Maglev system for loading, unloading and turnover of cargos

A cargo handling and turnover system technology, applied in loading/unloading, transportation and packaging, conveyors, etc., can solve the problems of high cost and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

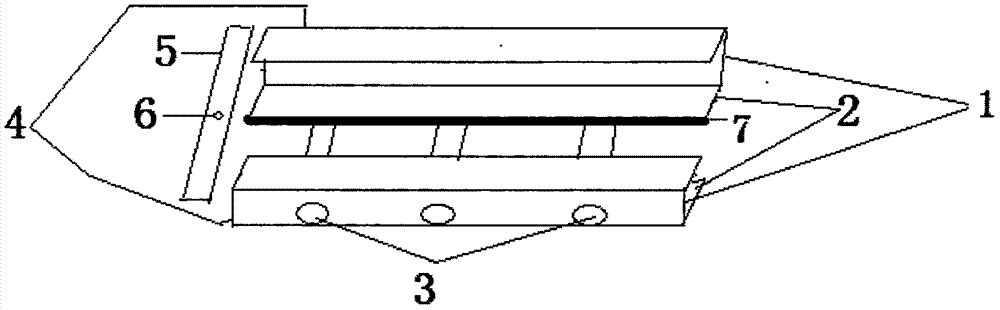

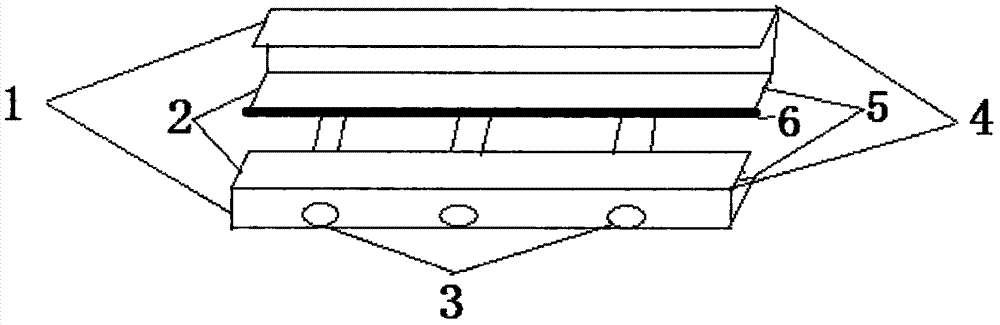

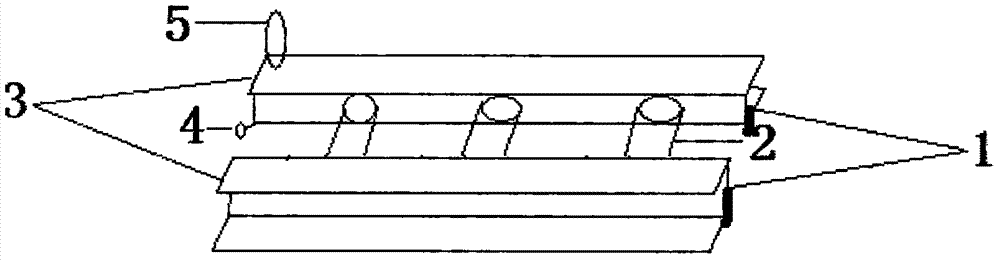

[0035] The working principle of the maglev cargo loading and unloading turnover system will be described below in conjunction with the accompanying drawings.

[0036] As shown in the attached figure, before the cargo loading and unloading operation, the connecting rod ( figure 1 Middle 1) and pin set piece ( figure 2 Middle 1), butt the power plug ( figure 1 Middle 2) and docking power plug ( figure 2 In the combination of 2), the magnetic levitation track body ( Figure 6-2 ) and the magnetic levitation track body on the field ( Figure 6-3 ) is fixed into a magnetic levitation track body, and then the pulley contact power connector ( image 3 in 1) with figure 2 Middle 6 is the contact power track ( figure 2 Middle 6) is connected, and then the site power plug ( figure 2 Middle 5) Connect to the current output interface ( Figure 8 Middle 5), finally put the magnetic levitation mobile car tray ( Figure 6-1 ) is connected to the motor ( Figure 8 In 3) the pow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com