Automatic loading and unloading device for PECVD (plasma enhanced chemical vapor deposition) equipment

A technology for automatic loading and unloading and equipment, which is applied in the manufacture of electrical components, manipulators, semiconductors/solid-state devices, etc. It can solve problems such as high labor intensity, damage to graphite boats, and shortened life, so as to reduce work intensity and achieve good coating uniformity. The effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

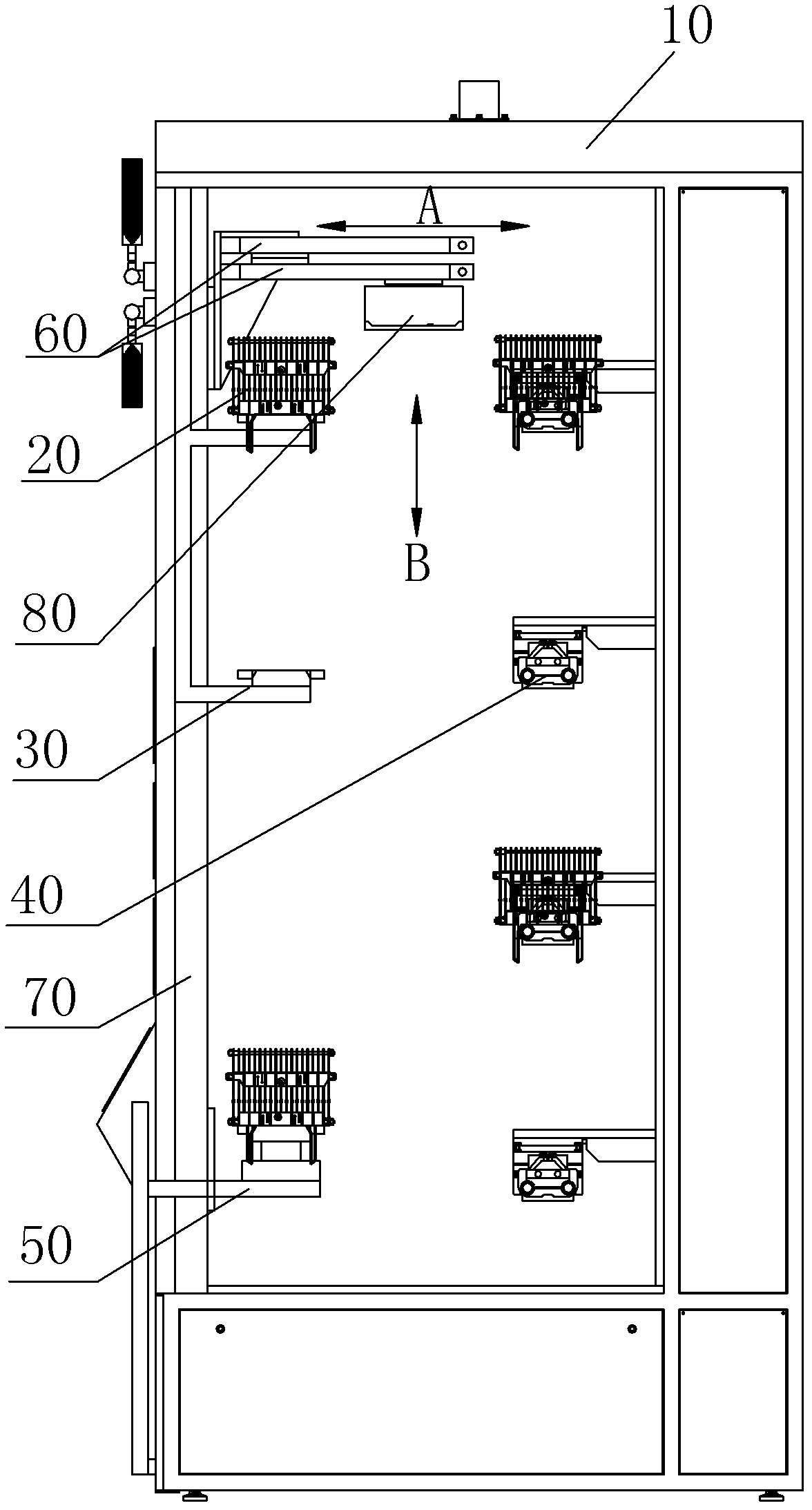

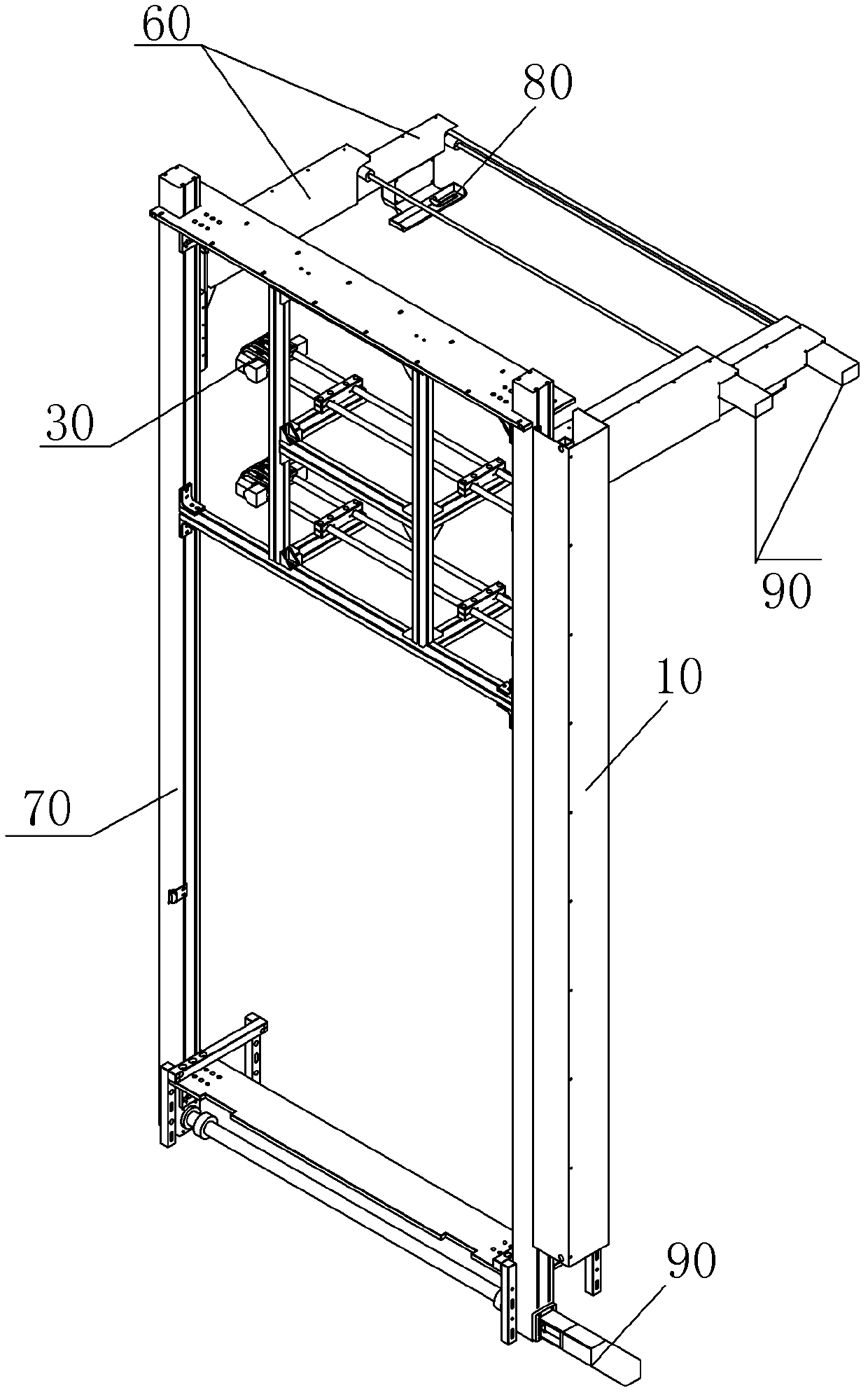

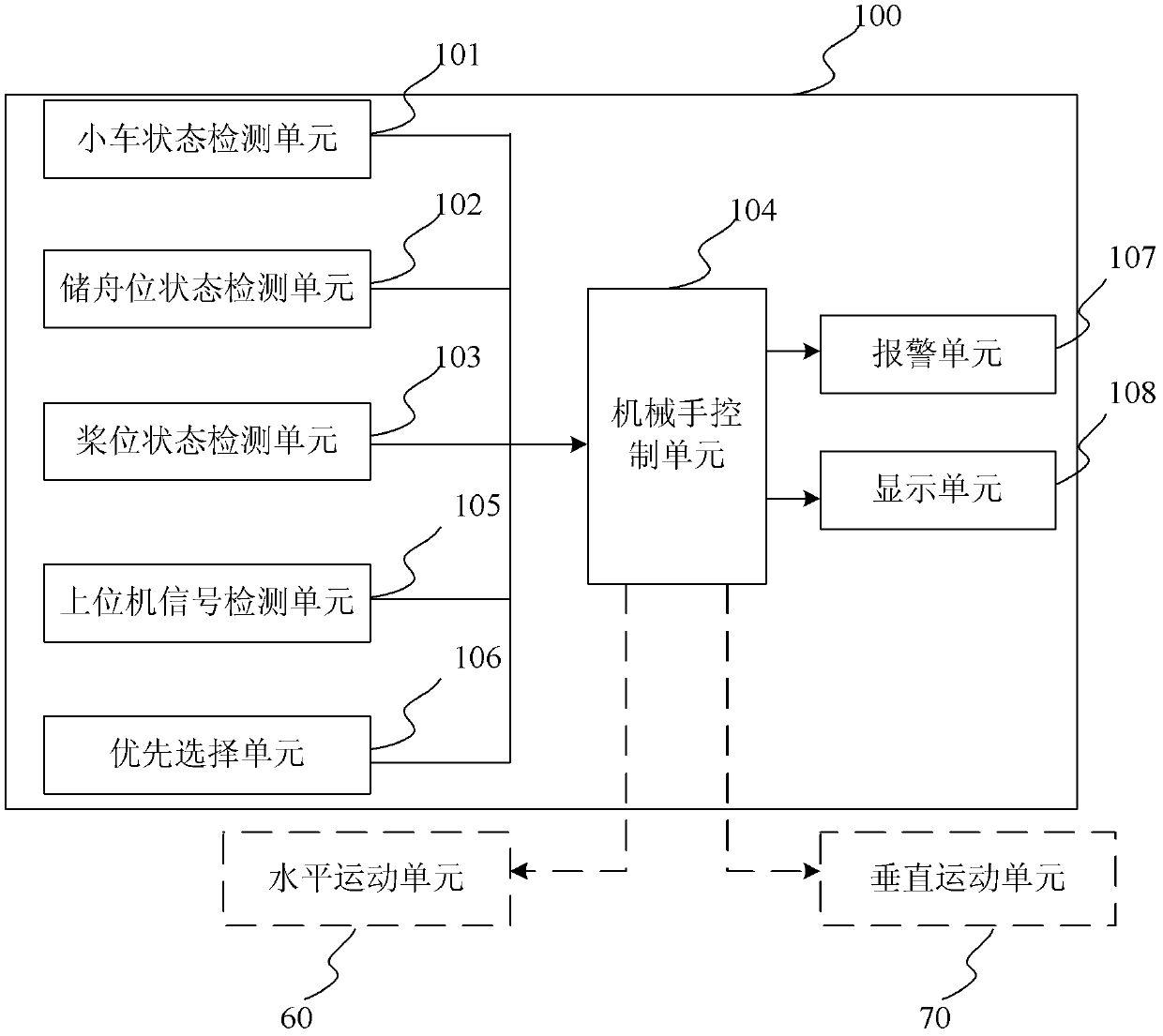

[0035] The schematic diagram of the overall structure of the automatic loading and unloading device for PECVD equipment in a preferred embodiment of the present invention is as follows figure 1 shown, see also figure 2 and image 3 , the device includes a control module 100 and a support 10; the support 10 is provided with a storage boat position 30, a dolly 50 and a paddle position 40 for placing a graphite boat 20, and is provided with a storage position 30 for completing the graphite boat 20. , the manipulator 80 accessed on the dolly 50 and the paddle position 40. A horizontal movement unit 60 for controlling the movement of the manipulator 80 in the horizontal direction A and a vertical movement unit 70 for controlling the movement of the manipulator 80 in the vertical direction B are also provided on the support 10 . Wherein, the control module 100 is connected with the upper computer (not shown) of the PECVD equipment, and is used to obtain the graphite boat signal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com