Telescopic handler

A technology for forklifts and forks, applied in motor vehicles, lifting devices, transportation and packaging, etc., can solve the problems of reduced reliability, limited loading and unloading capacity, etc., and achieve long unloading distance, large unloading angle range, and cargo handling operations flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

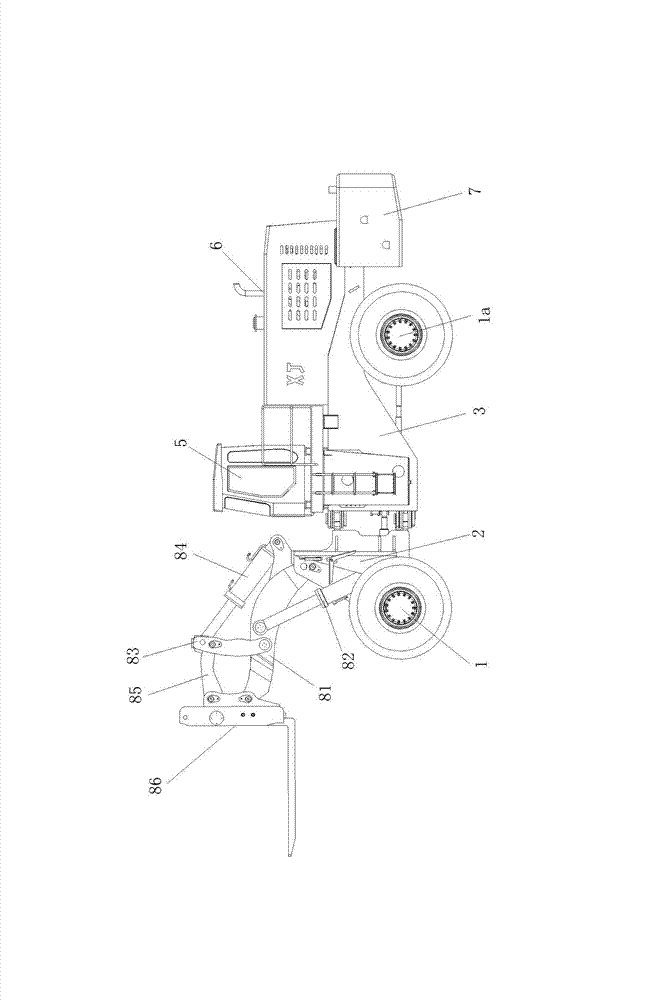

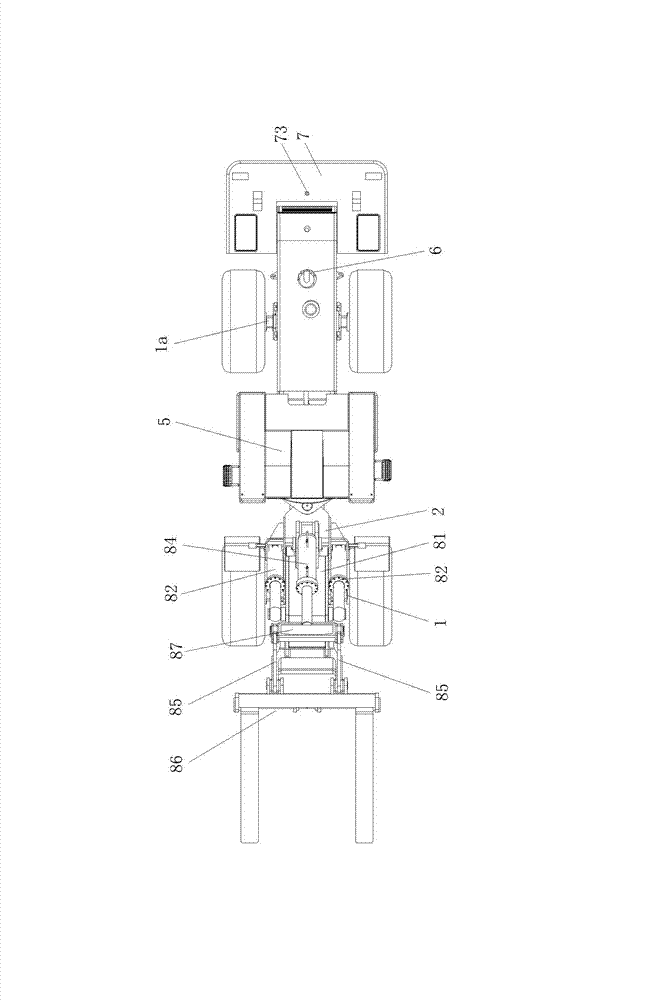

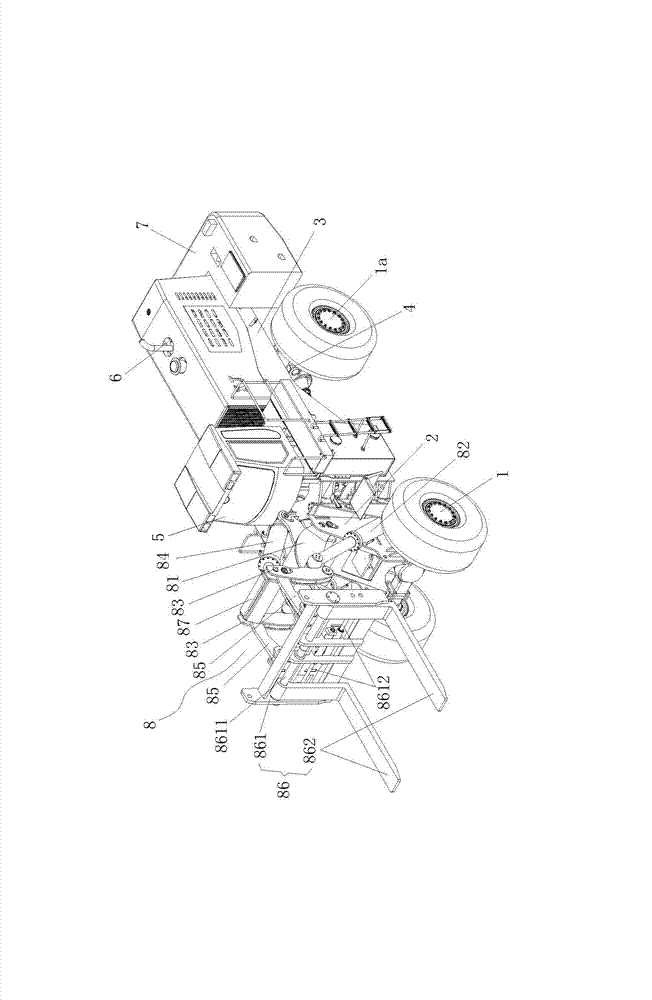

[0034] Figure 1 to Figure 3 As shown, a forklift truck includes front and rear drive axles 1, 1a with tires, front frame 2, rear frame 3, subframe 4, cab 5, engine 6, torque converter, speed changer Box, transmission shaft, balance weight 7, working device 8, the front side of the lower part of the front frame 2 is installed on the front drive axle 1, the lower part of the rear frame 3 is connected to the rear drive axle 1a through the subframe 4, and the cab 5. The engine 6 is installed on the rear frame 3, the engine 6 is connected to the front and rear drive axles 1 and 1a through a torque converter, a gearbox, and a drive shaft, and the balance weight 7 is connected to the rear of the rear frame 3;

[0035] The working device 8 includes a boom 81, two boom cylinders 82, two rocking arms 83, a bucket cylinder 84, two pull rods 85...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com