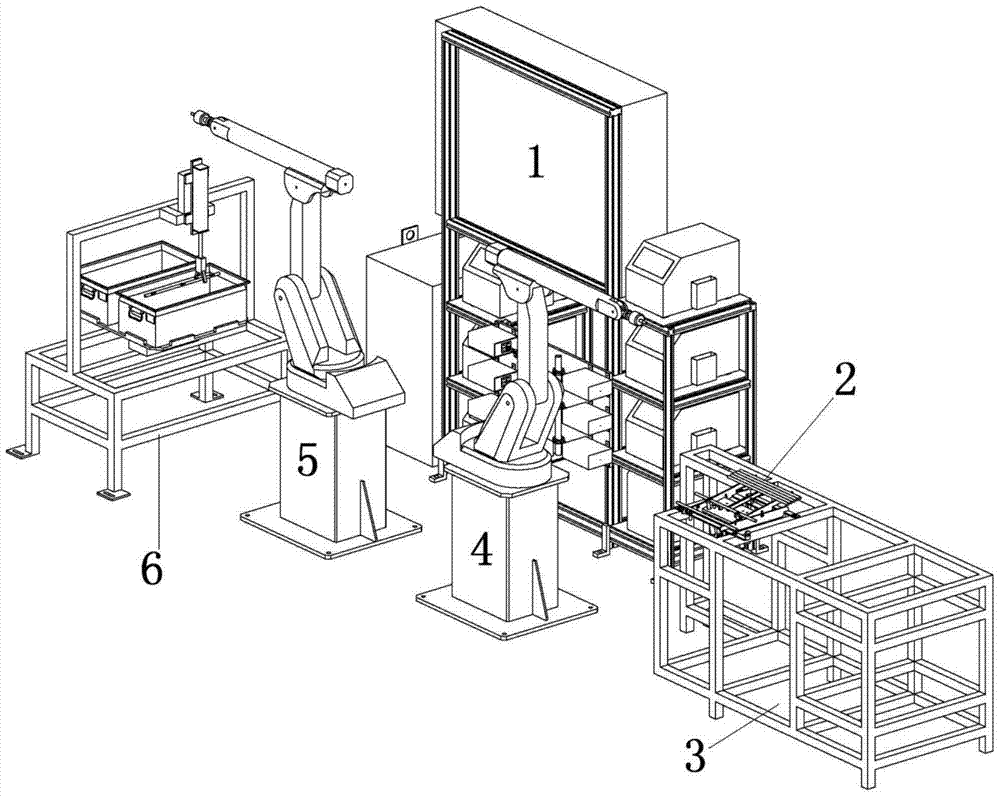

Spot welding and brazing integrated device of nuclear fuel element cladding pipe

ActiveCN104511673ARealize automatic sequenceRealize automatic unloadingWelding/cutting auxillary devicesAuxillary welding devicesSpot weldingIntegrated devices

The invention belongs to the technical field of nuclear fuel element machining electromechanical integration, in particular relates to a spot welding and brazing integrated device of a nuclear fuel element cladding pipe. The device comprises a brazing system, a spot welding system, a feed mechanism, a discharge mechanism, a loading robot and an unloading robot, wherein the spot welding system performs the spot welding of a support pad and an isolation block on the cladding pipe; two robots are symmetrically mounted on the central surface of the brazing system; the feed mechanism and the loading robot are arranged at the feed side of the brazing system; the discharge mechanism and the unloading robot are arranged at the discharge side of the brazing system; and in working, the spot welding system works firstly to prepare materials for the brazing system. Two ABB robots are used as intermediate links, and the spot welding and the brazing are integrated as a whole, so that the automatic sequence transfer after the spot welding and the automatic discharge after the brazing of the cladding pipe are realized, the research on the nuclear fuel element manufacturing aspect is enriched, and the foundation of developing the fuel element manufacturing develops to the direction of integration and full automatization and reducing the inference of manmade middle link factors as far as possible is laid.

Owner:CHINA NUCLEAR BAOTOU GUANGHUA CHEM IND

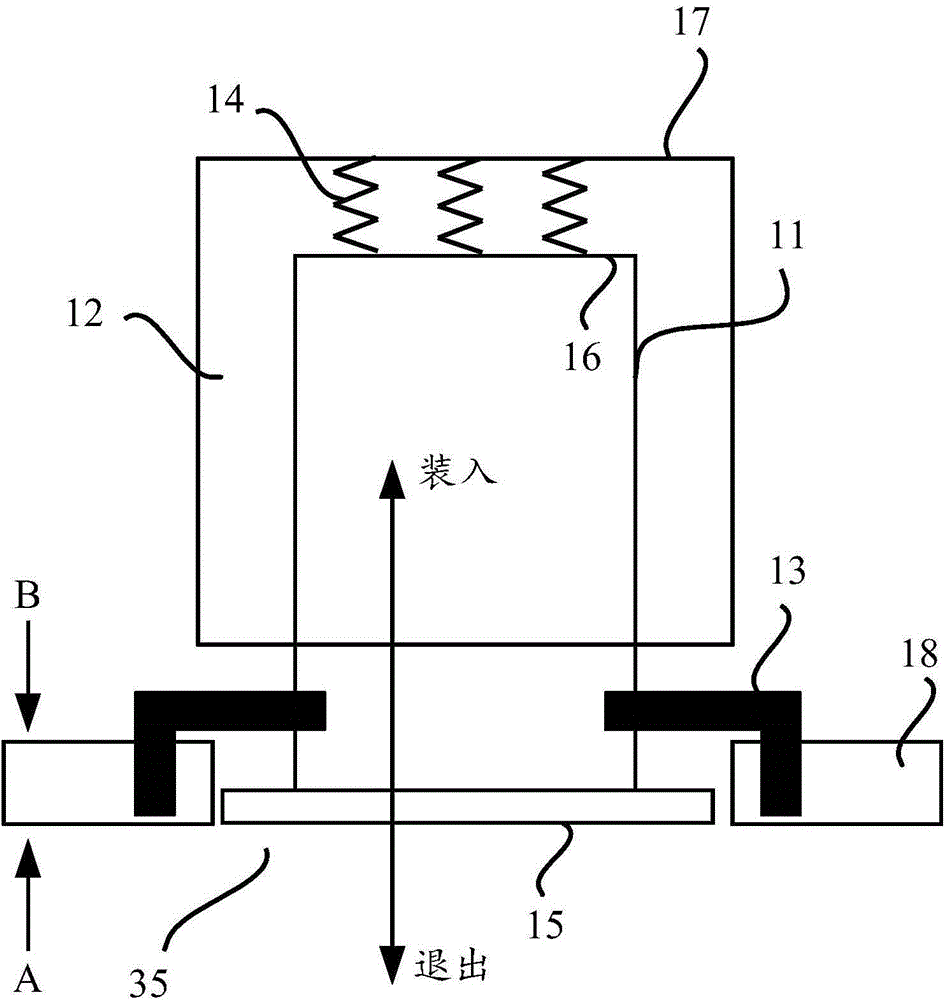

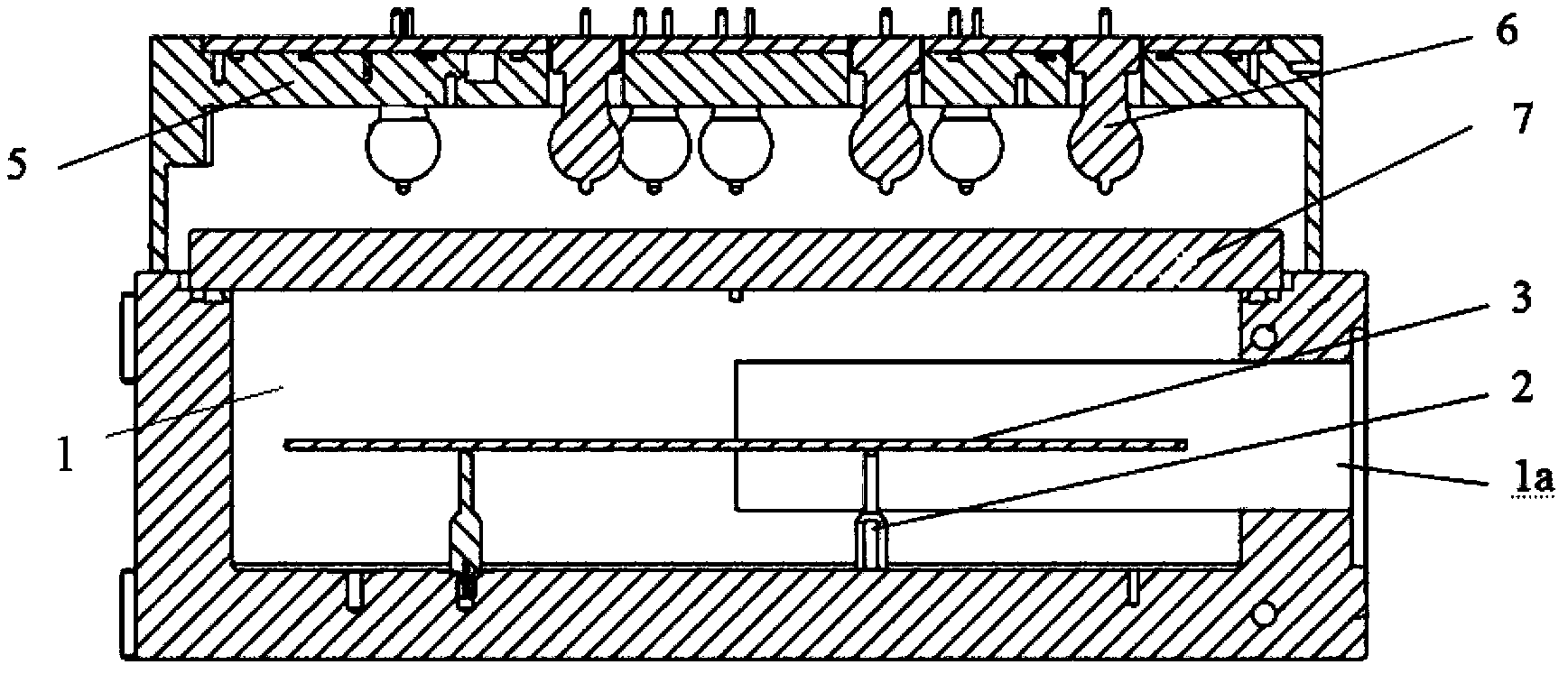

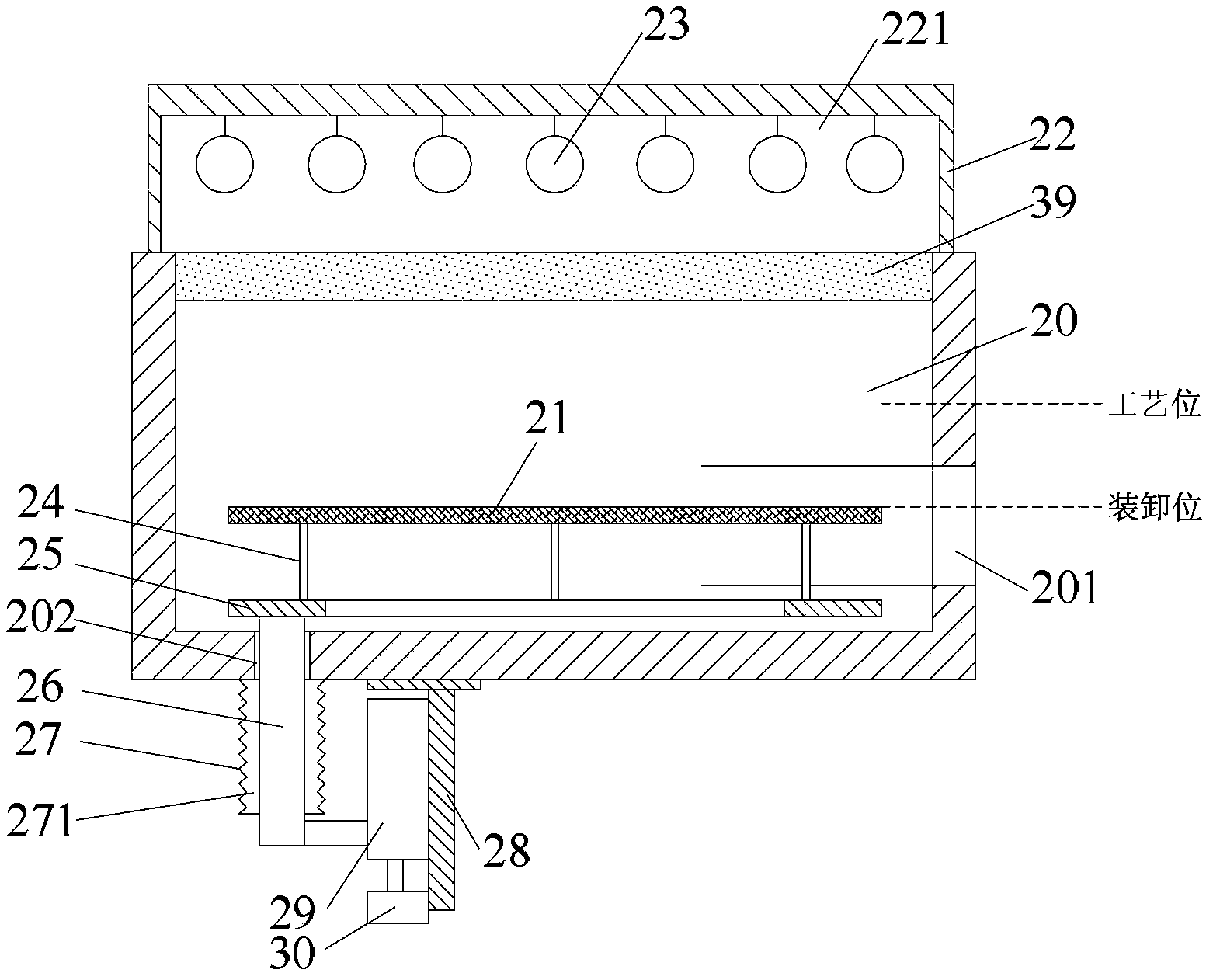

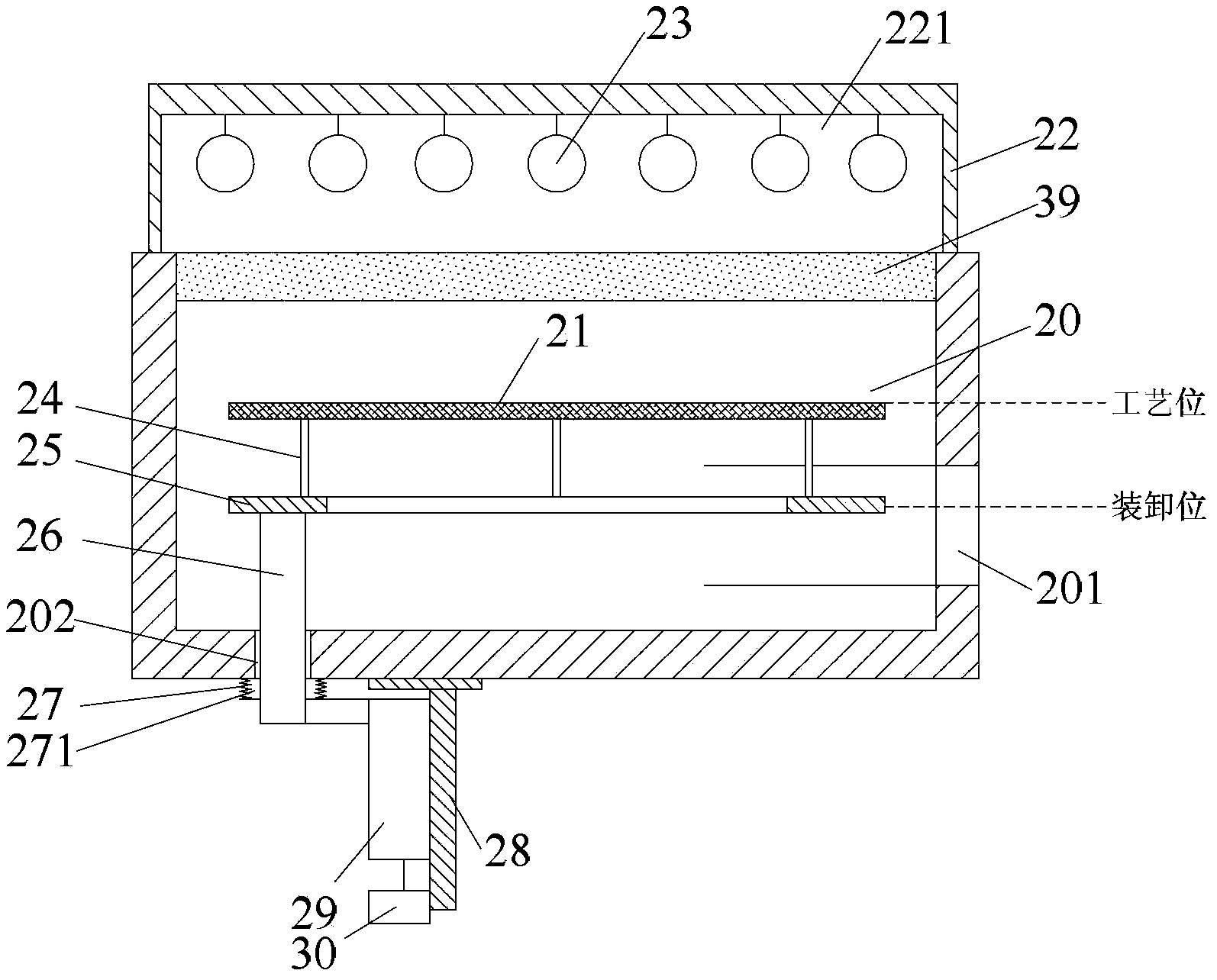

Heating chamber and plasma processing apparatus

InactiveCN104233191ARealize loading and unloadingUniform temperatureVacuum evaporation coatingSputtering coatingThermal radiationMechanical engineering

The invention provides a heating chamber and a plasma processing apparatus. The top of the heating chamber is provided with a heating unit for irradiating heat energy to the interior of the heating chamber in a heat radiation manner; the inner circumference wall of the heating chamber is provided with a piece-transferring opening for moving a to-be-processed workpiece in and out of the heating chamber; and the heating chamber comprises a bearing device. The bearing device comprises a lifting unit and ejection pin devices; the ejection pin devices are disposed in the heating chamber and are used for supporting the to-be-processed workpiece; the lifting unit is used for driving the ejection pin devices to rise or descend, so as to drive the to-be-processed workpiece on the ejection pin devices to rise to a preset process position above the piece-transferring opening to carry out the process or descend to a preset loading and unloading position corresponding to the piece-transferring opening to carry out loading and unloading operations. The heating chamber provided by the invention can heat the to-be-processed workpiece uniformly, and thus temperature uniformity of the to-be-processed workpiece is increased and uniformity of the process can be increased.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

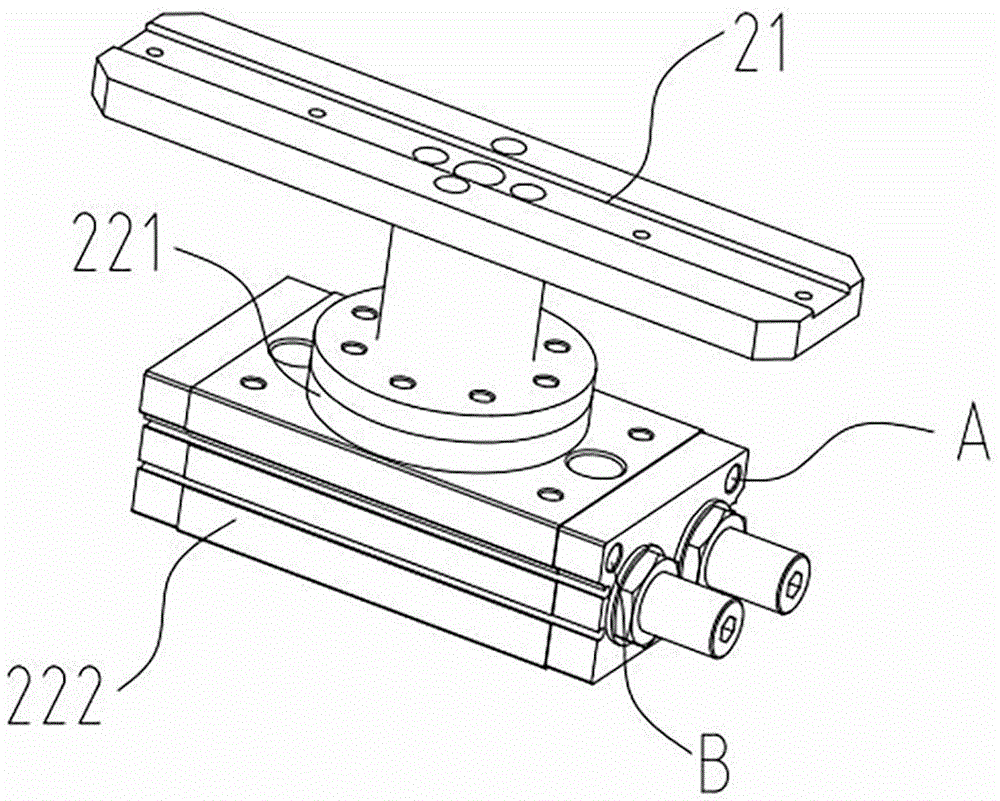

Clamp for automatic quick replacing

The invention discloses a clamp for automatic quick replacing, which is characterized in that: the clamp is provided with an A part device arranged on the side gesture of a mechanical arm and a B part device arranged on a jig, wherein the A part device is matched and connected with the B part device; the A part device is provided with an arm side installation plate; a plurality of air vents, check valves and threaded connection holes are formed on a plate body; a circular groove is formed in the middle of the plate body; a central shaft with a piston is arranged in the circular groove; an outer ring of the central shaft piston is in sealing fit with the inner diameter of the circular groove; a matching shaft sleeve is sleeved outside the piston of the central shaft; the B part device is provided with a jig side installation plate; and the middle of the jig side installation plate is provided with a central circular hole matched with a shaft head of the matching shaft sleeve on the arm side installation plate, a plug or a socket matched with the socket or the plug, the air vents matched with the check valves and ventilating joints connected to the air vents. The clamp for automatic quick replacing can quickly replace the jig and is small in volume and advanced in functions.

Owner:NINGBO WELLLIH ROBOTS TECH CO LTD

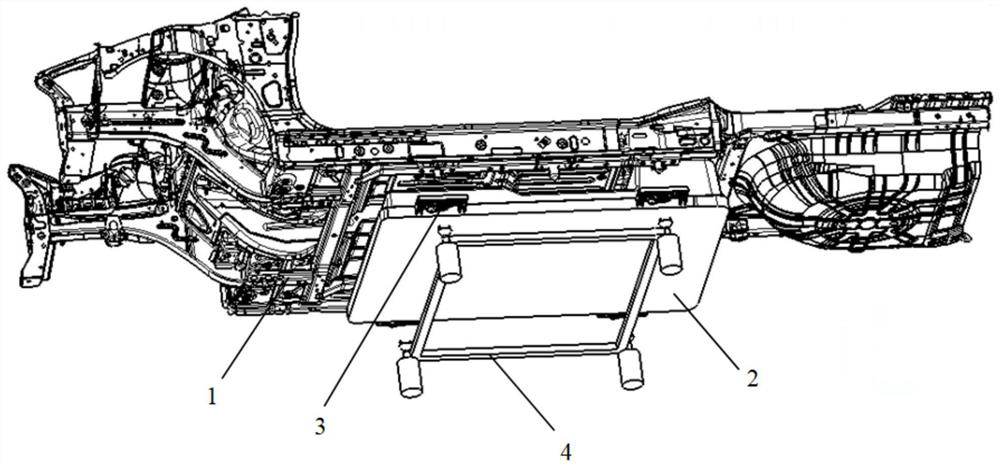

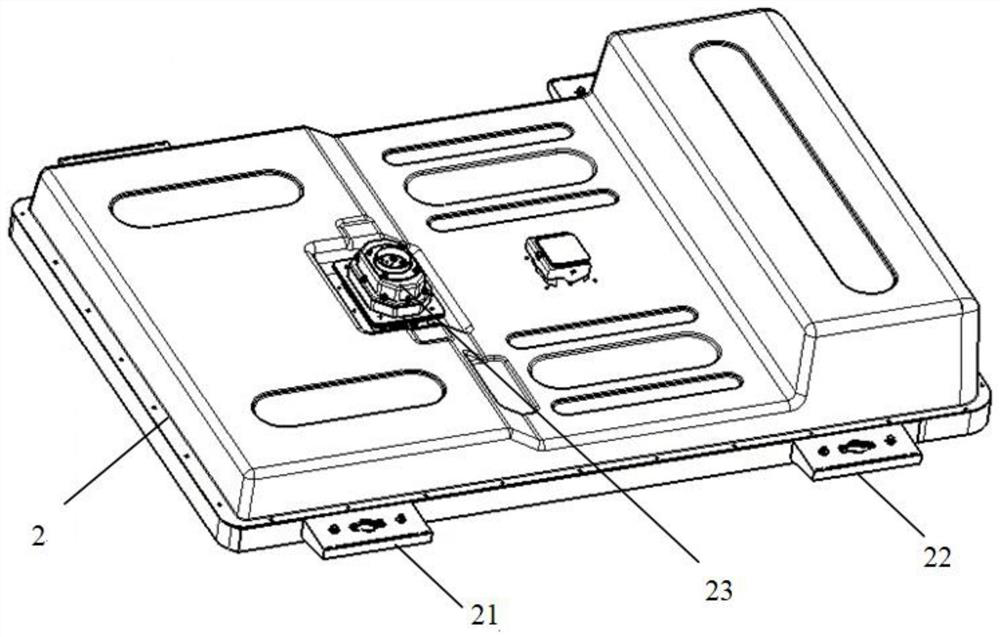

Quick assembling and disassembling locking mechanism of battery box

ActiveCN112109536ARealize loading and unloadingQuick loading and unloadingCharging stationsElectric propulsion mountingEngineeringTorsion spring

The invention discloses a quick assembling and disassembling locking mechanism of a battery box. The quick assembling and disassembling locking mechanism comprises a fixed locking seat, a locking piece arranged on the locking seat in a self-rotating manner and a torsion spring with the two ends extending outwards to form a V shape. a cross-shaped hook through hole is formed in the upper portion ofthe locking piece, the middle of the locking piece can contain a cross-shaped hook passing through the cross-shaped hook through hole, and the lower portion of the locking piece can be matched with atool for operating the locking piece to rotate; when the locking piece rotates, two extreme positions, namely a locking position and an opening position, exist on the locking seat; the locking pieceis hung on the cross-shaped hook when located at the locking position and disengaged from the cross-shaped hook through the cross-shaped hook through hole when located at the opening position, the twoends of the torsional spring are connected with the locking piece and the locking seat respectively, and the two ends of the torsional spring are shrunk and then expanded when the locking piece is switched between the locking position and the opening position; and the two ends of the torsional spring always have the expansion tendency under the condition without external force action, and the locking piece can be kept at the locking position and the opening position. The quick assembling and disassembling locking mechanism can be quickly assembled and disassembled and is not easy to slip.

Owner:DONGFENG MOTOR CORP HUBEI

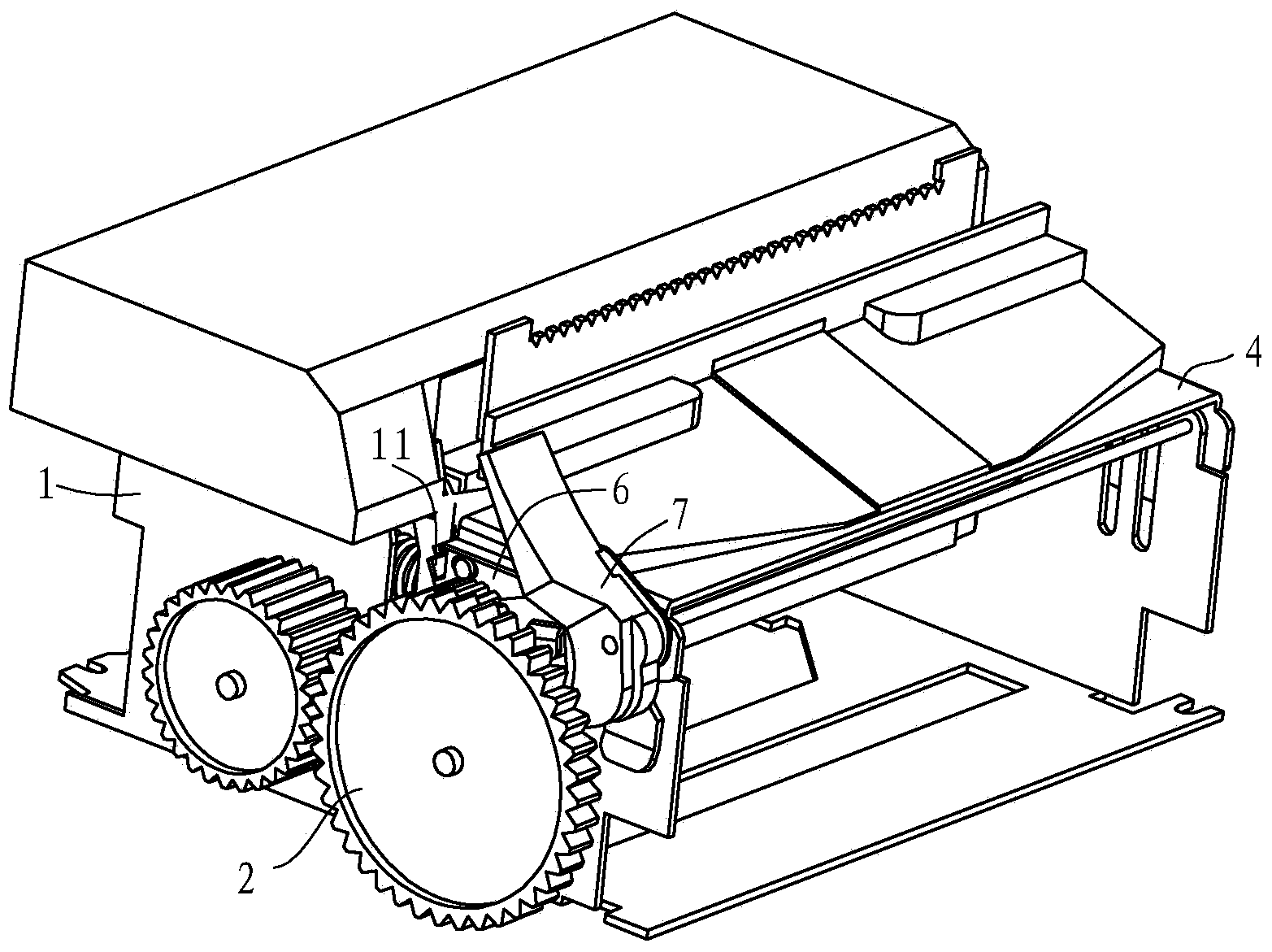

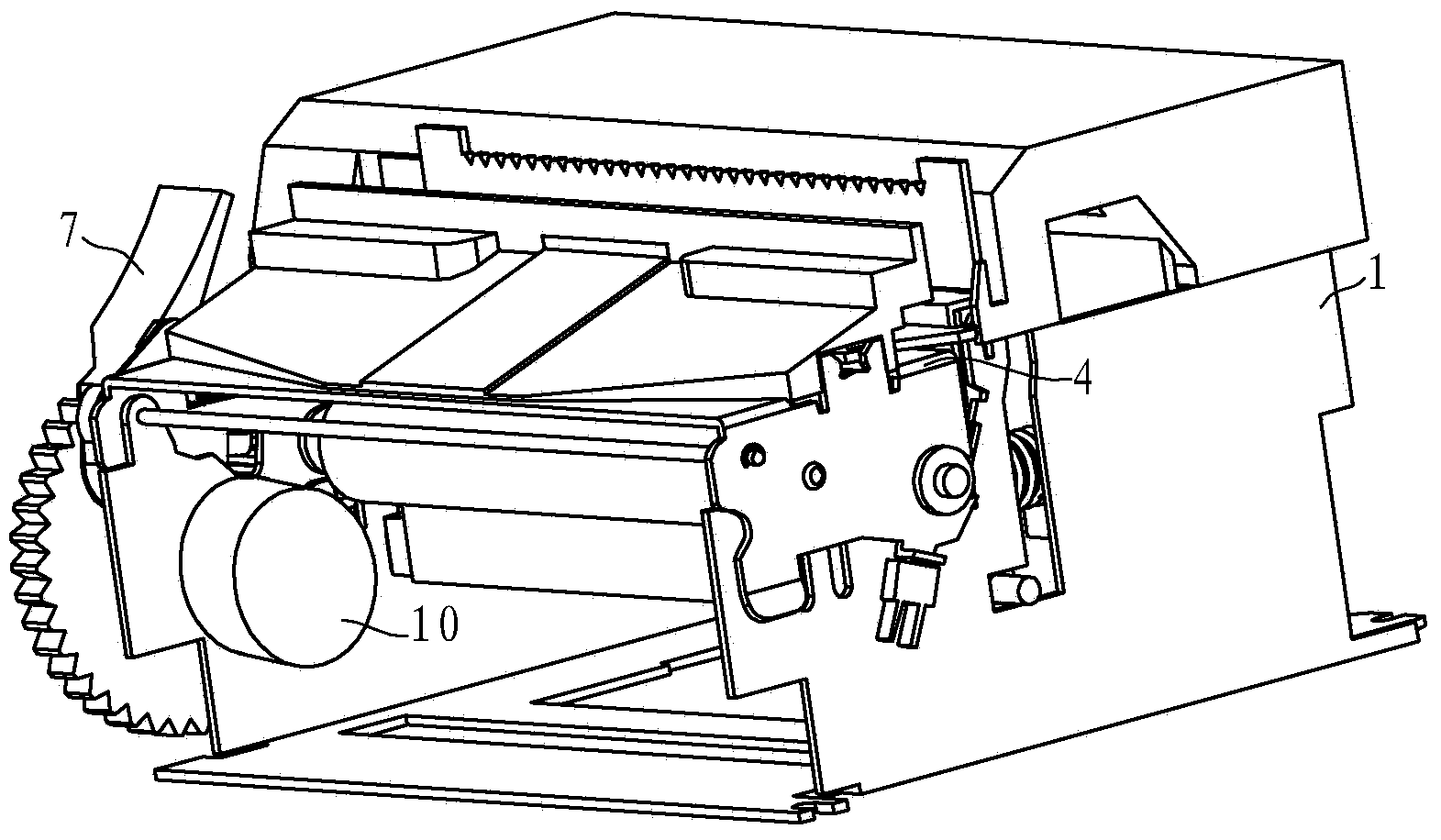

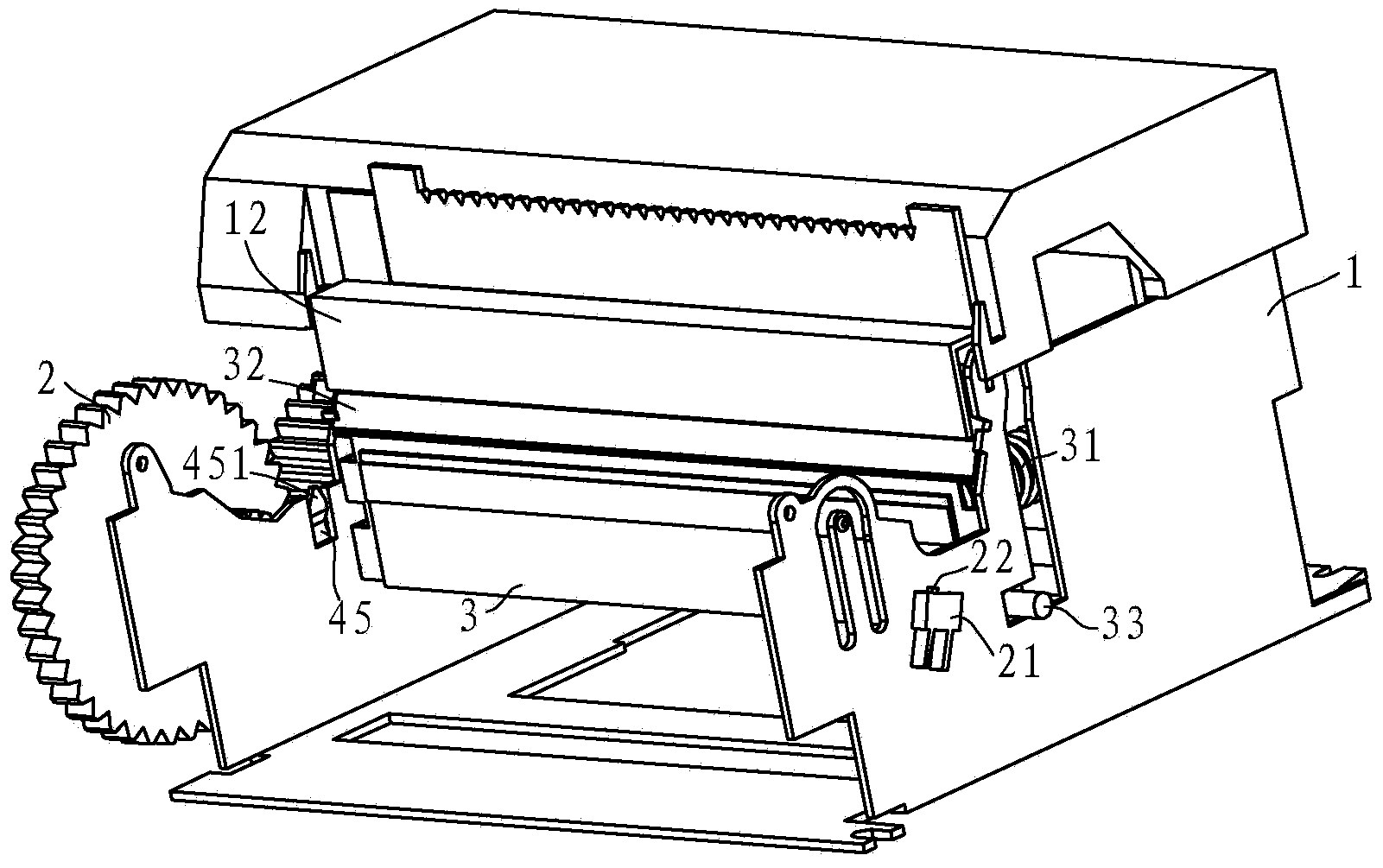

Note thermal printer

The invention provides a note thermal printer which comprises a machine base, a motor, a transmission gear set, a print head assembly, a support and a rubber roll. One end of the support is arranged on one side of the machine base in an overturning mode and opposite to the print head assembly. The other end of the support is connected with the machine base through a detachable mechanism. The note thermal printer is characterized in that the side, close to the support, of the machine base is provided with a limiting block; the detachable mechanism comprises a wrench, a limiting sliding piece and a reset spring, one end of the wrench is arranged on the support in a rotating mode, and the other end of the wrench is a wrench portion; the limiting sliding piece can be arranged on the support in a sliding mode, one end of the limiting sliding piece is connected with the wrench and can be driven by the wrench to move back and forth, the other end of the limiting sliding piece extends outwards to form an extension portion capable of being matched with the limiting block to position the support. Compared with the prior art, the note thermal printer has the advantages that the wrench is pulled, the limiting sliding piece is pulled while the elastic force of the reset spring is overcome, the limiting sliding piece is separated from the limiting block, one side of the support is separated from the machine base, the rubber roll is separated from the print head assembly after the support is turned over, disassembly and assembly of printing paper can be achieved, and the note thermal printer is convenient and fast to use, simple in structure and easy to manufacture.

Owner:宁波精芯科技有限公司

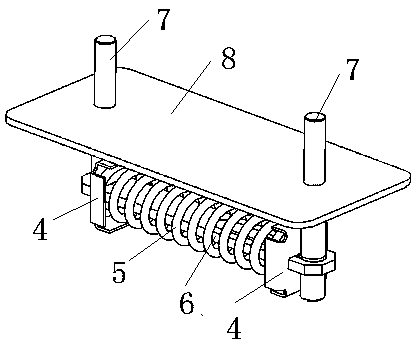

Spring assembly auxiliary loading and unloading tooling

ActiveCN109249349ARealize loading and unloadingLoading and unloading is realized through this auxiliary loading and unloading toolMetal-working hand toolsPull forceEngineering

The invention relates to a spring assembly auxiliary loading and unloading tooling. The spring assembly auxiliary loading and unloading tooling comprises a first base, a second base and a driving mechanism, wherein the driving mechanism is used for driving the first base and the second base to move oppositely and move on the contrary, the first base is in guided cooperation with the second base through a telescopic guide structure, and the first base and the second base are provided with force application parts arranged at the two ends of a corresponding spring assembly respectively to exert pressure or tension on a spring in the corresponding spring assembly. The spring assembly auxiliary loading and unloading tooling has the advantages that loading and unloading of the spring assembly are achieved, one person can perform operation, the operation time is saved, and the operation efficiency is increased; through the arrangement of the guide structure, the loading and unloading toolingcan achieve the stationarity of the guide movement in the process of pulling and pressing the spring and reduce the axial deformation by force of the spring assembly during compression.

Owner:PINGGAO GRP +2

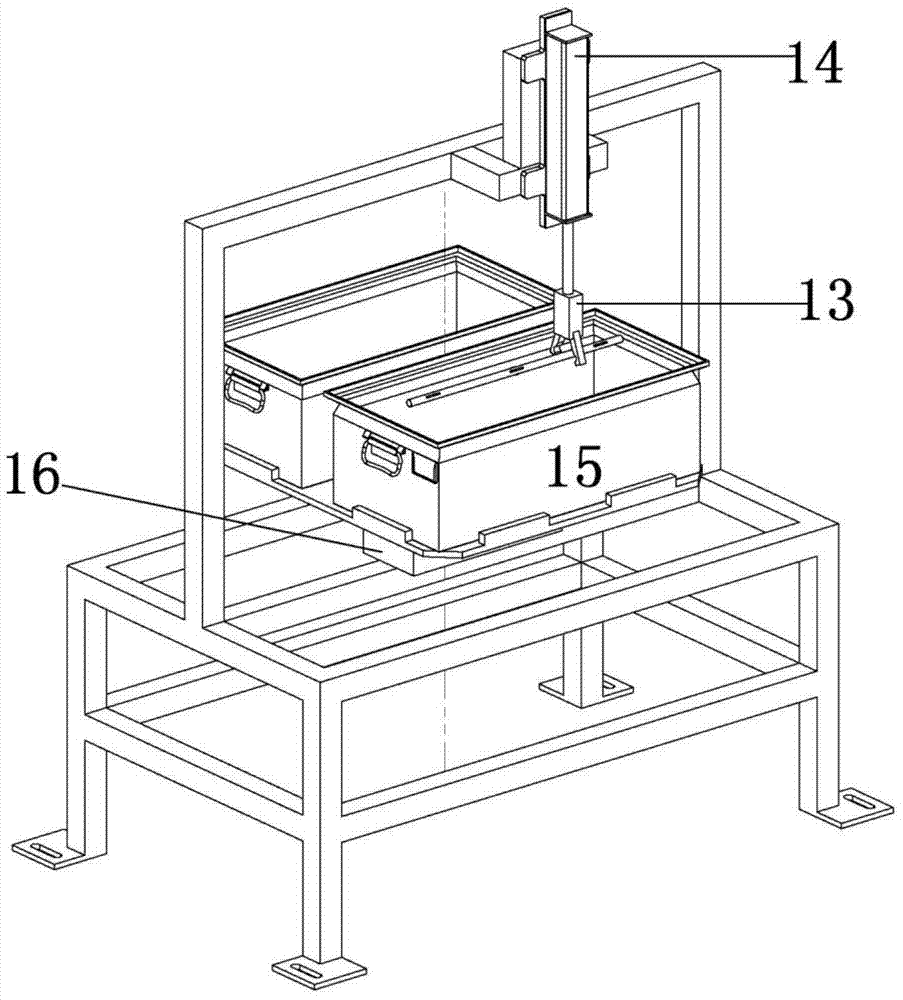

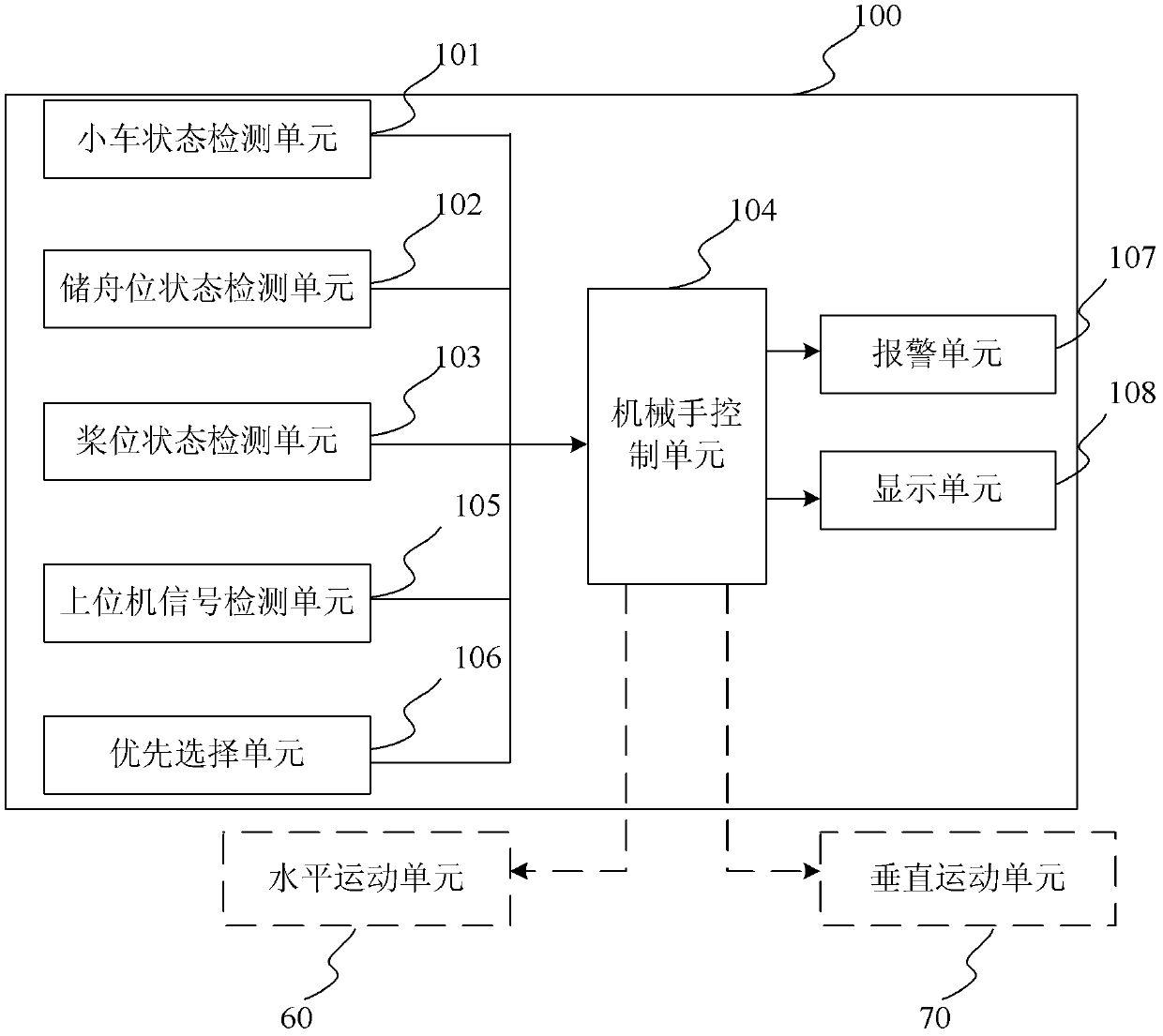

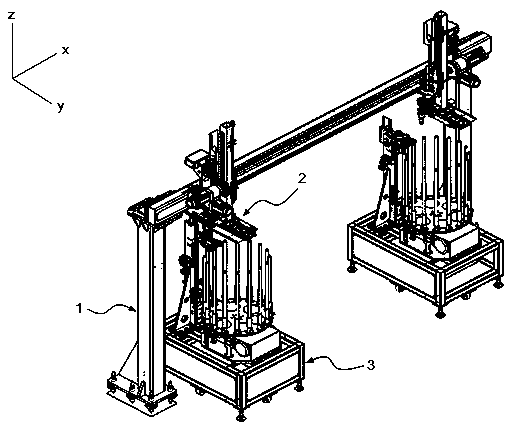

Automatic loading and unloading device for PECVD (plasma enhanced chemical vapor deposition) equipment

ActiveCN102709212ARealize loading and unloadingImprove efficiencySemiconductor/solid-state device manufacturingManipulatorBogieGraphite

The invention relates to an automatic loading and unloading device for PECVD (plasma enhanced chemical vapor deposition) equipment. The automatic loading and unloading device comprises a control module and a support. The support is provided with a boat storage workstation for storing graphite boats, a bogie, a paddle workstation and a manipulator taking and storing the graphite boats at the boat storage workstation, the bogie and the paddle workstation. The support is further provided with a horizontal moving unit and a perpendicular moving unit, wherein the horizontal moving unit is used for controlling moving of the manipulator in the horizontal direction, and the perpendicular moving unit is used for controlling moving of the manipulator in the perpendicular direction. The control module is connected with an upper computer of the PECVD equipment and used for controlling the horizontal moving unit and the perpendicular moving unit to drive the manipulator according to state signals about whether the graphite boats are on the boat storage workstation, the bogie and the paddle workstation and signals about taking and loading the graphite boats from the upper computer. The automatic loading and unloading device for the PECVD equipment is capable of accurately positioning, is high in loading and unloading efficiency, work intensity of operators is reduced, the graphite boats are protected from damage, uniformity of film plating is fine and the service lives of the graphite boats can be prolonged greatly.

Owner:深圳市大族光伏装备有限公司

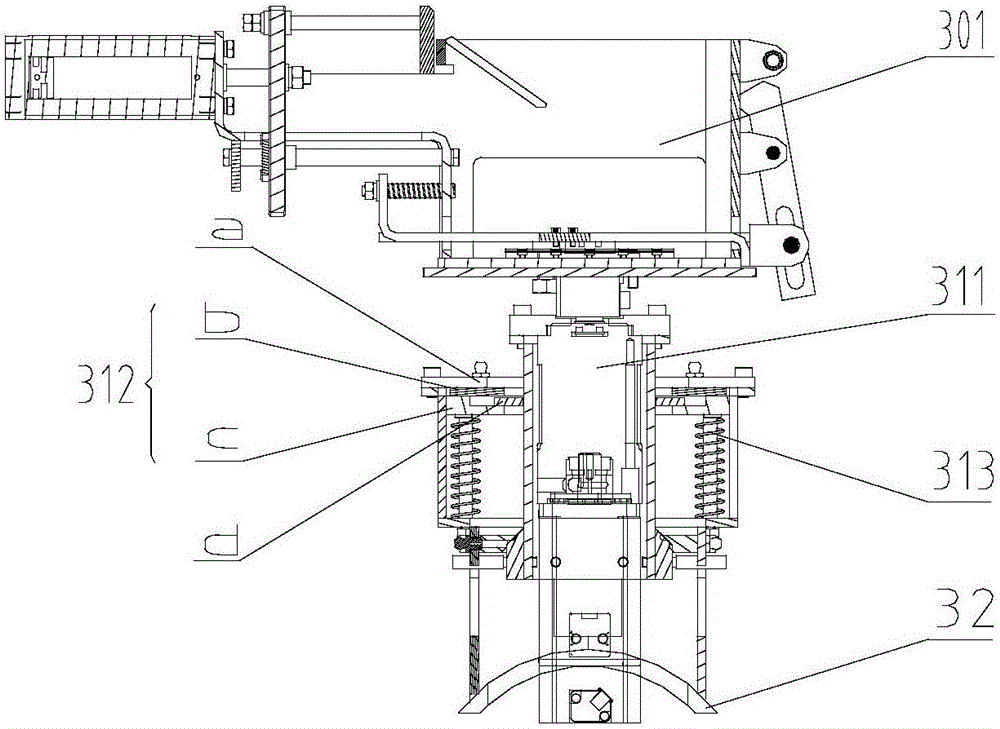

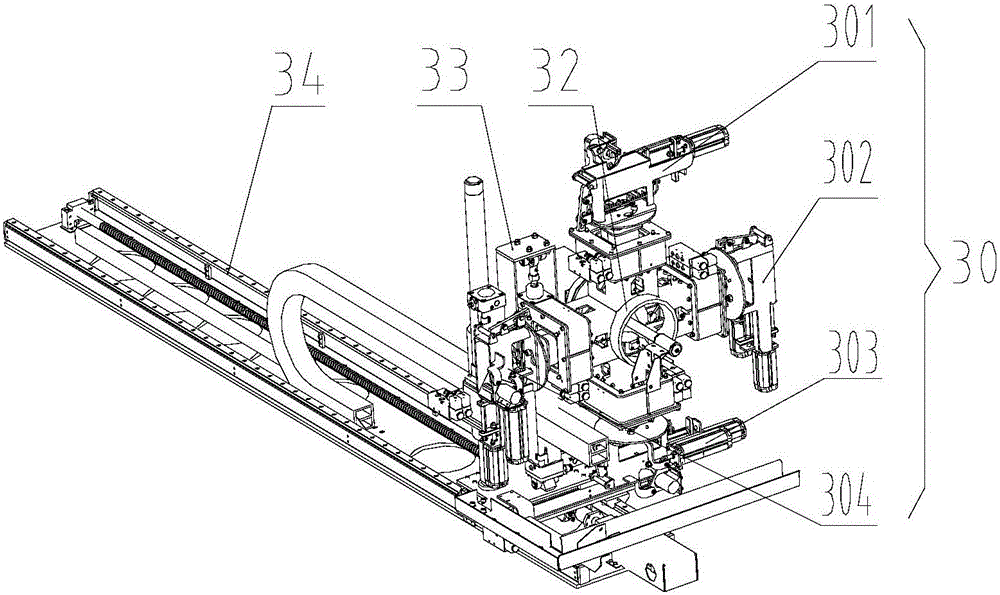

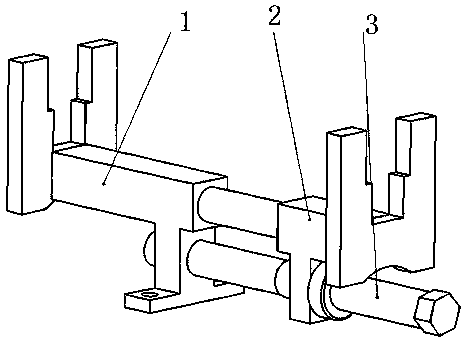

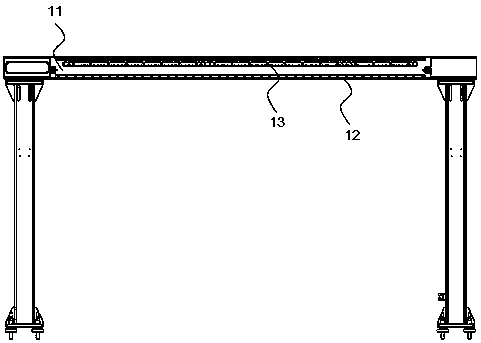

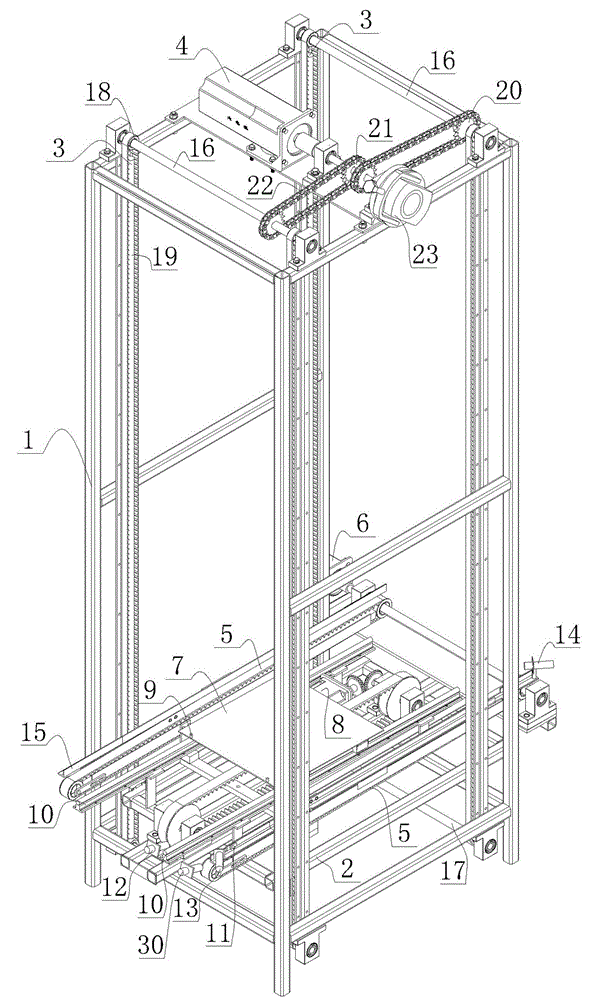

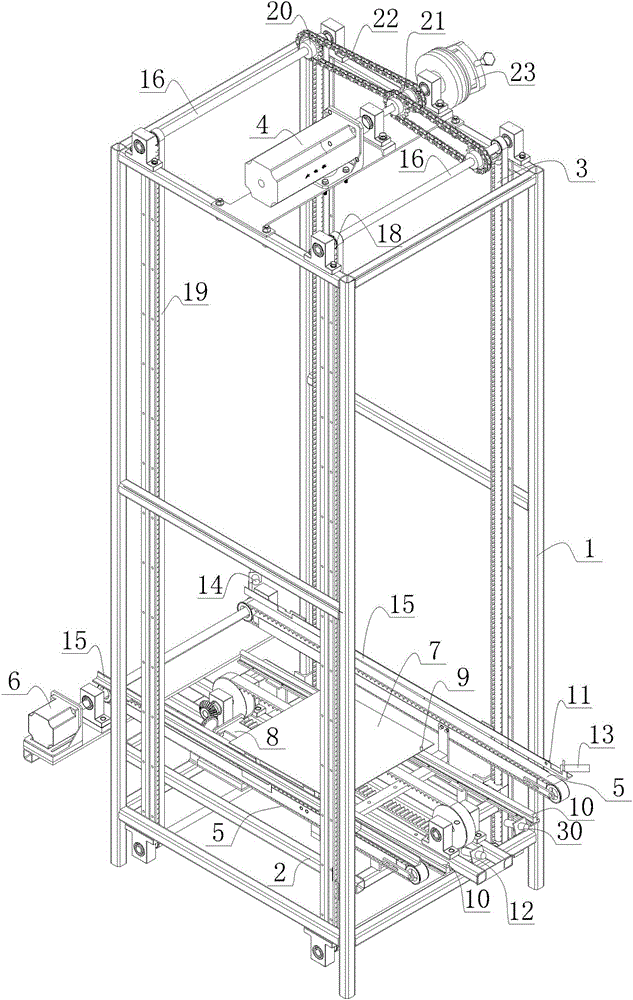

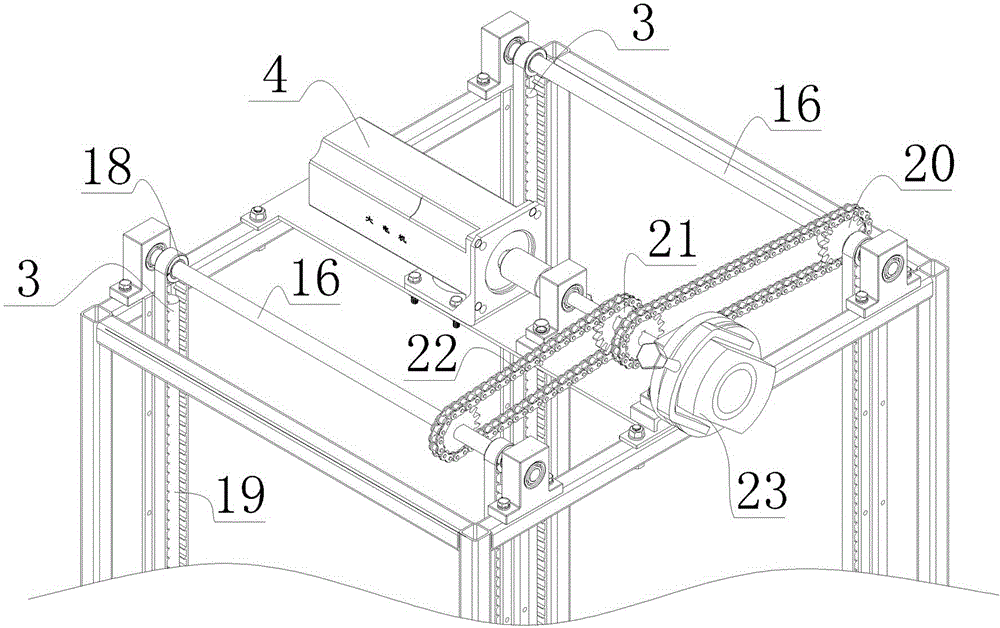

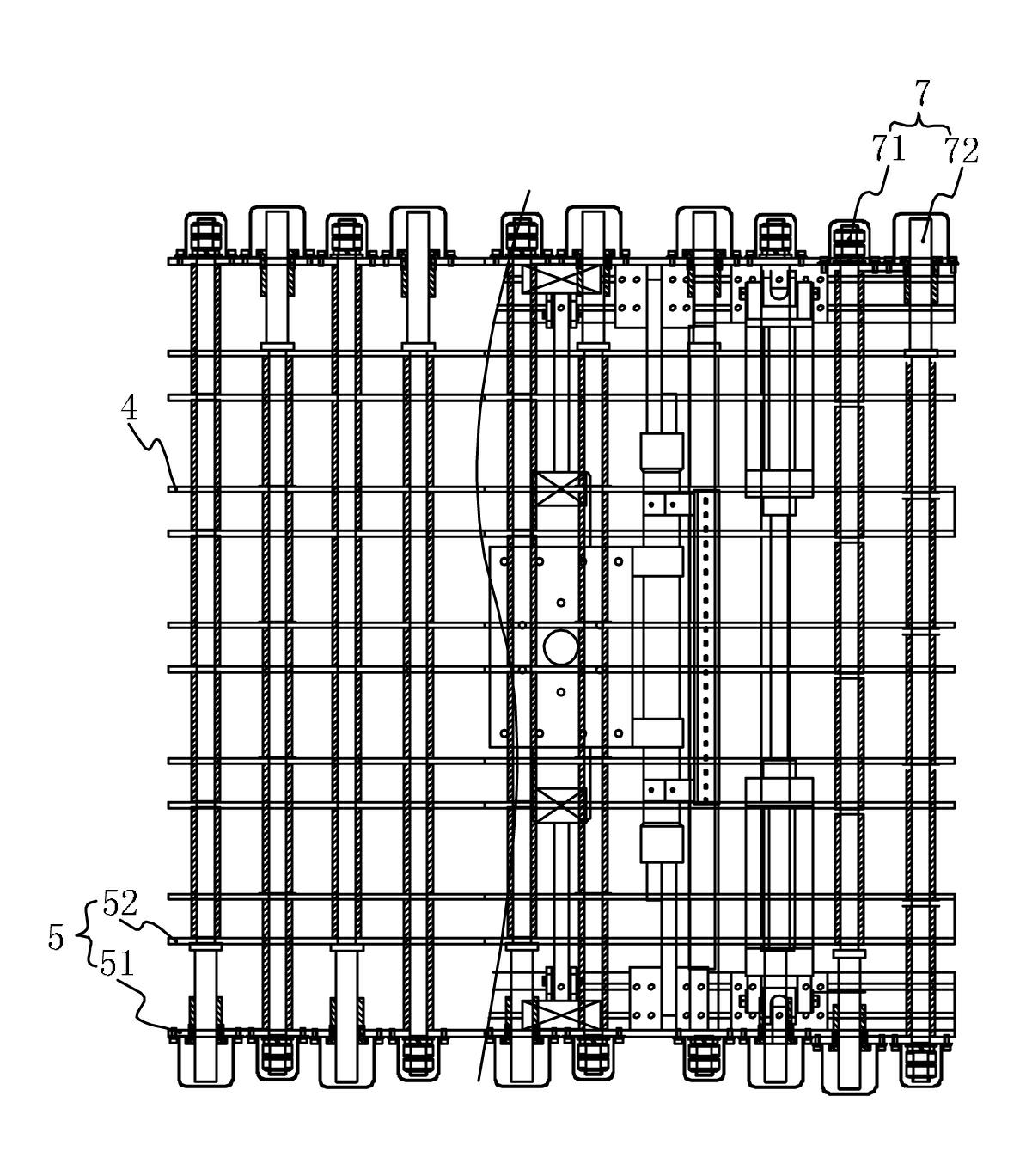

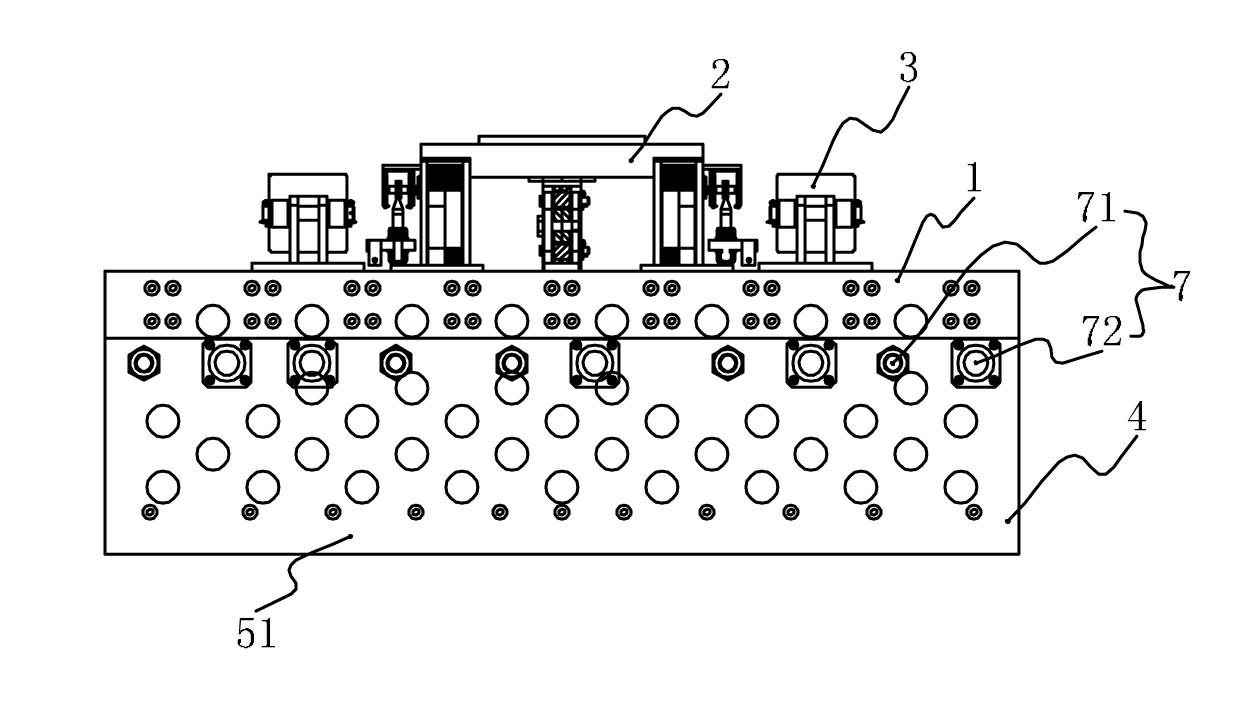

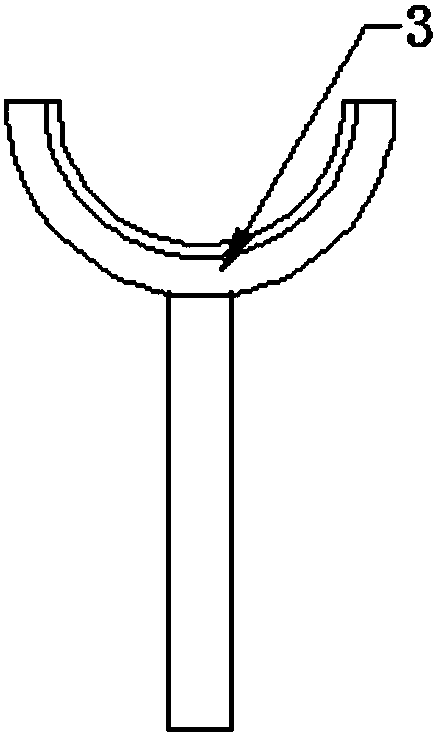

Loading and unloading mechanism for small-module bevel gears

PendingCN111439574ARealize loading and unloadingSmooth feedingDe-stacking articlesGear-cutting machinesGear wheelBevel gear

The invention belongs to the field of gear machining, and discloses a loading and unloading mechanism for small-module bevel gears. The loading and unloading mechanism comprises a portal truss, a feeding mechanism and a storing mechanism; the portal truss comprises a cross beam; double guiding rails A are fixed to one side of the cross beam; a rack is arranged between the double guiding rails A; the feeding mechanism is arranged on the cross beam and comprises internal expansion fixtures, the internal expansion fixtures realize three-dimensional actions of the space through driving mechanisms,and the driving mechanisms are connected onto the double guiding rails A; the storing mechanism is arranged below the cross beam and comprises a group of bases used for loading and unloading respectively, rotating disk mechanisms are arranged above the bases, and clamping mechanisms A are arranged beside the rotating disk mechanisms. By the aid of the loading and unloading mechanism, the problemsof difficulty in clamping, relatively slow loading and unloading of products and the like during machining of the small-module bevel gears are solved.

Owner:江苏双环齿轮有限公司

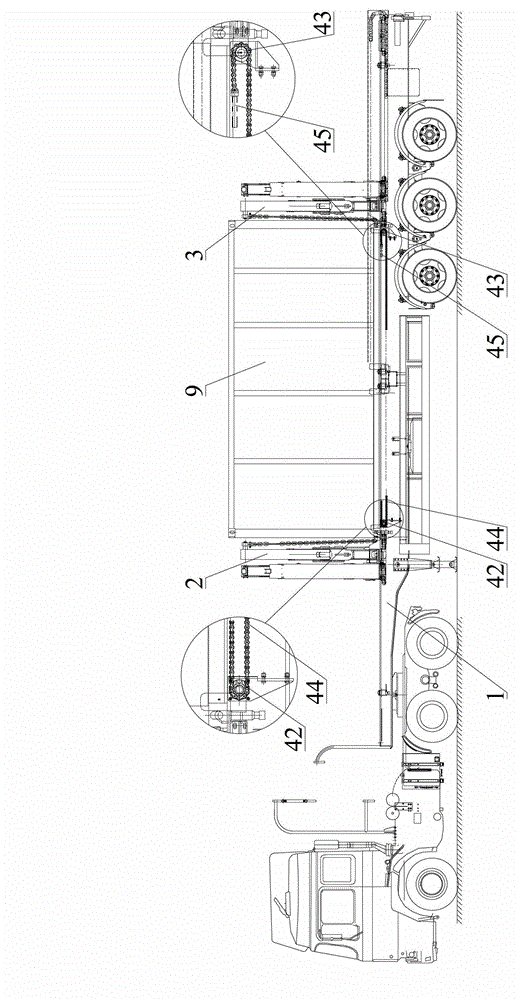

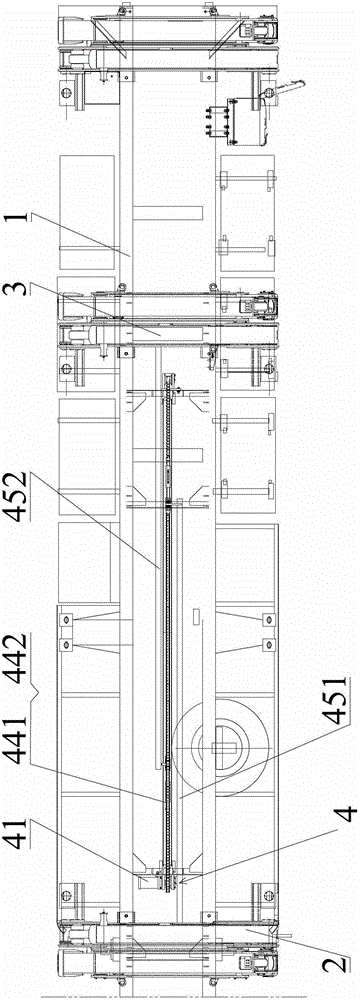

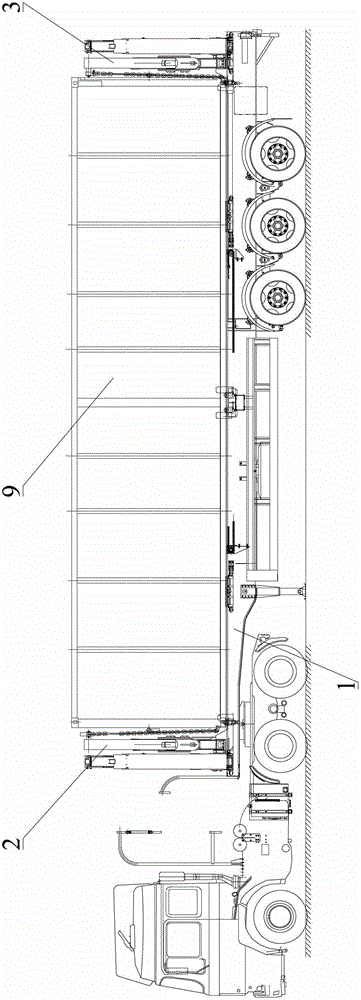

Self-loading and unloading carrier vehicle

InactiveCN102745118AImprove work efficiencyIncrease useLoading/unloading vehicle arrangmentTransportation itemsEngineeringMechanical engineering

Owner:SANY GRP

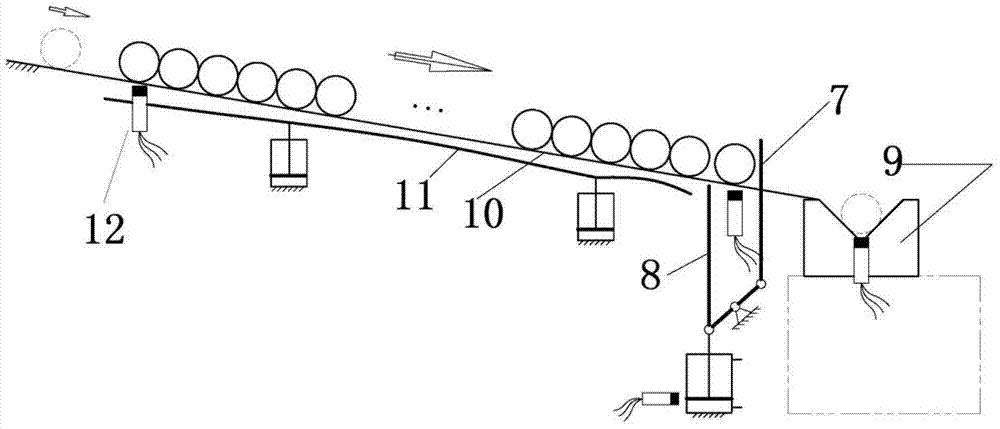

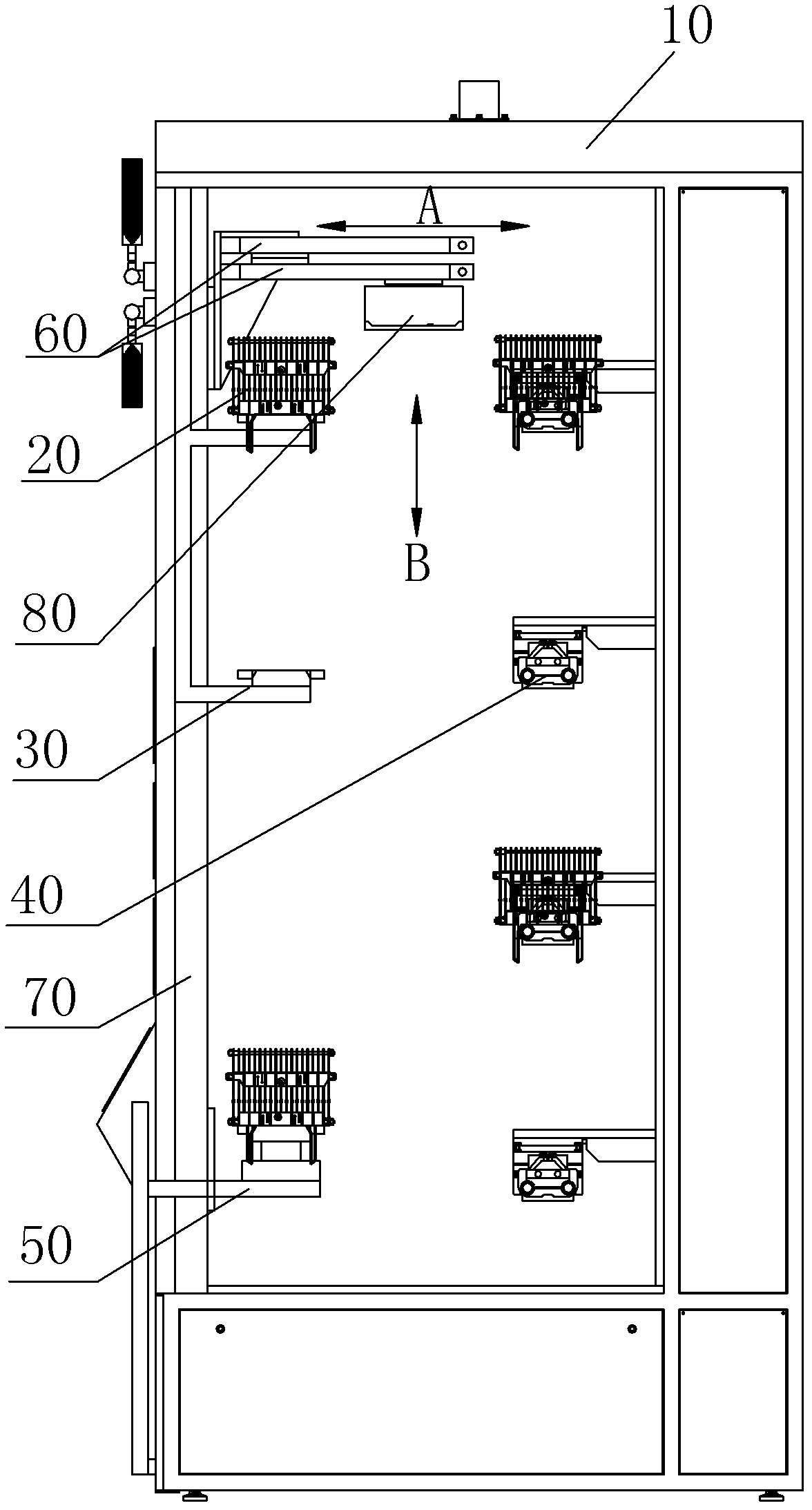

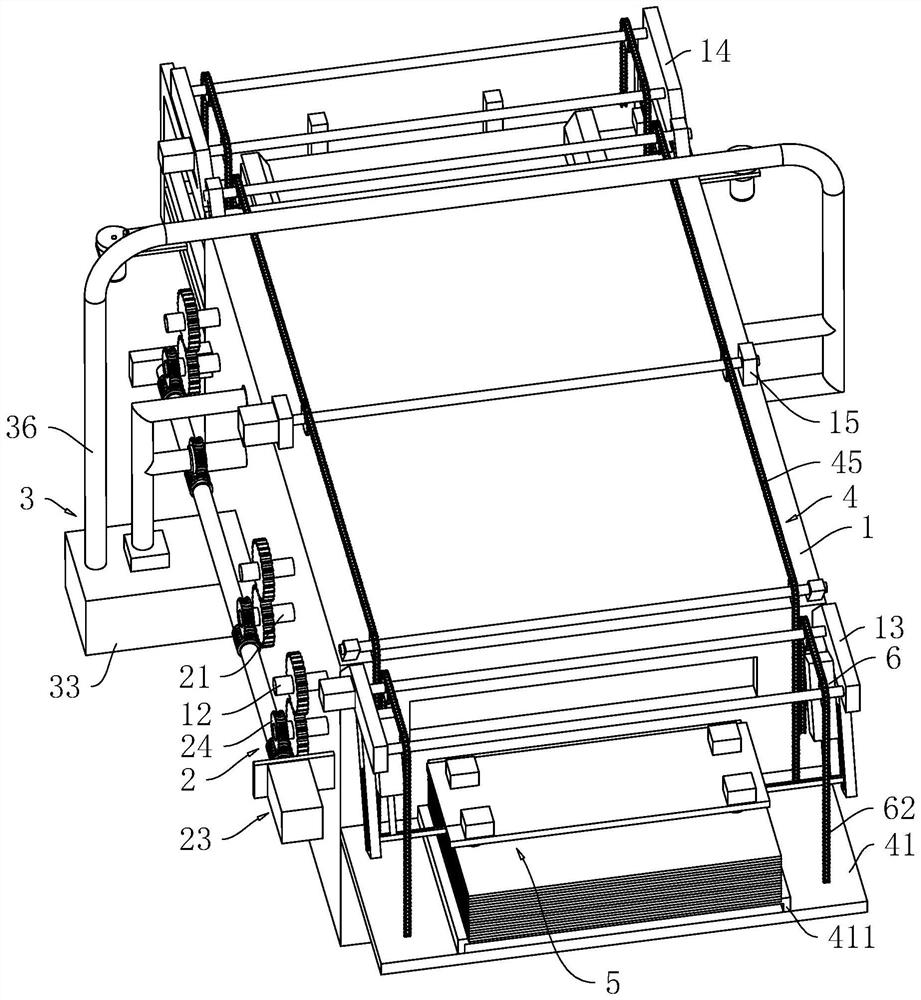

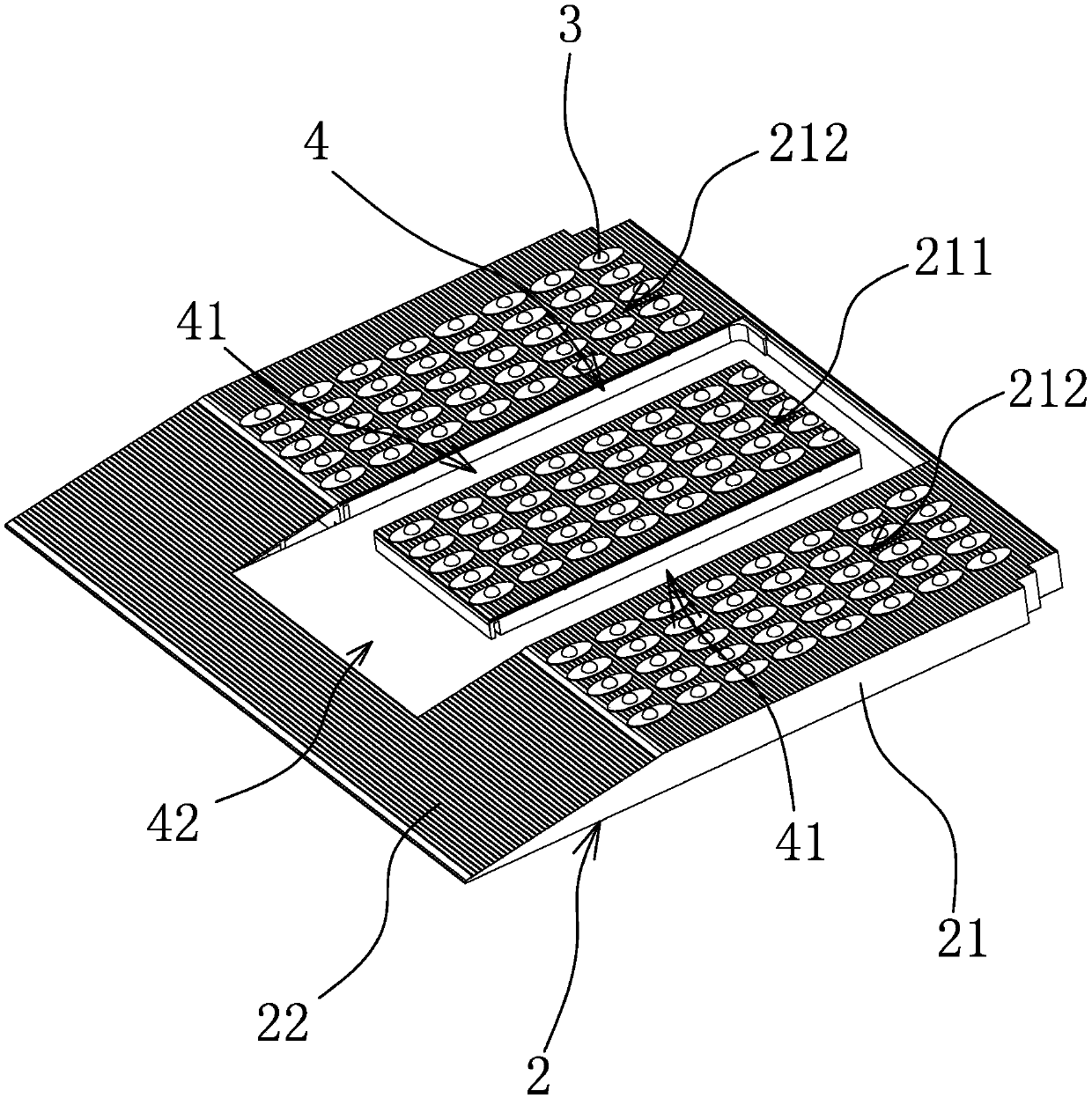

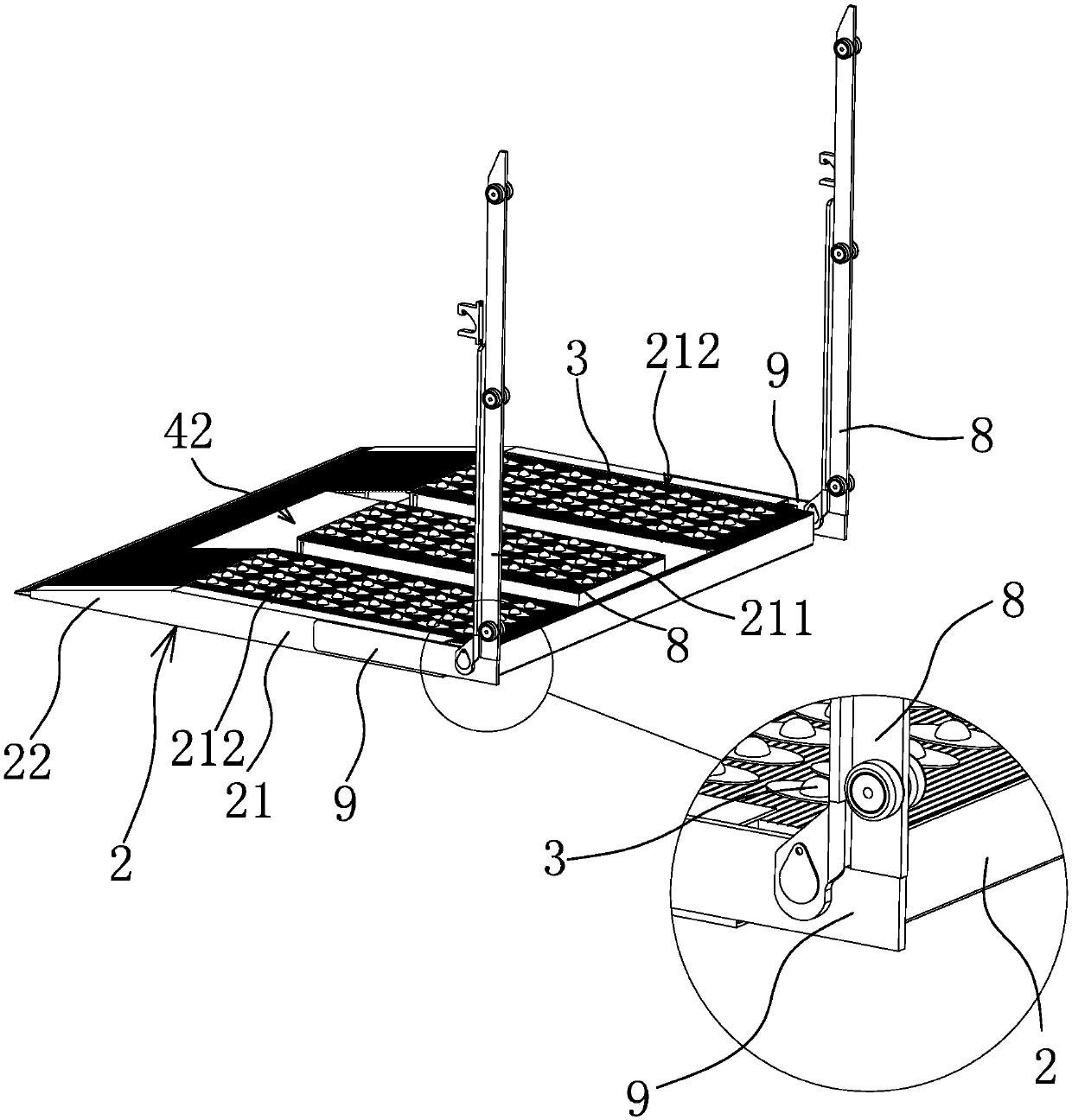

Full-automatic embryo egg detection equipment

ActiveCN104663510ARealize up and down movementShort detection cycleAvicultureMaterial analysisLoading unloadingIrradiation

The invention discloses full-automatic embryo egg detection equipment. The full-automatic embryo egg detection equipment comprises an automatic egg tray loading-unloading device for automatically taking egg trays down from and putting the egg trays back onto an egg tray vehicle, and an automatic vaccine embryo egg detection device for automatically detecting embryo eggs on the egg trays, wherein the automatic egg tray loading-unloading device is used for taking the egg trays down from the egg tray vehicle and feeding the egg trays onto the automatic vaccine embryo egg detection device; the automatic vaccine embryo egg detection device is used for feeding the egg trays back onto the automatic egg tray loading-unloading device after automatically detecting the embryo eggs, and the automatic egg tray loading-unloading device is used for feeding the egg trays back onto the egg tray vehicle. By adopting the full-automatic embryo egg detection equipment, the egg trays at any height on the egg tray vehicle can be taken out automatically through a tray device, automatic irradiation of the embryo eggs on the egg trays can be finished automatically by the automatic detection device, and the egg trays are loaded back onto the egg tray vehicle through a lifting platform, so that manual participation is not required in the whole process, the labor intensity is lowered, the embryo detection period is shortened, the production efficiency is increased, the beneficial effect is remarkable, and convenience is brought to application and popularization.

Owner:滨州市五岳机械设备有限公司

Double-sided printing machine

InactiveCN112793297ASave energyShorten the timeRotary pressesOther printing apparatusPrinting pressComputer engineering

The invention relates to a double-sided printing machine, and relates to the technical field of printing machines. The double-sided printing machine comprises a box body and conveying rollers, wherein a printing device is arranged on the box body, and comprises two printing rollers, an ink coating mechanism and a driving mechanism, and the two printing rollers are rotatably arranged on the box body and are vertically arranged at an interval; and the ink coating mechanism is arranged on the box body and used for coating ink on the printing rollers, and the driving mechanism is arranged on the box body and drives the two printing rollers to rotate reversely. According to the invention, the two conveying rollers drive paper to move to the printing rollers, the ink coating mechanism coats the ink onto the two printing rollers, and the driving mechanism drives the two printing rollers to rotate to print the two sides of the paper, so that the two sides of the paper can be printed at the same time, and then energy and time used for paper printing are saved.

Owner:绍兴市大禹印刷有限公司

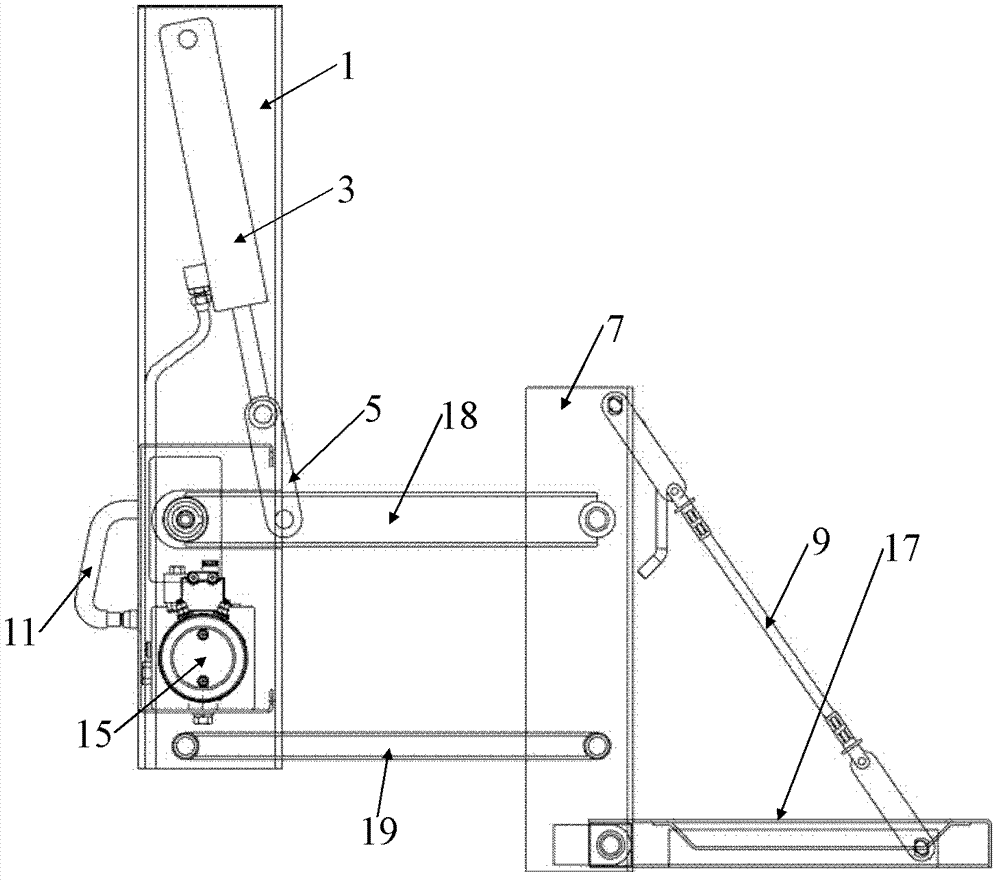

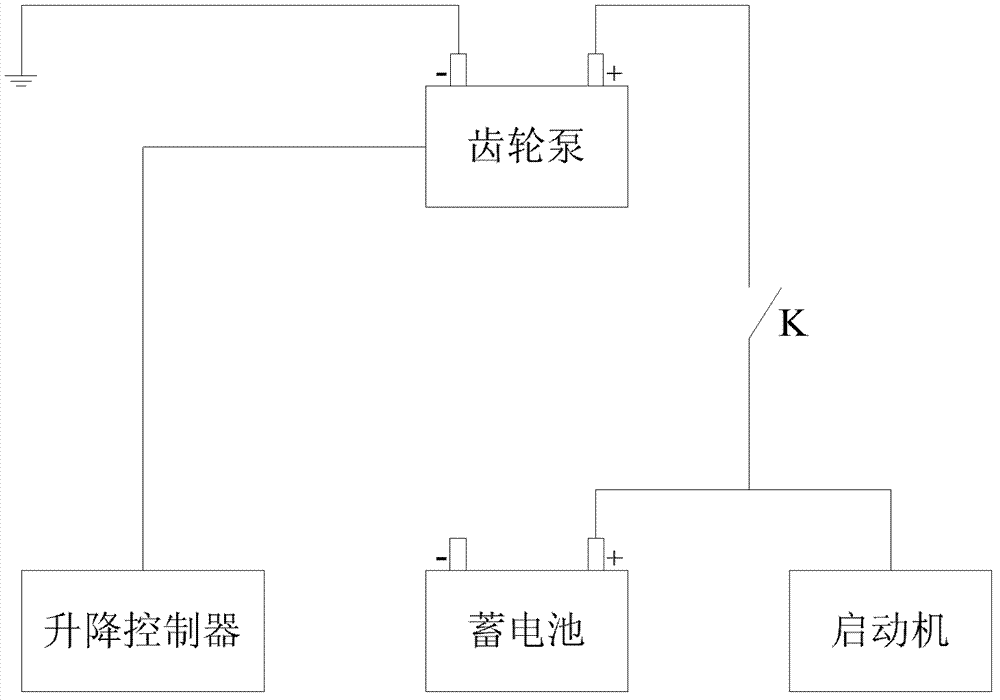

Hydraulic lifting tail-board mechanism

ActiveCN102951059ARealize loading and unloadingImprove operational efficiencyVehicle with pivoted armsVehicle with raised loading platformUltimate tensile strengthTruck

The invention discloses a hydraulic lifting tail-board mechanism which comprises a hydraulic drive unit and a lifting tail-board unit connected with the same. The hydraulic drive unit is connected with the lifting tail-board unit through a connecting rod unit. The hydraulic drive unit is disposed at the rear of a car cargo tank and drives the connecting rod unit to retract as being close to the car cargo tank and to extend as being far away from the car cargo tank. The connecting rod unit is disposed at the rear of the car cargo, is connected with the lifting tail-board unit and drives the lifting tail-board unit to move up when the connecting rod unit retracts and to move down when the connecting rod unit extends. Lifting of the lifting tail-board unit can be achieved by driving the connecting rod unit by the hydraulic drive unit, structure is simple, weight is light, and production cost is low; and manufacture process is simple, the hydraulic lifting tail-board mechanism can be additionally mounted on the original car in conventional way, mounting and demounting of cargoes can be achieved by operating a control unit by one person, and accordingly labor intensity is lowered and operation efficiency of a truck is improved.

Owner:BEIQI FOTON MOTOR CO LTD

Maglev system for loading, unloading and turnover of cargos

InactiveCN107298311ARealize loading and unloadingReduce breakage rateNon-mechanical conveyorsLoading/unloadingButt jointEngineering

The maglev cargo handling and turnover system announced an intelligent, economical and efficient cargo handling and turnover mode. This system can reduce the labor cost of cargo transit, improve the transit timeliness of cargo, and avoid repeated loading and unloading of some cargo during transportation. And sorting, thereby reducing the damage rate and loss rate of goods. The system can be widely used in the logistics transportation industry, the express delivery industry, and the specific equipment manufacturing industry with frequent displacement. The system includes a magnetic levitation mobile car tray, a magnetic levitation track body on the car chassis, a magnetic levitation track body on the field, a docking mechanism, and a current frequency conversion device. Its characteristics are: using electromagnetic levitation force to offset the weight of the pallet, and combining the magnetic levitation track body on the car chassis and the magnetic levitation track body on the field to form an integrated track, through the magnetic levitation sliding of the car tray between the car chassis and the field track, to Complete the loading, unloading and turnover of the goods, and upload the overall weight of the car pallet through the Bluetooth weighing device.

Owner:付中华

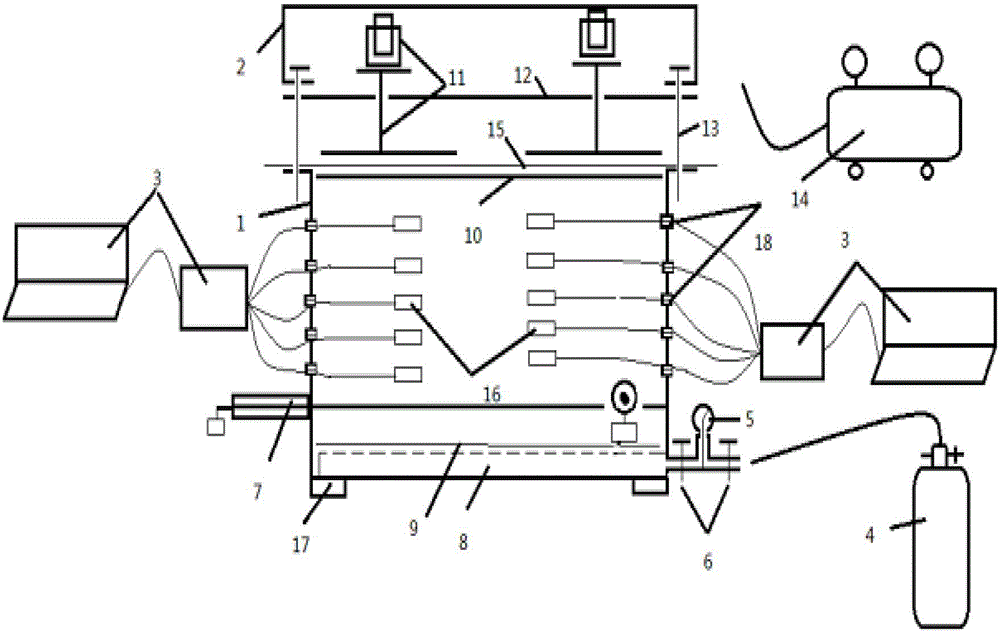

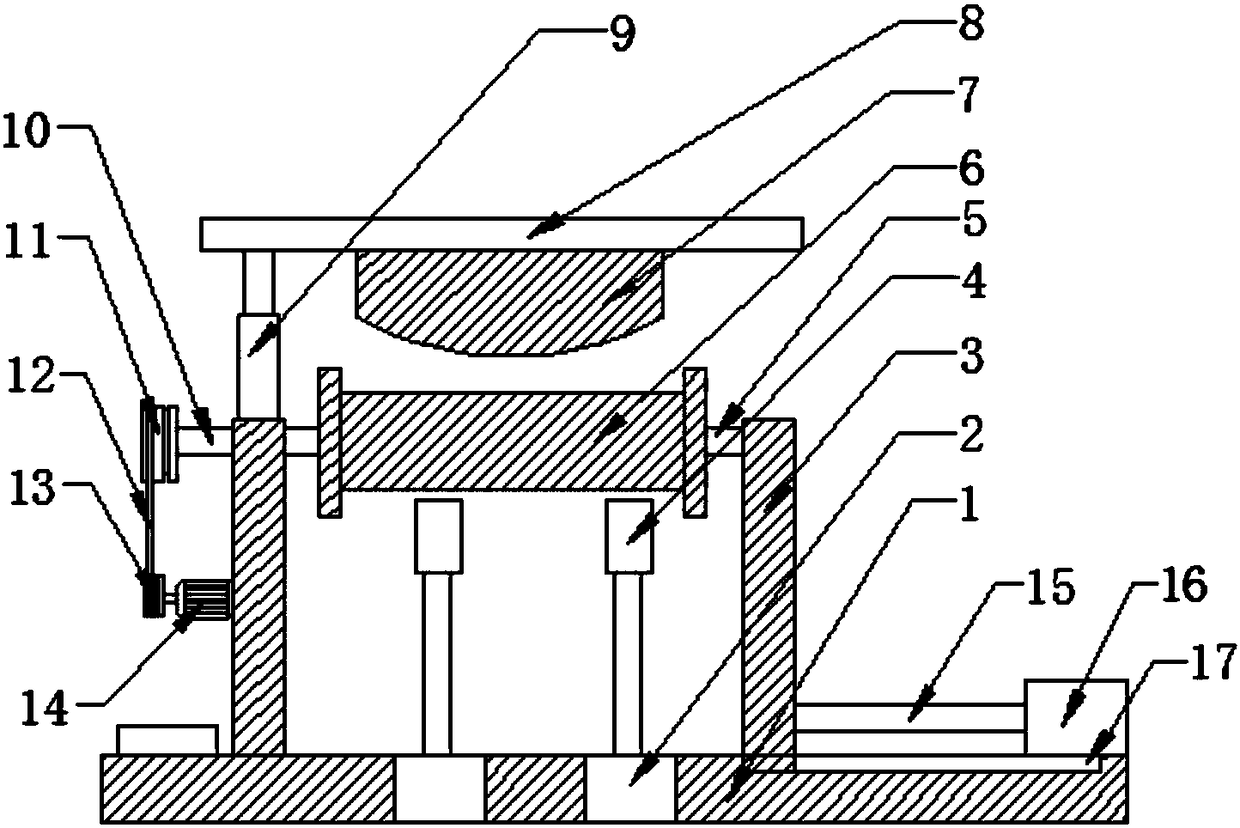

Simulation test system for gas adsorption and desorption of large-scale coal

The invention provides a simulation test system for gas adsorption and desorption of large-scale coal. The simulation test system comprises a large-scale cavity, a loading system, a gas feeding system, a vacuum pump, a monitoring system of gas adsorption and desorption parameters, wherein the large-scale cavity is composed of a one-side open cavity and a cover plate; the wall of the large-scale cavity is provided with sensor screwed holes; the monitoring system of the gas adsorption and desorption parameters comprises a sensor which penetrates into the large-scale cavity through the sensor screwed holes and is connected with the monitoring system of the gas adsorption and desorption parameters disposed out of the large-scale cavity; the loading system hermetically passes through the cover plate and regulates stress environment of the coal in the large-scale cavity; the gas feeding system is communicated with the large-scale cavity through an air inlet pipe; and the vacuum pump is communicated with the large-scale cavity through the air inlet pipe. The test system can realize laboratory experiment study of the gas adsorption and desorption laws of the large-scale coal, and is reliable, economic and simple experimental means.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

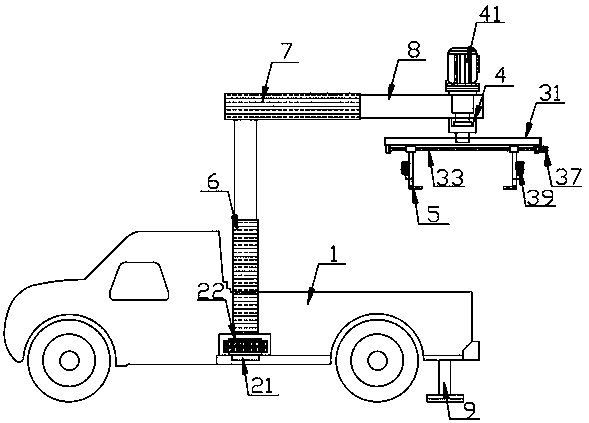

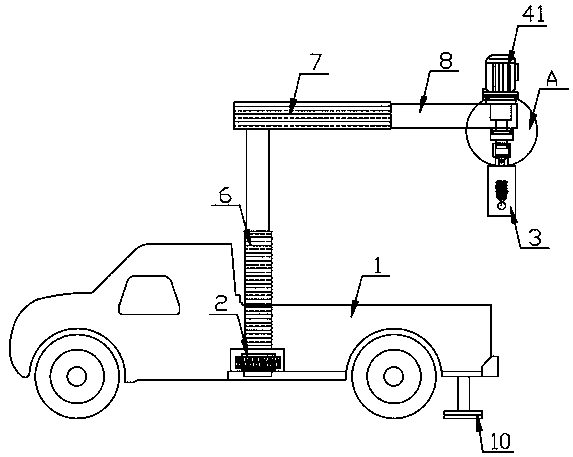

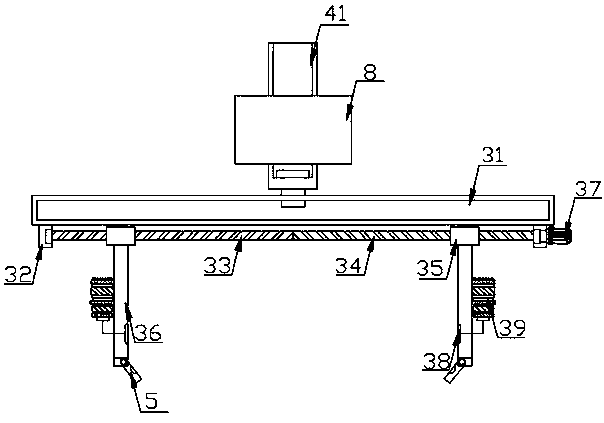

Lifting device for loading and unloading equipment for electric overhaul vehicle

ActiveCN110577159ARealize loading and unloadingEasy loading and unloadingCranesHydraulic cylinderEngineering

The invention discloses a lifting device for loading and unloading equipment for an electric overhaul vehicle. The device comprises a vehicle tail hopper, a lifting base, a lifting frame assembly, a driving mechanism and a suspension mechanism, wherein the lifting base is fixedly arranged at one side, close to a vehicle head, in the vehicle tail hopper; the top of the lifting base is fixedly provided with a first hydraulic cylinder; the output end of the first hydraulic cylinder is fixedly provided with a hydraulic rod; one end, far away from the first hydraulic cylinder, of the hydraulic rodis fixedly arranged with a second hydraulic cylinder in an L shape, and the output end of the second hydraulic cylinder is fixedly arranged with a lifting arm through the hydraulic rod. According to the device, the lifting assembly and the suspension mechanism are arranged and enable clamping lifting and suspension lifting modes of the lifting device, so that applicable lifting range is expanded;a vacuum chuck is capable of performing vacuum adsorption on a clamped article, so that the clamping and lifting stability can be effectively improved; the electric overhaul vehicle is subjected to loading and unloading without manual carrying; in addition, the loading and unloading are convenient and time and force saving, so that the working intensity of electric overhaul workers can be effectively reduced.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO YANTAI CITY FUSHAN DISTRICT POWER SUPPLY CO

Conveying trolley for thermally-expanded steel pipes

InactiveCN103481932ARealize loading and unloadingLow costHand carts with multiple axesEngineeringCaster

Owner:天津腾飞钢管有限公司

Brick setting robot gripper

InactiveCN102616579ANot easy to damageFacilitate the deliveryStacking articlesDe-stacking articlesInterference fitBrick

The invention discloses a brick setting robot gripper which comprises an even number of clamp plates, wherein the clamp plates are parallel to each other and arrayed vertically; the clamp plates at two ends are fixed on a top frame body and connected with a flexible power device; every two clamp plates form a group; each group of clamp plates comprises a left clamp plate and a right clamp plate; pull rods transversely penetrate through the clamp plates; the pull rods comprise at least one group of driving pull rods which comprise a left driving pull rod and a right driving pull rod; the left driving pull rod is fixed with the left clamp plate of each group of clamp plates and in interference fit with the right clamp plate of each group of clamp plates; and the right driving pull rod is fixed with the right clamp plate of each group of clamp plates and in interference fit with the left clamp plate of each group of clamp plates. The clamp plates of the device move at the same time, so that the horizontal positions of green bricks do not change in the clamping process, no horizontal displacement occurs, the green bricks are clamped without being moved, safety and convenience are provided, and the green bricks are not easy to damage.

Owner:重庆信奇建材机械制造有限公司

Rolling device for textile machine

InactiveCN108342815AReduce labor intensityAvoid damageLoomsAuxillary apparatusDrive wheelDrive shaft

The invention discloses a rolling device for a textile machine. The rolling device for the textile machine comprises a bottom plate; a blanking mechanism is arranged at the middle part of the bottom plate; two supporting plates are fixedly arranged at the top of the bottom plate; a motor is fixedly arranged on one side of one supporting plate; an output shaft of the motor is in transmission connection with a driving wheel; and the driving wheel is in transmission connection with a driven wheel through a belt. According to the scheme, the blanking mechanism is provided, transmission is conducted through the blanking mechanism in the assembling and disassembling process of a rolling cylinder, a first hydraulic machine and a first hydraulic rod drive a bracket to move up and down, and the height of the rolling cylinder is adjusted; a cloth pressing block and an electric telescopic rod are provided, the height of the cloth pressing block is adjusted through the electric telescopic rod, thecloth is spread out by the cloth pressing block, and damage to the quality of the cloth caused by the fact that the cloth is stacked in the rolling process is avoided; and a second hydraulic machineand a second hydraulic rod are provided, and the second hydraulic rod drives the supporting plates to move so as to drive the driven shaft to move.

Owner:HUZHOU WUXING YONGMAO NEEDLE TEXTILE CO LTD

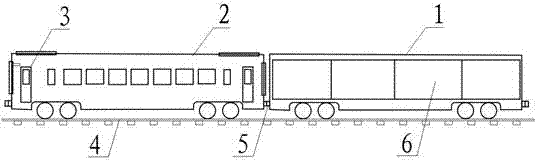

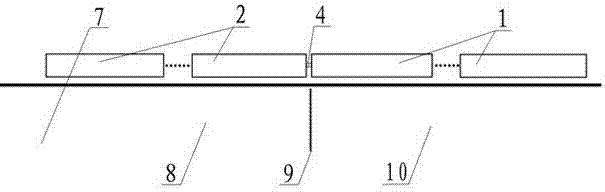

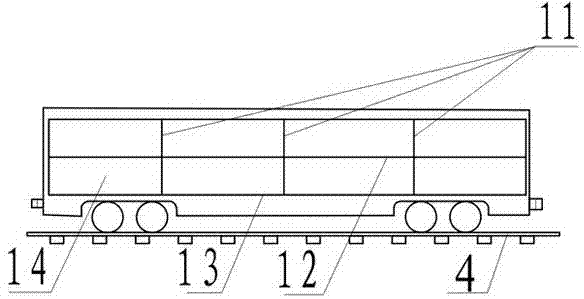

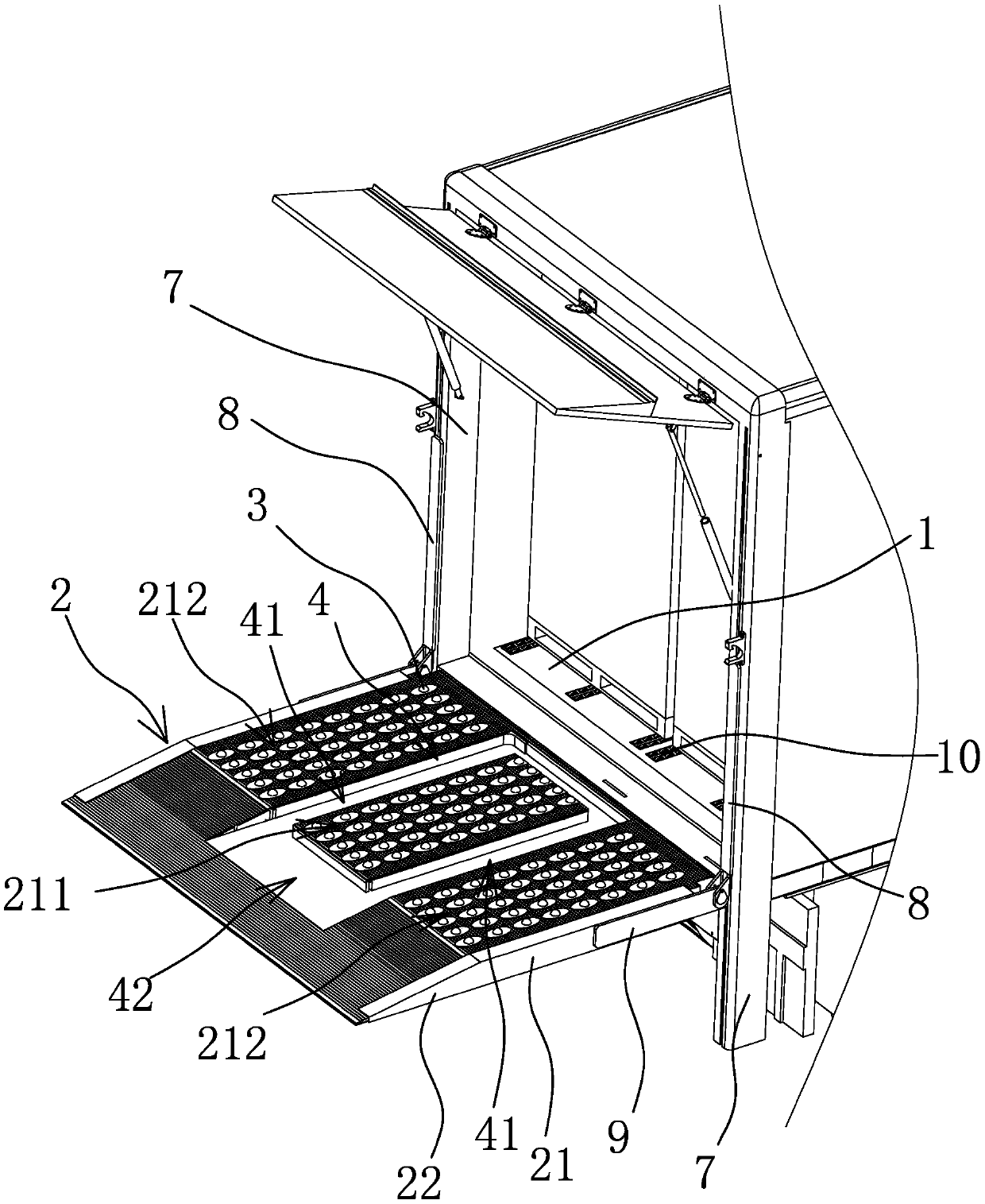

Passenger and car integrated transportation method based on railway passenger transportation mode

InactiveCN104260728ARealize loading and unloadingEasy transferWagons/vansLoading/unloadingControl theoryPassenger train

The invention relates to a transportation method, in particular to a railway passenger transportation and less-than-carload freight car integrated transportation method. The passenger and car integrated transportation method based on a railway passenger transportation mode comprises an operating method and a car loading and unloading method and is characterized in that passenger transportation compartments and car transportation compartments are fixedly marshaled and coupled to achieve organization operation in a passenger train mode, and the compartments stop at common stations to complete getting off of passengers and loading and unloading of cars; doors of the car transportation compartments are side-opening doors, car loading and unloading devices are arranged at the stations, and the cars are loaded and unloaded from side doors of the car transportation compartments through the car loading and unloading devices.

Owner:LANZHOU JIAOTONG UNIV +4

Loading and unloading device for truck

InactiveCN109624817AQuick loading and unloadingEasy loading and unloadingVehicle with rollersVehicle with loading rampTruckMechanical engineering

The invention provides a loading and unloading device for a truck and belongs to the technical field of physical distribution transportation equipment. The technical problem of troublesome cargo loading and unloading of the truck in the prior art is solved. The loading and unloading device for the truck comprises a bearing plate hinged to the edge of a truck floor, multiple rolling parts capable of supporting cargoes to move vertically and horizontally on the bearing plate are arranged on the upper plate face of the bearing plate, and a concave cavity is further formed in the upper plate faceof the bearing plate, wherein a carrying device is placed in the concave cavity, and the cargoes can move from the rolling parts to the carrying device. The device has the advantages that the cargoesare conveniently loaded and unloaded, and the universality is high.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

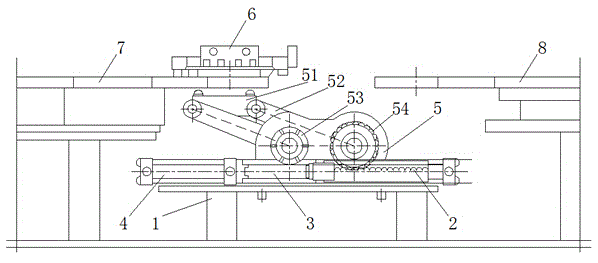

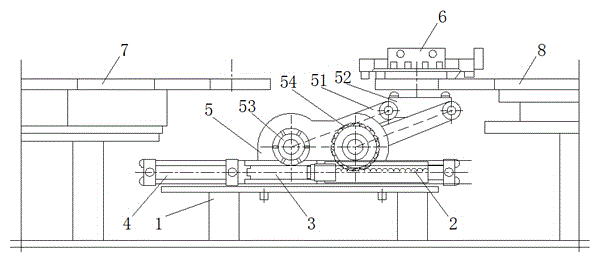

Double-swing rod loading/unloading mechanism for flexible unit

InactiveCN104889795ASmall structural design impactReduce distanceMetal working apparatusDrive wheelGear wheel

The invention discloses a double-swing rod loading / unloading mechanism for a flexible unit. The mechanism comprises a support frame body arranged between a working table and a machine tool, wherein a rack is fixed on the upper surface of the support frame body, and is connected with a driving oil cylinder through a driving rod; a base with double swing rods is arranged above the rack; the double swing rods are arranged in parallel, the upper ends are connected with a carrying platform, and the lower ends are respectively connected with driving wheels positioned in the base; and a gear rotationally connected with the rack is coated at the periphery of the driving wheel near the machine tool side. The mechanism has the advantages of simple structure, space saving and easy production, and can preferably realize the loading / unloading of a multi-tray flexible machining center unit.

Owner:安徽省安庆市汉城电子通讯有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com