Ultrastrong diamond compact bit

A diamond composite sheet, super-strong technology, applied in drill bits, drilling equipment, earthwork drilling and other directions, can solve the problems of easy caving of the diamond composite sheet, affecting the drilling depth of a single drill bit, and low wear resistance of the drill bit. The effect of insignificant diameter reduction, high construction efficiency and fast rock breaking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

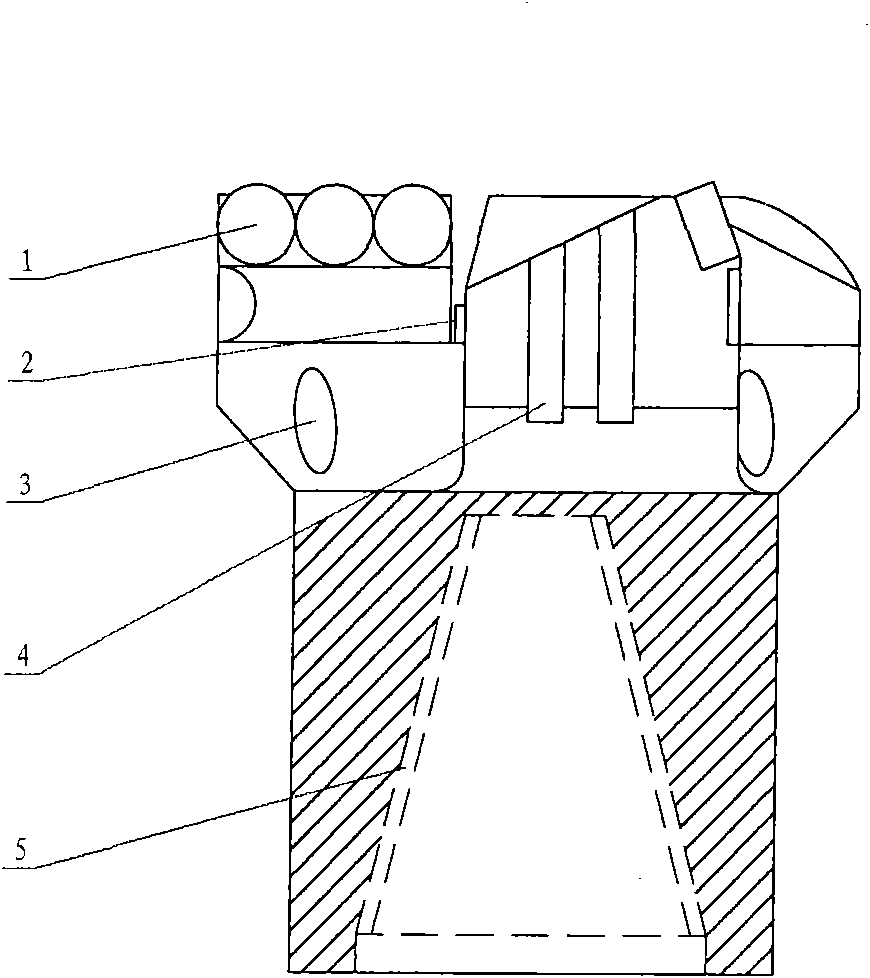

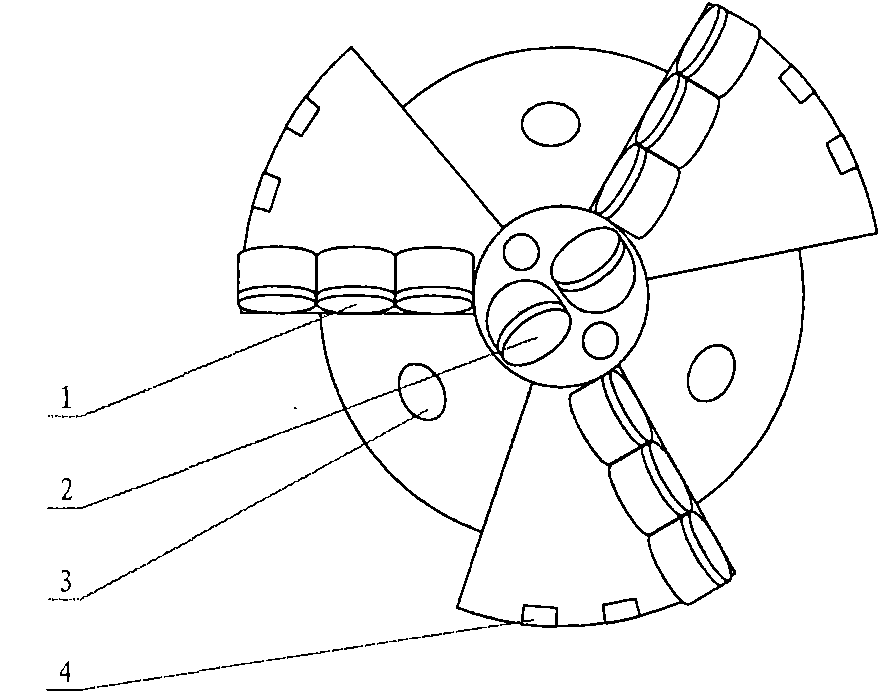

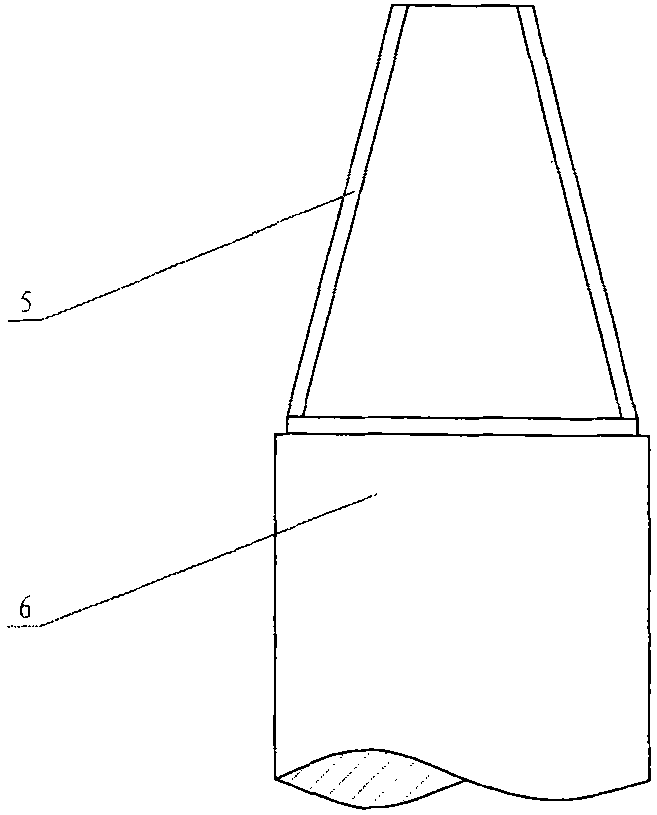

[0010] Example: figure 1 , figure 2 , image 3 As shown, the present embodiment comprises drill bit, drill rod 6, and drill rod 6 is connected with drill bit by screw thread, and rock-breaking column 2 is inlaid on the drill bit, and diamond composite sheet 1 and gage bar 4 are brazed, that is, the end of the drill bit. There are three blades in equal parts, the rock breaking pillar 2, the diamond composite sheet 1 and the gage strip 4 are all set on the blade, and the drill bit is provided with a water outlet hole 3 to ensure blade cooling and chip removal in the rock drilling process .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com