Dual-spindles dual-turret symmetrical turning center layout structure

A turning center and layout structure technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing, etc., can solve the assembly process, difficult control of technical requirements, reduced precision of processed parts, difficult assembly, etc., to achieve easy The effect of assembly precision, compact layout and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

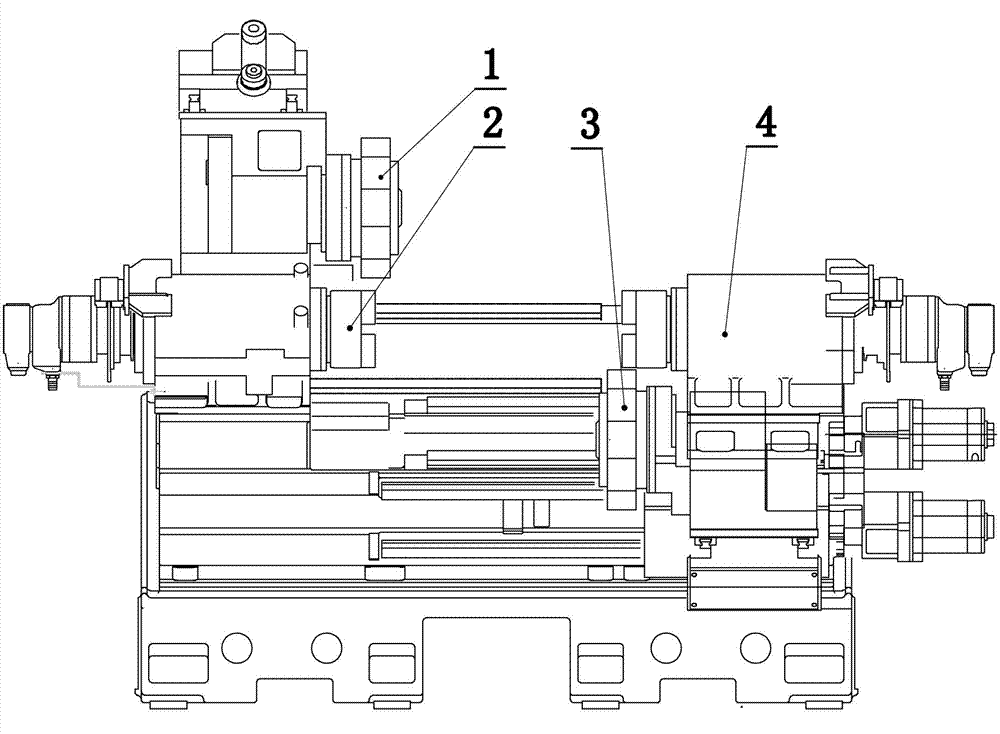

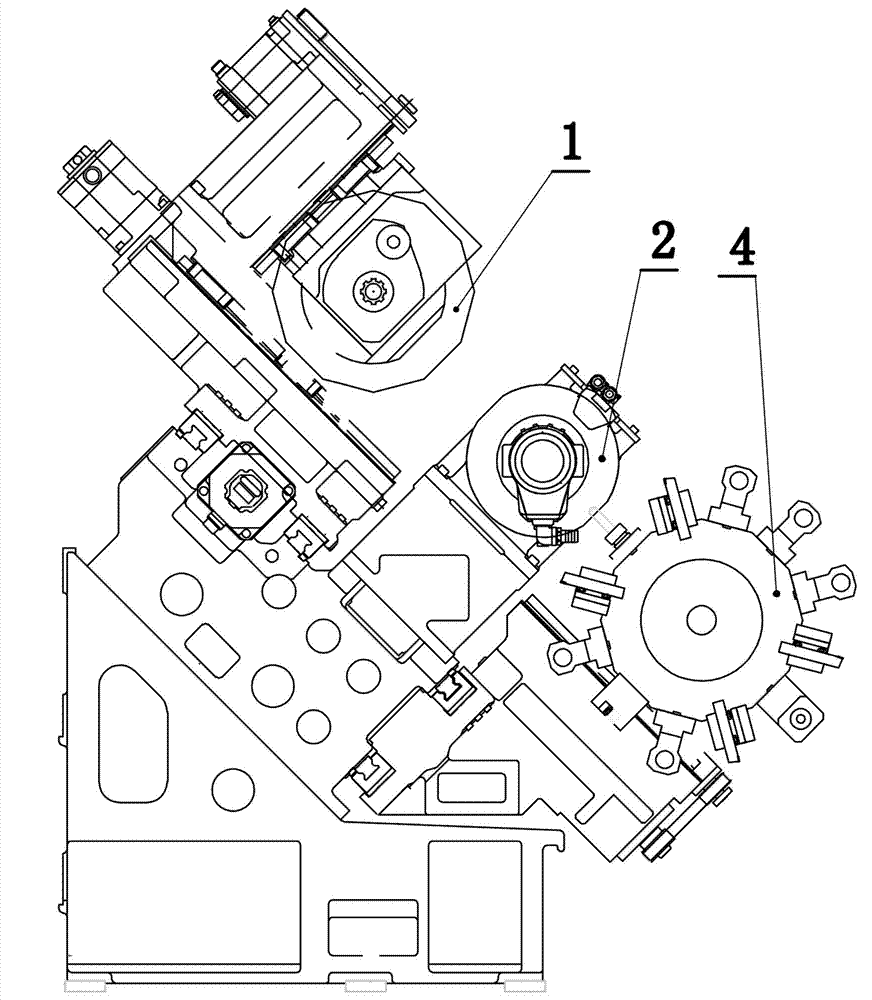

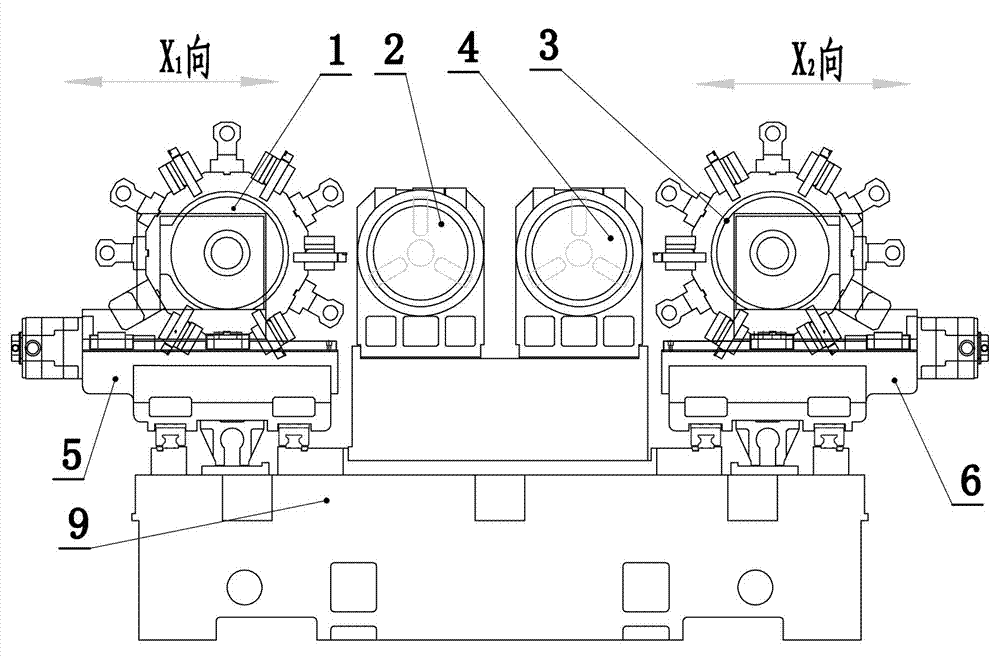

[0015] As shown in 1 and 2, currently in the entire machine tool industry, most of the lathes of turning centers use inclined bed structures. The machine tool structure of this design is a rectangular flat bed layout, two main shafts are parallel, and the turrets are opposite to each other, which is a symmetrical structure. The invention provides two spindle boxes side by side, and two turrets are installed on the machine tool oppositely. The big slide is installed on the bed through wire rails, the small slide is installed on the big slide through wire rails, and the turret is installed on the small slide. Two spindle boxes are fixed side by side on the bed, and two turrets are installed side by side on the left and right sides of the machine tool. The turret is driven by the motor to move in the X and Z directions. The machine tool can withstand a relatively large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com