Double-sided printing machine

A printing machine, double-sided technology, applied to printing machines, rotary printing machines, printing, etc., can solve the problems of wasting energy and time, and spending a lot of energy and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

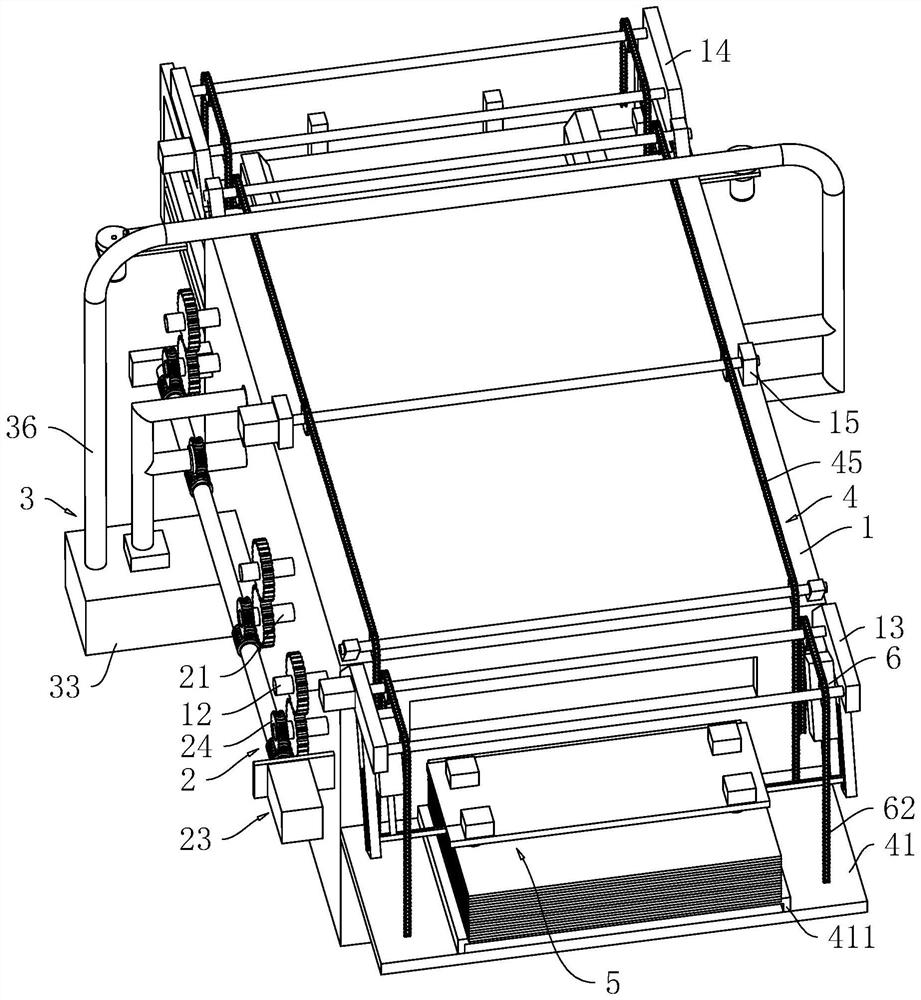

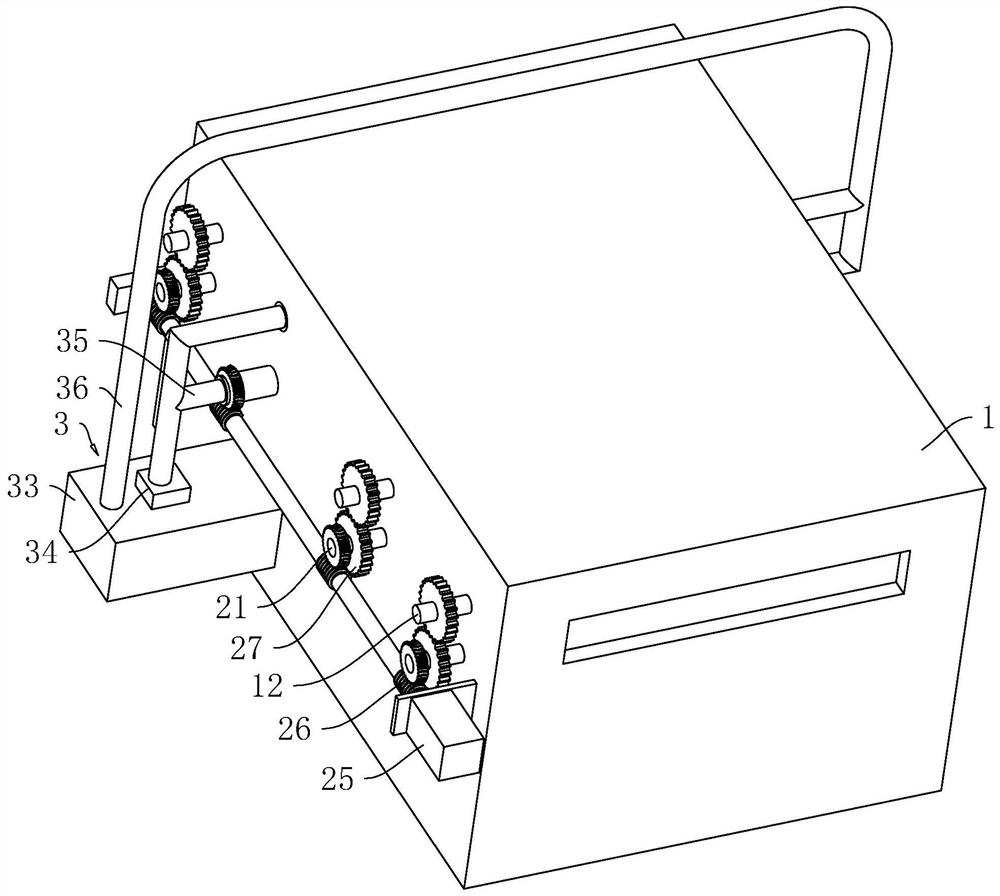

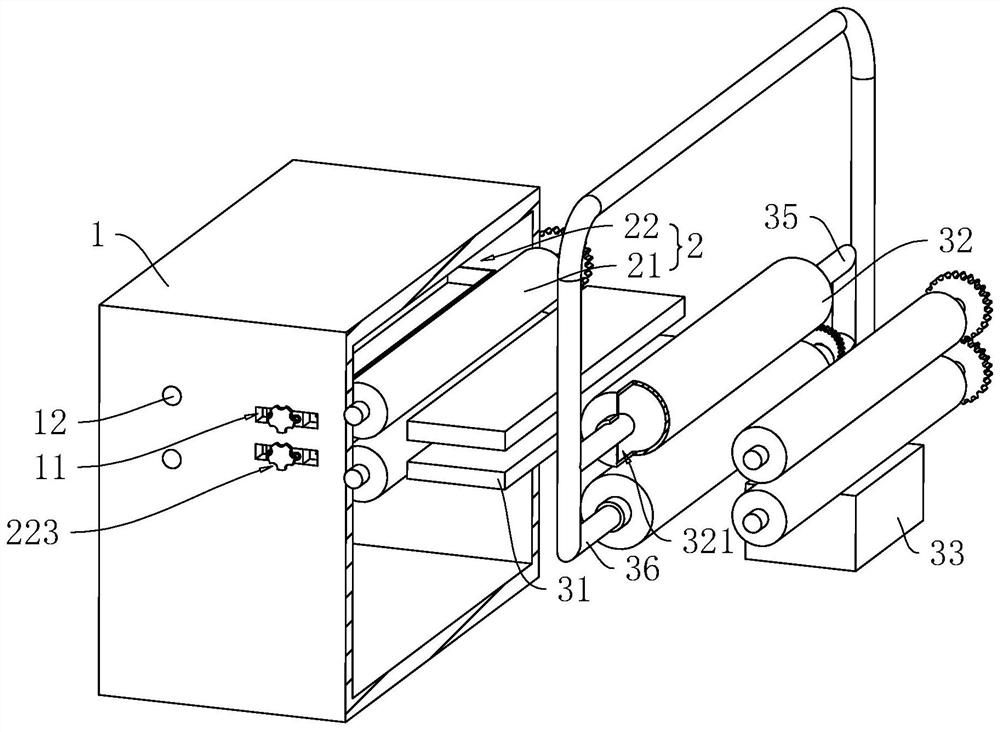

[0039] 1-7 will be described in further detail below in conjunction with the accompanying drawings.

[0040] The embodiment of the present application discloses a double-sided printing machine.

[0041] In this embodiment, the model of the infrared sensor 47 is TB12J-D15N1.

[0042] refer to figure 1 , the double-sided printing machine includes a box body 1, a material inlet and a material outlet are opened on the opposite side walls of the box body 1, two sets of horizontal conveying rollers 12 are installed on the inner wall of the box body 1, and the conveying rollers 12 are vertical Two sets of conveying rollers 12 are arranged at intervals. At the same time, two groups of conveying rollers 12 are respectively located on the side close to the feeding port and the discharging port. Paper is output from the output port.

[0043] refer to figure 2 and image 3 , the box 1 is provided with a printing device 2, the printing device 2 includes two printing rollers 21, an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com