Double-swing rod loading/unloading mechanism for flexible unit

A dual-swing rod, flexible technology, applied in metal processing and other directions, can solve the problems of slowing down the production efficiency, large volume, and complex structure of the multi-station flexible manufacturing system of the machining center, and achieves a compact structure that reduces the lifting and falling of pallets. , The effect of structural design has little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

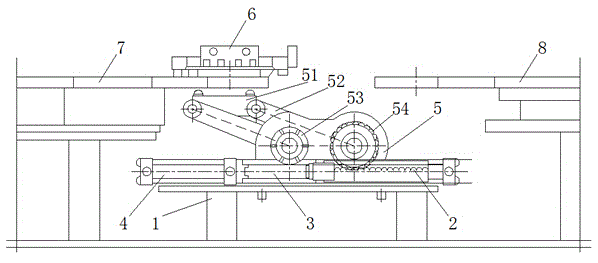

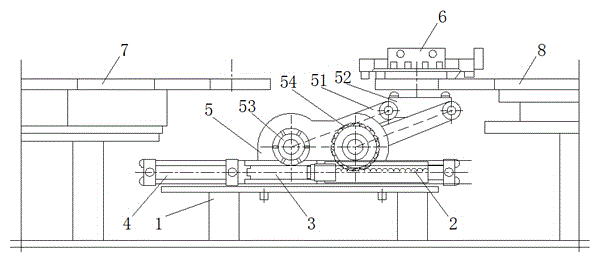

[0016] like figure 1 and figure 2 As shown, a double swing rod loading and unloading mechanism for a flexible unit includes a support frame body 1 arranged between a workbench 7 and a machine tool 8, and a rack 2 is fixed on the upper surface of the support frame body 1, so that The rack 2 is connected with a drive cylinder 4 through a drive rod 3, and a base 5 with double swing rods 51 is arranged above the rack 2. The double swing rods 51 are arranged in parallel, and a transport platform 52 is connected to the upper end. Each of the lower ends is connected with a driving wheel 53 located in the base 5 , and the outer circumference of the driving wheel 53 near the machine tool 8 is fitted with a gear 54 rotatably connected with the rack 2 .

[0017] Further, the workbench 7 and the machine tool 8 are provided with a transfer pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com