Conveying trolley for thermally-expanded steel pipes

A practical and trolley technology, which is applied in the field of transport trolleys for thermal expansion steel pipes, can solve the problems of large hoisting equipment, poor flexibility and versatility, and potential safety hazards, and achieve the effect of low cost and flexibility and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

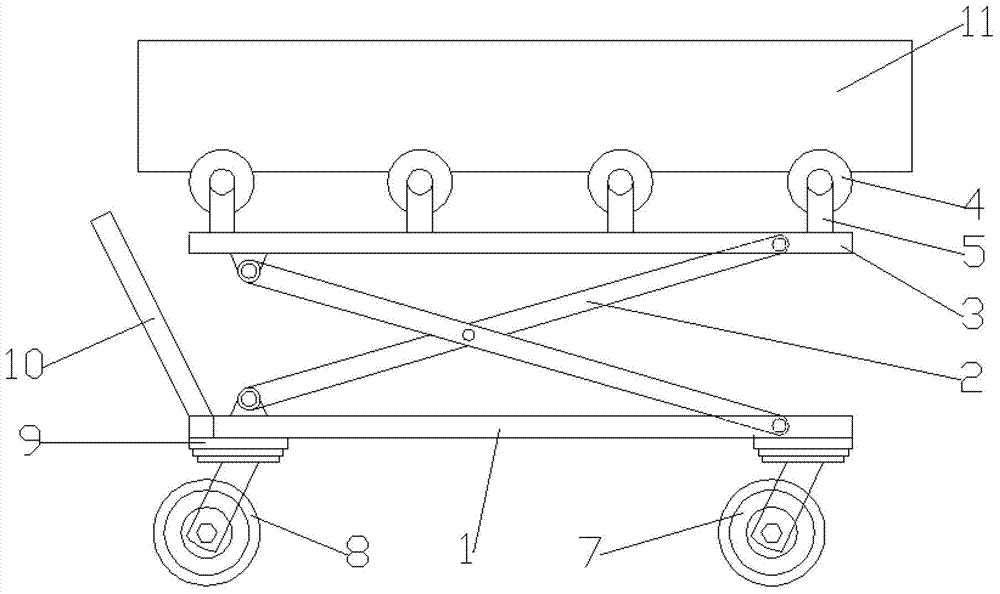

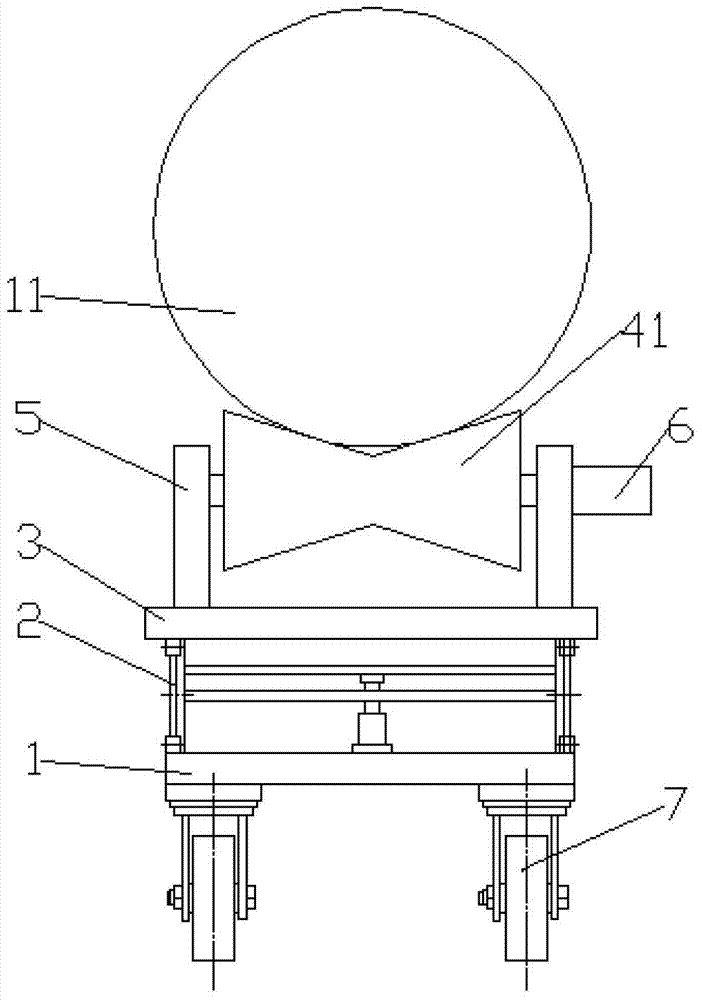

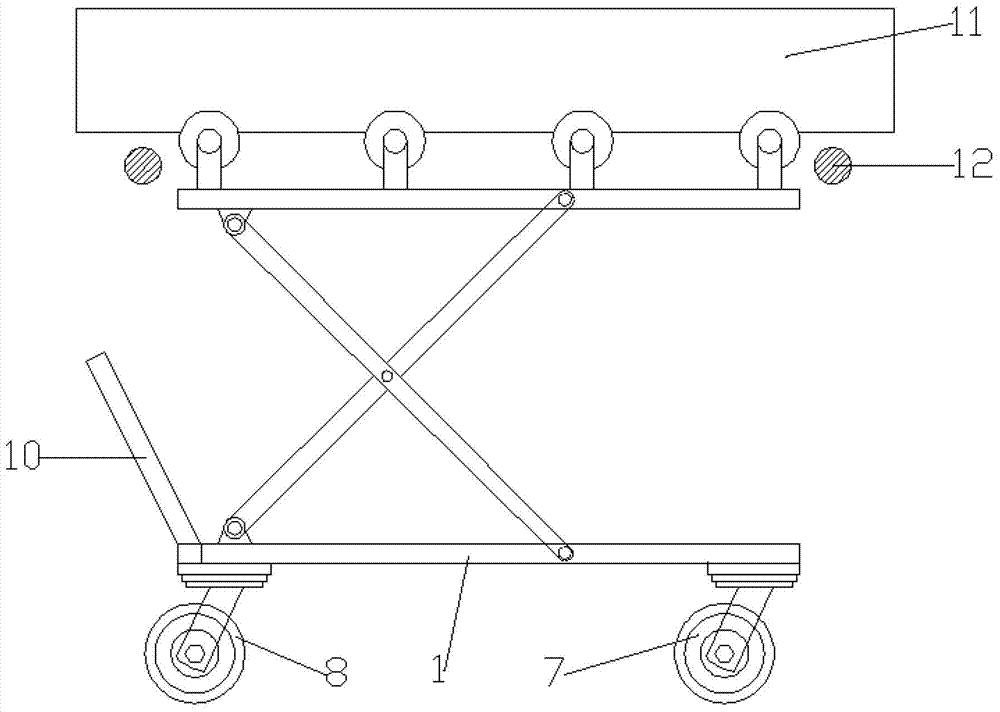

[0022] Such as Figure 1-3 As shown, the transport trolley for heat-expanded steel pipes of the present invention comprises an underframe 1, four casters are arranged at the four corners of the bottom surface of the underframe 1, and a scissor lift 2 is fixed on the underframe 1, and the scissor lift 2 The lifting platform 3 is provided with four idlers 4 parallel to the lifting platform 3 and parallel to each other. The diameter of the two ends of the idler 4 is large, and the diameter of the middle is small. It is a V-shaped idler 41, and the four V-shaped idlers 41 pass through The bracket 5 is fixed on the lifting platform 3 , and one end of the V-shaped roller 41 is connected with a driving motor 6 .

[0023] Two of the four casters in this embodiment are universal brake casters 7, and the other two are directional casters 8. Both the universal brake casters 7 and the directional casters 8 are commercially available products. The two universal brake casters 7 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com