Brick setting robot gripper

A technology of robot and brick stacking, which is applied in the field of gripping hands of the brick stacking robot, can solve the problems of easily damaged bricks, affecting brick-making production efficiency, and long shrinkage time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

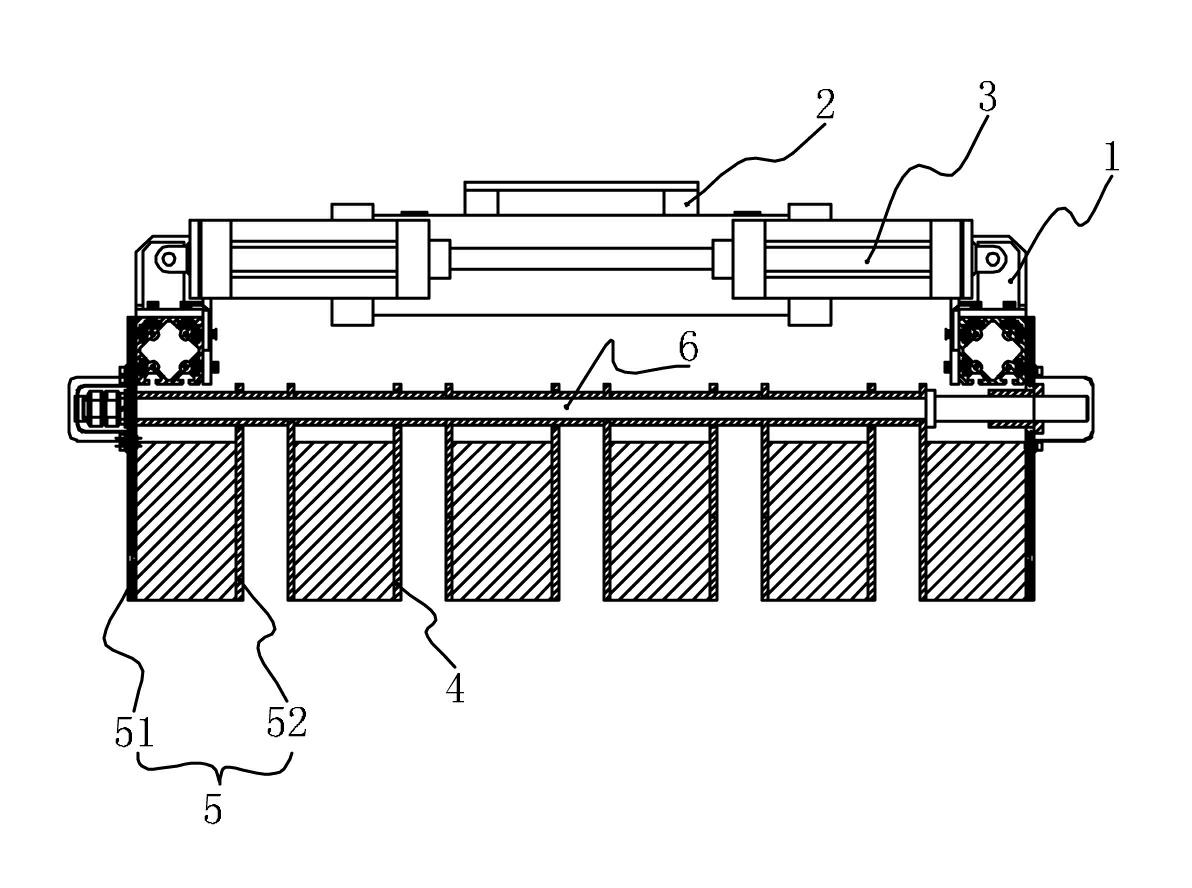

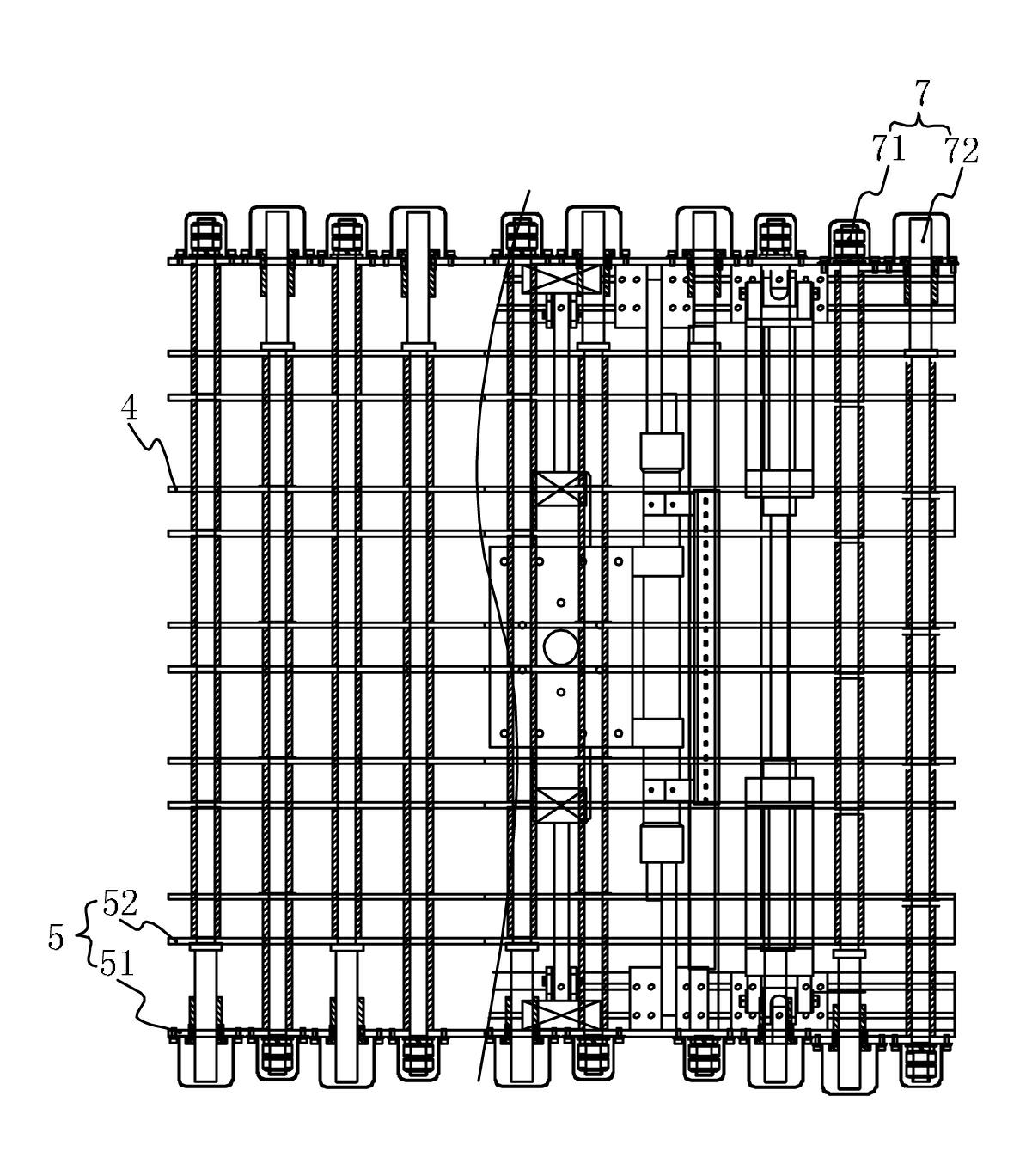

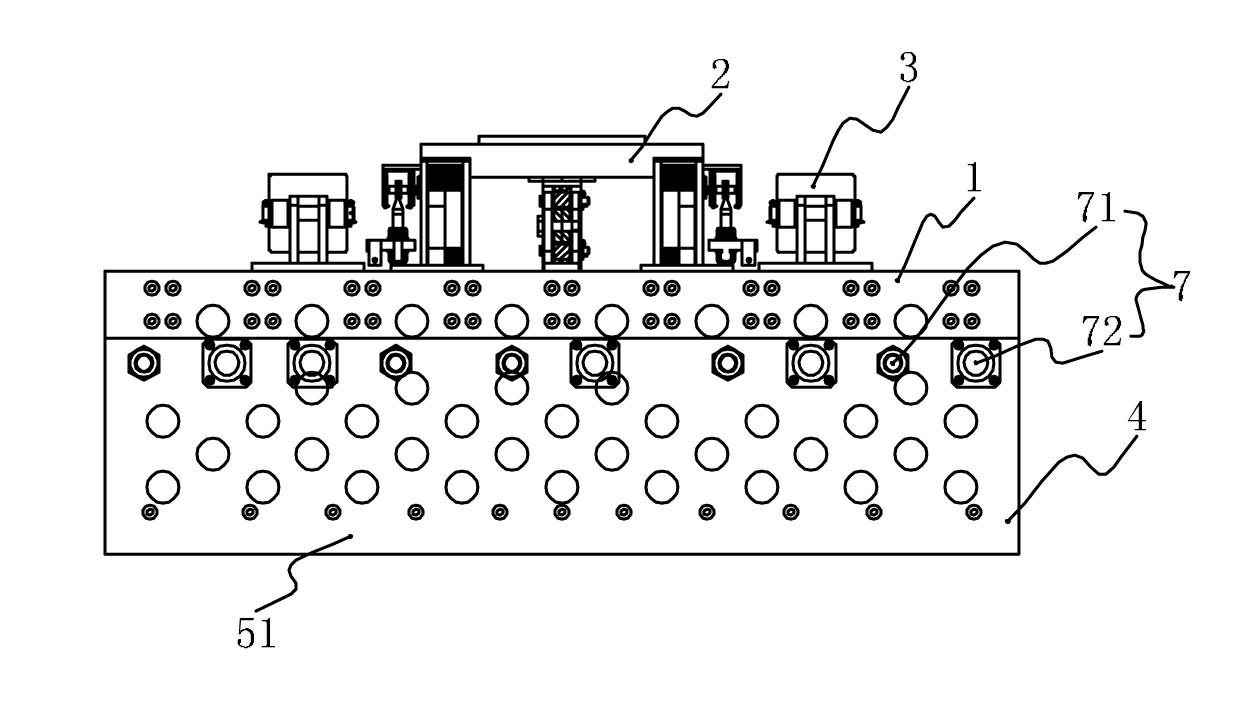

[0013] Such as figure 1 , 2 and image 3 As shown, the gripper of the brick-coding robot of the present invention includes a top frame body 1 on which a mounting base 2 and a pneumatic device 3 are fixed through guide rails, and a machine gripper is connected to the bottom of the top frame body 1 . The machine gripper includes an even number of splints 4, the splints 4 are parallel to each other and vertically arranged, every two adjacent splints 4 form a splint group 5, and each splint group is composed of a left splint 51 and a right splint 52 . There are pull rods 6 transversely running through the gripper of the machine, and every two groups of the pull rods 6 form four groups of drive pull rods 7, and the drive pull rods 7 include a left drive pull rod 71 and a right drive pull rod 72, and the left drive pull rod 71 is fixed with the left splint 51 of each splint group 5, and cooperates with the right splint 52 of each splint group in clearance; Cooperate.

[0014] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com