Combined line printing method and device for three-dimensional line printing objects

A three-dimensional printing and object technology, applied in manufacturing auxiliary devices, liquid material additive processing, comprehensive factory control, etc., can solve the problems of precision control difficulty, waste, increase printing consumables and printing time, etc., to achieve precision Ease of control, improved print quality, reduced print consumables and print time effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and examples.

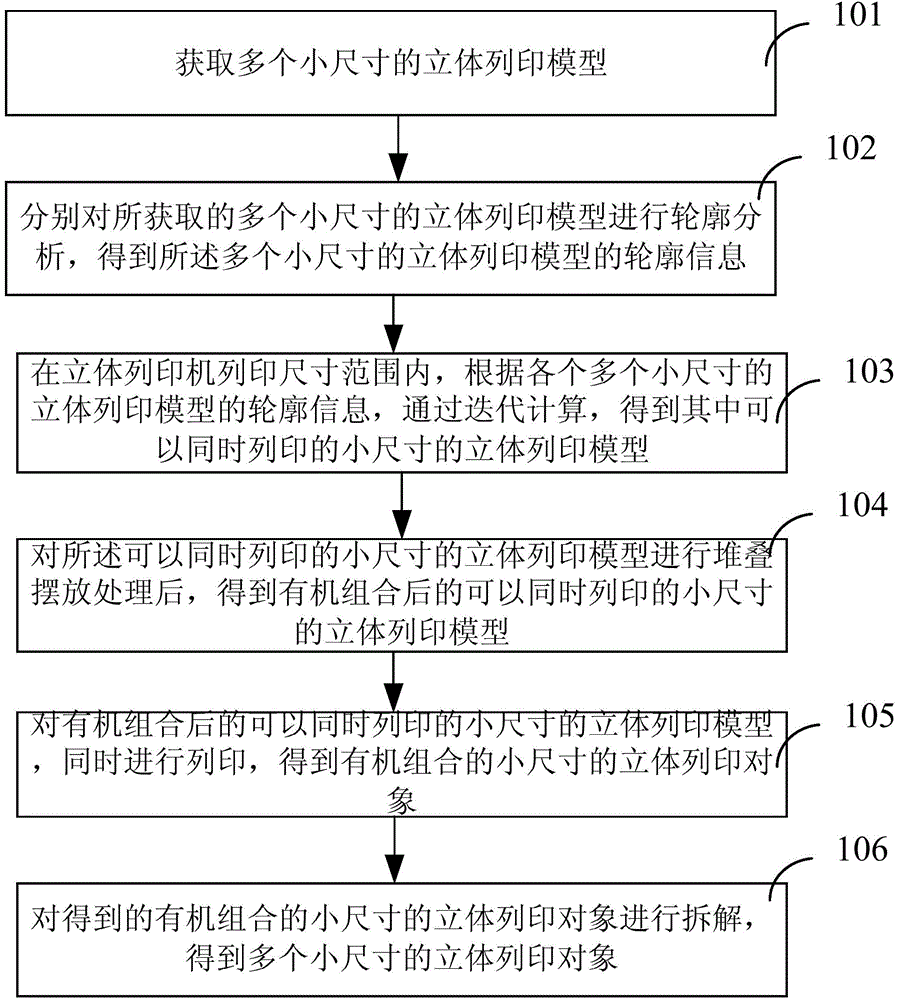

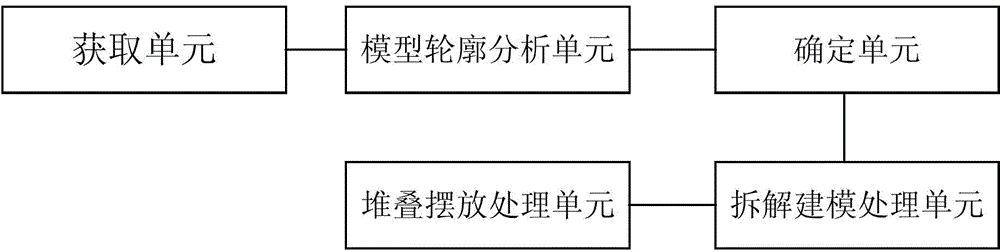

[0039] In order to save printing resources and improve the printing quality of small-sized 3D printing objects, the embodiment of the present invention organically combines multiple small-sized 3D printing models within the printing size range of the 3D printing machine, and simultaneously adopts Printed by a printer, and then disassembled into multiple small-sized 3D printed objects.

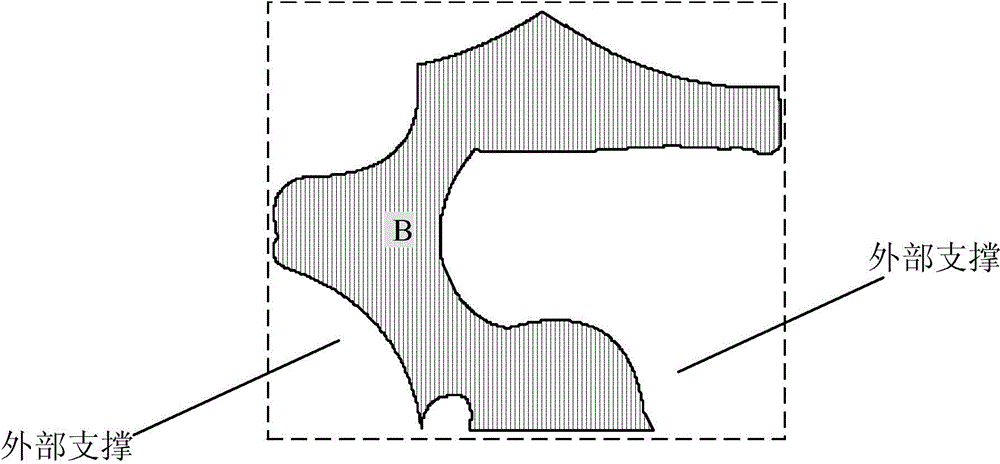

[0040] In this way, the external supporting parts of a single small-size 3D printing model during 3D printing can be reduced, and printing resources such as printing consumables and printing time can be reduced. Furthermore, since the 3D printing machine prints a plurality of 3D printing models suitable for the combination of the printing size range of the 3D printing ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com