Clamp for automatic quick replacing

An automatic and fast technology, applied in the field of manipulators, can solve problems that affect production efficiency, tediousness, waste of manpower and time, etc., and achieve the effects of increased production efficiency, small size, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

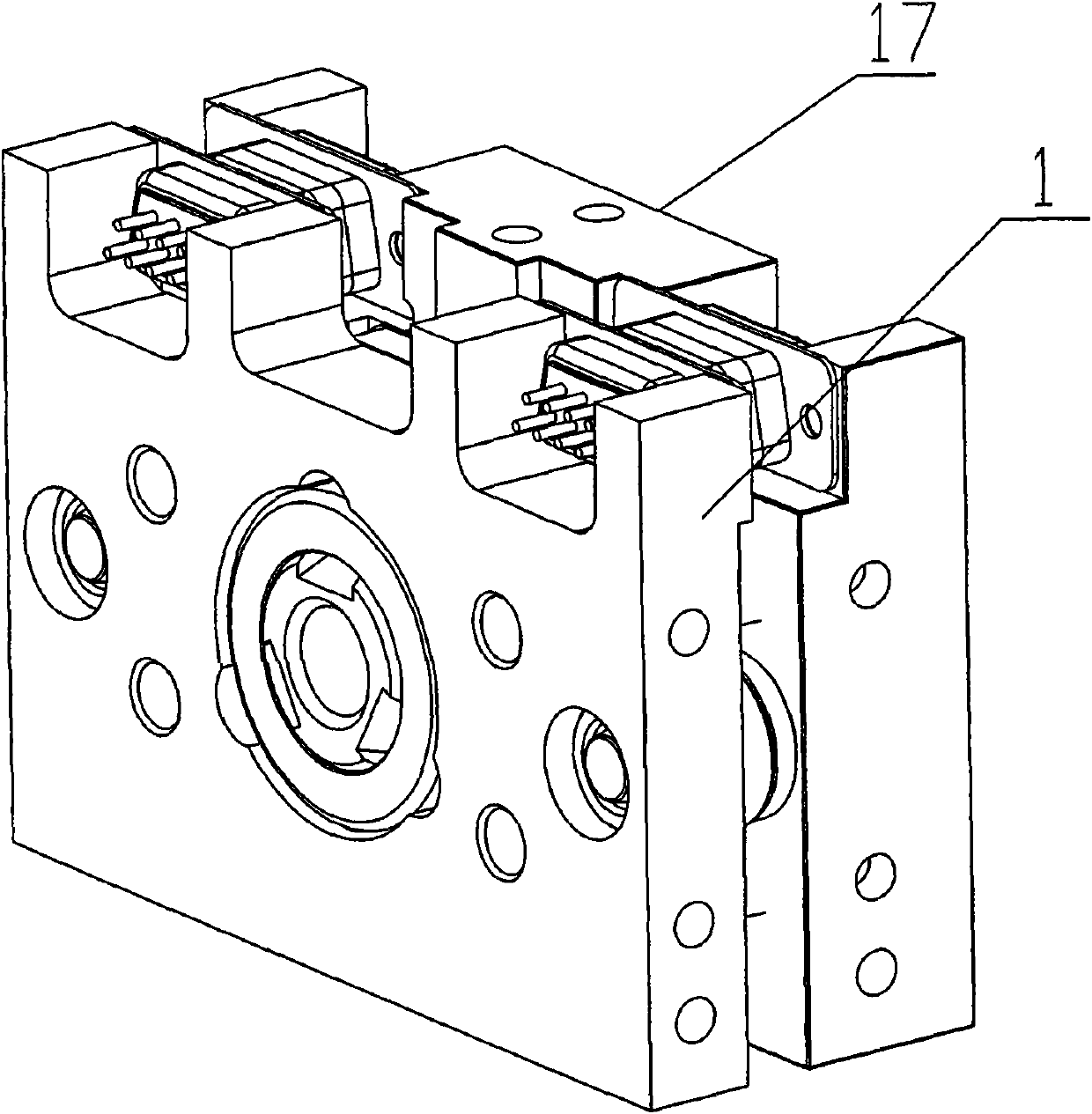

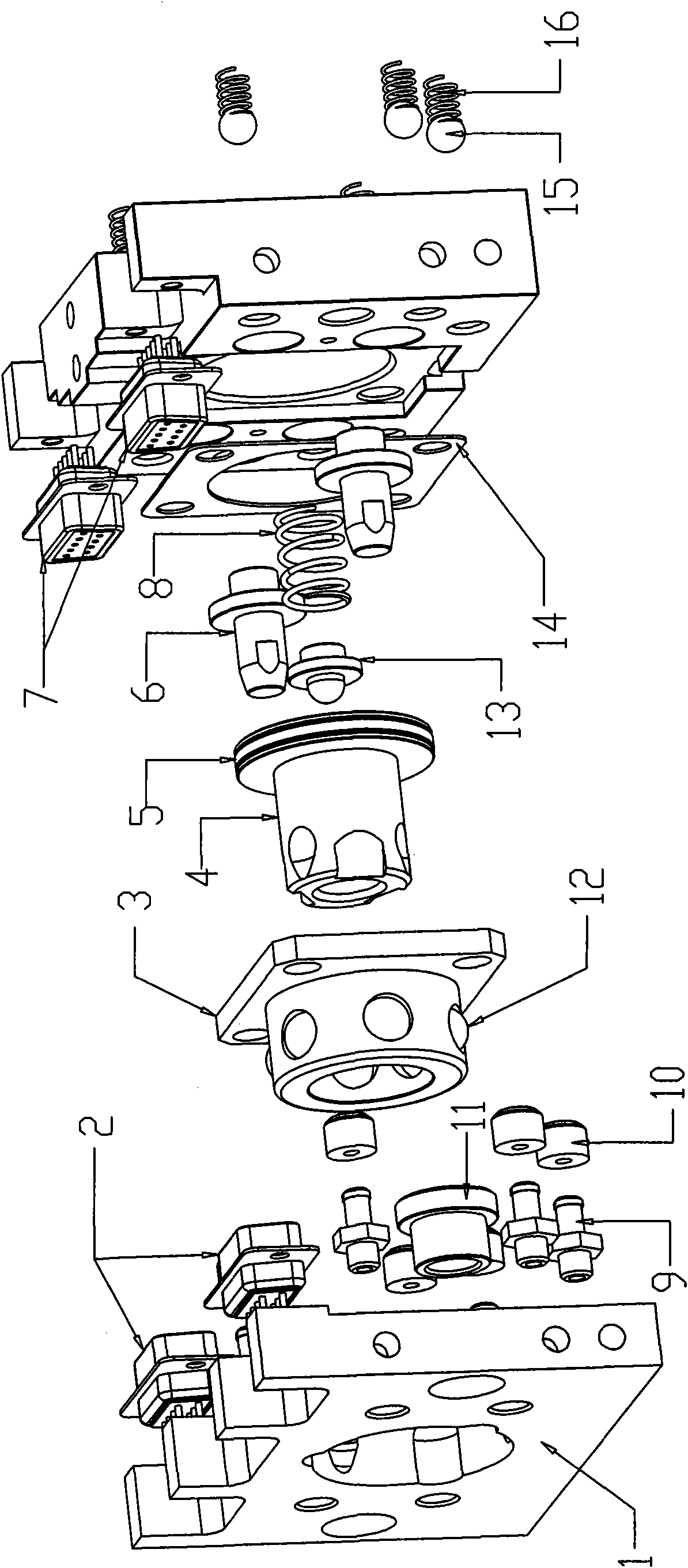

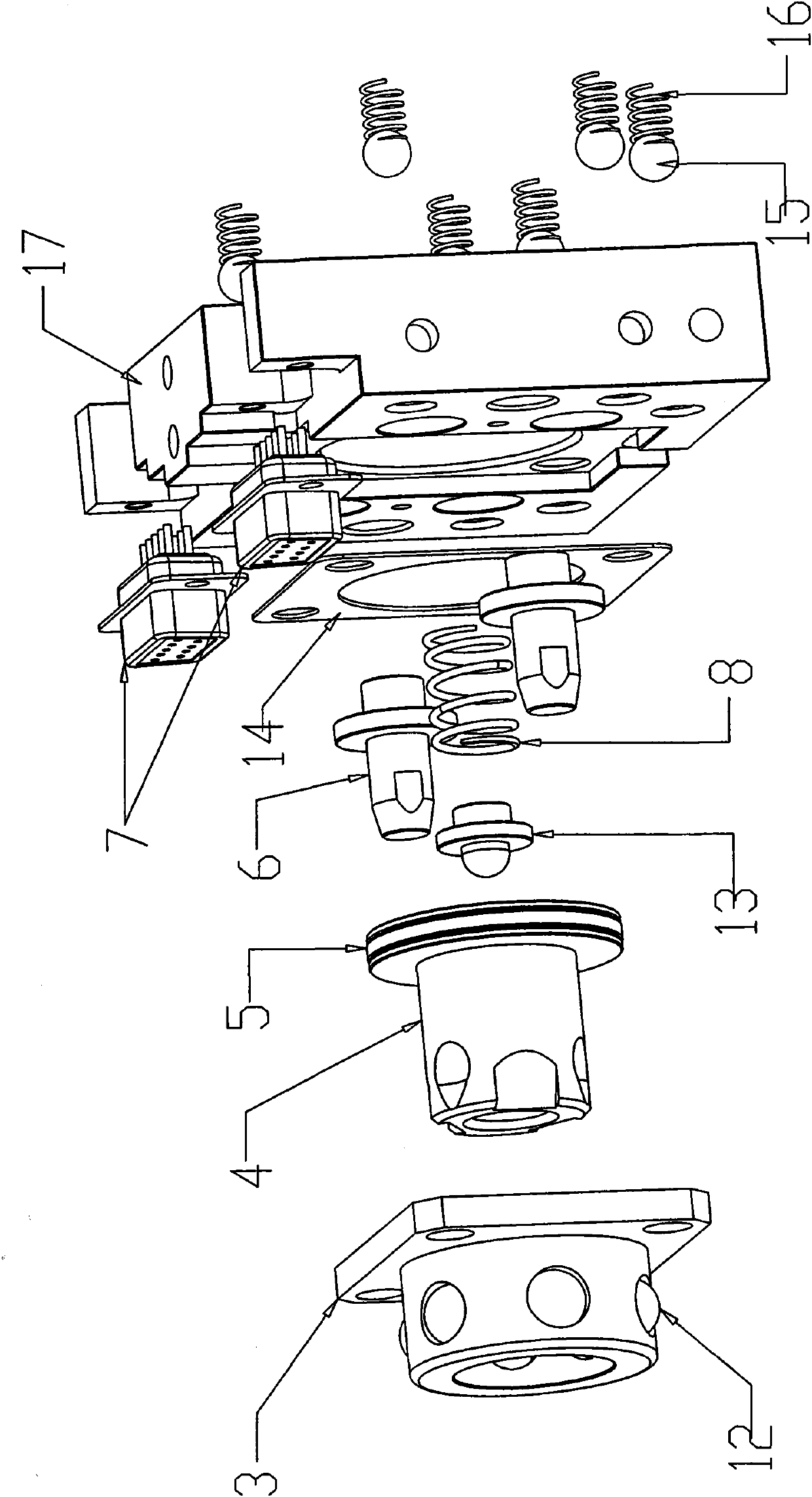

[0030] Such as figure 1 , figure 2 , image 3 , Figure 4 The automatic quick-change jig is divided into two parts, the A-part device and the B-part device. Among them, the device of part A is installed on the side posture of the manipulator. The structure of the A part device is: the arm side mounting plate 17 is used as the base body of the A part, and the plate body is processed with a plurality of ventilation holes and threaded connection holes. The spring A8 is placed in the center of the circular groove of the mounting plate 17 on the arm side, and the spring positioning head 13 is placed on the upper end of the spring A8. The hole at the piston end of the central axis 4 is aligned with the spring positioning head 13 and pressed down. The sealing ring 5 is installed, and the piston end is set in the circular groove of the arm side mounting plate 1; there are six steel ball placement holes for the shaft sleeve 3, and six steel balls A12 of corresponding specification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com