Movable type loading and unloading device for heat treatment products

A mobile, loading and unloading technology, applied in the direction of transportation and packaging, conveyors, mechanical conveyors, etc., can solve the problems of waste of resources, labor and time-consuming loading and unloading products, etc., to achieve convenient use and safety, simple mechanism, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

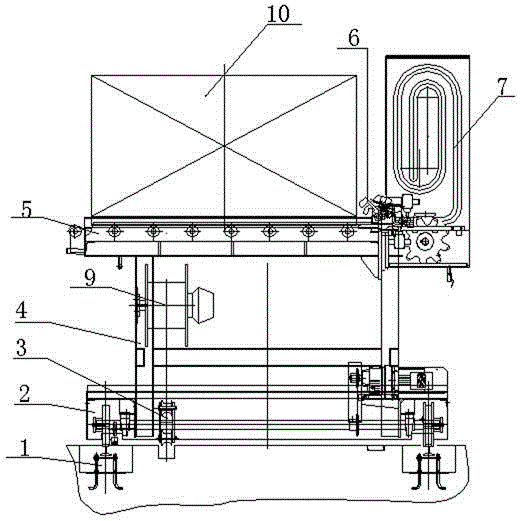

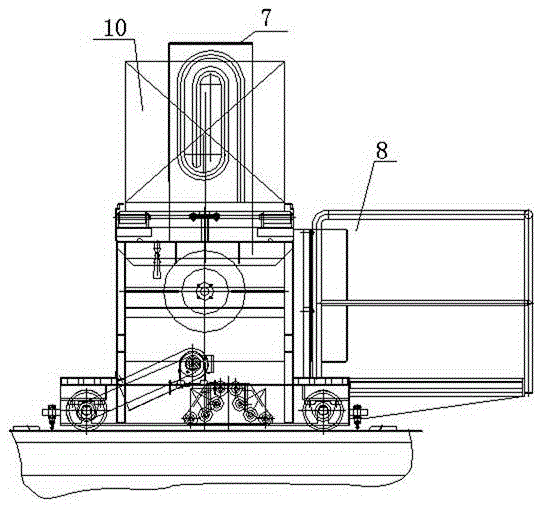

[0012] The present invention as figure 1 , 2 shown.

[0013] A mobile loading and unloading device for heat treatment products, including a guide rail 1 installed on the ground, a walking trolley 2 is mounted on the guide rail 1, a walking device 3 is arranged inside the walking trolley 2, a bracket 4 is provided on the trolley 2, and a bracket 4 is mounted on the trolley 2 A roller table 5 is provided, one side of the roller table 5 is aligned with the equipment entrance, and the other end is provided with a claw 6, and the claw 6 is connected with a push-pull chain mechanism 7; the side of the bracket 4 is provided with a control platform 8.

[0014] A coiling device 9 is provided in the support 4 to roll up or loosen the cables of the trolley 2 .

[0015] When the present invention is in use, the fast and slow speed conversion is realized by a two-speed motor. The normal movement adopts a high speed. When the device is close to the equipment target, it switches to a slow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com